S.-I. MORITA ET AL. 53

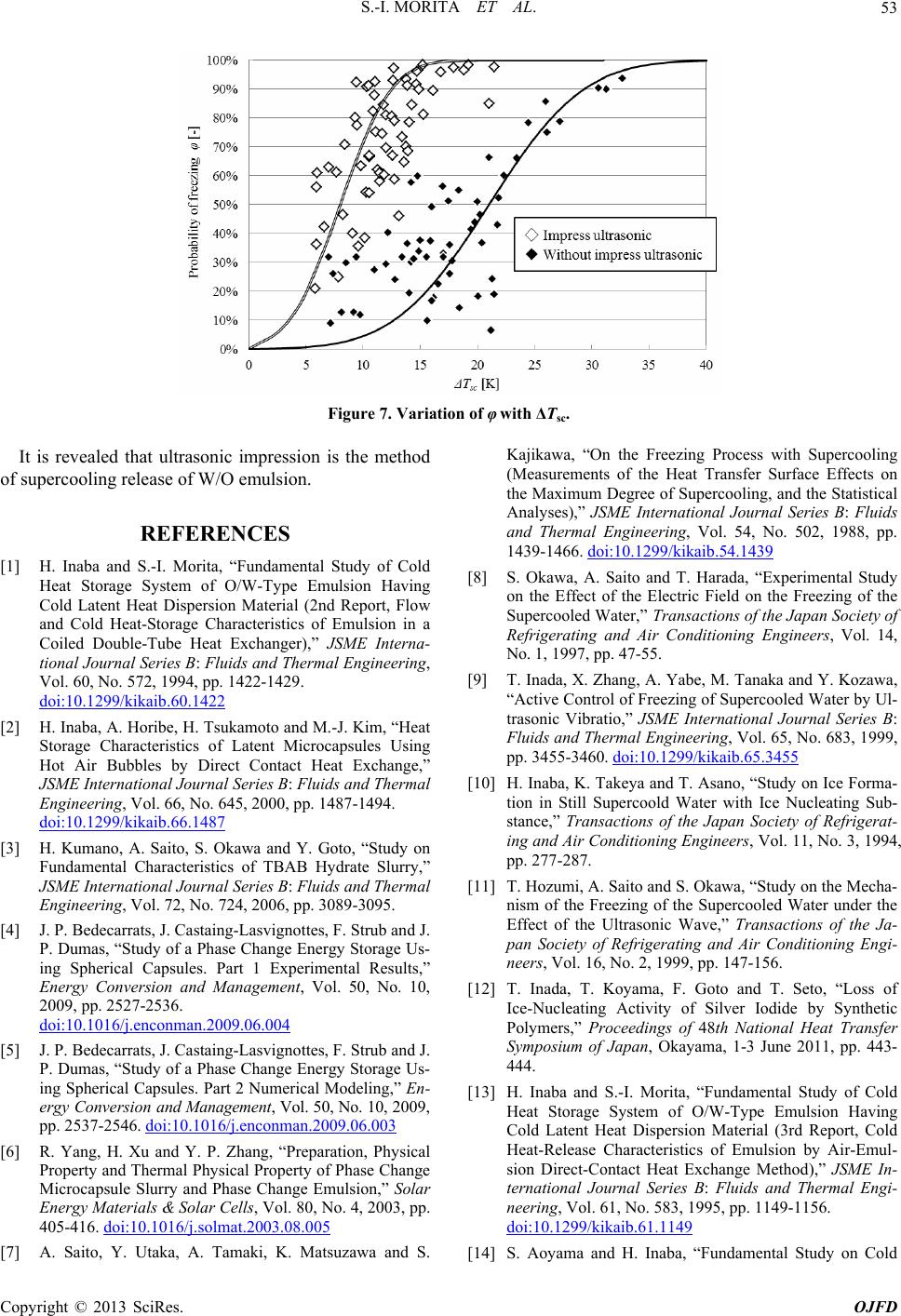

Figure 7. Variation of φ with ΔTsc.

It is revealed that ultrasonic impression is the method

of supercooling release of W/O emulsion.

