H. SUZUKI ET AL.

86

Figure 2. Piping system.

compressors and passes through the air dryer, surge tank,

and oil mist separator. The compressed air is supplied

into the plenum chamber to which convergent nozzle is

attached in the soundproof room. The stagnation pr essure

of the air in the plenum chamber can be manually regu-

lated by two gate valves and is measured by a digital

manometer. An acoustic absorbent sheet is glued to the

exit plane of the convergent nozzle. In this study, the

convergent nozzle is adopted. The diameter of the con-

vergent nozzle exit is D = 10 mm and the radius of the

internal surface of the nozzle R = 20 mm, which is well

finished. And a flat plate is placed to be perpendicular to

the jet axis, downstream of the nozzle.

The experiment is carried out under the condition of

the nozzle pressure ratio p0/pa = 3.0 to 3.8 with 0.1 steps

and the nozzle plate distance l/D = 1.5 to 2.5 with 0.1

steps, where p0 is the pressure in the plenum chamber

and pa the atmospheric pressure. The behavior of jet,

vortex moving along j et boundary and plate shock above

plate was examined under the conditions as mentioned

above.

The flow fields were visualized using Schlieren pho-

tography and shadowgraphy. The spark bulb is employed

as source of light, which emits flushing light duration a

period of 18 0 n s .

