Paper Menu >>

Journal Menu >>

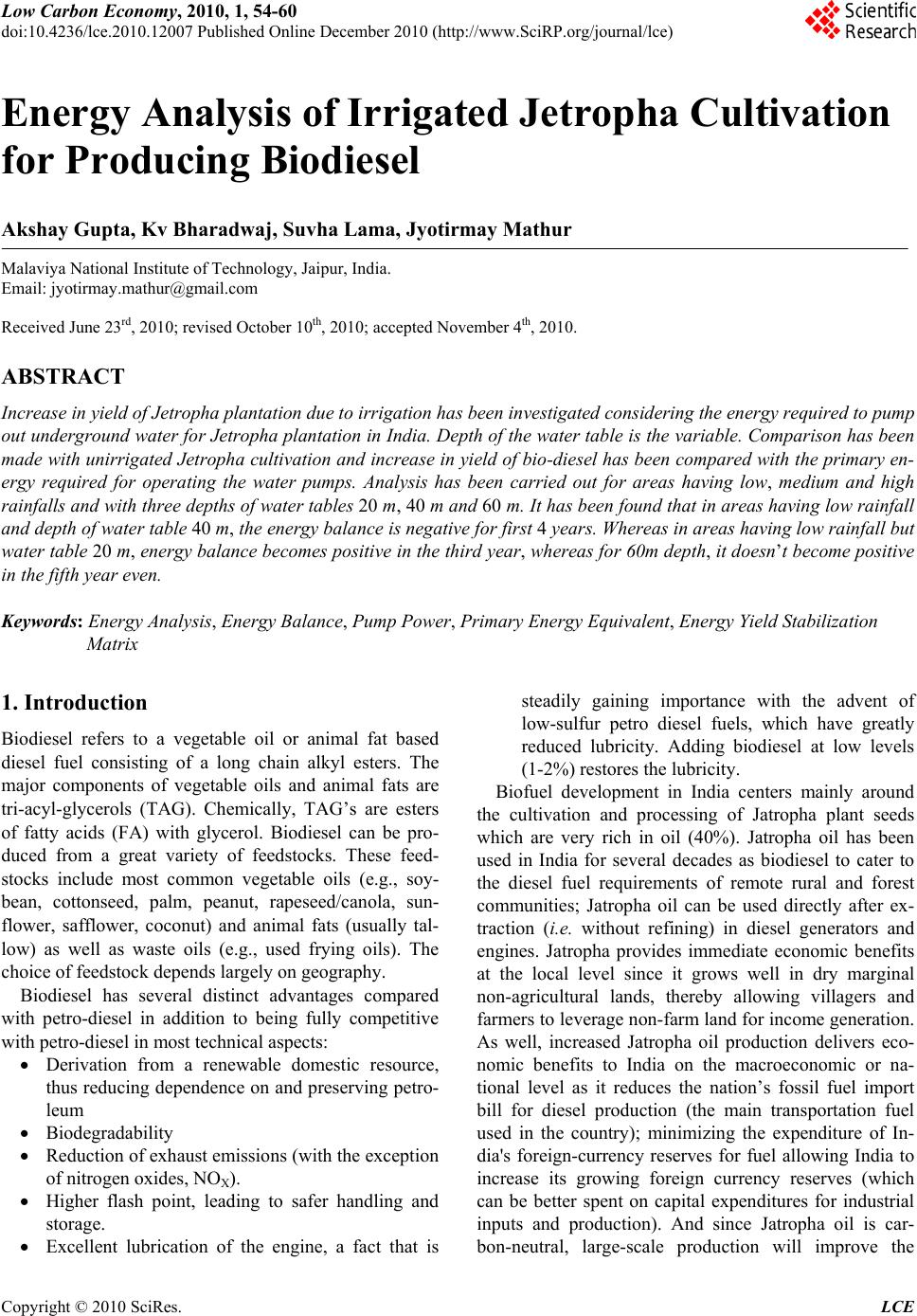

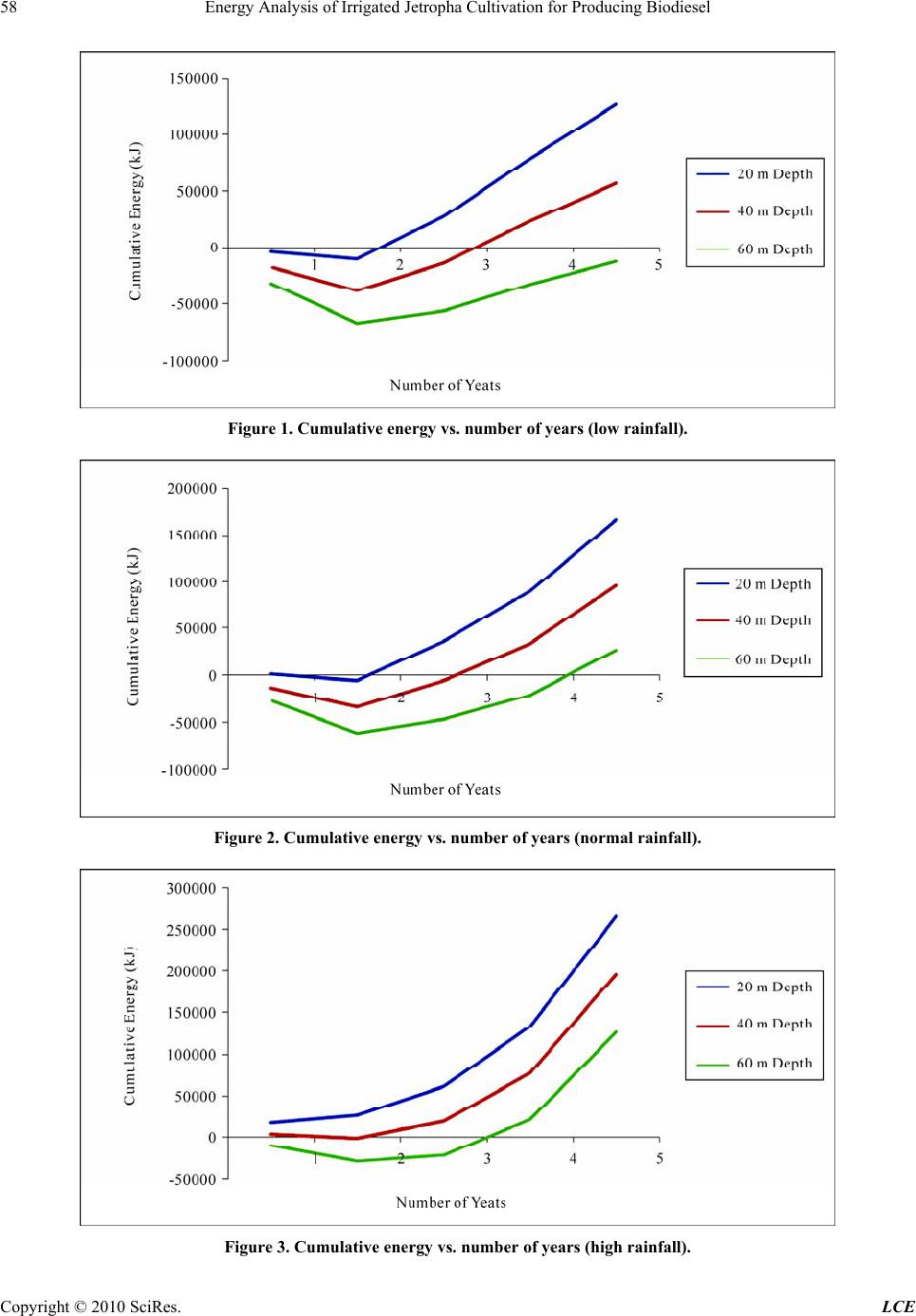

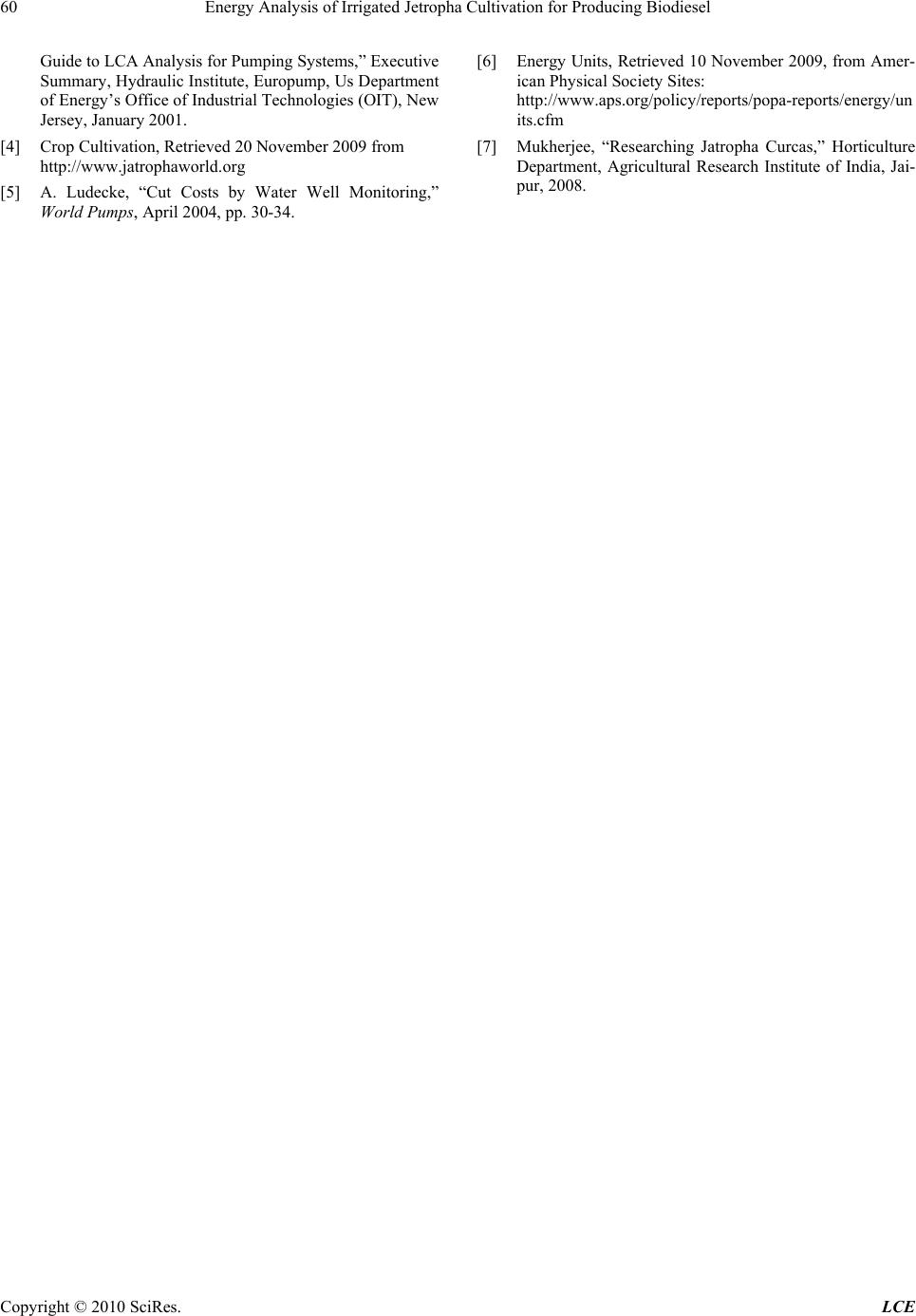

Low Carbon Economy, 2010, 1, 54-60 doi:10.4236/lce.2010.12007 Published Online December 2010 (http://www.SciRP.org/journal/lce) Copyright © 2010 SciRes. LCE Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Akshay Gupta, Kv Bharadwaj, Suvha Lama, Jyotirmay Mathur Malaviya National Institute of Technology, Jaipur, India. Email: jyotirmay.mathur@gmail.com Received June 23rd, 2010; revised October 10th, 2010; accepted November 4th, 2010. ABSTRACT Increase in yield of Jetropha plantation due to irrigation has been investigated considering the energy required to pump out underground water for Jetropha plantation in India. Depth of the water table is the variable. Comparison has been made with unirrigated Jetropha cultivation and increase in yield of bio-diesel has been compared with the primary en- ergy required for operating the water pumps. Analysis has been carried out for areas having low, medium and high rainfalls and with three depths of water tables 20 m, 40 m and 60 m. It has been found that in areas having low rainfall and depth of water table 40 m, the energy balance is negative for first 4 years. Whereas in areas having low rainfall but water table 20 m, energy balance becomes positive in the third year, whereas for 60m depth, it doesn’t become positive in the fifth year even. Keywords: Energy Analysis, Energy Balance, Pump Power, Primary Energy Equivalent, Energy Yield Stabilization Matrix 1. Introduction Biodiesel refers to a vegetable oil or animal fat based diesel fuel consisting of a long chain alkyl esters. The major components of vegetable oils and animal fats are tri-acyl-glycerols (TAG). Chemically, TAG’s are esters of fatty acids (FA) with glycerol. Biodiesel can be pro- duced from a great variety of feedstocks. These feed- stocks include most common vegetable oils (e.g., soy- bean, cottonseed, palm, peanut, rapeseed/canola, sun- flower, safflower, coconut) and animal fats (usually tal- low) as well as waste oils (e.g., used frying oils). The choice of feedstock depends largely on geography. Biodiesel has several distinct advantages compared with petro-diesel in addition to being fully competitive with petro-diesel in most technical aspects: Derivation from a renewable domestic resource, thus reducing dependence on and preserving