Advances in Pure Mathematics, 2013, 3, 430-437 http://dx.doi.org/10.4236/apm.2013.34061 Published Online July 2013 (http://www.scirp.org/journal/apm) Quasi-Static Problem of Thermoelasticity for Thermosensitive Infinite Circular Cylinder of Complex Heat Exchange Halyna Harmatij1, Marta Król2, Vasyl Popovycz1 1Pidstryhach Institute for Applied Problems of Mechanics and Mathematics National Academy of Sciences of Ukraine, Lviv, Ukraine 2Faculty of Mathematics and Applied Physics, Rzeszow University of Technology, Rzeszow, Poland Email: dept19@iapmm.lviv.ua, krolmb@prz.edu.pl Received January 20, 2013; revised March 10, 2013; accepted April 13, 2013 Copyright © 2013 Halyna Harmatij et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT Nonlinear nonstationary heat conduction problem for infinite circular cylinder under a complex heat transfer taking into account the temperature dependence of thermophysical characteristics of materials is solved numerically by the method of lines. Directing it to the Cauchy’s problem for systems of ordinary differential equations studied feature which takes place on the cylinder axis. Taken into account the dependence on the temperature coefficient of heat transfer that the different interpretation of its physical content makes it possible to consider both convective and convective-ray or heat ray. Using the perturbation method, the corresponding thermoelasticity problem taking into account the temperature dependence of mechanical properties of the material is construed. The influence of the temperature dependence of the material on the distribution of temperature field and thermoelastic state of infinite circular cylinder made of titanium alloy Ti-6Al-4V by radiant heat transfer through the outer surface has been analyzed. Keywords: Thermoelastic State; Heat Transfer; Boundary Value Problem 1. Introduction It is of interest to consider the condition of convective heat transfer coefficient depending on the temperature of heat transfer t t tt 0 c S tt n t Sn S . (1) Here t—coefficient of thermal conductivity, which depends on the temperature; c t—temperature environ- ment, which washes the body surface ; -external nor- mal to the surface . That kind of heat transfer condi- tions also considers heating or cooling the body by ra- diation, or heat when carried out simultaneously by con- vection and radiation. Thus the physical content of Equ- ation (1) is quite different. For radiation heat transfer co- efficient t is called the coefficient of radiation heat transfer, it has the same dimension as the coefficient of convective heat transfer is: 22 cc ttttt , (2) — Stefan-Boltzmann constance, —coefficient of black- ness. The coefficient is the total coefficient of con- vective heat transfer k and coefficient of radiation t kt r ,,rz in the case of convective heat transfer beam where . (3) Transient heat transfer body will be called convective heat transfer with temperature depending on the heat transfer coefficient. The mechanism of that heat transfer is described by the Relation (1). In the study of processes of heat conduction in solids, which are shaped circular cylinder radius 0 using a cy- lindrical coordinate system . If the temperature is independent of and (the case of axial symme- try), the heat equation has the form: z —reduced rate of radiation, 0 1,0 tv tt rct rr rr r (4) ctwhere v The solution of Equation (4) satisfies the boundary condition of the third kind, the described types of heat transfer are as follows: —volumetric heat capacity. C opyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 431 0, t tr tt r 0,0 c trt 0r , (5) and at satisfies the condition of boundedness of solution, which is equivalent to the condition 0 m 0 tt tr li r ,0 . (6) Besides, the solution of Equation (4) satisfies the ini- tial condition tr t, (7) where t t t r —the initial temperature of the cylinder. Thus, the mathematical model to determine the tem- perature field in a circular cylinder has the form of non- linear boundary value Problems (4)-(7). For the convenience of calculations in constructing the solution to the Problems (4)-(7) we pass to dimensionless variables. To do this, take the temperature of the heating medium c by counting the temperature 0, and radius 0 for the typical size. We introduce the dimensionless temperature 0 and coordinate Ttt0 rr . The growth temperature T denoted by TT, where 0 t pp Tt ,tct . 