Paper Menu >>

Journal Menu >>

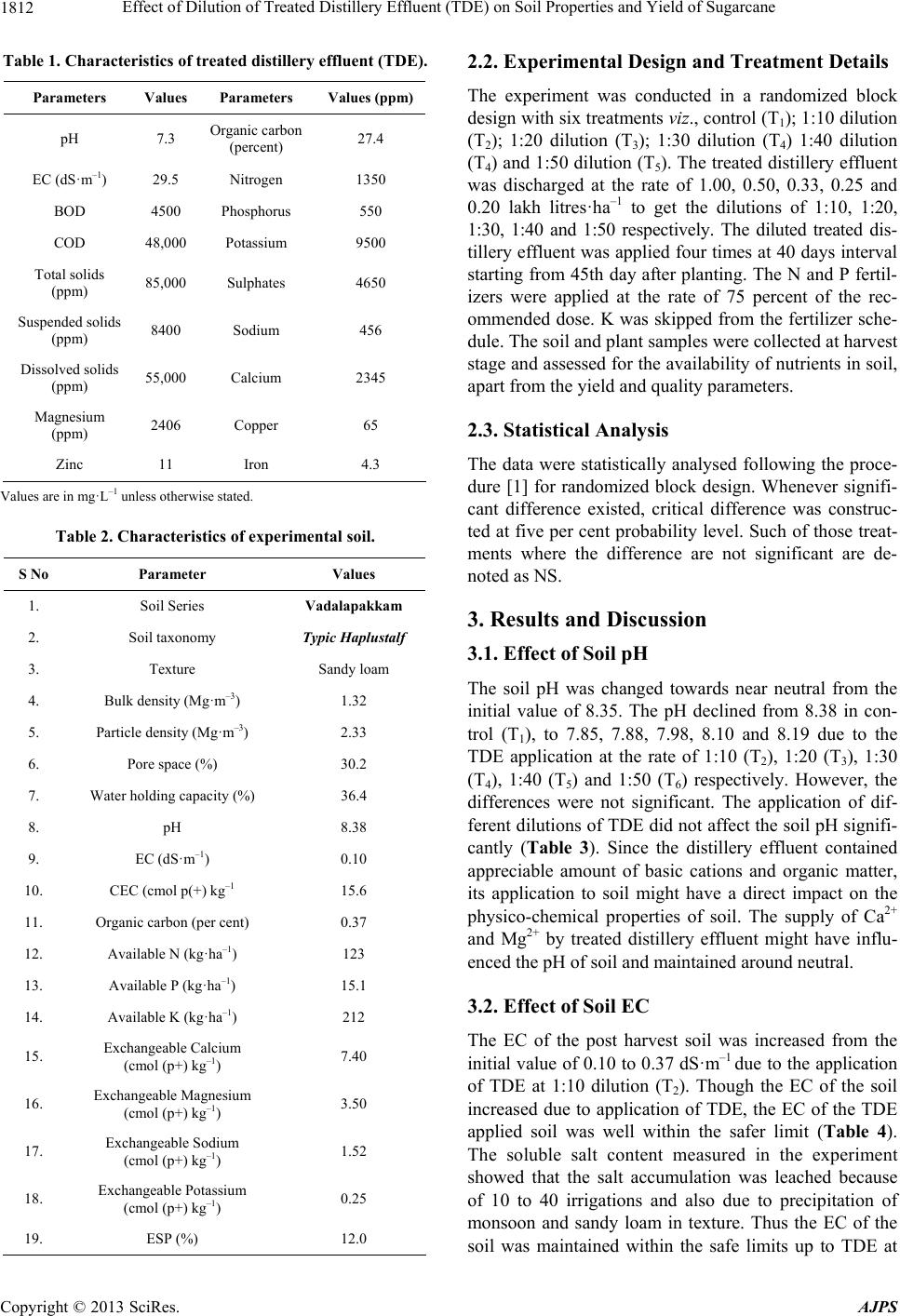

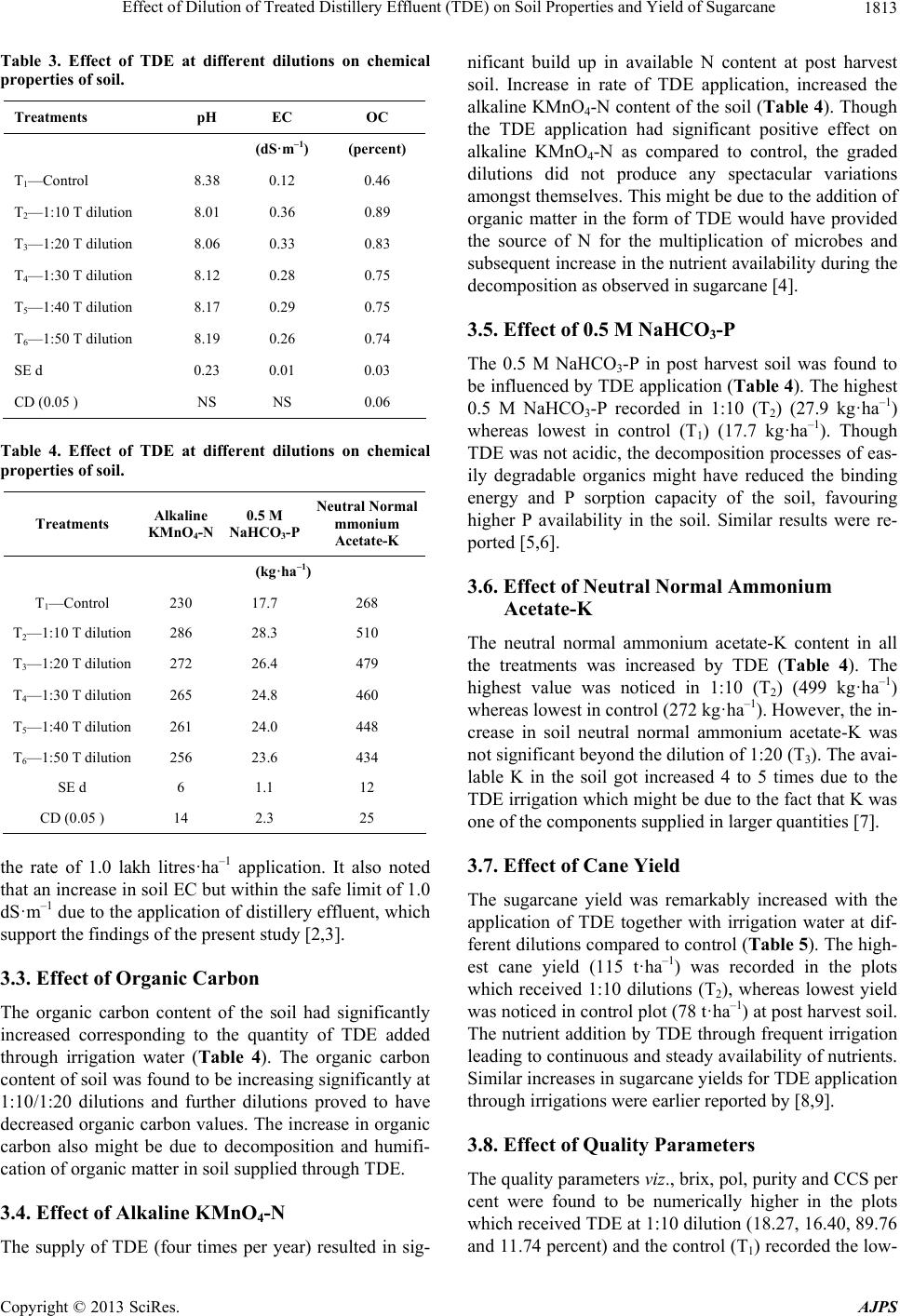

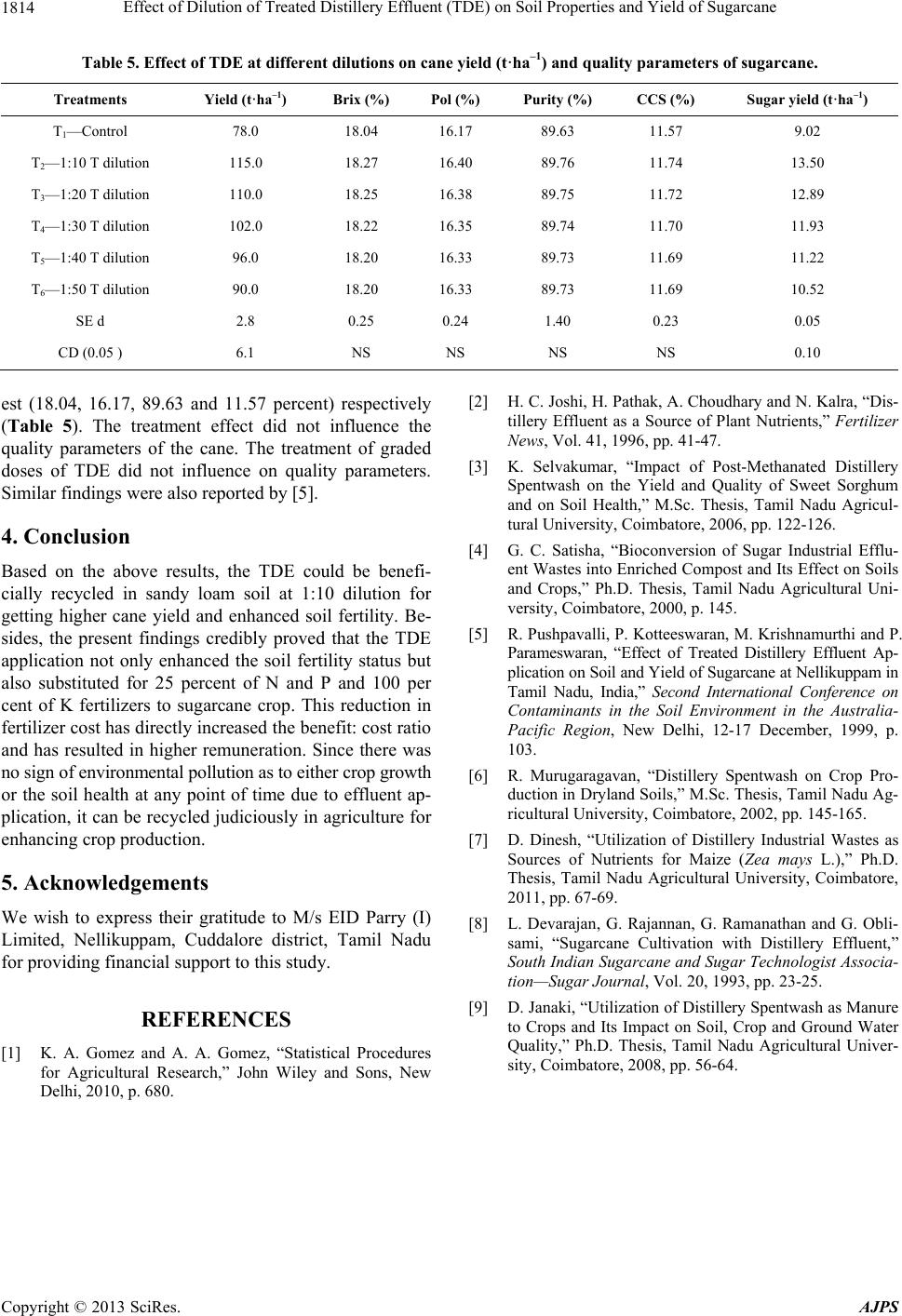

American Journal of Plant Sciences, 2013, 4, 1811-1814 http://dx.doi.org/10.4236/ajps.2013.49222 Published Online September 2013 (http://www.scirp.org/journal/ajps) Effect of Dilution of Treated Distillery Effluent (TDE) on Soil Properties and Yield of Sugarcane Previna Sivaloganathan*, Baskar Murugaiyan, Saravanan Appavou, Leninraja Dharmaraj Department of Soil Science and Agricultural Chemistry, Anbil Dharmalingam Agricultural College and Research Institute, Trichira- palli, India. Email: *previyuti@gmail.com Received June 16th, 2013; revised July 17th, 2013; accepted August 19th, 2013 Copyright © 2013 Previna Sivaloganathan et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT Sugarcane is one of the most important cash crops, which plays a pivotal role in India’s agricultural and indu strial econ- omy. The treated distillery effluent (TDE) being plant originated, contains all p lant nutrients and organic matter. There- fore, it is being used as a cheap source of nutrients and organic manure in agricultu re activities in soil besides improving soil physical properties. The experiment was conducted during August, 2010-2011 and 2011-2012 with CO 86032 in a randomized block design with six treatments and was replicated four times. The TDE was discharged @ 1.00, 0.50, 0.33, 0.25 and 0.20 lakh liters·ha–1 to get the dilutions of 1:10, 1:20, 1:30, 1:40 and 1:50 dilutions respectively. It was applied four times at 40 days in terval starting from 45th day after planting. The fertilizers viz., N and P @ 75 percent of the recommended dose were applied and K was skipped. The results revealed that irrigation with TDE at 1:10 dilution resulted in higher yield of sugarcane. The TDE did not have any influence on quality parameters of sugarcane. The TDE application favourably influenced the available nutrients and organic carbon content in the soil. Besides, the present findings credibly proved that the TDE application not only enhanced the soil fertility status but also substituted for 25 percent of N and P and 100 percent of K fertilizers to sugarcane crop. Keywords: TDE; Dilution; Sugarcane; Yield; Soil