petro- leum Biodegradability Reduction of exhaust emissions (with the exception of nitrogen oxides, NOX). Higher flash point, leading to safer handling and storage. Excellent lubrication of the engine, a fact that is steadily gaining importance with the advent of low-sulfur petro diesel fuels, which have greatly reduced lubricity. Adding biodiesel at low levels (1-2%) restores the lubricity. Biofuel development in India centers mainly around the cultivation and processing of Jatropha plant seeds which are very rich in oil (40%). Jatropha oil has been used in India for several decades as biodiesel to cater to the diesel fuel requirements of remote rural and forest communities; Jatropha oil can be used directly after ex- traction (i.e. without refining) in diesel generators and engines. Jatropha provides immediate economic benefits at the local level since it grows well in dry marginal non-agricultural lands, thereby allowing villagers and farmers to leverage non-farm land for income generation. As well, increased Jatropha oil production delivers eco- nomic benefits to India on the macroeconomic or na- tional level as it reduces the nation’s fossil fuel import bill for diesel production (the main transportation fuel used in the country); minimizing the expenditure of In- dia's foreign-currency reserves for fuel allowing India to increase its growing foreign currency reserves (which can be better spent on capital expenditures for industrial inputs and production). And since Jatropha oil is car- bon-neutral, large-scale production will improve the  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 55 country’s carbon emissions profile. Finally, since no food producing farmland is required for producing this biofuel (unlike corn or sugar cane ethanol, or palm oil diesel), it is considered the most politically and morally acceptable choice among India’s current biofuel options; it has no known negative impact on the production of the massive amounts grains and other vital agriculture goods India produces to meet the food requirements of its massive population. Other biofuels which displace food crops from viable agricultural land such as corn ethanol or palm biodiesel have caused serious price increases for basic food grains and edible oils in other countries. Jat- ropha plant cultivation and subsequent production of bio-fuel is a crucial part of India’s plan to attain energy sustainability. The paper on ‘Jatropha