2. Preliminaries Specifications of the material tv and heat transfer coefficient are represented as: t 0 0 0 , , , ttt vvv tT ccT tT ,,c ct (8) where 000tv —basic coefficients that are relevant dimension, and, ,,TcT T T tv —functions that describe the dependence of these characteristics on di- mensionless temperature , and 1 vp TcT tp . We introduce the dimensionless time 2 000 00 t oa rac and Bios criterion’ 00 0t Bi r . That Problems (4)-(7) to increase the temperature in the dimensionless quantity becomes a 1 tT Tc ,0 1 T T Fo , (9) 1, 1, TFo TBiT 0 tc TFoT (10) 0 lim 0 tT T , (11) 00 Fo T , (12) where ccp TTT. Nonlinear boundary value Problems (9)-(12) will be solved numerically using the method of lines. We intro- duce a uniform grid ;0,, 1 hi ih iNhN 01 in the interval . The differential operator 1 tT T , (13) has been replaced by the difference operator [1] at the points of the grid,1, 1 iiN 12, , 1 iii i i T , (14) where 12, 1 2, ii iii hTTTh , ,1iii TTTh i , and the value determined by the formula 1 2 ii it TT (15) or 1 2 ti ti i TT h . (16) The difference operator (14) approximates the dif- ferential operator (13) to the second order in . We will approach these functions ,TT Fo ii by using the functions ,0,yyFoi N ii , which are based on Equation (9) satisfying the system of ordinary differ- ential equations 11 12 112 d d 1, 1, 1 i ii ii ii ii ii y Fo yy yy hc hh iN (17) where ccT 1 ivi We construct the difference boundary condition for the second-order approximation for N . . The expan- sion of these values in series Taylor in neighborhood of the point is written as follows: 1 2 2 ,12 2 2 2 2 NN N NN NN Nt Nt TT h ThT TOh h TTOh Then considering the differential Equation (9) at the point we receive Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 432 2 2 2. N N N NN t T TOh T Oh Oh 12 , 2 2 2 1 2 2 N N N NNN tt t tN tNt T Th TT T Th TT ThT TcT Fo Hence, taking into account that N Ty, we obtain 12 , NN N y d2 d NNN NN y Fo h c , (18) where 1 1 c T T Bi T . The difference analog of condition is constructed (11). The values ,0 T і 1 decompose in the Taylor series: 2 2 0 , . TO h Oh 2 ,0 2 00 10 2 2 tt ThT h TT Then 00 2 2 0 T TOh TOh 1,0 0 2 2 0 0 2 2 tt t tt T Th TT T Th TT (19) In view of Equation (9) we write t tT TTT TcT o . (20) Since 0 lim 0 T , then we have uncertainty 0 tTT of type 0 0. We now turn to the border and reveal uncertainty using the rule of de L’Hospitala, we get 0 0 lim t t TTT T . Thus from (20) we obtain 0 0 0 1 2 tTT TcT Fo . (21) Taking into account (21), we write (19) as 2 1,0 0 0 4v hT TcT Oh Fo . (22) Since the value of 0 approaches 0, then from (22) we obtain the following differential equation at the point Ty 0 0 1,0 d4 d yy, (23) ohc where . 00 v ccT Thus, we obtain the Cauchy problem for systems of ordinary differential equations approximating the partial derivatives of the space variables with the second-order boundary-value Problems (8)-(11) 0 11 0 2 0 d4 d yyy Foc h , (24) 12 11121 2 d1, d 1,1 , iiiii iiii ii yyy yy Fo hc iN (25) 1 12 d2 d NNN NN NN NN yyy Fo h ch 00 i y , (26) . (27) Thus, the dependence forms of the heat transfer co- efficient t t , thermal conductivity t and volu- metric heat capacity ct v of the selected material are dependent on temperature, then we solve the system numerically (24)-(27). As a result, we obtain the value of temperature increase in grid points ,1,iN i along the radius of the cylinder for a given time o ,, rr zz . 