Properties 1. Introduction Molasses based distillery units discharge large quantities of effluent and these units face problems in the disposal of effluent. This effluent has high percentage of organic materials, which have high percentage of biological oxy- gen demand (BOD) (90,000 to 100,000 mg·L–1). Indis- criminate disposal of the effluent in water and on d ilution land leads to serious pollution and changes the nutrient and biological status of the soil where they are disposed of. So it should be diluted with irrigation water and then applied to growing crops. Technology has been devel- oped to use this effluent as fertigation source to crops like sugarcane, sunflower etc., after diluting it with irri- gation water to reduce the BOD level in the ratios of 1:10 to 1:50. The present study was undertaken with a view to study the effect of treated distillery effluent on the sug- arcane yield and quality and also their nutrient status in the soil. 2. Materials and Methods 2.1. Experimental Site The research was conducted with application of TDE through irrigation water during off season of 2010-2011 and 2011-2012 at experimental site of M/s EID Parry (I) Ltd., cane farm, Edayanvelli, Cuddalore district, Tamil Nadu. The experimental site lies geographically in be- tween 11˚46' and 19˚6' North Latitude and 79˚40' and 5˚1' East Longitude and at an altitu de of 62 metres above mean sea level. Trail was conducted with sandy loam in texture and the so il, the intial soil pH was 8.40, ESP 11.2 per cent and EC 0.10 dS·m–1. The soil organic carbon content was 0.50 per cent and the soil available N was low in status, whereas available P and K were medium in status (Table 1). The treated distillery effluent (TDE) used in this stud y was collected from the molasses based distillery industry M/s EID Parry India Ltd., Nellikup- pam, Cuddalore District, Tamil Nadu (Table 2). It was analysed for various physic-chemical properties. *Corresponding author. Copyright © 2013 SciRes. AJPS  Effect of Dilution of Treated Distillery Effluent (TDE) on Soil Properties and Yield of Sugarcane 1812 Table 1. Characteristics of treated distillery effluent (TDE). Parameters Values Parameters Values (ppm) pH 7.3 Organic carbon (percent) 27.4 EC (dS·m–1) 29.5 Nitrogen 1350 