Forming Stages of Polycrystalline TiN Films Depending on the Nitrogen Concentration in Mixed Gas

12

Globular stage:

forming of globules

without substrate

surface wetting

(50%) and with the

one (70%, 90%)

Forming of 3D

formations with

grain

substructure:

non-ordered at

50%, 70%;

ordered at 90%

Integration of the 3D

formations with grain

substructure: without

ordering at 50%; initial

ordering at 70%; forming

of pseudoplains {100} on

surface at 90%

Germi-nati

on of

polycrysta

lline

constituent

of the film

Forming

of

polycrysta

lline 2D

island s

Forming

of

continuou

s

polycrysta

lline film

Forming of 3D

ordered grain (70%)

and 2D ordered

column (90%)

formations on the

continuous film

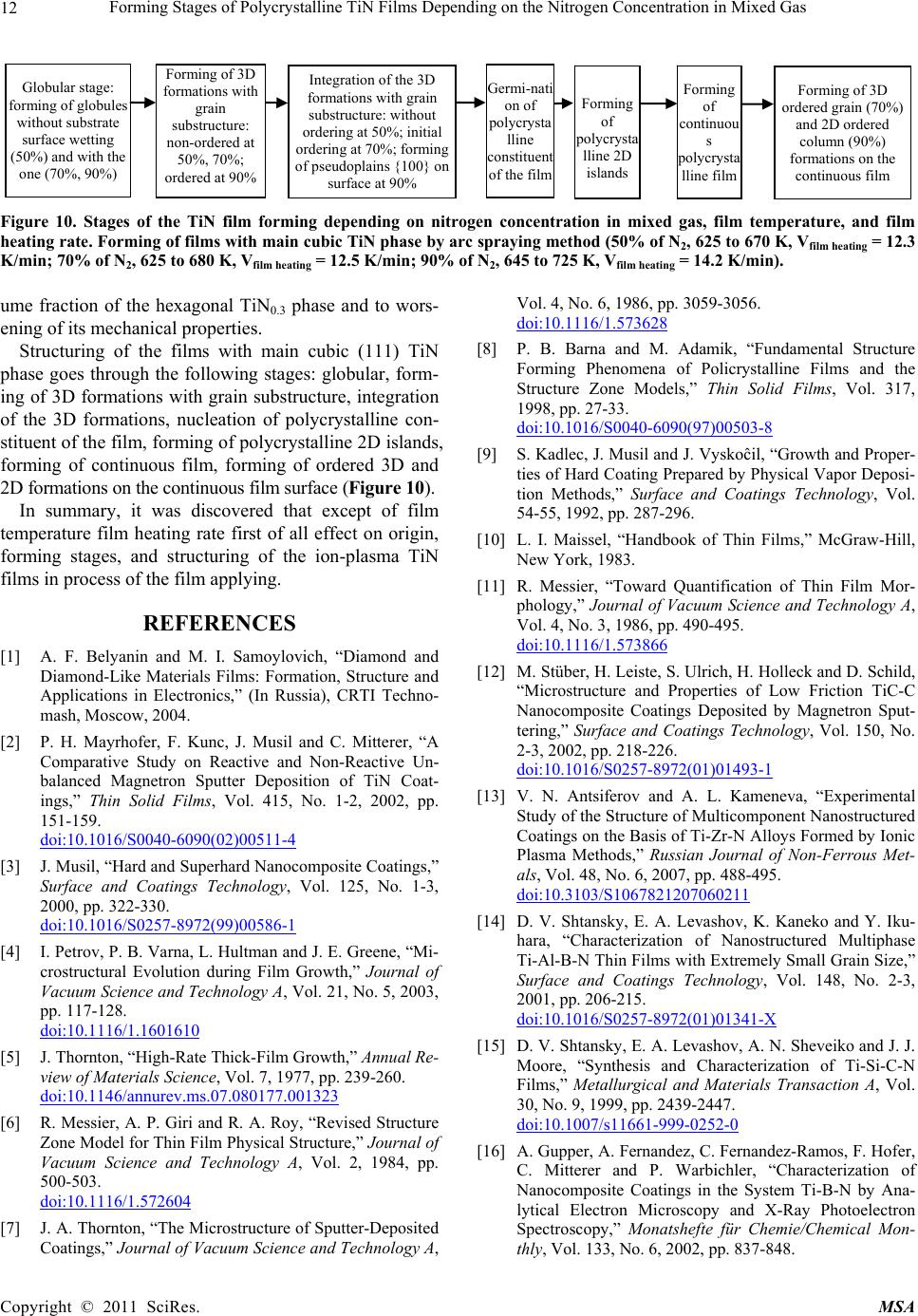

Figure 10. Stages of the TiN film forming depending on nitrogen concentration in mixed gas, film temperature, and film

heating rate. Forming of films with main cubic TiN phase by arc spraying method (50% of N2, 625 to 670 K, Vfilm heating = 12.3

K/min; 70% of N2, 625 to 680 K, Vfilm heating = 12.5 K/min; 90% of N2, 645 to 725 K, Vfilm heating = 14.2 K/min).

ume fraction of the hexagonal TiN0.3 phase and to wors-

ening of its mechanical properties.