biodiesel production and use’ by Achten [1] discusses the best available methods, their shortcomings and the potential risks and remedies for each production step. Work done by Mr. Mukherjee, Department of Horticulture, Agricultural Research Cen- ter, Jaipur provides insights into cultivation practices and economic feasibility of Jatropha plantation, its use as an alternative fuel and as a tool for protection of environ- ment. The information regarding pump energy and re- lated data was obtained from ‘Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems’, an execu- tive summary developed in collaboration between Hy- draulic Institute, Europump and the US Department of Energy’s Office of Industrial Technologies. Data gener- ated in these and various other research papers was ap- plied in our research work in estimation of the feasibility of Jatropha plantation with regard to the amount of rain- fall and the depth of the water table of a particular area. Scope of this work covered finding the energy balance of irrigated Jetropha cultivation of obtaining biodiesel by calculating the primary energy consumption for water pumping from underground water sources and comparing the same with the calorific value of the bio-diesel. 2. Primary Energy Req ui r em e nt fo r Irrigation In many parts of rural India, the major source of irriga- tion is wells. So we used the energy required for the pumps to pull water from the wells as our input energy. The water table depth is very low in few states, such as Rajasthan. The depth of the ground water table varies from few meters to almost 100 m in some areas, meaning we need to dig almost 300 ft to reach the water table. In some parts, the depth of the water table is decreasing rapidly at approximately 2-3 m each year [2]. The first step in calculating the energy required for water pump, the following correlation for pump power was used [3] 366 p m PQH (1) where, Q – Volumetric flow rate, H – Depth of the water, ηp ηm – Efficiencies of pump and motor respectively The required water quantity ‘Q’ was calculated using the fact that the irrigational requirement of Jetropha Karkus plant species is 1500 mm water per hectare per year [4]. Assuming one hectare of plantation, the irriga- tional requirement was converted as: 3 1.5 10000Qmyr (2) 10 hrs per day is considered as the duration of watering of the plant [4]. Hence the volumetric flow rate is: 3 41.1Qmyr (3) The average efficiency of the pump and motor com- bined (ηp * ηm) is considered to be approx. 