BOD 4500 Phosphorus 550 COD 48,000 Potassium 9500 Total solids (ppm) 85,000 Sulphates 4650 Suspended solids (ppm) 8400 Sodium 456 Dissolved solids (ppm) 55,000 Calcium 2345 Magnesium (ppm) 2406 Copper 65 Zinc 11 Iron 4.3 Values are in mg·L–1 unless otherwise stated. Table 2. Characteristics of experimental soil. S No Parameter Values 1. Soil Series Vadalapakkam 2. Soil taxonomy Typic Haplustalf 3. Texture Sandy loam 4. Bulk density (Mg·m–3) 1.32 5. Particle density (Mg·m–3) 2.33 6. Pore space (%) 30.2 7. Water holding capacity (%) 36.4 8. pH 8.38 9. EC (dS·m–1) 0.10 10. CEC (cmol p(+) kg–1 15.6 11. Organic carbon (per cent) 0.37 12. Available N (kg·ha–1) 123 13. Available P ( kg·ha–1) 15.1 14. Available K (kg·ha–1) 212 15. Exchangeable Calcium (cmol (p+) kg–1) 7.40 16. Exchangeable Magnesium (cmol (p+) kg–1) 3.50 17. Exchan ge a b l e S o d i um (cmol (p+) kg–1) 1.52 18. Exchangeable Potassium (cmol (p+) kg–1) 0.25 19. ESP (%) 12.0 2.2. Experimental Design and Treatment Details The experiment was conducted in a randomized block design with six treatments viz., control (T1); 1:10 dilution (T2); 1:20 dilution (T3); 1:30 dilution (T4) 1:40 dilution (T4) and 1:50 dilution (T5). The treated distillery efflu ent was discharged at the rate of 1.00, 0.50, 0.33, 0.25 and 0.20 lakh litres·ha–1 to get the dilutions of 1:10, 1:20, 1:30, 1:40 and 1:50 respectively. The diluted treated dis- tillery effluent was applied four times at 40 days interval starting from 45th day after planting. The N and P fertil- izers were applied at the rate of 75 percent of the rec- ommended dose. K was skipped from the fertilizer sche- dule. The soil and plant samples were collected at harvest stage and assessed for the availability of nutrients in soil, apart from the yield and quality parameters. 2.3. Statistical Analysis The data were statistically analysed following the proce- dure [1] for randomized block design. Whenever signifi- cant difference existed, critical difference was construc- ted at five per cent p robability level. Such of those treat- ments where the difference are not significant are de- noted as NS. 3. Results and Discussion 3.1. Effect of Soil pH The soil pH was changed towards near neutral from the initial value of 8.35. The pH declined from 8.38 in con- trol (T1), to 7.85, 7.88, 7.98, 8.10 and 8.19 due to the TDE application at the rate of 1:10 (T2), 1:20 (T3), 1:30 (T4), 1:40 (T5) and 1:50 (T6) respectively. However, the differences were not significant. The application of dif- ferent dilutions of TDE did not affect the soil pH sign ifi- cantly (Table 3). Since the distillery effluent contained appreciable amount of basic cations and organic matter, its application to soil might have a direct impact on the physico-chemical properties of soil. The supply of Ca2+ and Mg2+ by treated distillery effluent might have influ- enced the pH of soil and maintained around neutral. 3.2. Effect of Soil EC The EC of the post harvest soil was increased from the initial value of 0.10 to 0.37 dS·m–1 due to the application of TDE at 1:10 dilution (T2). Though the EC of the soil increased due to application of TDE, the EC of the TDE applied soil was well within the safer limit (Table 4). The soluble salt content measured in the experiment showed that the salt accumulation was leached because of 10 to 40 irrigations and also due to precipitation of monsoon and sandy loam in texture. Thus the EC of the soil was maintained within the safe limits up to TDE at Copyright © 2013 SciRes. AJPS  Effect of Dilution of Treated Distillery Effluent (TDE) on Soil Properties and Yield of Sugarcane 1813 Table 3. Effect of TDE at different dilutions on chemical properties of soil. Treatments pH EC OC (dS·m–1) (percent) T1—Control 8.38 0.12 0.46 T2—1:10 T dilution 8.01 0.36 0.89 T3—1:20 T dilution 8.06 0.33 0.83 T4—1:30 T dilution 8.12 0.28 0.75 T5—1:40 T dilution 8.17 0.29 0.75 T6—1:50 T dilution 8.19 0.26 0.74 SE d 0.23 0.01 0.03 CD (0.05 ) NS NS 0.06 Table 4. Effect of TDE at different dilutions on chemical properties of soil. Treatments Alkaline KMnO4-N 0.5 M NaHCO3-P Neutral Normal mmonium Acetate-K (kg·ha–1) T1—Control 230 17.7 268 T2—1:10 T dilution 286 28.3 510 T3—1:20 T dilution 272 26.4 479 T4—1:30 T dilution 265 24.8 460 T5—1:40 T dilution 261 24.0 448 T6—1:50 T dilution 256 23.6 434 SE d 6 1.1 12 CD (0.05 ) 14 2.3 25 the rate of 1.0 lakh litres·ha–1 application. It also noted that an increase in so il EC but within the safe li mit of 1.0 dS·m–1 due to the application of distillery effluent, which support the findings of the present study [2,3]. 