K. W. GUO 575

0.25μ

0.25μm

0.25μm

(a) (b) (c)

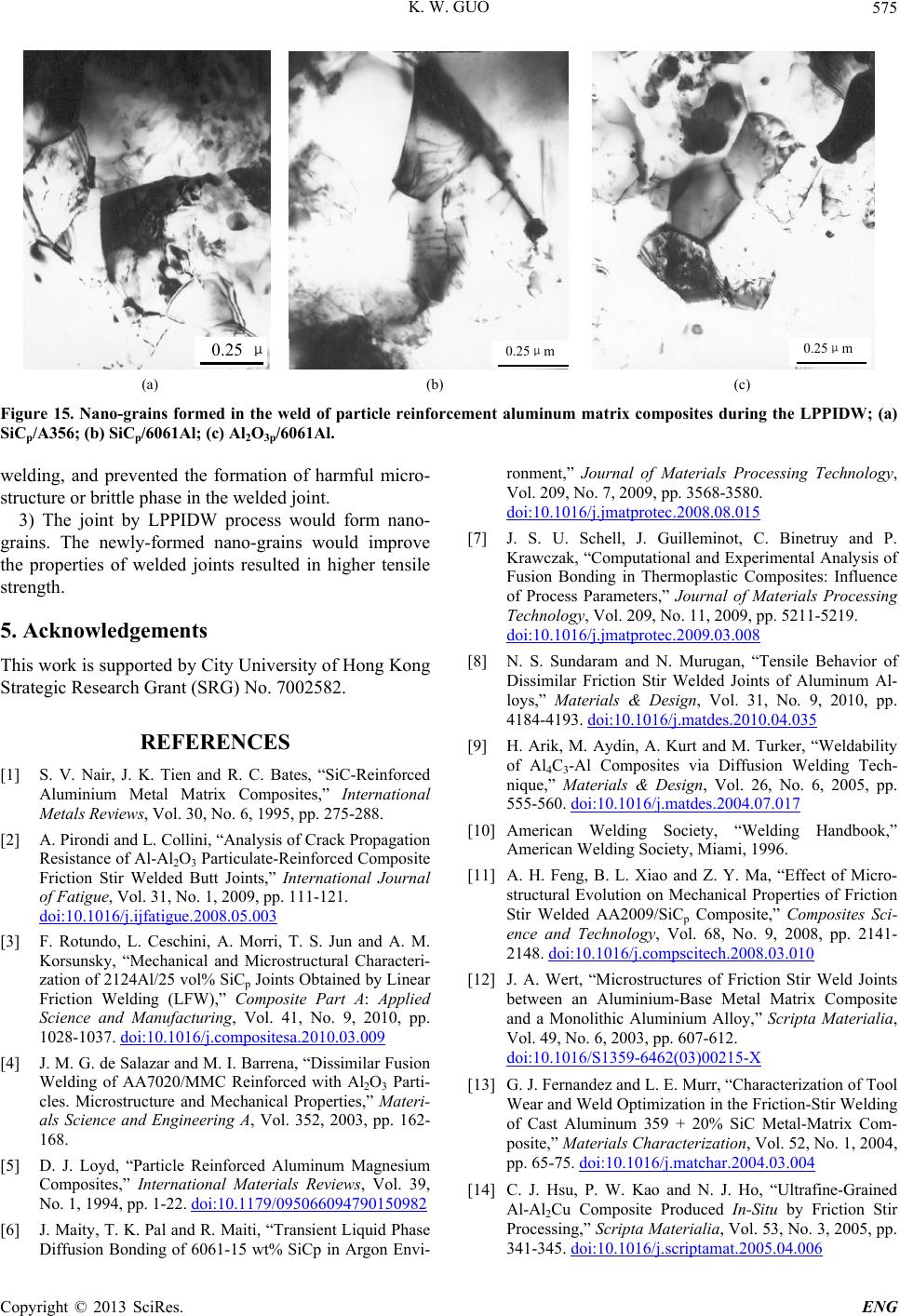

Figure 15. Nano-grains formed in the weld of particle reinforcement aluminum matrix composites during the LPPIDW; (a)

SiCp/A356; (b) SiCp/6061Al; (c) Al2O3p/6061Al.

welding, and prevented the formation of harmful micro-

structure or brittle phase in the welded joint.

3) The joint by LPPIDW process would form nano-

grains. The newly-formed nano-grains would improve

the properties of welded joints resulted in higher tensile

strength.