3. Thermoelastic State of a Cylinder The thermoelastic cylinder state with the activity of the found axisymmetric temperature field are defined by three non-zero components of stress tensor , which in dimensionless form is rewritten as: 00 ,, ,, 2 rr zz to Gt 0 G0t , where і —supporting values of the shear mo- Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 433 dulus and coefficient of linear thermal expansion. However, they are expressed through the dimension- less radial displacement 00to u urt , so * 1, uu T e TT 1GT T (28) 1, T e TT 1 uu GT T T (29) * e T 1 uu GT TT (30) and satisfy the equation of balance 0 . (31) Here 0 z e e to t , where z e—was the axial strain; 0 1 ,d 12 1 T t GT T GT T TT , ( ,,TTGT t—the function describing the de- pendence of the Poisson coefficient of the linear thermal expansion and modulus of the dimensionless temperature increase. If we substitute the dependence (28)-(30) into equilibrium Equation (31), we get the differential equa- tion , T 1u Tuu nTeTmT (32) where ln 1, 1 1 TGTT mTGT TGT GT nT GT T 1, . T T The solution of Equation (32), which satisfies the con- dition of the limited movement of the cylinder axis, found by perturbation [1-3] has the form of: 0 k k uu , (33) where 02 010 002 11 1 2 1 2nn uc HHH eHH (34) 02 1 02 11 1 2 11 ,1 2 k kkn n kk e ucH H HHk (35) 0 0 0 11 0 11 1 d d d d . mm mm n mm kk kk k HT HT Hn Hf uu fTmT ,, According to (33) the thermal stress 0 ,,,, , is found by the formulas: pk kk k , (36) where 0102 0 12 , n TH GT c HeTH (37) 11 ,1, pk kknk GT ceTHHk (38) 0 01 2 0 12 12 , n TH GT cTT HevTH (39) Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 434 1 k kk n GT ceTHH 1 ,1 kk (40) 0 01 0 0 212 1, n GTT cTT evTvTH 0 T H (41) 1 0 1 21 k kk k GTT ceT TH 0 ,1 n T H k (42) where 02 , ,, 1. H nk 10 k 0 k ek 2 12 1 2 T HH The sustainable integration ck and parts of the development of axial strain determine the conditions on the outer surface 10 k 1 0 d0 k and relations for unmounted ends of the cylinder , by solving system of linear equations ,0 kk B kAX , (43) where 1 1 1 1 1 11 12 21 22 1112 11 21 0 22 0 10 111 20 1 0 111 0 21 0 ,, 1, 2d 1 , k kk k n kk kk c aa e aa aa H aGTT aGTT bHH bGT T bH bGTTH 1 2 0 0 d d d. k k n b b TH TH AX B Here 111 111 1 1,,1 2 ,TGGT. 0e For fixed ends of the cylinder we have . If the thermomechanical properties of the material the cylinder does not depend on temperature, then transfer and thermal stresses are calculated by the formulas: 0 1,d , 1 iti iii i uTFoc (44) 2 0 11 ,d , 112 i iti ii iii ii GTFone (45) 2 0 11,d , 1 1, 12 i iti iii i iii i GTFoTFo ne (46) 1 2121 ,, 12 1 i ii iii iitii ii Gce TFo (47) where 1 2 10 13 ,d 1 iti ii i cTFo , 1 2 2 10 0 111 2,d 12 ii ti ii i eTFo , ,TFo * ,G trr 300 Kt t i—increase of temperature in the cylinder for constant thermophysical characteristics; i—steel coefficient of linear thermal expansion and modulus ta- ken at the initial or maximum temperature, or mean inte- gral value of the selected temperature range. 4. Numerical Study This section investigated the temperature field and ther- moelastic state of thermosensitive infinite circular cylin- der. Radiant heat exchange with the environment at a temperature c is due to the surface 0 of the cylin- der, which is free from power loads. In that case, the ra- diant heat exchange has been formed to convective heat transfer coefficient in the form of (2). The initial tem- perature of the cylinder is p. The medium tem- perature c is equal to 1100 K and it is selected by sup- porting. Titanium alloy Ti-6Al-4V taken by the material. Temperature dependence of thermal and mechanical properties of the alloy are the form [4] in the temperature range from 300 K to 1100 K. Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 435 1.1 0.017 , t vp tt ct ctt Wm K (48) 3kJ kgK , 21 42 7 3.510 8.7810 9.74104.43 10 p ct t tt (49) 3 .0kgm 4420.0 1.0300 ttt , (50) 122 101 К,tt 69 7.43 105.56 102.69 t t (51) 122.7 0.0565 GEt tPa 6 8832.010tt , (52) 0.28 . (53) For the purpose of comparison, we studied the tem- perature field and caused it thermoelastic stable in the same noetherian sensitive cylinder under constant ther- mal and mechanical characteristics of titanium alloy. This steel coefficient of thermal conductivity t ct Gt 300 K t, volumetric heat capacity v, modulus , coeffi- cient of linear thermal expansion and coefficient of Poisson , we take as: a) the initial temperature p, and b) the maximum temperature of tc = 1100 K, c) mean-integral temperature range from 300 - 1100 K, under tt t t 1d n p t np t ctt . The results of numerical studies of the temperature T 0.1Fo 1 growth, which were obtained in dimensionless form, are presented in graphs in Figures 1-2. The distribution rates of temperature along the radial coordinate cylinder for values of the Fourier criterion are shown in Figure 1. The dependence of the temperature growth on the criterion of Fourier on the surface of the cylinder is illustrated in Figure 2. Here curve 1 correspond to the results of calculations taking into account the temperature dependence of ther- Figure 1. Temperature dependence of the radial coordinate. mophysical characteristics of titanium alloy (48)-(51), curve 2—at maxtt tt vv ct ct, max ; curve 3 —at tt maxtt, ct ctmaxvv; curve 4—for sustainable medium-integer values of material from a selected range of temperature. The analysis of the re- search shows that the largest discrepancy between the temperature growth in the cylinder taking into account the temperature dependence of thermophysical charac- teristics of materials and for stable values of characteris- tics is in the case ,ttct ct max maxtt vv As it is visible from the graphs in Figure 2 the ma- ximum difference between the increases of temperature . T1 on the surface of the cylinder by taking into account the temperature dependence of thermophysical of characteristics material (curve 1) and stable medium- integer values of thermal conductivity and volumetric heat capacity (curve 4) does not exceed 10% (for ). 0.1Fo Figures 3-9 show graphs of distributions of displace- ment and stress tensor component along the radial coor- dinate for the Fourier criterion and on the surface of the cylinder 0.1Fo 1 o. depending on Here curve 1 correspond to the results of calculations taking into account the temperature dependence of ther- mal and mechanical characteristics of titanium alloy (48)-(53). Figure 2. Temperature dependence of the criterion of the Fourier. Figure 3. Temperature dependence of the radial coordinate. Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. 436 Figure 4. Temperature dependence of the criterion of the Fourier. Figure 5. Temperature dependence of the radial coordinate. Figure 6. Temperature dependence of the criterion of the Fourier. The curves 2 - 4 correspond to displacement or stress, found by constant values of thermal and mechanical properties of the material: curve 2—initially under the temperature curve 3—the maximum temperature curve 4—for sustainable medium-integer values of titanium alloy with a temperature range 300 - 1100 K in Figures 3-9. In the form of curves 5 - 7 there are the data distri- butions for the temperature-dependent thermal properties shown tv , and constant values of mechanical properties (which are taken for the initial (curve 5), and the maximum temperature (curve 6)) and sustainable me- Figure 7. Temperature dependence of the radial coordinate. Figure 8. Temperature dependence of the criterion of the Fourier. Figure 9. Temperature dependence of the radial coordinate. dium integer values of mechanical