Structuring of the films with main cubic (111) TiN

phase goes through the following stages: globular, form-

ing of 3D formations with grain substructure, integration

of the 3D formations, nucleation of polycrystalline con-

stituent of the film, forming of polycrystalline 2D islands,

forming of continuous film, forming of ordered 3D and

2D formations on the continuous film surface (Figure 10).

In summary, it was discovered that except of film

temperature film heating rate first of all effect on origin,

forming stages, and structuring of the ion-plasma TiN

films in process of the film applying.

REFERENCES

[1] A. F. Belyanin and M. I. Samoylovich, “Diamond and

Diamond-Like Materials Films: Formation, Structure and

Applications in Electronics,” (In Russia), CRTI Techno-

mash, Moscow, 2004.

[2] P. H. Mayrhofer, F. Kunc, J. Musil and C. Mitterer, “A

Comparative Study on Reactive and Non-Reactive Un-

balanced Magnetron Sputter Deposition of TiN Coat-

ings,” Thin Solid Films, Vol. 415, No. 1-2, 2002, pp.

151-159.

doi:10.1016/S0040-6090(02)00511-4

[3] J. Musil, “Hard and Superhard Nanocomposite Coatings,”

Surface and Coatings Technology, Vol. 125, No. 1-3,

2000, pp. 322-330.

doi:10.1016/S0257-8972(99)00586-1

[4] I. Petrov, P. B. Varna, L. Hultman and J. E. Greene, “Mi-

crostructural Evolution during Film Growth,” Journal of

Vacuum Science and Technology A, Vol. 21, No. 5, 2003,

pp. 117-128.

doi:10.1116/1.1601610

[5] J. Thornton, “High-Rate Thick-Film Growth,” Annual Re-

view of Materials Science, Vol. 7, 1977, pp. 239-260.

doi:10.1146/annurev.ms.07.080177.001323

[6] R. Messier, A. P. Giri and R. A. Roy, “Revised Structure

Zone Model for Thin Film Physical Structure,” Journal of

Vacuum Science and Technology A, Vol. 2, 1984, pp.

500-503.

doi:10.1116/1.572604

[7] J. A. Thornton, “The Microstructure of Sputter-Deposited

Coatings,” Journal of Vacuum Science and Technology A,

Vol. 4, No. 6, 1986, pp. 3059-3056.

doi:10.1116/1.573628

[8] P. B. Barna and M. Adamik, “Fundamental Structure

Forming Phenomena of Policrystalline Films and the

Structure Zone Models,” Thin Solid Films, Vol. 317,

1998, pp. 27-33.

doi:10.1016/S0040-6090(97)00503-8

[9] S. Kadlec, J. Musil and J. Vyskoĉil, “Growth and Proper-

ties of Hard Coating Prepared by Physical Vapor Deposi-

tion Methods,” Surface and Coatings Technology, Vol.

54-55, 1992, pp. 287-296.

[10] L. I. Maissel, “Handbook of Thin Films,” McGraw-Hill,

New York, 1983.

[11] R. Messier, “Toward Quantification of Thin Film Mor-

phology,” Journal of Vacuum Science and Technology A,

Vol. 4, No. 3, 1986, pp. 490-495.

doi:10.1116/1.573866

[12] M. Stüber, H. Leiste, S. Ulrich, H. Holleck and D. Schild,

“Microstructure and Properties of Low Friction TiC-C

Nanocomposite Coatings Deposited by Magnetron Sput-

tering,” Surface and Coatings Technology, Vol. 150, No.

2-3, 2002, pp. 218-226.

doi:10.1016/S0257-8972(01)01493-1

[13] V. N. Antsiferov and A. L. Kameneva, “Experimental

Study of the Structure of Multicomponent Nanostructured

Coatings on the Basis of Ti-Zr-N Alloys Formed by Ionic

Plasma Methods,” Russian Journal of Non-Ferrous Met-

als, Vol. 48, No. 6, 2007, pp. 488-495.

doi:10.3103/S1067821207060211

[14] D. V. Shtansky, E. A. Levashov, K. Kaneko and Y. Iku-

hara, “Characterization of Nanostructured Multiphase

Ti-Al-B-N Thin Films with Extremely Small Grain Size,”

Surface and Coatings Technology, Vol. 148, No. 2-3,

2001, pp. 206-215.

doi:10.1016/S0257-8972(01)01341-X

[15] D. V. Shtansky, E. A. Levashov, A. N. Sheveiko and J. J.

Moore, “Synthesis and Characterization of Ti-Si-C-N

Films,” Metallurgical and Materials Transaction A, Vol.

30, No. 9, 1999, pp. 2439-2447.

doi:10.1007/s11661-999-0252-0

[16] A. Gupper, A. Fernandez, С. Fernandez-Ramos, F. Hofer,

С. Mitterer and P. Warbichler, “Characterization of

Nanocomposite Coatings in the System Ti-B-N by Ana-

lytical Electron Microscopy and X-Ray Photoelectron

Spectroscopy,” Monatshefte für Chemie/Chemical Mon-

thly, Vol. 133, No. 6, 2002, pp. 837-848.

Copyright © 2011 SciRes. MSA