5. Acknowledgements

This work is supported by City University of Hong Kong

Strategic Research Grant (SRG) No. 7002582.

REFERENCES

[1] S. V. Nair, J. K. Tien and R. C. Bates, “SiC-Reinforced

Aluminium Metal Matrix Composites,” International

Metals Reviews, Vol. 30, No. 6, 1995, pp. 275-288.

[2] A. Pirondi and L. Collini, “Analysis of Crack Propagation

Resistance of Al-Al2O3 Particulate-Reinforced Composite

Friction Stir Welded Butt Joints,” International Journal

of Fatigue, Vol. 31, No. 1, 2009, pp. 111-121.

doi:10.1016/j.ijfatigue.2008.05.003

[3] F. Rotundo, L. Ceschini, A. Morri, T. S. Jun and A. M.

Korsunsky, “Mechanical and Microstructural Characteri-

zation of 2124Al/25 vol% SiCp Joints Obtained by Linear

Friction Welding (LFW),” Composite Part A: Applied

Science and Manufacturing, Vol. 41, No. 9, 2010, pp.

1028-1037. doi:10.1016/j.compositesa.2010.03.009

[4] J. M. G. de Salazar and M. I. Barrena, “Dissimilar Fusion

Welding of AA7020/MMC Reinforced with Al2O3 Parti-

cles. Microstructure and Mechanical Properties,” Materi-

als Science and Engineering A, Vol. 352, 2003, pp. 162-

168.

[5] D. J. Loyd, “Particle Reinforced Aluminum Magnesium

Composites,” International Materials Reviews, Vol. 39,

No. 1, 1994, pp. 1-22. doi:10.1179/095066094790150982

[6] J. Maity, T. K. Pal and R. Maiti, “Transient Liquid Phase

Diffusion Bonding of 6061-15 wt% SiCp in Argon Envi-

ronment,” Journal of Materials Processing Technology,

Vol. 209, No. 7, 2009, pp. 3568-3580.

doi:10.1016/j.jmatprotec.2008.08.015

[7] J. S. U. Schell, J. Guilleminot, C. Binetruy and P.

Krawczak, “Computational and Experimental Analysis of

Fusion Bonding in Thermoplastic Composites: Influence

of Process Parameters,” Journal of Materials Processing

Technology, Vol. 209, No. 11, 2009, pp. 5211-5219.

doi:10.1016/j.jmatprotec.2009.03.008

[8] N. S. Sundaram and N. Murugan, “Tensile Behavior of

Dissimilar Friction Stir Welded Joints of Aluminum Al-

loys,” Materials & Design, Vol. 31, No. 9, 2010, pp.

4184-4193. doi:10.1016/j.matdes.2010.04.035

[9] H. Arik, M. Aydin, A. Kurt and M. Turker, “Weldability

of Al4C3-Al Composites via Diffusion Welding Tech-

nique,” Materials & Design, Vol. 26, No. 6, 2005, pp.

555-560. doi:10.1016/j.matdes.2004.07.017

[10] American Welding Society, “Welding Handbook,”

American Welding Society, Miami, 1996.

[11] A. H. Feng, B. L. Xiao and Z. Y. Ma, “Effect of Micro-

structural Evolution on Mechanical Properties of Friction

Stir Welded AA2009/SiCp Composite,” Composites Sci-

ence and Technology, Vol. 68, No. 9, 2008, pp. 2141-

2148. doi:10.1016/j.compscitech.2008.03.010

[12] J. A. Wert, “Microstructures of Friction Stir Weld Joints

between an Aluminium-Base Metal Matrix Composite

and a Monolithic Aluminium Alloy,” Scripta Materialia,

Vol. 49, No. 6, 2003, pp. 607-612.

doi:10.1016/S1359-6462(03)00215-X

[13] G. J. Fernandez and L. E. Murr, “Characterization of Tool

Wear and Weld Optimization in the Friction-Stir Welding

of Cast Aluminum 359 + 20% SiC Metal-Matrix Com-

posite,” Materials Characterization, Vol. 52, No. 1, 2004,

pp. 65-75. doi:10.1016/j.matchar.2004.03.004

[14] C. J. Hsu, P. W. Kao and N. J. Ho, “Ultrafine-Grained

Al-Al2Cu Composite Produced In-Situ by Friction Stir

Processing,” Scripta Materialia, Vol. 53, No. 3, 2005, pp.

341-345. doi:10.1016/j.scriptamat.2005.04.006

Copyright © 2013 SciRes. ENG