N. Abd-Ta lib et al. / Agricultural Sciences 4 (2013) 78-83

80

3. RESULTS AND DISCUSSION

3.1. Formulations study of Encapsulation

Agent

Try and error method carried out to get the suitable

emulsion formulation in order to get the good product.

Based on previous studies, four basic materials which

can contribute on production of good powder product

were selected. After doing some try and error formula-

tion and stability checked, the observ ation were shown in

Table 3.

After doing the observation, the stability test resulted

that Formulation A and Formulation D show a highest

potential in maintaining the stable characteristics after

keeping for two hours. The maximum duration of spray

drying is about two hours. So, at least the formulation

can homogenized well at the duration time is more than

enough. Lecithin was an economic an effective wall ma-

terial but unfortunately it cannot homogenize well with

other wall material selected. The ability of solid per-

centage used in the solution has been checking up after

selection of the suitable emulsion formulation successful.

Formulation A and Formulation D were the only two

formulations that have been selected to the next part of

study.

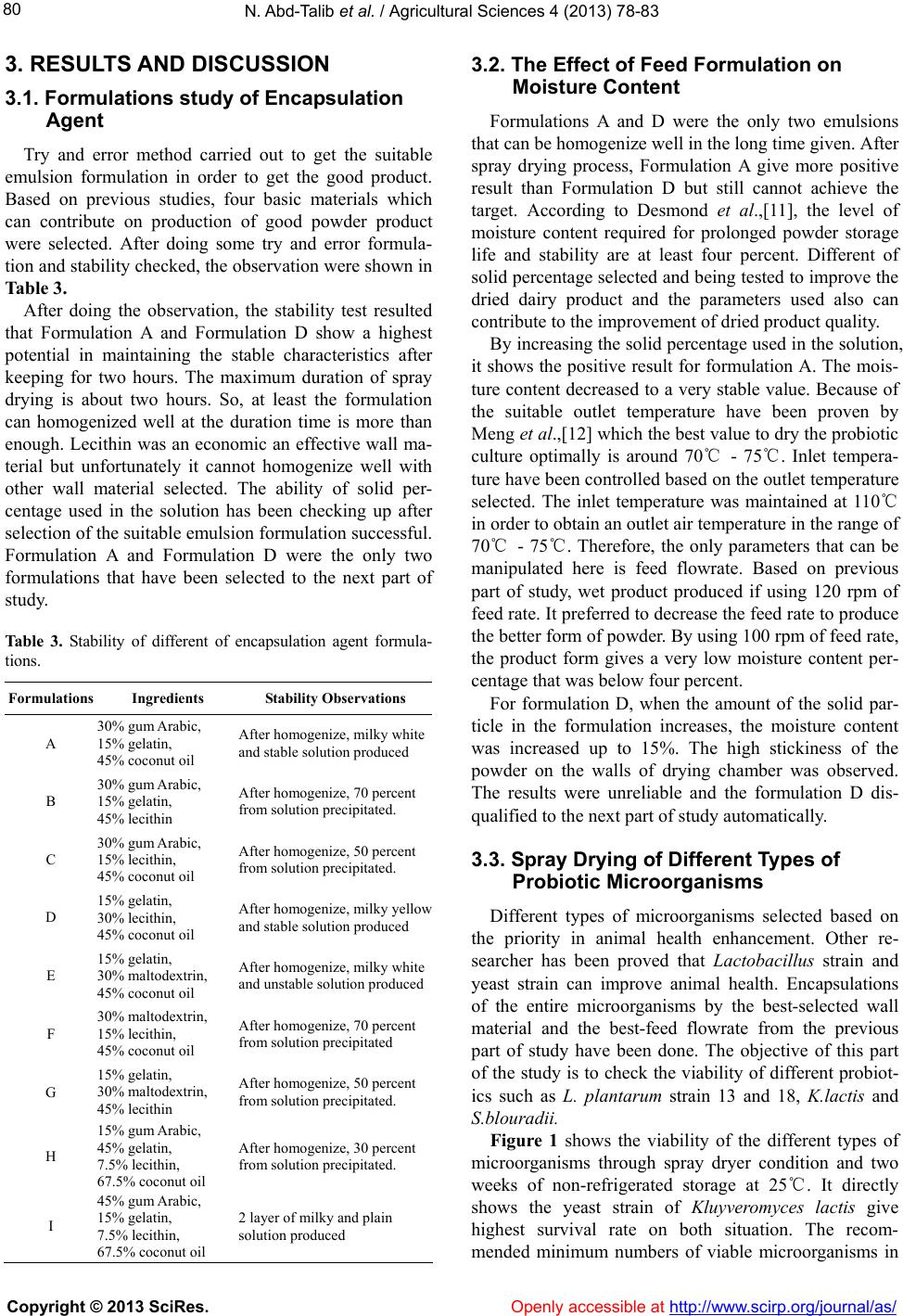

Table 3. Stability of different of encapsulation agent formula-

tions.

Formulations Ingredients Stability Observations

A 30% gum Arabic,

15% gelatin,

45% coconut oil

After homogenize, milky whit e

and stable solution produced

B 30% gum Arabic,

15% gelatin,

45% lecithin

After homogenize, 70 percent

from solution precipitated.

C 30% gum Arabic,

15% lecithin,

45% coconut oil

After homogenize, 50 percent

from solution precipitated.

D 15% gelatin,

30% lecithin,

45% coconut oil

After homogenize, m ilk y y ell ow

and stable solution produced

E 15% gelatin,

30% maltodextrin,

45% coconut oil

After homogenize, milky whit e

and unstable solution produced

F 30% maltodextrin,

15% lecithin,

45% coconut oil

After homogenize, 70 percent

from solution precipitated

G 15% gelatin,

30% maltodextrin,

45% lecithin

After homogenize, 50 percent

from solution precipitated.

H

15% gum Arabic,

45% gelatin,

7.5% lecithin,

67.5% coconut oil

After homogenize, 30 percent

from solution precipitated.

I

45% gum Arabic,

15% gelatin,

7.5% lecithin,

67.5% coconut oil

2 layer of milky a n d p l a i n

solution produced

3.2. The Effect of Feed Formulation on

Moisture Content

Formulations A and D were the only two emulsions

that can be homogenize well in the long time given. After

spray drying process, Formulation A give more positive