63.5% [5] 0.635 pm (4) After substitution of these values, the only remaining variable in (1) is the depth of the water table. Assuming the water table depth from ground level to be ‘H’ meters, we calculate the energy required to pump the water ,1500366 0.635 64.54 input electricalel el EHKWh HKWh (5) Considering the primary energy to electrical energy average conversion factor to be 30% [6], primary energy equivalent of electrical energy used for water pumping can be calculated as given below: 64.54 36000.33 697.101 inputprimary primary EH H MJenergy ha yr (6) 3. Calculation of Energy Output as Biodiesel Information about increase in yield of Jetropha kurkas with irrigation was collected from the Agricultural Re- search Institute of India (ARII), Jaipur [7]. There is a marked difference between the net yield from a rain fed plants and irrigated plants as shown in Tables 1, 2 and 3. This difference increased considerably with increase in number of years, varying from 250 kg seeds/hectare of yield in the first year to almost 8000 kg seeds/hectare of yield by the 6th year onwards. This data was concentrated to the arid regions of Rajasthan and taking the average rainfall of about 600 mm per year into consideration [2]. Since after the end of fifth year, the yield in both the categories does not change, the energy balance calcula- tions have been carried out only for first five years. If the energy balance is negative at the end of fifth year, the deficit of energy would never reduce thereafter.  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 56 Let us assume that increase in yield is X kg seeds/ hectare of plantation. Considering 38% oil in the seed cake, 90% efficiency of mechanical extraction, Calorific value of the oil obtained as 40 MJ/litre and specific grav- ity of the oil as 0.913 g/cm3 [5], the total energy obtained from the plant is calculated as: 3 0.380.940 100.913 14.983 outputprimary EX X MJ ofenergyhayr (7) Table 1. Yield of jetropha due to irri gation. Year after planting Expected yield–Rain fed (kg seeds/ha/yr) Expected yield–Irrigated (kg seeds/ha/yr) Change in yield (kg seeds/ha/yr) 1st - 250 250 2nd 250 1000 750 3rd 1000 2500 1500 4th 2000 5000 3000 5th 3000 8000 5000 6th and onwards 4000 12000 8000 Table 2. Total yield of jetropha without irrigation (MT seeds/ha). Low Normal High Year 1 0.10 0.25 0.40 