characteristics of tita- nium alloy with temperature range 300 - 1100 K (curve 7). The analysis of differences between the values of both displacements and stresses, which are calculated for all dependent on the temperature characteristics of the mate- rial (heat-sensitive body), and their values calculated by the constant characteristics (not heat-sensitive body) in- dicates that: they exceed 60%, if the properties take non heat-sen- sitive value for thermo-sensitive characteristics at ma- ximum temperature; ,tct within 12% - 40% when take on characteristics non Copyright © 2013 SciRes. APM  H. HARMATIJ ET AL. Copyright © 2013 SciRes. APM 437 heat-sensitive body thermo-sensitive properties at the initial temperature; they are within 4% - 20%, when the characteristics non heat-sensitive body take mid-integral values of thermal and mechanical characteristics. Then the ma- ximum difference between them exceeds 60%. Thus, studies show that by ignoring the temperature dependence of thermal and mechanical characteristics of the material, the distribution of temperature field and de- fined by its thermo-elastic state of the body that differ significantly from the true can be achieved. The likely thermoelastic state of structural elements of modern technology, which in the process of their manu- facture and operation exposed to high heat or cooled to low temperatures, preferably determined, based on the model of thermosensitive bodies [5,6]. In that model we consider the temperature dependence of thermal and mechanical properties of the material. That mathematical model to determine the thermoelastic parameters is sig- nificantly more complicated in comparison with the same model by neglecting thermo-sensitive material. The tem- perature is determined from the nonlinear problem, which is not only nonlinear heat equation and boundary condi- tions and in case of default on the body surface heat flux, convective or convective-radiation heat transfer [7,8]. The corresponding thermoelasticity problem is the same boundary value problem for differential equations with variable coefficients [5]. For these mathematical models the construction of solution is usually carried out by nu- merical methods [9]. REFERENCES [1] J. J. Burak and R. M. Kushnir, “Modeling and Optimiza- tion in Termomehanitsi Electrically Inhomogeneous Bod- ies,” In: J. J. Burak and R. M. Kushnir, Eds., Thermoelas- ticity Thermosensitive Bodies, Vol. 3, Lviv, 2009, p. 412. [2] V. A. Lomakin, “The Theory of Elasticity of Inhomogene- ous Bodies,” Moscow State University Press, Moscow, 1976, p. 367. [3] N. H. Moiseev, “The Asymptotic Methods of Nonlinear Mechanics,” Nauka, Moscow, 1981, p. 400. [4] R. M. Kushnir and V. Popovycz, “Stressed State Thermo- sensitive Body Rotation in the Plane Axialsymmetric Tem- perature Field,” Visnuk Dnipropetrovskoho University, Median Mechanics, No. 2, 2006, pp. 91-96. [5] Y. Tanigawa, T. Akai, R. Kawamura and N. Oka, “Tran- sient Heat Conduction and Thermal Stress Problems of a Nonhomogeneous Plate with Temperature-Dependent Ma- terial Properties,” Journal of Thermal Stresses, Vol. 19, No. 1, 1996, pp. 77-102. doi:10.1080/01495739608946161 [6] N. Noda, “Thermal Stresses in Materials with Tempera- ture-Dependent Properties,” Thermal Stresses Journal, 1986, pp. 391-483. [7] V. S. Popovych and H. Yu Harmatiy, “Analytical and Nu- merical Methods of Solutions of Heat Conduction Problems with Temperature-Sensitive Body Convective Heat Trans- fer,” Problems of Mechanics and Mathematics, Pidstryhach, No. 13-93, Lviv, 1993, p. 67. [8] H. Yu. Harmatiy, M. B. Kutniv and V. S. Popovich, “Nu- merical Solution of Unsteady Heat Conduction Problems with Temperature-Sensitive Body Convective Heat Trans- fer,” Engineering, No. 1, 2002, pp. 21-25. [9] A. Samarskiy, “The Theory of Difference Schemes,” Nau- ka, Moscow, 1977, p. 656.