REFERENCES

[1] H. Inaba and S.-I. Morita, “Fundamental Study of Cold

Heat Storage System of O/W-Type Emulsion Having

Cold Latent Heat Dispersion Material (2nd Report, Flow

and Cold Heat-Storage Characteristics of Emulsion in a

Coiled Double-Tube Heat Exchanger),” JSME Interna-

tional Journal Series B: Fluids and Thermal Engineering,

Vol. 60, No. 572, 1994, pp. 1422-1429.

doi:10.1299/kikaib.60.1422

[2] H. Inaba, A. Horibe, H. Tsukamoto and M.-J. Kim, “Heat

Storage Characteristics of Latent Microcapsules Using

Hot Air Bubbles by Direct Contact Heat Exchange,”

JSME International Journal Series B: Fluids and Thermal

Engineering, Vol. 66, No. 645, 2000, pp. 1487-1494.

doi:10.1299/kikaib.66.1487

[3] H. Kumano, A. Saito, S. Okawa and Y. Goto, “Study on

Fundamental Characteristics of TBAB Hydrate Slurry,”

JSME International Journal Series B: Fluids and Thermal

Engineering, Vol. 72, No. 724, 2006, pp. 3089-3095.

[4] J. P. Bedecarrats, J. Castaing-Lasvignottes, F. Strub and J.

P. Dumas, “Study of a Phase Change Energy Storage Us-

ing Spherical Capsules. Part 1 Experimental Results,”

Energy Conversion and Management, Vol. 50, No. 10,

2009, pp. 2527-2536.

doi:10.1016/j.enconman.2009.06.004

[5] J. P. Bedecarrats, J. Castaing-Lasvignottes, F. Strub and J.

P. Dumas, “Study of a Phase Change Energy Storage Us-

ing Spherical Capsules. Part 2 Numerical Modeling,” En-

ergy Conversion and Management, Vol. 50, No. 10, 2009,

pp. 2537-2546. doi:10.1016/j.enconman.2009.06.003

[6] R. Yang, H. Xu and Y. P. Zhang, “Preparation, Physical

Property and Thermal Physical Property of Phase Change

Microcapsule Slurry and Phase Change Emulsion,” Solar

Energy Materials & Solar Cells, Vol. 80, No. 4, 2003, pp.

405-416. doi:10.1016/j.solmat.2003.08.005

[7] A. Saito, Y. Utaka, A. Tamaki, K. Matsuzawa and S.

Kajikawa, “On the Freezing Process with Supercooling

(Measurements of the Heat Transfer Surface Effects on

the Maximum Degree of Supercooling, and the Statistical

Analyses),” JSME International Journal Series B: Fluids

and Thermal Engineering, Vol. 54, No. 502, 1988, pp.

1439-1466. doi:10.1299/kikaib.54.1439

[8] S. Okawa, A. Saito and T. Harada, “Experimental Study

on the Effect of the Electric Field on the Freezing of the

Supercooled Water,” Transactions of the Japan Society of

Refrigerating and Air Conditioning Engineers, Vol. 14,

No. 1, 1997, pp. 47-55.

[9] T. Inada, X. Zhang, A. Yabe, M. Tanaka and Y. Kozawa,

“Active Control of Freezing of Supercooled Water by Ul-

trasonic Vibratio,” JSME International Journal Series B:

Fluids and Thermal Engineering, Vol. 65, No. 683, 1999,

pp. 3455-3460. doi:10.1299/kikaib.65.3455

[10] H. Inaba, K. Takeya and T. Asano, “Study on Ice Forma-

tion in Still Supercoold Water with Ice Nucleating Sub-

stance,” Transactions of the Japan Society of Refrigerat-

ing and Air Conditioning Engineers, Vol. 11, No. 3, 1994,

pp. 277-287.

[11] T. Hozumi, A. Saito and S. Okawa, “Study on the Mecha-

nism of the Freezing of the Supercooled Water under the

Effect of the Ultrasonic Wave,” Transactions of the Ja-

pan Society of Refrigerating and Air Conditioning Engi-

neers, Vol. 16, No. 2, 1999, pp. 147-156.

[12] T. Inada, T. Koyama, F. Goto and T. Seto, “Loss of

Ice-Nucleating Activity of Silver Iodide by Synthetic

Polymers,” Proceedings of 48th National Heat Transfer

Symposium of Japan, Okayama, 1-3 June 2011, pp. 443-

444.

[13] H. Inaba and S.-I. Morita, “Fundamental Study of Cold

Heat Storage System of O/W-Type Emulsion Having

Cold Latent Heat Dispersion Material (3rd Report, Cold

Heat-Release Characteristics of Emulsion by Air-Emul-

sion Direct-Contact Heat Exchange Method),” JSME In-

ternational Journal Series B: Fluids and Thermal Engi-

neering, Vol. 61, No. 583, 1995, pp. 1149-1156.

doi:10.1299/kikaib.61.1149

[14] S. Aoyama and H. Inaba, “Fundamental Study on Cold

Copyright © 2013 SciRes. OJFD