Paper Menu >>

Journal Menu >>

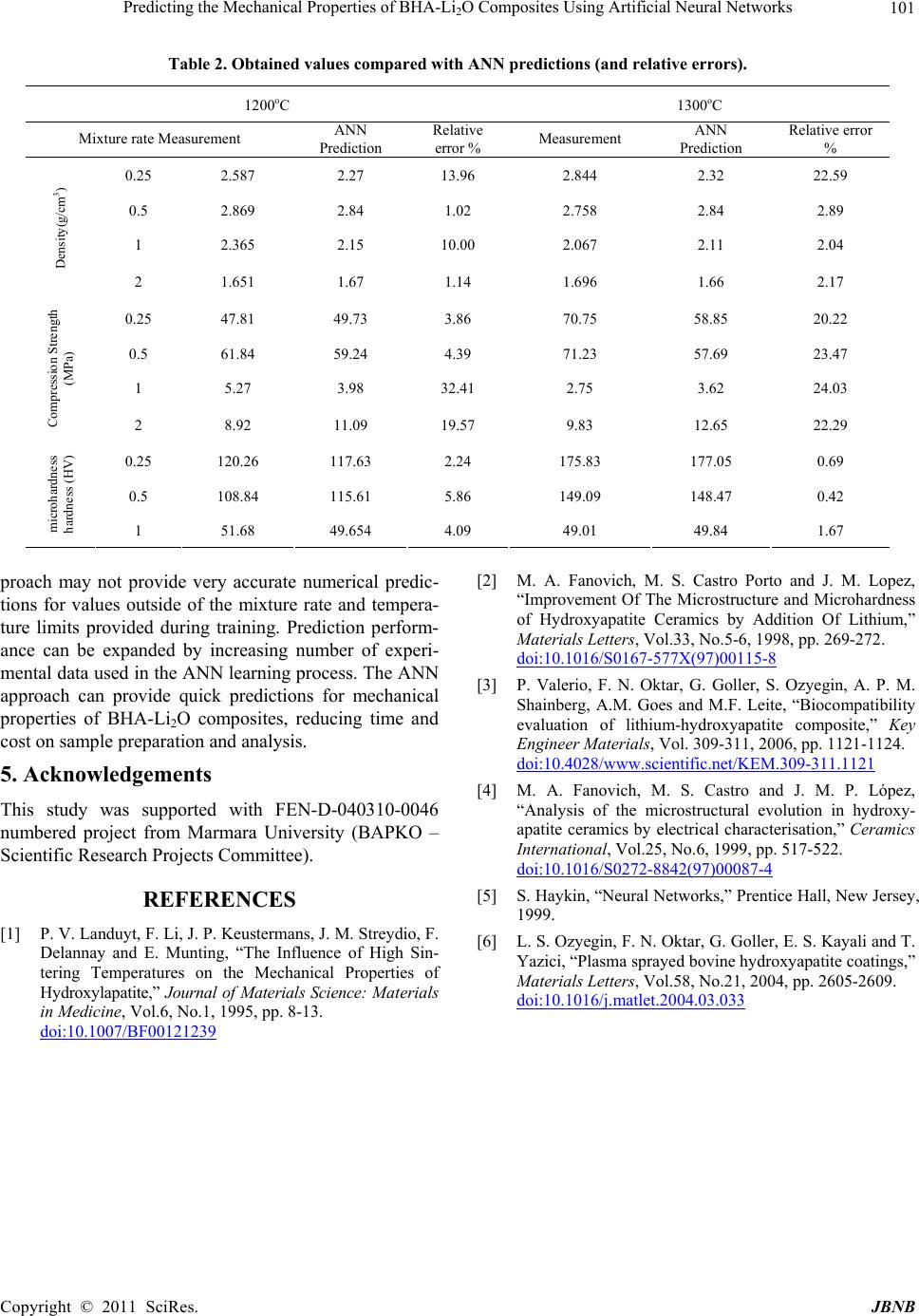

Journal of Biomaterials and Nanobiotechnology, 2011, 2, 98-101 doi:10.4236/jbnb.2011.21013 Published Online January 2011 (http://www.SciRP.org/journal/jbnb) Copyright © 2011 SciRes. JBNB Predicting the Mechanical Properties of BHA-Li2O Composites Using Artificial Neural Networks Hasan Huseyin Celik1*, Oguzhan Gunduz2,6*, Nazmi Ekren3,6, Zeeshan Ahmad4, Faik Nuzhet Oktar5,6 1School of Technical Education, Department of Electronic and Computer Education, Marmara University, Istanbul, Turkey; 2Department of Metal Education, Marmara University, Istanbul, Turkey; 3 School of Technical Education, Department of Electrical and Electronic Engineering, Marmara University, Istanbul, Turkey; 4School of Pharmacy and Biomedical, Science Unive r sity of Portsmouth, Portsmouth, UK; 5School of Health Related Professions, Department of Medical Imaging Technics, Marmara University, Istanbul, Turkey; 6Nanotechnology and Biomaterials Application & Research Centre, Marmara University, Istanbul, Turkey. Email: {hcelik, oguzhan}@marmara.edu.tr Received October 13th, 2010; revised November 20th, 2010; accepted November 28th, 2010. ABSTRACT In this study the mechanical properties of bovine hydroxyapatite (BHA)-Li2O composites are predicted using artificial neural networks (ANN) and then compared with obtained experimental values. BHA was mixed with lithium carbonate (Li2CO3) and sintered at various temperatures between 900-1300°C. Selected experimental values obtained for the compression strength, microhardness and density were used to define and train the ANN system. Intermediate data val- ues not used to train the ANN model were then used to compare and determine the reliability of the ANN system. The results demonstrate the viable potential in using the ANN approach in predicting mechanical properties even with lim- ited data sets. Keywords: Artificial Neural Network, Hydroxyapatite, Li2O Composites, Bioceramic 1. Introduction Hydroxyapatite (HA) is an attractive material used in several hard tissue orthopedic applications. Its crystallo- graphic and chemical properties closely resemble those of bone and tooth minerals [1]. However, because of its poor mechanical properties, HA is often used in devices as a coating, where the bioactive properties of the mate- rial can still be utilized, whilst benefiting from the me- chanical properties of the substrate (e.g. stainless steel). The mechanical properties of HA, however, may be im- proved by additives, which can modify the sintering process, allowing the resultant material to achieve higher densities [2]. One such additive that is of interest is lith- ium and lithium based composites, which have demon- strated reasonable biocompatibility [3]. The relative knowledge concerning the effects of lithium compounds in such orthopedic systems on living organism is scarce; and for this reason reduced quantities of such materials must be utilized e.g. Fanowich et al. have utilized mini- mal quantities of lithium in their research (0.2, 0.4 and 0.6 wt. %) [2,4]. Artificial Neural Networks (ANN) are parallel proc- essing models which can be deployed in predicting outcomes based on input-output data (parameters and relationships), demonstrating a degree of robustness and self-learning capability [5]. The accuracy and reli- ability of predicted outcomes can be increased based on the number of input values. In this way accumulation of data sets into an ANN system can enhance the out- come and predictability as the likelihood of any value