Year 2 0.50 1.00 1.50 Year 3 0.75 1.25 1.75 Year 4 0.90 1.75 2.25 Year 5 1.10 2.00 2.75 Table 3. Total yield of jetropha with irrigation (MT seeds/ ha). Low Normal High Year 1 0.75 1.25 2.50 Year 2 1.00 1.50 3.00 Year 3 4.25 5.00 5.00 Year 4 5.25 6.25 8.00 Year 5 5.25 8.00 12.50 Table 4. Energy balance for jetropha plantation with 20 m water table depth. Year Yield Without Irrigation (MT seeds/ha/yr) Yield with irrigation (MT seeds/ha/yr) Increase in Yield (MT seeds/ha/yr) Energy Output due to increase in Yield (kJ) Energy required for irrigation (kJ) Energy Balance (Out–In) (kJ) Cumulative Energy Balance (kJ) Low rainfall and 20 m depth 1 0.1 0.75 0.65 9737 13942 −4205 −4205 2 0.5 1.0 0.5 7490 13942 −6452 −10657 3 0.75 4.25 3.5 52430 13942 38488 27831 4 0.9 5.25 4.35 65163 13942 51221 79052 5 1.1 5.25 4.11 61567 13942 47625 126677 Normal Rainfall and 20 m Depth 1 0.25 1.25 1.0 14980 13942 1038 1038 2 1.0 1.5 0.5 7490 13942 −6452 −5414 3 1.25 5.0 3.75 56175 13942 42233 36819 4 1.75 6.25 4.5 67410 13942 53468 90287 5 2.0 8.0 6.0 89880 13942 75938 166225 High Rainfall and 20 m Depth 1 0.4 2.5 2.1 31458 13942 17516 17516 2 1.5 3.0 1.5 22470 13942 8528 26044 3 1.75 5.0 3.25 48685 13942 34743 60787 4 2.25 8.0 5.75 86135 13942 72193 132980 5 2.75 12.5 9.75 146055 13942 132113 265093  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 57 Table 5. Energy balance for jetropha plantation with 40 m water table depth. Year Yield Without Irrigation (MT seeds/ha/yr) Yield with irrigation (MT seeds/ha/yr) Increase in Yield (MT seeds/ha/yr) Energy Output due to increase in Yield (kJ) Energy required for irrigation (kJ) Energy Balance (Out–In) (kJ) Cumulative Energy Balance (kJ) Low Rainfall and 40 m Depth 1 0.1 0.75 0.65 9737 27884 −18147 −18147 2 0.5 1.0 0.5 7490 27884 −20394 −38541 3 0.75 4.25 3.5 52430 27884 24546 −13995 4 0.9 5.25 4.35 65163 27884 37279 23284 5 1.1 5.25 4.11 61567 27884 33683 56967 Normal Rainfall and 40 m Depth 1 0.25 1.25 1.0 14980 27884 −12904 −12904 2 1.0 1.5 0.5 7490 27884 −20394 −33298 3 1.25 5.0 3.75 56175 27884 28291 −5007 4 1.75 6.25 4.5 67410 27884 39526 34519 5 2.0 8.0 6.0 89880 27884 61996 96515 High Rainfall and 40 m Depth 1 0.4 2.5 2.1 31458 27884 3574 3574 2 1.5 3.0 1.5 22470 27884 −5414 −1840 3 1.75 5.0 3.25 48685 27884 20801 18961 4 2.25 8.0 5.75 86135 27884 58251 77212 5 2.75 12.5 9.75 146055 27884 118171 195383 Table 6. Energy balance for jetropha plantation with 60 m water table