S. S. PATIL, A. D. SHALIGRAM 73

0.0, 0.1, 0.2, 0.3, 0.4 and 0.5 molar concentrations are

prepared representing 0%, 10%, 20%, 30%, 40% and

50% salinity of water. The experiment was carried out

for 0% salinity (distilled water) up to 50% salinity using

the developed sensor probe and signal conditioning cir-

cuit. The amount of reflected light received by receiving

fiber depends on the refractive index of the salt solution.

The sensor output is directly proportional to refractive

index of salt solution and hence the concentration of the

salt in the solution.

5. Results and Discussion

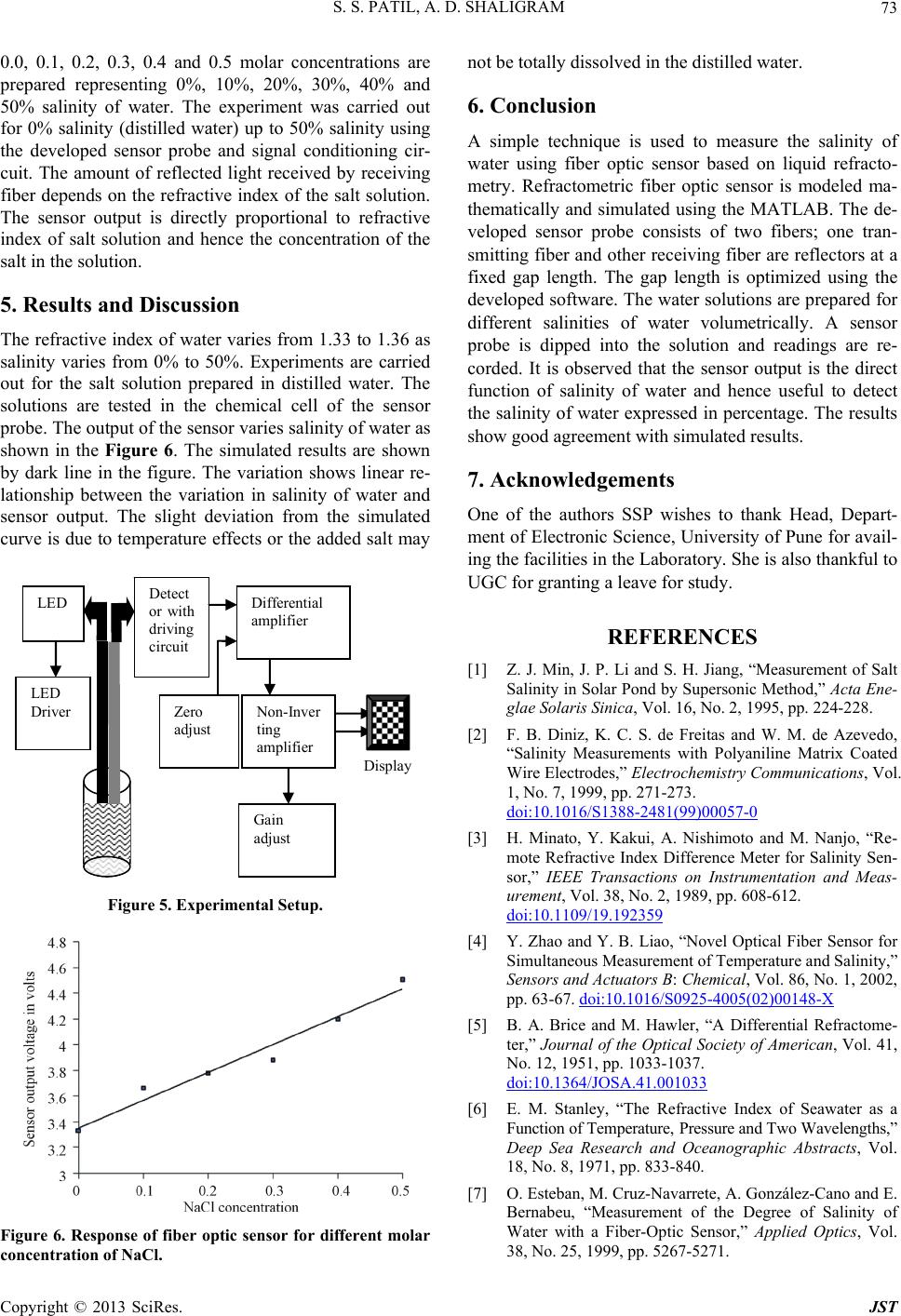

The refractive index of water varies from 1.33 to 1.36 as

salinity varies from 0% to 50%. Experiments are carried

out for the salt solution prepared in distilled water. The

solutions are tested in the chemical cell of the sensor

probe. The output of the sensor varies salinity of water as

shown in the Figure 6. The simulated results are shown

by dark line in the figure. The variation shows linear re-

lationship between the variation in salinity of water and

sensor output. The slight deviation from the simulated

curve is due to temperature effects or the added salt may

LED

Driver

Detect

or with

driving

circuit

Display

LED Differential

amplifier

Zero

adjust

Non-Inver

ting

amplifier

Gain

adjust

Figure 5. Experimental Setup.

Figure 6. Response of fiber optic sensor for different molar

concentration of NaCl.

not be totally dissolved in the distilled water.

6. Conclusion

A simple technique is used to measure the salinity of

water using fiber optic sensor based on liquid refracto-

metry. Refractometric fiber optic sensor is modeled ma-

thematically and simulated using the MATLAB. The de-

veloped sensor probe consists of two fibers; one tran-

smitting fiber and other receiving fiber are reflectors at a

fixed gap length. The gap length is optimized using the

developed software. The water solutions are prepared for

different salinities of water volumetrically. A sensor