will be based on previous experimental data. This makes the ANN system robust as it is an adaptive sys- tem which can change based on information it has al- ready acquired or will obtain. This study describes the use of ANN to predict the mechanical properties of bovine hydroxyapatite (BHA)-Li2O composites. Pa- rameters of compression strength, microhardness and density were produced by experiments in various mix- ture rates and temperatures. The model used was based on a feed-forward system based on sintering tempera- ture and material composition. BHA lithium carbonate composite, like other bioac- tive composites are key mater ials in the develop ment of several orthopedic applications. However, sintering temperatures and compositional values for such mate- rials occupy considerable time periods (impact on me- chanical properties) and therefore the outlook provided  Predicting the Mechanical Properties of BHA-Li2O Composites Using Artificial Neural Networks Copyright © 2011 SciRes. JBNB 99 by ANN systems can be extremely valuable. If a suffi- cient number of data sets can be provided then pre- dicted data from ANN systems can suffice; reducing preliminary testing to determine mechanical properties for each type of composite or sintering temperature. In addition to orthopedics, bioceramics and their compos- ites are also finding applications in other areas of bio- materials and biotechnologies (such as drug delivery and tissue engineering) and these predictive methods may also assist in enhancing these frontiers. 2. Materials and Methods 2.1. Materials BHA, was prepared in similar fashion to an earlier study [6]. Lithium carbonate (Li2CO3) was purchased from (Sigma Aldrich) and was added to BHA in the composi- tions of 0.25, 0.5, 1 and 2 wt % Li2CO3. Ball-milled BHA- Li2CO3 powders were then pressed to cylindrical compacts (British Standard, No. 7253) which were then sintered in an open atmospheric furnace for 4 hours (Na- bertherm HT 16/17, Lilienthal, Germany) at 900, 1000, 1100, 1200, and 1300°C. D ensity, Vick ers microhard ness, and compression strength were measured for all samples. 2.2. Mechanical Testing Compression strength tests on sintered samples were carried out using a universal testing machine (DVT.e, Devotrans Inc. Istanbul, Turkey; speed 2 mm/min). The densities were determined using the Archimedes method and microhardness (TUKON, Wilson Instruments, Group of Instron, Darmstadt, Germany; 200 gr. load) was measured three times and a mean value was taken. 2.3. Artificial Neural Networks In a feed forward ANN system, the input data is proc- essed from input to output. The neurons are classified in three layers called input layer, hidden layer and output layer. The feed forward ANN structure is illustrated in Figure 1. The network input(s) and output(s) of the hid- den and output layers are denoted as Xi, Yj, Ok. The ANN process is governed by the following equations: 00,1,2 i Nh netXW N jiij i, (1) j Ynet j f (2) 00,1,2, Mo jjk j netY W jM k (3) 0,1,2, kk Ofnet kP (4) Figure 1. Feedforward neural network architecture. here W is weight of connections and f(.) is neuron active- tion function that can be selected as hard limiter, linear or nonlinear. Because of th e continuity, the activation func- tion is frequently selected as a sigmoidal function. It can be defined as: -net fnet e (5) The parameter λ describes the rate of the activation function. In supervised training, ANN applications re- quire a training data set to learn the relationsh ip between inputs and outputs. The training set should consist of sufficient number of samples that define a process. Oth- erwise, insufficient learning can limit the performance of the ANN approach. 