M. ZAHER, S. CETINKUNT

350

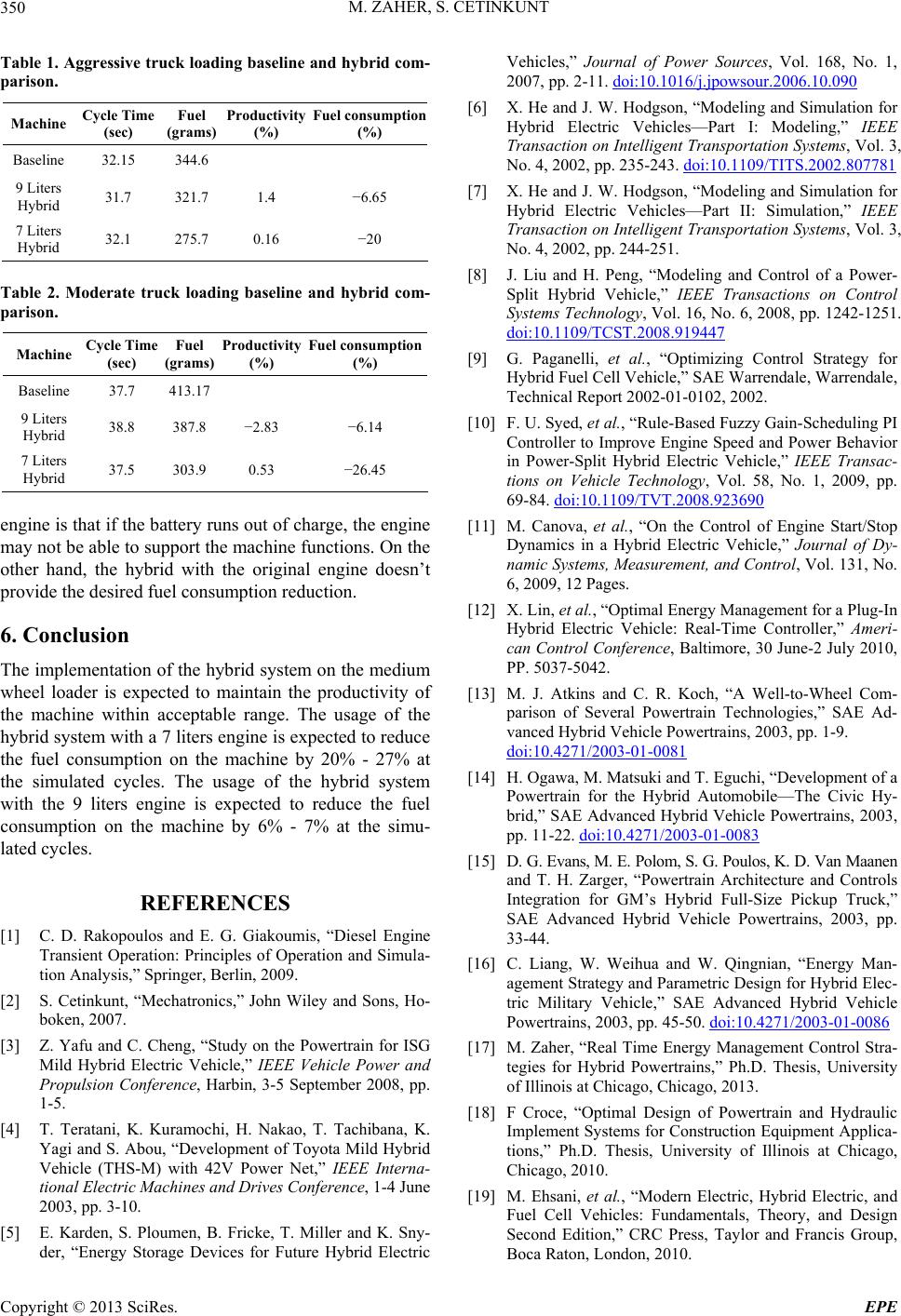

Table 1. Aggressive truck loading baseline and hybrid com-

parison.

