Real-Time Air Monitoring of Trichloroethylene and Tetrachloroethylene Using Mobile TAGA Mass Spectrometry 101

the Hurricane Katrina response [16]. In 2010, US EPA

TAGA units monitored the BP oil spill in the Gulf of

Mexico along the Gulf Coast [17].

2.2. Real-Time On-Site Air Monitoring

Traditional analytical methods for measuring VOCs in

ambient air involve the collection of samples with ad-

sorbent cartridges or canisters, which are then trans-

ported to a laboratory and analyzed at a later time using

the gas chromatograph (GC), or the combination of MS

in single mode (GC/MS), or in tandem mode (GC/MS/

MS) [18]. While these methods are particularly useful for

low levels (μg/m3) [13], they are quite time consuming

due to sample transportation, VOCs thermal desorption,

GC column separation and analyte detection. The con-

centrations obtained using these methods are time aver-

aged response and no instantaneous levels are provided

during sampling. In addition, these off-site analysis tech-

niques are usually not useful during emergency situations

(e.g., at the site of chemical fire, chemical spill, and

chemical train derailment) when minute by minute deci-

sions are critical especially fast assessment to determine

the evacuation zones or whether affected areas are safe

for residents. TAGA provides unique approach to per-

form real-time on-site continuous monitoring of airborne

VOCs, allowing rapid and reliable evaluation during

emergency situations as well as routine field surveys.

A low pressure chemical ionization source (LPCI)

source has been developed for the TAGA to measure

ambient chlorinated hydrocarbons in real-time yielding

reliable quantitative results with a low detection limit yet

a wide range (i.e. 0 - 3000 μg/m3). The LPCI source,

normally operated at a pressure of 3.5 Torr and 55 μA, is

based on a glow discharge in the ionization region using

ambient air as the support gas [12,13]. It is interfaced to

the TAGA triple quadrupole (Q1, Q2, Q3) MS. Airborne

chemicals undergo charge transfer reactions with reagent

ions (typically NO+, 2 and 2

O) to yield parent ions

which are mass analyzed in the quadrupole Q1 region,

dissociated in the Q2 region and, the daughter ions are

identified in the Q3 region. The monitoring of parent/

daughter (P/D) ions is used to identify airborne chemi-

cals and determine their concentrations.