3. Results and Discussion Sintering of BHA-Li2CO3 composites results in the for- mation of BHA-Li2O [6]. Table 1 illustrates experimen- tal values for density, Vickers microhardness and com- pression strength for defined sintering temperatures and Li2CO3 compositions. For 0.25% and 0.50%, it is seen that density values increased with increments to tem- perature and Li2CO3 content. The highest values com- pression strength were obtained at 1300°C; ~73.75 MPa for 0.25% and ~75.23 MPa for 0.50%. This can be at- tributed to the occurrence of a glass phase, which has a wetting effect through the grain boundaries. The lowest compression strength values were observed at 1200°C; ~2.25 MPa for 1% and ~5.92 MPa for 2% Li2CO3 addi- tions. Evidently, high amounts of Li2CO3 addition cause a decrease in compression strength. For compacts con- taining 0.25% Li2CO3, the Vickers hardness values in- creased with increasing sintering temperature. However, the same outcome was not observed for samples with 0.5, 1 and 2% quantities because of increased porosity. Experimental values obtained for BHA composites consist of five sets of sintering temperatures (ranging from 900-1300oC) and within these, properties such as density, microhardness and compression strength will  Predicting the Mechanical Properties of BHA-Li2O Composites Using Artificial Neural Networks Copyright © 2011 SciRes. JBNB 100 Table 1. Mechanical Properties of BHA-Li2O c o mposites with different Li2CO3 content. T[oC] 0.25% 0.50% 1% 2% d HV d HV d HV d HV 900 2.104 36.02 41.9 2.816 56.01 114.892.33 38.43 59.53 1.742 15.02 NA 1000 2.192 38.64 53.12 2.826 57.82 88.24 2.109 17.13 65.08 1.661 12.43 NA 1100 2.215 43.11 62.46 2.852 59.32 102.452.24888.67 49 1.713 10.57 NA 1200 2.587 47.81 120.26 2.869 61.84 108.842.36525.27 51.68 1.651 8.92 NA 1300 2.844 70.75 175.83 2.758 72.23 149.092.06722.75 49.01 1.696 9.83 NA *NA = not applicable vary. Three temperature sets (900, 1000, 1100oC) were used to train the ANN model. A Back-propagation algo- rithm was used in the training process with a sigmoid type of activation function. Here, ANN models have two inputs and one output (Figure 2). The inputs consisted of sintering temperature and mixture rate (Figure 3) and the output is a predicted value (for a selected property) based on the training obtained from data provided. Training experiments were performed individually for the predic- tion of each property, which is now set as an outcome (density, microhardness and compression strength). Part of the training phase is to examine the different number of neuron networks (or connections). The output value for a property (density, microhardness and com- pression strength) can be enhanced by increasing the number of neurons or data entry during the training stage. After the training step, the ANN was used to predict me chanical properties of the last two groups (1200 and 1300ºC) which were withheld during the training process. A comparison between the predicted (using ANN) and obtained results are illustrated in Table 2. ANN based predictions of the compression strength at 1200 and 130 0°C have an average maximum error rate of ~17%. Prediction error rates of density and microhard- ness obtained were ~7% and ~2.5% respectively. When comparing the total prediction errors of the two tested data sets (1200°C and 1300°C) , it is observed that data obtained for 1300°C is less accurate when compared to those