depth. Year Yield Without Irrigation (MT seeds/ha/yr) Yield with irrigation (MT seeds/ha/yr) Increase in Yield (MT seeds/ha/yr) Energy Output due to increase in Yield (kJ) Energy required for irrigation (kJ) Energy Balance (Out–In) (kJ) Cumulative Energy Balance (kJ) Low Rainfall and 60 m Depth 1 0.1 0.75 0.65 9737 41826 −32089 −32089 2 0.5 1.0 0.5 7490 41826 −34336 −66425 3 0.75 4.25 3.5 52430 41826 10604 −55821 4 0.9 5.25 4.35 65163 41826 23337 −32484 5 1.1 5.25 4.11 61567 41826 19741 −12743 Normal Rainfall and 60 m Depth 1 0.25 1.25 1.0 14980 41826 −26846 −26846 2 1.0 1.5 0.5 7490 41826 −34336 −61182 3 1.25 5.0 3.75 56175 41826 14349 −46833 4 1.75 6.25 4.5 67410 41826 25584 −21249 5 2.0 8.0 6.0 89880 41826 48054 26805 High Rainfall and 60 m Depth 1 0.4 2.5 2.1 31458 41826 −10368 −10368 2 1.5 3.0 1.5 22470 41826 −19356 −29724 3 1.75 5.0 3.25 48685 41826 6859 −22865 4 2.25 8.0 5.75 86135 41826 44309 21444 5 2.75 12.5 9.75 146055 41826 104229 125673  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 58 Figure 1. Cumulative energy vs. number of years (low rainfall). Figure 2. Cumulative energy vs. number of years (normal rainfall). Figure 3. Cumulative energy vs. number of years (high rainfall).  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 59 Figure 4. Energy yield stabilization. 4. Energy Balance of Irrigated Jetropha Cultivation Due to variation of depth of water table and rainfall, cas- es for three different values of depth of water tables have been considered, 20 m, 40 m and 60 m. Each of the three depths has been examined with different annual rainfall denoted as low, average and high rainfall conditions. Thus nine combinations were made for the analysis. Re- sults of the year wise energy balance for these combina- tions are presented in Tables 4-6. The graphical repre- sentation of the energy balance is provided in Figures 1, 2 and 3. 5. Energy Matrix When we correlate the data obtained from the 3 tables above, an “Energy Yield Stabilization” matrix can be created with Depth of the water table on the vertical axis and the Degree of rainfall on the horizontal axis. The number of years it takes to pay back the primary energy used for irrigation (termed as year of stabilization in this paper) can be indicated as shown in Table 7 below. The graphical representation of the matrix is provided in Figure 4. If we consider the case of Jaipur, the average amount of rainfall is 500 mm per annum with the average depth of water table being 40 m [2]. From the above data, if anyone plans to invest in Jatropha plantation, he/she would start obtaining profits from the 4th year onwards. 