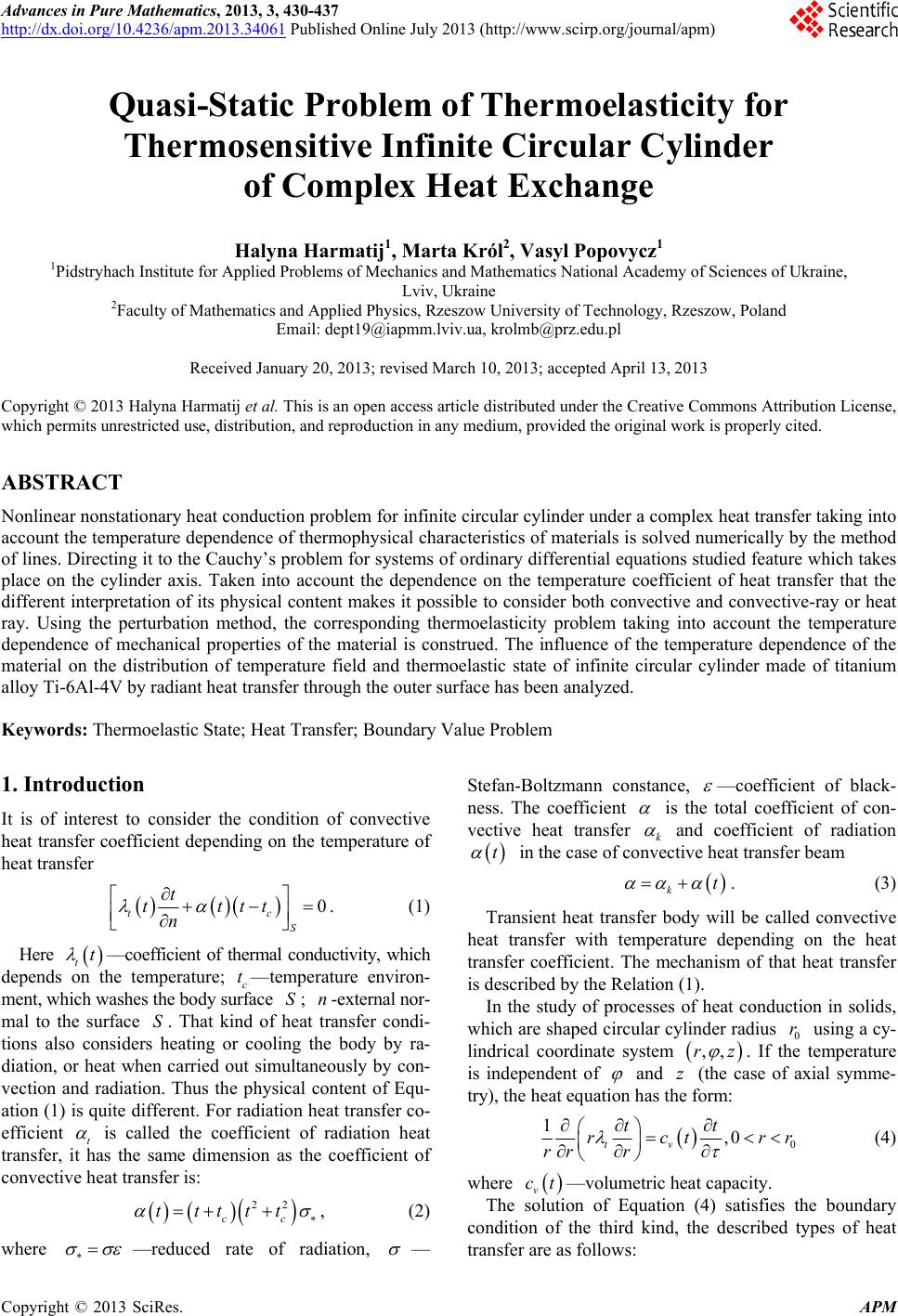