obtained for 1200ºC, and this can be seen by com- paring the predicting and corresponding values for den- sity and compression strength. However, the reverse is Figure 2. Defined ANN model prediction. (a) (b) (c) Figure 3. ANN predicted values for a) density, b) compres- sion strength, c) microhardness. true for microhardness predictions. The results of ANN pred iction for density, microhard- ness and compression strength are also illustrated in Figures 3 a, b and c; where the trend between the pre- dicted and obtained values is clearly evident, although there are differences in the actual values. 4. Conclusion According to the findings, the ANN approach can supply reasonable predicted values fo r limited mixture rates and temperature. Because of non-linear changes to density, compression strength and microhardness, the ANN ap-  Predicting the Mechanical Properties of BHA-Li2O Composites Using Artificial Neural Networks Copyright © 2011 SciRes. JBNB 101 Table 2. Obtained values compared with ANN predictions (and relative errors). 1200oC 1300oC Mixture rate Measurement ANN Prediction Relative error % Measurement ANN Prediction Relative error % 0.25 2.587 2.27 13.96 2.844 2.32 22.59 0.5 2.869 2.84 1.02 2.758 2.84 2.89 1 2.365 2.15 10.00 2.067 2.11 2.04 Density(g/cm3) 2 1.651 1.67 1.14 1.696 1.66 2.17 0.25 47.81 49.73 3.86 70.75 58.85 20.22 0.5 61.84 59.24 4.39 71.23 57.69 23.47 1 5.27 3.98 32.41 2.75 3.62 24.03 Compression Strength (MPa) 2 8.92 11.09 19.57 9.83 12.65 22.29 0.25 120.26 117.63 2.24 175.83 177.05 0.69 0.5 108.84 115.61 5.86 149.09 148.47 0.42 microhardness hardness (HV) 1 51.68 49.654 4.09 49.01 49.84 1.67 proach may not provide very accurate numerical predic- tions for values outside of the mixture rate and tempera- ture limits provided during training. Prediction perform- ance can be expanded by increasing number of experi- mental data used in th e ANN learning process. Th e ANN approach can provide quick predictions for mechanical properties of BHA-Li2O composites, reducing time and cost on sample preparation and analysis. 5. Acknowledgements This study was supported with FEN-D-040310-0046 numbered project from Marmara University (BAPKO – Scientific Research Projects Committee). REFERENCES [1] P. V. Landuyt, F. Li, J. P. Keusterma ns, J. M. Strey dio, F. Delannay and E. Munting, “The Influence of High Sin- tering Temperatures on the Mechanical Properties of Hydroxylapatite,” Journal of Materials Science: Materials in Medicine, Vol.6, No.1, 1995, pp. 8-13. doi:10.1007/BF00121239 [2] M. A. Fanovich, M. S. Castro Porto and J. M. Lopez, “Improvement Of The Microstructure and Microhardness of Hydroxyapatite Ceramics by Addition Of Lithium,” Materials Letters, Vol.33, No.5-6, 1998, pp. 269-272. doi:10.1016/S0167-577X(97)00115-8 [3] P. Valerio, F. N. Oktar, G. Goller, S. Ozyegin, A. P. M. Shainberg, A.M. Goes and M.F. Leite, “Biocompatibility evaluation of lithium-hydroxyapatite composite,” Key Engineer Materials, Vol. 309-311, 2006, pp. 1121-1124. doi:10.4028/www.scientific.net/KEM.309-311.1121 [4] M. A. Fanovich, M. S. Castro and J. M. P. López, “Analysis of the microstructural evolution in hydroxy- apatite ceramics by electrical characterisation,” Ceramics International, Vol.25, No.6, 1999, pp. 517-522. doi:10.1016/S0272-8842(97)00087-4 [5] S. Haykin, “Neural Networks,” Prentice Hall, New Jersey, 1999. [6] L. S. Ozyegin, F. N. Oktar, G. Goller, E. S. Kayali and T. Yazici, “Plasma sprayed bovine hydroxyapatite coatings,” Materials Letters, Vol.58, No.21, 2004, pp. 2605-2609. doi:10.1016/j.matlet.2004.03.033 |