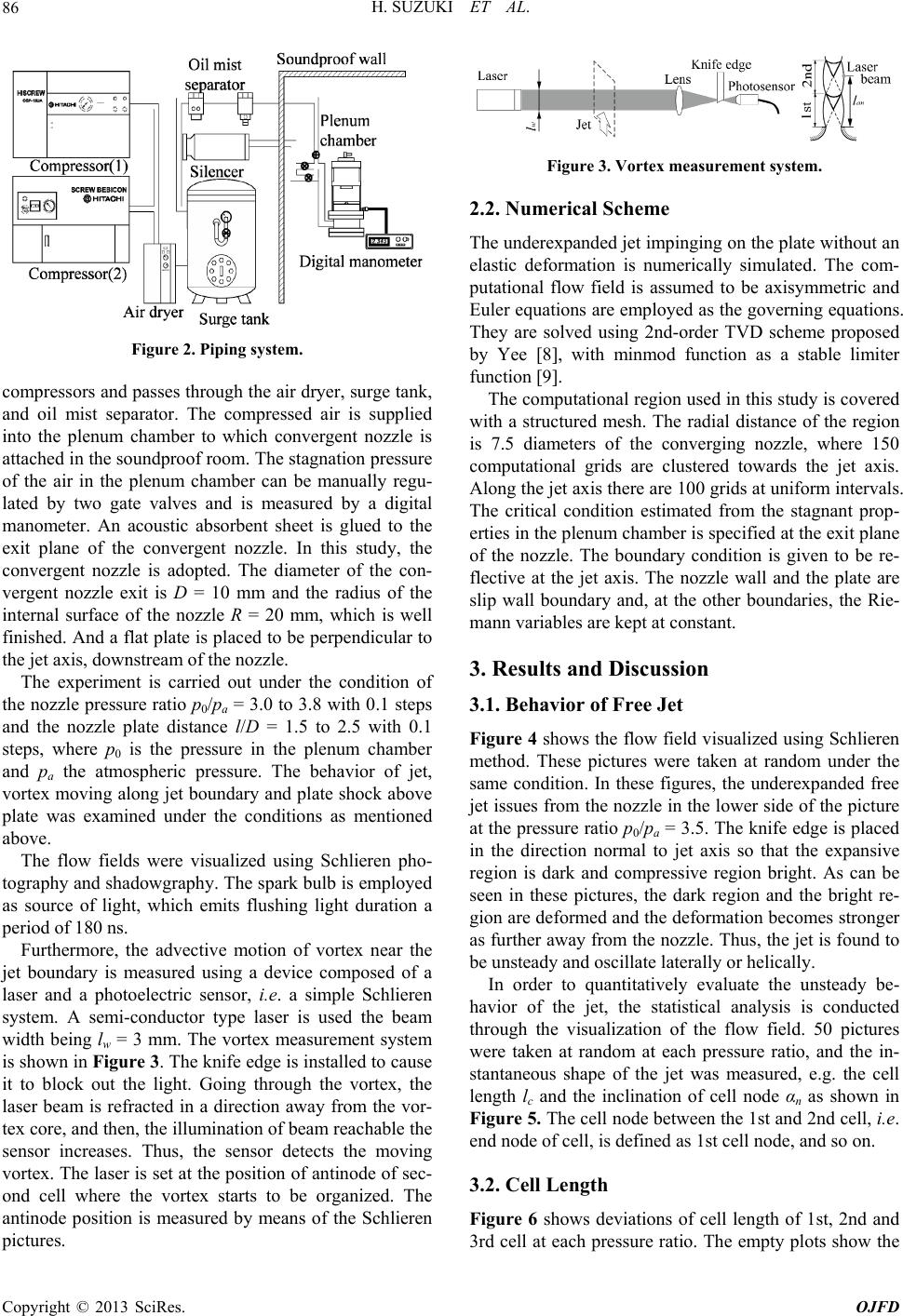

Furthermore, the advective motion of vortex near the

jet boundary is measured using a device composed of a

laser and a photoelectric sensor, i.e. a simple Schlieren

system. A semi-conductor type laser is used the beam

width being lw = 3 mm. The vortex measurement system

is shown in Figure 3. The knife edge is installed to cause

it to block out the light. Going through the vortex, the

laser beam is refracted in a direction away from the vor-

tex core, and then, the illumination of beam reachable the

sensor increases. Thus, the sensor detects the moving

vortex. The laser is set at the position of antinode of sec-

ond cell where the vortex starts to be organized. The

antinode position is measured by means of the Schlieren

pictures.

Figure 3. Vortex measurement system.

2.2. Numerical Scheme

The underexpanded jet impinging on the plate without an

elastic deformation is numerically simulated. The com-

putational flow field is assumed to be axisymmetric and

Euler equations are employed as the governing equations.

They are solved using 2nd-order TVD scheme proposed

by Yee [8], with minmod function as a stable limiter

function [9].

The computational region used in this study is covered

with a structured mesh. The radial distance of the region

is 7.5 diameters of the converging nozzle, where 150

computational grids are clustered towards the jet axis.

Along the jet axis there are 100 grids at uniform intervals.

The critical condition estimated from the stagnant prop-

erties in the plenum chamber is specified at the exit plane

of the nozzle. The boundary condition is given to be re-

flective at the jet axis. The nozzle wall and the plate are

slip wall boundary and, at the other boundaries, the Rie-

mann variables are kept at constant.

3. Results and Discussion

3.1. Behavior of Free Jet

Figure 4 shows the flow field visualized using Sch lieren

method. These pictures were taken at random under the

same condition. In these figures, the underexpanded free

jet issues from the nozzle in the lower side of the picture

at the pressure ratio p0/pa = 3.5. The knife edge is placed

in the direction normal to jet axis so that the expansive

region is dark and compressive region bright. As can be

seen in these pictures, the dark region and the bright re-

gion are deformed and the deformation becomes stronger

as further away from the nozzle. Thus, the jet is found to

be unsteady and oscillate laterally or helically.

In order to quantitatively evaluate the unsteady be-

havior of the jet, the statistical analysis is conducted

through the visualization of the flow field. 50 pictures

were taken at random at each pressure ratio, and the in-

stantaneous shape of the jet was measured, e.g. the cell

length lc and the inclination of cell node αn as shown in

Figure 5. The cell node between the 1st and 2nd cell, i.e.

end node of cell, is defined as 1st cell node, and so on.

3.2. Cell Length

Figure 6 shows deviations of cell length of 1st, 2nd and

3rd cell at each pressure ratio. The empty plots show the

Copyright © 2013 SciRes. OJFD