Crystallinity, Microstructure and Mechanical Strength of Yttria-Stabilized Tetragonal Zirconia Ceramics for Optical

4 Ferrule

nized in sintered body, as shown in Figure 5.

Vickers’ hardness is plotted as Figure 8. It is found

that specimen B sintered at 1350˚C and specimen C sin-

tered at 1450˚C showed higher values. It should be

pointed out in this work that, for the specimen C, some

unclear problems, such as pores in sintered body and low

bending strength, were still existed, although their hard-

ness above ~1200 was sufficient for practical usage to

optical ferrule. Furthermore, for the specimen B, hard-

ness was rather lowered by high-temperature sintering.

We assume that hardness was probably decreased by ex-

istence of some amorphous-like phases in appearance, as

shown in Figure 5(c). Conclusively speaking, for the

specimen B, low-temperature sintering was favorable for

the sintered body with high tetragonality and good me-

chanical properties.

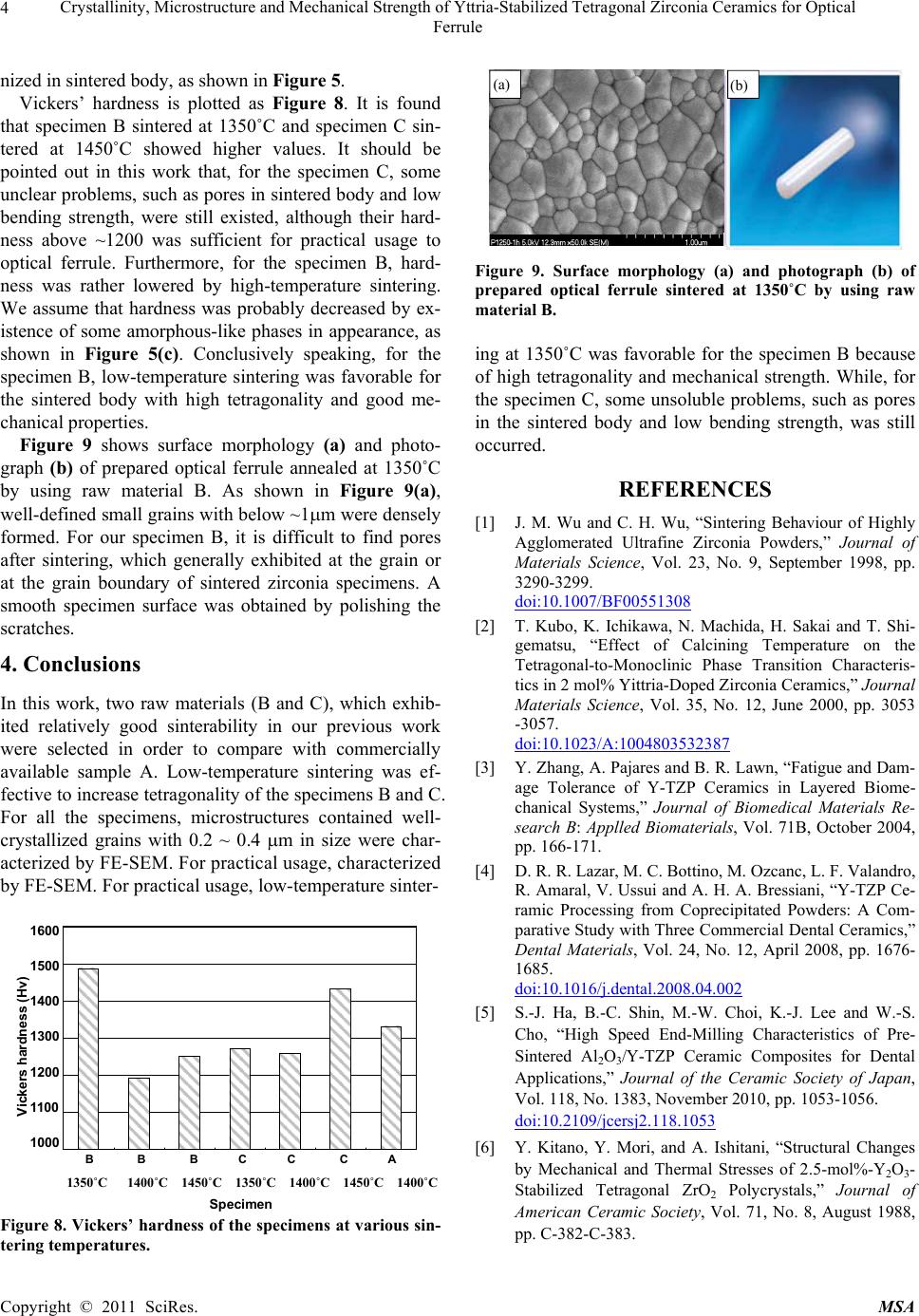

Figure 9 shows surface morphology (a) and photo-

graph (b) of prepared optical ferrule annealed at 1350˚C

by using raw material B. As shown in Figure 9(a),

well-defined small grains with below ~1μm were densely

formed. For our specimen B, it is difficult to find pores

after sintering, which generally exhibited at the grain or

at the grain boundary of sintered zirconia specimens. A

smooth specimen surface was obtained by polishing the

scratches.

4. Conclusions

In this work, two raw materials (B and C), which exhib-

ited relatively good sinterability in our previous work

were selected in order to compare with commercially

available sample A. Low-temperature sintering was ef-

fective to increase tetragonality of the specimens B and C.

For all the specimens, microstructures contained well-

crystallized grains with 0.2 ~ 0.4 μm in size were char-

acterized by FE-SEM. For practical usage, characterized

by FE-SEM. For practical usage, low-temperature sinter-

B BBC CCA

1350°C 1400 °C 1450 °C 1350 °C 1400 °C 1450 °C 1400 °C

Sp ecimen

Vi ckers hard ness ( Hv)

1600

1500

1400

1300

1200

1100

1000

