L. X. ZOU ET AL. 67

enhanced chemical vapor deposition (PECVD) on the

laser wafe. Then, the microdisk patterns are transferred

onto the SiO2 layer using standard photolithography and

inductively coupled-plasma (ICP) etching techniques,

and the laser wafer is etched to about 4.7 μm using the

ICP technique subsequently with the patterned SiO2 layer

as hard mask. After the ICP etching process, a 200 nm

silicon nitride (SiNx) layer is deposited by PECVD on the

wafer to prepare a plane with better adhesion for the fol-

lowing DVS-BCB(divinyl siloxane bisbenzocyclobutene)

spin-coating process, and protect the cavities from the

following non-selective BCB etching process at the same

time. The DVS-BCB Cyclotene 3022-46 is coated twice

onto the wafer to create a planar cladding layer and then

experiences soft and hard cure in turn, and then the BCB

film is etched to expose the top of microdisk resonators

by Reactive Ion Etching (RIE) without any mask. After

that, a contact window is opened by ICP etching for cur-

rent injection on top of each resonator buried in BCB, on

which pad-patterned P-electrodes are formed afterward

using lifting off technology. Finally, the laser wafer is

mechanically lapped down to a thickness of about 120

μm, and an Au-Ge-Ni metallization layer is used as n-

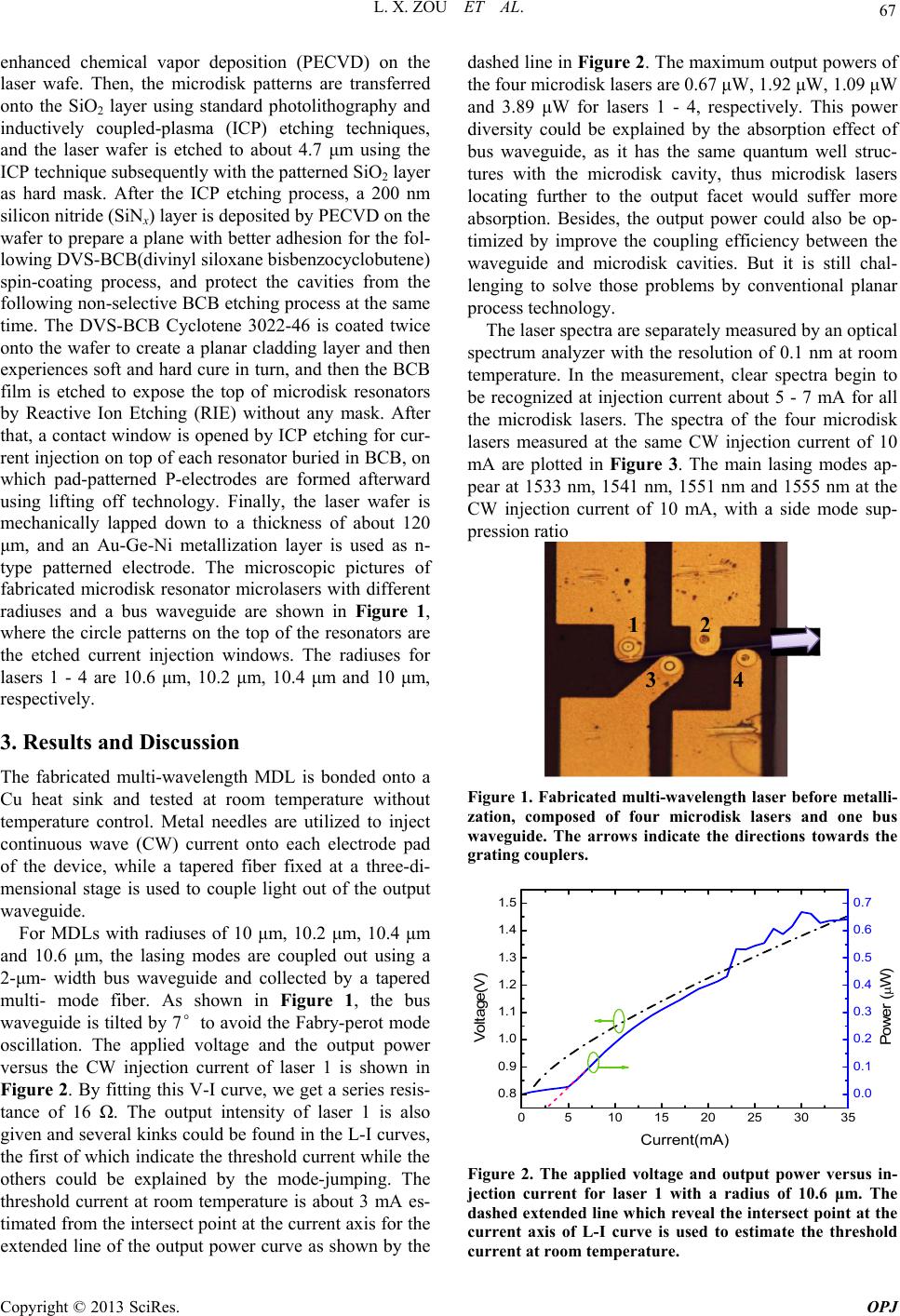

type patterned electrode. The microscopic pictures of

fabricated microdisk resonator microlasers with different

radiuses and a bus waveguide are shown in Figure 1,

where the circle patterns on the top of the resonators are

the etched current injection windows. The radiuses for

lasers 1 - 4 are 10.6 μm, 10.2 μm, 10.4 μm and 10 μm,

respectively.

3. Results and Discussion

The fabricated multi-wavelength MDL is bonded onto a

Cu heat sink and tested at room temperature without

temperature control. Metal needles are utilized to inject

continuous wave (CW) current onto each electrode pad

of the device, while a tapered fiber fixed at a three-di-

mensional stage is used to couple light out of the output

waveguide.

For MDLs with radiuses of 10 μm, 10.2 μm, 10.4 μm

and 10.6 μm, the lasing modes are coupled out using a

2-μm- width bus waveguide and collected by a tapered

multi- mode fiber. As shown in Figure 1, the bus

waveguide is tilted by 7°to avoid the Fabry-perot mode

