J. P. YUAN ET AL.

62

Prior to the laboratory test, it is important to predict

the various performance of these two ventilation systems

using the CFD technique. Airpak software was used to

simulate these two systems numerically and the com-

parison of performances of both ventilations will be re-

ported in both thermal comfort and indoor art quality

(IAQ) two aspects.

2. CFD Model and Boundary Conditions

2.1. Physical Model

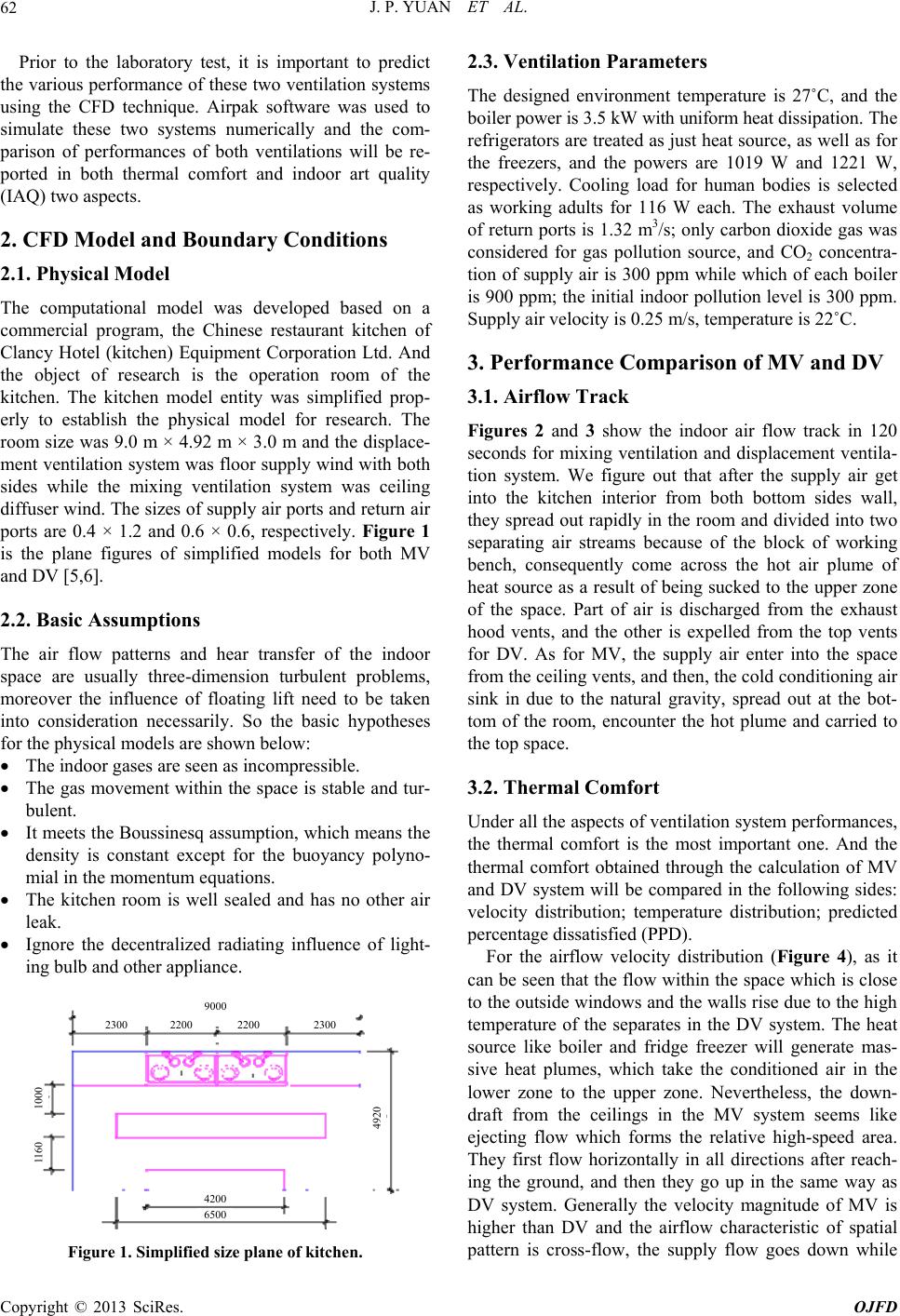

The computational model was developed based on a

commercial program, the Chinese restaurant kitchen of

Clancy Hotel (kitchen) Equipment Corporation Ltd. And

the object of research is the operation room of the

kitchen. The kitchen model entity was simplified prop-

erly to establish the physical model for research. The

room size was 9.0 m × 4.92 m × 3.0 m and the displace-

ment ventilation system was floor supply wind with both

sides while the mixing ventilation system was ceiling

diffuser wind. The sizes of supply air ports an d return air

ports are 0.4 × 1.2 and 0.6 × 0.6, respectively. Figure 1

is the plane figures of simplified models for both MV

and DV [5,6].

2.2. Basic Assumptions

The air flow patterns and hear transfer of the indoor

space are usually three-dimension turbulent problems,

moreover the influence of floating lift need to be taken

into consideration necessarily. So the basic hypotheses

for the physical models are shown below:

The indoor gases are seen as incompressible.

The gas movement within the space is stable and tur-

bulent.

It meets the Boussinesq assumption, which means the

density is constant except for the buoyancy polyno-

mial in the momentum equations.

The kitchen room is well sealed and has no other air

leak.

Ignore the decentralized radiating influence of light-

ing bulb and other appl i ance.

9000

2200 2200 2300 2300

4200

6500

1160 1000

4920

Figure 1. Simplified size plane of kitchen.

2.3. Ventilation Parameters

The designed environment temperature is 27˚C, and the

boi le r power is 3.5 kW with uniform heat dissi p at io n . Th e

refrigerators are treated as just heat source, as well as for

the freezers, and the powers are 1019 W and 1221 W,

respectively. Cooling load for human bodies is selected

as working adults for 116 W each. The exhaust volume