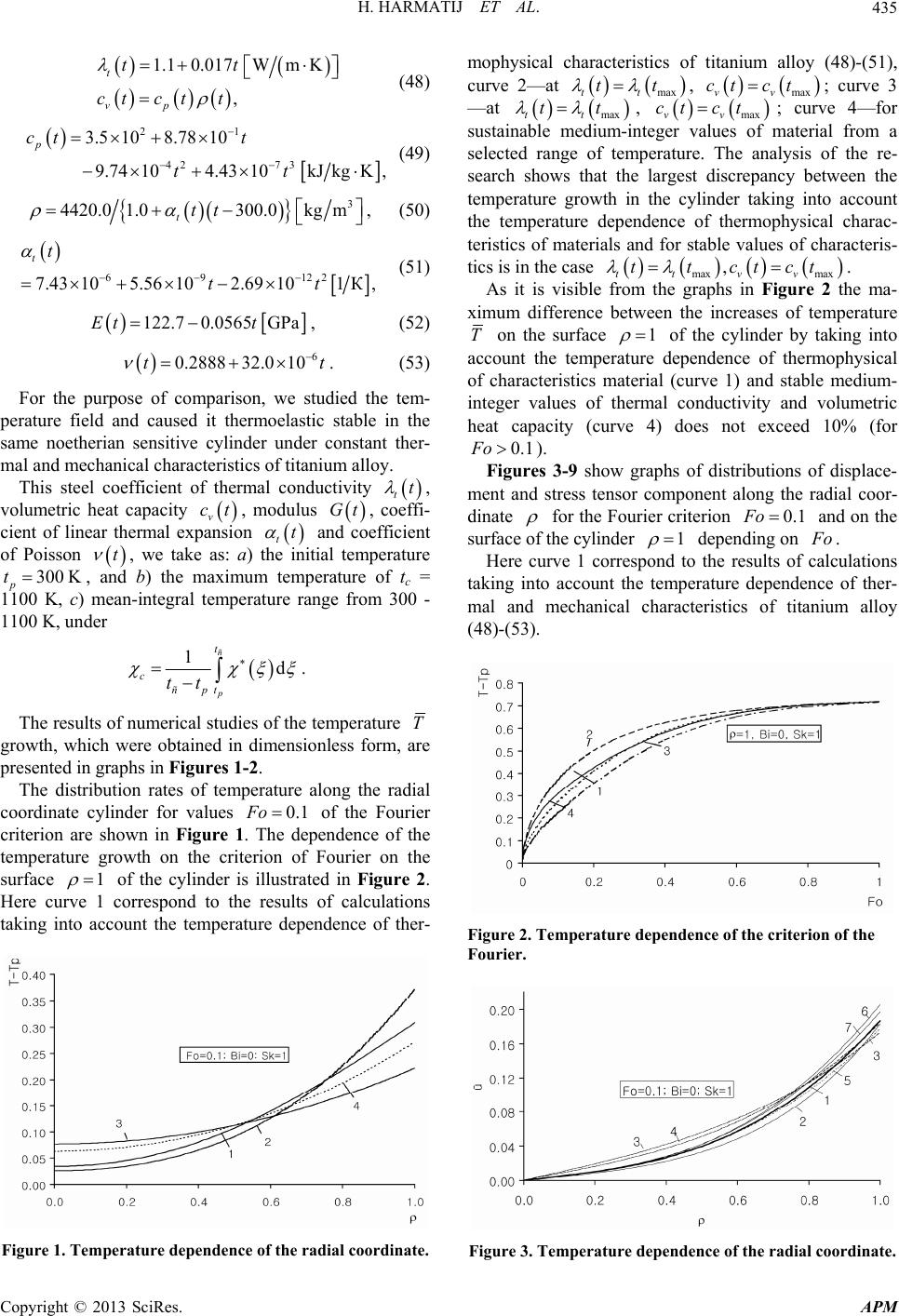