oscillation. The applied voltage and the output power

versus the CW injection current of laser 1 is shown in

Figure 2. By fitting this V-I curve, we get a series resis-

tance of 16 Ω. The output intensity of laser 1 is also

given and several kinks could be found in the L-I curves,

the first of which indicate the threshold current while the

others could be explained by the mode-jumping. The

threshold current at room temperature is about 3 mA es-

timated from the intersect point at the current axis for the

extended line of the output power curve as shown by the

dashed line in Figure 2. The maximum output powers of

the four microdisk lasers are 0.67 μW, 1.92 μW, 1.09 μW

and 3.89 μW for lasers 1 - 4, respectively. This power

diversity could be explained by the absorption effect of

bus waveguide, as it has the same quantum well struc-

tures with the microdisk cavity, thus microdisk lasers

locating further to the output facet would suffer more

absorption. Besides, the output power could also be op-

timized by improve the coupling efficiency between the

waveguide and microdisk cavities. But it is still chal-

lenging to solve those problems by conventional planar

process technology.

The laser spectra are separately measured by an optical

spectrum analyzer with the resolution of 0.1 nm at room

temperature. In the measurement, clear spectra begin to

be recognized at injection current about 5 - 7 mA for all

the microdisk lasers. The spectra of the four microdisk

lasers measured at the same CW injection current of 10

mA are plotted in Figure 3. The main lasing modes ap-

pear at 1533 nm, 1541 nm, 1551 nm and 1555 nm at the

CW injection current of 10 mA, with a side mode sup-

pression ratio

12

34

Figure 1. Fabricated multi-wavelength laser before metalli-

zation, composed of four microdisk lasers and one bus

waveguide. The arrows indicate the directions towards the

grating couplers.

0510 15 20 25 30 35

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

Current(mA)

Voltage(V)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Power (

W)

Figure 2. The applied voltage and output power versus in-

jection current for laser 1 with a radius of 10.6 μm. The

dashed extended line which reveal the intersect point at the

current axis of L-I curve is used to estimate the threshold

current at room temperature.

Copyright © 2013 SciRes. OPJ