6. Conclusions From the results shown in Tables 4-6, it can be con- cluded that areas having low rainfall and water table be Table 7. Energy yield stabilization matrix. Depth of Water Table (m) Low Rainfall Normal Rainfall High Rainfall 20 (m) 3rd year 3rd year 1st year 40 (m) 4th year 4th year 3rd year 60 (m) - 5th year 4th year low 60 m, irrigated cultivation of bio-diesel will always have negative energy balance due to high energy re- quirement for pumping underground water. Whereas, in areas having normal rainfall and 60 m deep water table, the energy balance becomes positive only in the fifth year. In cases of high rainfall, irrigated cultivation of bio-diesel becomes energy positive in the fourth year. Low rainfall areas having high water table at 20 m depth, have neutral energy balance in the third year. Therefore, irrigated farming of Jetropha in low rainfall and deep water table areas should be discouraged. Further, if the energy requirement for oil extraction from seeds, trans- esterification of oil and other stages is accounted, even areas having normal rainfall and deep water table would also become unattractive for irrigated cultivation of bio- diesel. REFERENCES [1] W. M. Achten, L. Verchot, Y. J. Franken, E. Mathijs, V. P. Singh R. Aerts, et al., “Jatropha Bio-Diesel Production and Use,” Biomass and Bioenergy, Vol. 22, 2008. [2] Ground Water Atlas of Rajasthan. Retrieved 20 Novem- ber 2009. http://www.indianwaterportal.org [3] E.U. Hydraulic Institute, “Pump Life Cycle Costs: A  Energy Analysis of Irrigated Jetropha Cultivation for Producing Biodiesel Copyright © 2010 SciRes. LCE 60 Guide to LCA Analysis for Pumping Systems,” Executive Summary, Hydraulic Institute, Europump, Us Department of Energy’s Office of Industrial Technologies (OIT), New Jersey, January 2001. [4] Crop Cultivation, Retrieved 20 November 2009 from http://www.jatrophaworld.org [5] A. Ludecke, “Cut Costs by Water Well Monitoring,” World Pumps, April 2004, pp. 30-34. [6] Energy Units, Retrieved 10 November 2009, from Amer- ican Physical Society Sites: http://www.aps.org/policy/reports/popa-reports/energy/un its.cfm [7] Mukherjee, “Researching Jatropha Curcas,” Horticulture Department, Agricultural Research Institute of India, Jai- pur, 2008. |