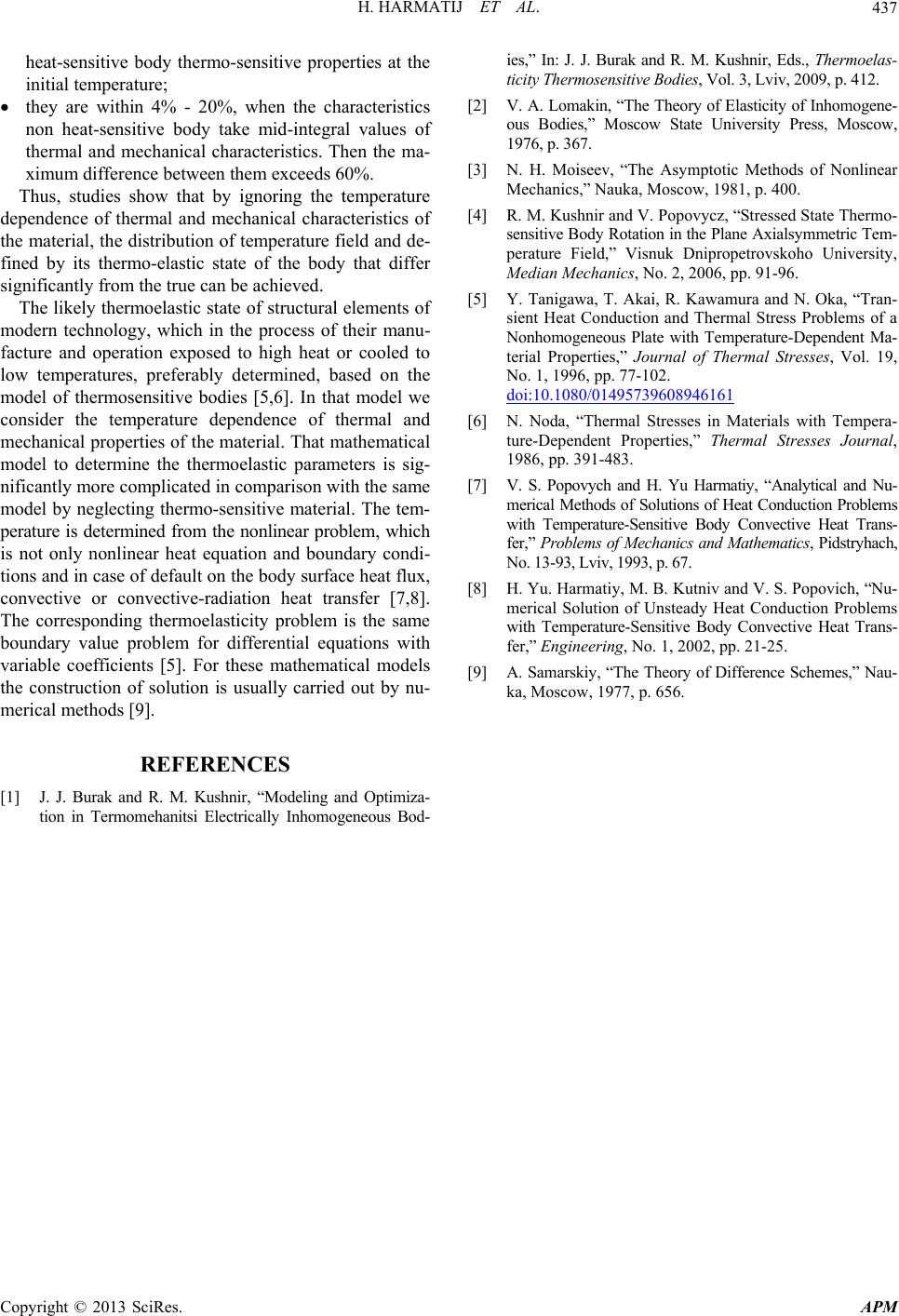

|