3.3. Effect of Organic Carbon The organic carbon content of the soil had significantly increased corresponding to the quantity of TDE added through irrigation water (Table 4). The organic carbon content of soil was found to be increasing significantly at 1:10/1:20 dilutions and further dilutions proved to have decreased organic carbon v alues. The increase in organic carbon also might be due to decomposition and humifi- cation of organic matter in soil supplied through TDE. 3.4. Effect of Alkaline KMnO4-N The supply of TDE (four times per year) resulted in sig- nificant build up in available N content at post harvest soil. Increase in rate of TDE application, increased the alkaline KMnO4-N content of the soil (Ta ble 4). Though the TDE application had significant positive effect on alkaline KMnO4-N as compared to control, the graded dilutions did not produce any spectacular variations amongst themselves. This might be due to the addition of organic matter in the form of TDE would have provided the source of N for the multiplication of microbes and subsequent increase in the nutrient av ailability during the decomposition as observed in sugarcane [4]. 3.5. Effect of 0.5 M NaHCO3-P The 0.5 M NaHCO3-P in post harvest soil was found to be influenced by TDE application (Table 4). The highest 0.5 M NaHCO3-P recorded in 1:10 (T2) (27.9 kg·ha–1) whereas lowest in control (T1) (17.7 kg·ha–1). Though TDE was not acidic, the decomposition processes of eas- ily degradable organics might have reduced the binding energy and P sorption capacity of the soil, favouring higher P availability in the soil. Similar results were re- ported [5,6 ]. 3.6. Effect of Neutral Normal Ammonium Acetate-K The neutral normal ammonium acetate-K content in all the treatments was increased by TDE (Table 4). The highest value was noticed in 1:10 (T2) (499 kg·ha–1) whereas lowest in control (272 kg·ha–1). However, the in- crease in soil neutral normal ammonium acetate-K was not significant beyond the dilution of 1:20 (T3). The avai- lable K in the soil got increased 4 to 5 times due to the TDE irrigation which might be due to the fact that K was one of the compon ents supplied in larger quantities [7 ]. 