probe is dipped into the solution and readings are re-

corded. It is observed that the sensor output is the direct

function of salinity of water and hence useful to detect

the salinity of water expressed in percentage. The results

show good agreement with simulated results.

7. Acknowledgements

One of the authors SSP wishes to thank Head, Depart-

ment of Electronic Science, University of Pune for avail-

ing the facilities in the Laboratory. She is also thankful to

UGC for granting a leave for study.

REFERENCES

[1] Z. J. Min, J. P. Li and S. H. Jiang, “Measurement of Salt

Salinity in Solar Pond by Supersonic Method,” Acta Ene-

glae Solaris Sinica, Vol. 16, No. 2, 1995, pp. 224-228.

[2] F. B. Diniz, K. C. S. de Freitas and W. M. de Azevedo,

“Salinity Measurements with Polyaniline Matrix Coated

Wire Electrodes,” Electrochemistry Communications, Vol.

1, No. 7, 1999, pp. 271-273.

doi:10.1016/S1388-2481(99)00057-0

[3] H. Minato, Y. Kakui, A. Nishimoto and M. Nanjo, “Re-

mote Refractive Index Difference Meter for Salinity Sen-

sor,” IEEE Transactions on Instrumentation and Meas-

urement, Vol. 38, No. 2, 1989, pp. 608-612.

doi:10.1109/19.192359

[4] Y. Zhao and Y. B. Liao, “Novel Optical Fiber Sensor for

Simultaneous Measurement of Temperature and Salinity,”

Sensors and Actuators B: Chemical, Vol. 86, No. 1, 2002,

pp. 63-67. doi:10.1016/S0925-4005(02)00148-X

[5] B. A. Brice and M. Hawler, “A Differential Refractome-

ter,” Journal of the Optical Society of American, Vol. 41,

No. 12, 1951, pp. 1033-1037.

doi:10.1364/JOSA.41.001033

[6] E. M. Stanley, “The Refractive Index of Seawater as a

Function of Temperature, Pressure and Two Wavelengths,”

Deep Sea Research and Oceanographic Abstracts, Vol.

18, No. 8, 1971, pp. 833-840.

[7] O. Esteban, M. Cruz-Navarrete, A. González-Cano and E.

Bernabeu, “Measurement of the Degree of Salinity of

Water with a Fiber-Optic Sensor,” Applied Optics, Vol.

38, No. 25, 1999, pp. 5267-5271.

Copyright © 2013 SciRes. JST