L. L. LU ET AL.

Copyright © 2013 SciRes. ENG

627

0

10

20

30

40

50

60

70

80

90

100

0510 1520 25 3035 4045 50

R/%

f

W

/%

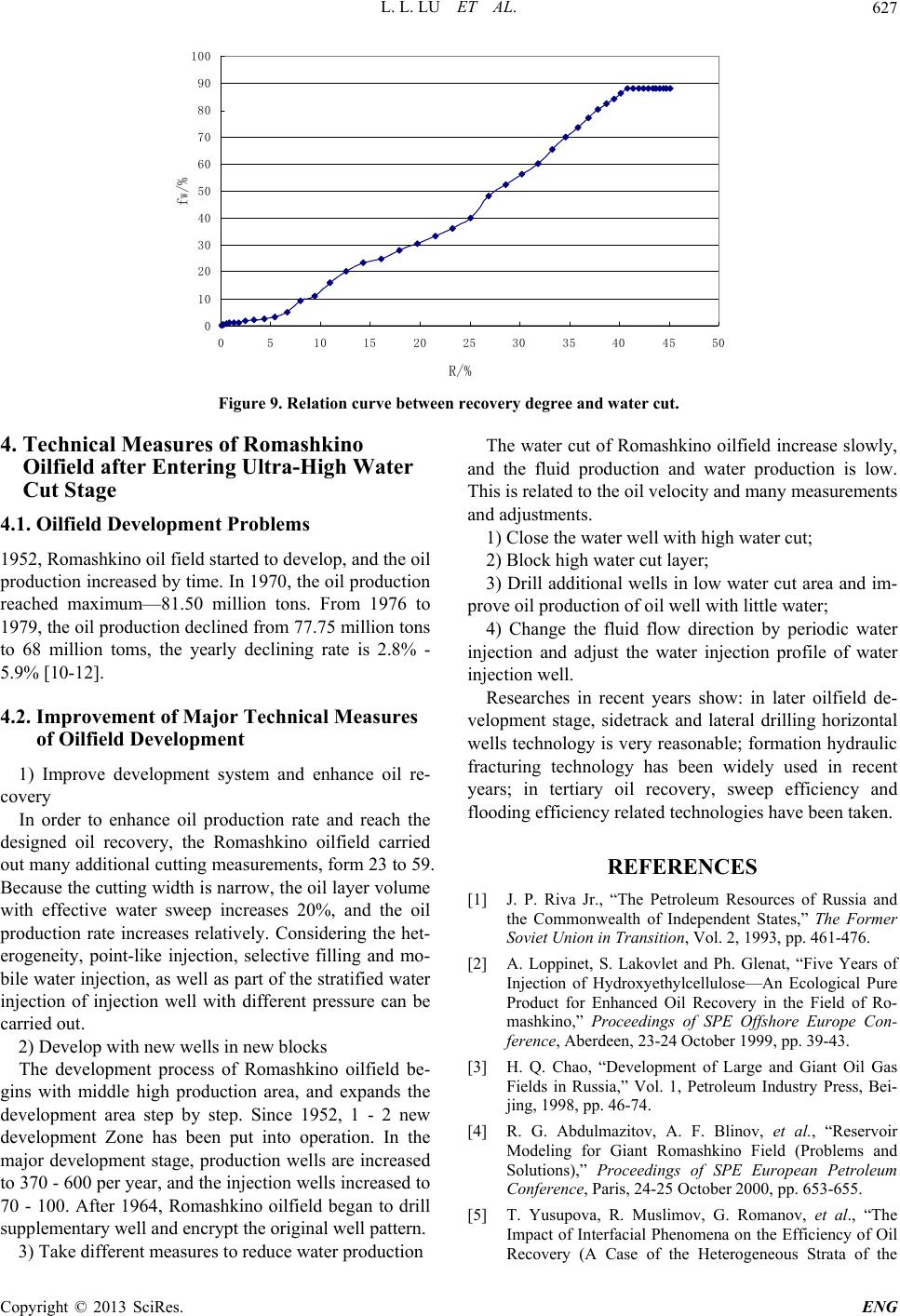

Figure 9. Relation curve between recovery degree and water cut.

4. Technical Measures of Romas h kino

Oilfield after Entering Ultra-

Cut Stage

4.1. Oilfield Development Problems

1952, Romashkino oil field started to develop, and the oil

production increased by time. In 1970, the oil production

reached maximum—81.50 million tons. From 1976 to

1979, the oil production declined from 77.75 million tons

to 68 million toms, the yearly declining rate is 2.8% -

5.9% [10-12].

4.2. Improvement of Major Technical Measures

of Oilfield Development

1) Improve development system and enhance oil re-

covery

In order to enhance oil p

esigned oil recovery, the R

to 59.

wi

idering the het-

g and mo-

ea step by step. Since 1952, 1 - 2 new

to 37 wells increased to

70

entary well and encrypt the original well pattern.

The water cut of Romashkino oilfield increase slowly,

duction and water production is low.

This is related to the oil velocity and many measurements

and adjustments.

1) Close the water well with high water cut;

2) Block high water cut layer;

3) Drill additional wells in low water cut area and im-

prove oil production of oil well with little water;

4) Change the fluid flow direction by periodic water

injection and adjust the water injection profile of water

injection well.

Researches in recent years show: in later oilfield de-

velopment stage, sidetrack and lateral drilling horizontal

wells technology is very reasonable; formation hydraulic

fracturing technology has been widely used in recent

years; in tertiary oil recovery, seep efficiency and

flooding efficiency related technologies have been taken.

iant Oil Gas

Recovery (A Case of the Heterogeneous Strata of the

High Water and the fluid pro

w

roduction rate and reach the

omashkino oilfield carried d

out many additional cutting measurements, form 23

Because the cutting width is narrow, the oil layer volume

th effective water sweep increases 20%, and the oil

production rate increases relatively. Cons

erogeneity, point-like injection, selective fillin

bile water injection, as well as part of the stratified water

injection of injection well with different pressure can be

carried out.

2) Develop with new wells in new blocks

The development process of Romashkino oilfield be-

gins with middle high production area, and expands the

development ar

development Zone has been put into operation. In the

major development stage, production wells are increased

0 - 600 per year, and the injection

- 100. After 1964, Romashkino oilfield began to drill

supplem

3) Take different measures to reduce water production

REFERENCES

[1] J. P. Riva Jr., “The Petroleum Resources of Russia and

the Commonwealth of Independent States,” The Former

Soviet Union in Transition, Vol. 2, 1993, pp. 461-476.

[2] A. Loppinet, S. Lakovlet and Ph. Glenat, “Five Years of

Injection of Hydroxyethylcellulose—An Ecological Pure

Product for Enhanced Oil Recovery in the Field of Ro-

mashkino,” Proceedings of SPE Offshore Europe Con-

ference, Aberdeen, 23-24 October 1999, pp. 39-43.

[3] H. Q. Chao, “Development of Large and G

Fields in Russia,” Vol. 1, Petroleum Industry Press, Bei-

jing, 1998, pp. 46-74.

[4] R. G. Abdulmazitov, A. F. Blinov, et al., “Reservoir

Modeling for Giant Romashkino Field (Problems and

Solutions),” Proceedings of SPE European Petroleum

Conference, Paris, 24-25 October 2000, pp. 653-655.

[5] T. Yusupova, R. Muslimov, G. Romanov, et al., “The

Impact of Interfacial Phenomena on the Efficiency of Oil