of return ports is 1.32 m3/s; only carbon dioxide gas was

considered for gas pollution source, and CO2 concentra-

tion of supply air is 300 ppm while which of each boiler

is 900 ppm; the initial indoor pollution lev el is 300 ppm.

Supply air velocity is 0.25 m/s, temperature is 22˚C.

3. Performance Comparison of MV and DV

3.1. Airflow Track

Figures 2 and 3 show the indoor air flow track in 120

seconds for mixing ventilation and displacement ventila-

tion system. We figure out that after the supply air get

into the kitchen interior from both bottom sides wall,

they spread out rapidly in the room and divided into two

separating air streams because of the block of working

bench, consequently come across the hot air plume of

heat source as a result of being sucked to the upper zone

of the space. Part of air is discharged from the exhaust

hood vents, and the other is expelled from the top vents

for DV. As for MV, the supply air enter into the space

from the ceiling vents, an d then, the co ld cond itioning air

sink in due to the natural gravity, spread out at the bot-

tom of the room, encounter the hot plume and carried to

the top space.

3.2. Thermal Comfort

Under all the aspects of ventilation system performances,

the thermal comfort is the most important one. And the

thermal comfort obtained through the calculation of MV

and DV system will be compared in the following sides:

velocity distribution; temperature distribution; predicted

percentage dissatisfied (PPD).

For the airflow velocity distribution (Figure 4), as it

can be seen that the flow within th e space which is close

to the outside windows and the walls rise due to the high

temperature of the separates in the DV system. The heat

source like boiler and fridge freezer will generate mas-

sive heat plumes, which take the conditioned air in the

lower zone to the upper zone. Nevertheless, the down-

draft from the ceilings in the MV system seems like

ejecting flow which forms the relative high-speed area.

They first flow horizontally in all directions after reach-

ing the ground, and then they go up in the same way as

DV system. Generally the velocity magnitude of MV is

higher than DV and the airflow characteristic of spatial

attern is cross-flow, the supply flow goes down while p

Copyright © 2013 SciRes. OJFD