result than Formulation D but still cannot achieve the

target. According to Desmond et al.,[11], the level of

moisture content required for prolonged powder storage

life and stability are at least four percent. Different of

solid percentage selected and being tested to impro ve the

dried dairy product and the parameters used also can

contribute to the improvement of dried product quality.

By increasing the solid percentage used in the solu tion,

it shows the positive result for formulation A. The mois-

ture content decreased to a very stable value. Because of

the suitable outlet temperature have been proven by

Meng et al.,[12] which the best value to dry the probiotic

culture optimally is around 70℃ - 75℃. Inlet tempera-

ture have been controlled based on the outlet temperature

selected. The inlet temperature was maintained at 110℃

in order to obtain an outlet air temperature in the range of

70℃ - 75℃. Therefore, the only parameters that can be

manipulated here is feed flowrate. Based on previous

part of study, wet product produced if using 120 rpm of

feed rate. It preferred to decrease the feed rate to produce

the better form of powder. By using 100 rpm of feed rate,

the product form gives a very low moisture content per-

centage that was below four percent.

For formulation D, when the amount of the solid par-

ticle in the formulation increases, the moisture content

was increased up to 15%. The high stickiness of the

powder on the walls of drying chamber was observed.

The results were unreliable and the formulation D dis-

qualified to the n ext part of study automatically.

3.3. Spray Drying of Different Types of

Probiotic Microorganisms

Different types of microorganisms selected based on

the priority in animal health enhancement. Other re-

searcher has been proved that Lactobacillus strain and

yeast strain can improve animal health. Encapsulations

of the entire microorganisms by the best-selected wall

material and the best-feed flowrate from the previous

part of study have been done. The objective of this part

of the study is to check the viability of different probiot-

ics such as L. plantarum strain 13 and 18, K.lactis and

S.blouradii.

Figure 1 shows the viability of the different types of

microorganisms through spray dryer condition and two

weeks of non-refrigerated storage at 25℃. It directly

shows the yeast strain of Kluyveromyces lactis give

highest survival rate on both situation. The recom-

mended minimum numbers of viable microorganisms in

Copyright © 2013 SciRes. Openly accessible at http://www.scirp.org/journal/as/