N

2.3. Identification

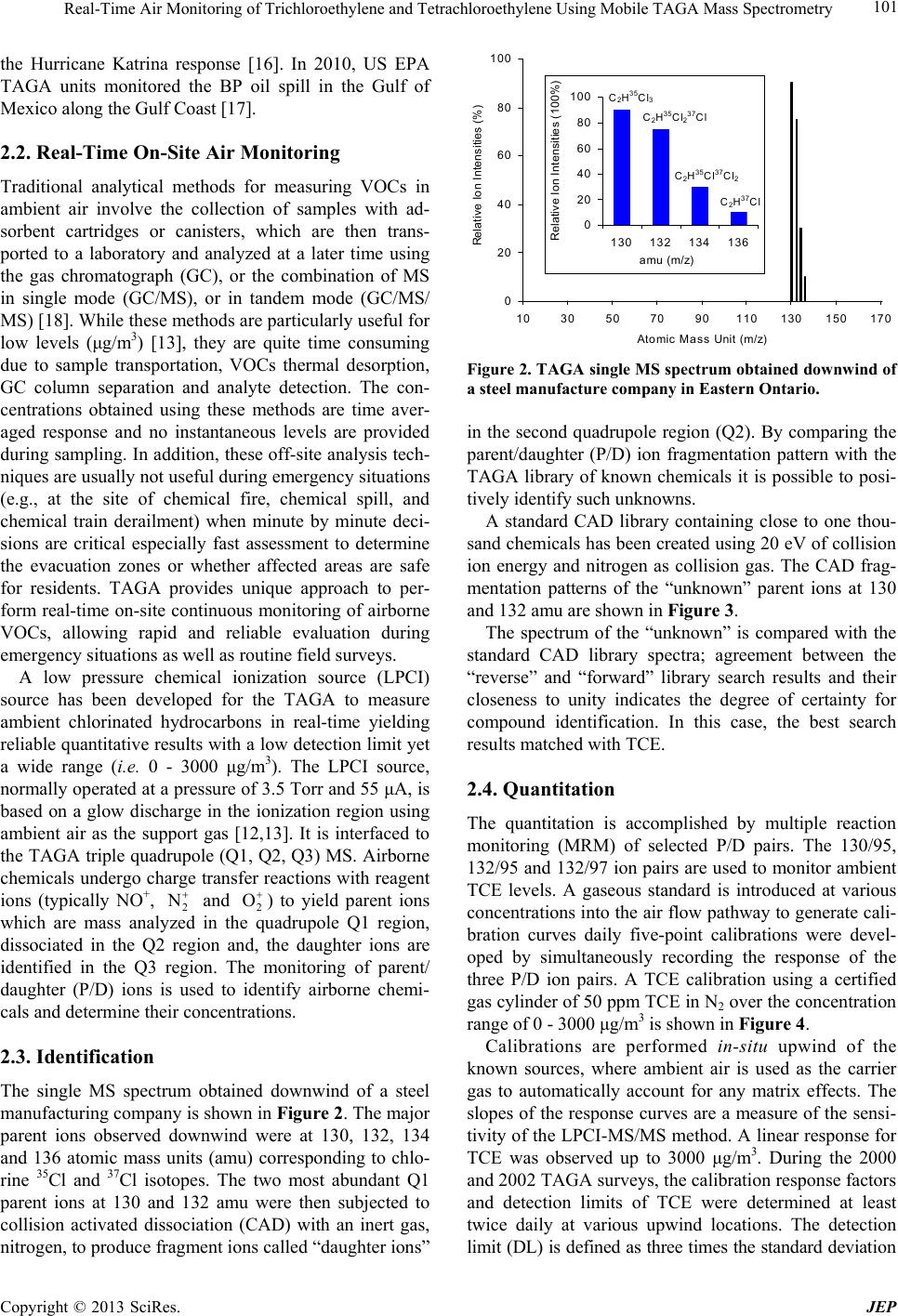

The single MS spectrum obtained downwind of a steel

manufacturing company is shown in Figure 2. The major

parent ions observed downwind were at 130, 132, 134

and 136 atomic mass units (amu) corresponding to chlo-

rine 35Cl and 37Cl isotopes. The two most abundant Q1

parent ions at 130 and 132 amu were then subjected to

collision activated dissociation (CAD) with an inert gas,

nitrogen, to produce fragment ions called “daughter ions”

0

20

40

60

80

100

1030507090110 130 150 170

Atomic Ma s s Unit (m/z)

Relative Ion Intensities (%)

0

20

40

60

80

100

130 132 134 136

Relative Ion Intensities (100%)

amu (m/z)

C2H35Cl237Cl

C2H35Cl3

C2H35Cl37Cl2

C2H37Cl

Figure 2. TAGA single MS spectrum obtained downwind of

a steel manufacture company in Eastern Ontario.

in the second quadrupole region (Q2). By comparing the

parent/daughter (P/D) ion fragmentation pattern with the

TAGA library of known chemicals it is possible to posi-

tively identify such unknowns.

A standard CAD library containing close to one thou-

sand chemicals has been created using 20 eV of collision

ion energy and nitrogen as collision gas. The CAD frag-

mentation patterns of the “unknown” parent ions at 130

and 132 amu are shown in Fi gure 3.

The spectrum of the “unknown” is compared with the

standard CAD library spectra; agreement between the

“reverse” and “forward” library search results and their

closeness to unity indicates the degree of certainty for

compound identification. In this case, the best search

results matched with TCE.

2.4. Quantitation

The quantitation is accomplished by multiple reaction

monitoring (MRM) of selected P/D pairs. The 130/95,

132/95 and 132/97 ion pairs are used to monitor ambient

TCE levels. A gaseous standard is introduced at various

concentrations into the air flow pathway to generate cali-

bration curves daily five-point calibrations were devel-

oped by simultaneously recording the response of the

three P/D ion pairs. A TCE calibration using a certified

gas cylinder of 50 ppm TCE in N2 over the concentration

range of 0 - 3000 μg/m3 is shown in Fi gure 4.

Calibrations are performed in-situ upwind of the

known sources, where ambient air is used as the carrier

gas to automatically account for any matrix effects. The

slopes of the response curves are a measure of the sensi-

tivity of the LPCI-MS/MS method. A linear response for

TCE was observed up to 3000 μg/m3. During the 2000

and 2002 TAGA surveys, the calibration response factors

and detection limits of TCE were determined at least

twice daily at various upwind locations. The detection

limit (DL) is defined as three tmes the standard deviation i

Copyright © 2013 SciRes. JEP