Figure 8. Vickers’ hardness of the specimens at various sin-

tering temperatures.

a) b)

Figure 9. Surface morphology (a) and photograph (b) of

prepared optical ferrule sintered at 1350˚C by using raw

material B.

ing at 1350˚C was favorable for the specimen B because

of high tetragonality and mechanical strength. While, for

the specimen C, some unsoluble problems, such as pores

in the sintered body and low bending strength, was still

occurred.

REFERENCES

[1] J. M. Wu and C. H. Wu, “Sintering Behaviour of Highly

Agglomerated Ultrafine Zirconia Powders,” Journal of

Materials Science, Vol. 23, No. 9, September 1998, pp.

3290-3299.

doi:10.1007/BF00551308

[2] T. Kubo, K. Ichikawa, N. Machida, H. Sakai and T. Shi-

gematsu, “Effect of Calcining Temperature on the

Tetragonal-to-Monoclinic Phase Transition Characteris-

tics in 2 mol% Yittria-Doped Zirconia Ceramics,” Journal

Materials Science, Vol. 35, No. 12, June 2000, pp. 3053

-3057.

doi:10.1023/A:1004803532387

[3] Y. Zhang, A. Pajares and B. R. Lawn, “Fatigue and Dam-

age Tolerance of Y-TZP Ceramics in Layered Biome-

chanical Systems,” Journal of Biomedical Materials Re-

search B: Applled Biomaterials, Vol. 71B, October 2004,

pp. 166-171.

[4] D. R. R. Lazar, M. C. Bottino, M. Ozcanc, L. F. Valandro,

R. Amaral, V. Ussui and A. H. A. Bressiani, “Y-TZP Ce-

ramic Processing from Coprecipitated Powders: A Com-

parative Study with Three Commercia l Dental Ceramics,”

Dental Materials, Vol. 24, No. 12, April 2008, pp. 1676-

1685.

doi:10.1016/j.dental.2008.04.002

[5] S.-J. Ha, B.-C. Shin, M.-W. Choi, K.-J. Lee and W.-S.

Cho, “High Speed End-Milling Characteristics of Pre-

Sintered Al2O3/Y-TZP Ceramic Composites for Dental

Applications,” Journal of the Ceramic Society of Japan,

Vol. 118, No. 1383, November 2010, pp. 1053-1056.

doi:10.2109/jcersj2.118.1053

[6] Y. Kitano, Y. Mori, and A. Ishitani, “Structural Changes

by Mechanical and Thermal Stresses of 2.5-mol%-Y2O3-

Stabilized Tetragonal ZrO2 Polycrystals,” Journal of

American Ceramic Society, Vol. 71, No. 8, August 1988,

pp. C-382-C-383.

1350˚C 1400˚C 1450˚C 1350˚C 1400˚C 1450˚C 1400˚C

(a) (b)

Copyright © 2011 SciRes. MSA