3.7. Effect of Cane Yield The sugarcane yield was remarkably increased with the application of TDE together with irrigation water at dif- ferent dilutions compared to co ntrol (Table 5). The high- est cane yield (115 t·ha–1) was recorded in the plots which received 1:10 dilutions (T2), whereas lowest yield was noticed in control plot (78 t·ha–1) at post harvest soil. The nutrient addition by TDE th rough frequent irrigation leading to continuous and steady availability of nu trients. Similar increases in sugarcane yields for TDE application through irrigations were earlier reported by [8,9]. 3.8. Effect of Quality Parameters The quality para meters viz., brix, pol, purity and CCS per cent were found to be numerically higher in the plots which received TDE at 1:10 dilution (18.27, 16.40, 89.76 nd 11.74 per cent) and the contro l (T1) reco rded the low- a Copyright © 2013 SciRes. AJPS  Effect of Dilution of Treated Distillery Effluent (TDE) on Soil Properties and Yield of Sugarcane Copyright © 2013 SciRes. AJPS 1814 Table 5. Effect of TDE at different dilutions on cane yield (t·ha–1) and quality parameters of sugarcane. Treatments Yield (t·ha–1) Brix (%) Pol (%) Purity (%) CCS (%) Sugar yield (t·ha–1) T1—Control 78.0 18.04 16.17 89.63 11.57 9.02 T2—1:10 T dilution 115.0 18.27 16.40 89.76 11.74 13.50 T3—1:20 T dilution 110.0 18.25 16.38 89.75 11.72 12.89 T4—1:30 T dilution 102.0 18.22 16.35 89.74 11.70 11.93 T5—1:40 T dilution 96.0 18.20 16.33 89.73 11.69 11.22 T6—1:50 T dilution 90.0 18.20 16.33 89.73 11.69 10.52 SE d 2.8 0.25 0.24 1.40 0.23 0.05 CD (0.05 ) 6.1 NS NS NS NS 0.10 est (18.04, 16.17, 89.63 and 11.57 percent) respectively (Table 5). The treatment effect did not influence the quality parameters of the cane. The treatment of graded doses of TDE did not influence on quality parameters. Similar findings were also reported by [5]. 4. Conclusion Based on the above results, the TDE could be benefi- cially recycled in sandy loam soil at 1:10 dilution for getting higher cane yield and enhanced soil fertility. Be- sides, the present findings credibly proved that the TDE application not only enhanced the soil fertility status but also substituted for 25 percent of N and P and 100 per cent of K fertilizers to sugarcane crop. This reduction in fertilizer cost has directly increased the benefit: cost ratio and has resulted in higher remuneration. Since there was no sign of environmental pollution as to ei t her crop growth or the soil health at any point of time due to effluent ap- plication, it can be recycled judiciously in agriculture for enhancing crop production. 5. Acknowledgements We wish to express their gratitude to M/s EID Parry (I) Limited, Nellikuppam, Cuddalore district, Tamil Nadu for providing financial support to this study. REFERENCES [1] K. A. Gomez and A. A. Gomez, “Statistical Procedures for Agricultural Research,” John Wiley and Sons, New Delhi, 2010, p. 680. [2] H. C. Joshi, H. Pathak, A. Choudhary and N. Kalra, “Dis- tillery Effluent as a Source of Plant Nutrients,” Fertilizer News, Vol. 41, 1996, pp. 41-47. [3] K. Selvakumar, “Impact of Post-Methanated Distillery Spentwash on the Yield and Quality of Sweet Sorghum and on Soil Health,” M.Sc. Thesis, Tamil Nadu Agricul- tural University, Coimbatore, 2006, pp. 122-126. [4] G. C. Satisha, “Bioconversion of Sugar Industrial Efflu- ent Wastes into Enriched Compost and Its Effect on Soils and Crops,” Ph.D. Thesis, Tamil Nadu Agricultural Uni- versity, Coimbatore, 2000, p. 145. [5] R. Pushpavalli, P. Kotteeswaran, M. Krishnamurthi and P. Parameswaran, “Effect of Treated Distillery Effluent Ap- plication on Soil and Yield of Sugarcane at Nellikuppam in Tamil Nadu, India,” Second International Conference on Contaminants in the Soil Environment in the Australia- Pacific Region, New Delhi, 12-17 December, 1999, p. 103. [6] R. Murugaragavan, “Distillery Spentwash on Crop Pro- duction in Dryland Soils,” M.Sc. Thesis, Tami l Nadu Ag- ricultural University, Coimbatore, 2002, pp. 145-165. [7] D. Dinesh, “Utilization of Distillery Industrial Wastes as Sources of Nutrients for Maize (Zea mays L.),” Ph.D. Thesis, Tamil Nadu Agricultural University, Coimbatore, 2011, pp. 67-69. [8] L. Devarajan, G. Rajannan, G. Ramanathan and G. Obli- sami, “Sugarcane Cultivation with Distillery Effluent,” South Indian Sugarcane and Sugar Technologist Associa- tion—Sugar Journal, Vol. 20, 1993, pp. 23-25. [9] D. Janaki, “Utilization of Distillery Spentwash as Manure to Crops and Its Impact on Soil, Crop and Ground Water Quality,” Ph.D. Thesis, Tamil Nadu Agricultural Univer- sity, Coimbatore, 2008, pp. 56-64. |