Machine Cycle Time

(sec) Fuel

(grams)

Productivity

(%) Fuel consumption

(%)

Baseline 32.15 344.6

9 Liters

Hybrid 31.7 321.7 1.4 −6.65

7 Liters

Hybrid 32.1 275.7 0.16 −20

Table 2. Moderate truck loading baseline and hybrid com-

parison.

Machine Cycle Time

(sec) Fuel

(grams)

Productivity

(%) Fuel c onsumption

(%)

Baseline 37.7 413.17

9 Liters

Hybrid 38.8 387.8 −2.83 −6.14

7 Liters

Hybrid 37.5 303.9 0.53 −26.45

engine is that if the battery runs out of charge, the engine

may not be able to support the machine functions. On the

other hand, the hybrid with the original engine doesn’t

provide the desired fuel consumption reduction.

6. Conclusion

The implementation of the hybrid system on the medium

wheel loader is expected to maintain the productivity of

the machine within acceptable range. The usage of the

hybrid system with a 7 liters engine is expected to reduce

the fuel consumption on the machine by 20% - 27% at

the simulated cycles. The usage of the hybrid system

with the 9 liters engine is expected to reduce the fuel

consumption on the machine by 6% - 7% at the simu-

lated cycles.

REFERENCES

[1] C. D. Rakopoulos and E. G. Giakoumis, “Diesel Engine

Transient Operation: Principles of Operation and Simula-

tion Analysis,” Springer, Berlin, 2009.

[2] S. Cetinkunt, “Mechatronics,” John Wiley and Sons, Ho-

boken, 2007.

[3] Z. Yafu and C. Cheng, “Study on the Powertrain for ISG

Mild Hybrid Electric Vehicle,” IEEE Vehicle Power and

Propulsion Conference, Harbin, 3-5 September 2008, pp.

1-5.

[4] T. Teratani, K. Kuramochi, H. Nakao, T. Tachibana, K.

Yagi and S. Abou, “Development of Toyota Mild Hybrid

Vehicle (THS-M) with 42V Power Net,” IEEE Interna-

tional Electric Machines and Drives Conference, 1-4 June

2003, pp. 3-10.

[5] E. Karden, S. Ploumen, B. Fricke, T. Miller and K. Sny-

der, “Energy Storage Devices for Future Hybrid Electric

Vehicles,” Journal of Power Sources, Vol. 168, No. 1,

2007, pp. 2-11. doi:10.1016/j.jpowsour.2006.10.090

[6] X. He and J. W. Hodgson, “Modeling and Simulation for

Hybrid Electric Vehicles—Part I: Modeling,” IEEE

Transaction on Intelligent Transportation Systems, Vol. 3,

No. 4, 2002, pp. 235-243. doi:10.1109/TITS.2002.807781

[7] X. He and J. W. Hodgson, “Modeling and Simulation for

Hybrid Electric Vehicles—Part II: Simulation,” IEEE

Transaction on Intelligent Transportation Systems, Vol. 3,

No. 4, 2002, pp. 244-251.

[8] J. Liu and H. Peng, “Modeling and Control of a Power-

Split Hybrid Vehicle,” IEEE Transactions on Control

Systems Technology, Vol. 16, No. 6, 2008, pp. 1242-1251.

doi:10.1109/TCST.2008.919447

[9] G. Paganelli, et al., “Optimizing Control Strategy for

Hybrid Fuel Cell Vehicle,” SAE Warrendale, Warrendale,

Technical Report 2002-01-0102, 2002.

[10] F. U. Syed, et al., “Rule-Based Fuzzy Gain-Scheduling PI

Controller to Improve Engine Speed and Power Behavior

in Power-Split Hybrid Electric Vehicle,” IEEE Transac-

tions on Vehicle Technology, Vol. 58, No. 1, 2009, pp.

69-84. doi:10.1109/TVT.2008.923690

[11] M. Canova, et al., “On the Control of Engine Start/Stop

Dynamics in a Hybrid Electric Vehicle,” Journal of Dy-

namic Systems, Measurement, and Control, Vol. 131, No.

6, 2009, 12 Pages.

[12] X. Lin, et al., “Optimal Energy Management for a Plug-In

Hybrid Electric Vehicle: Real-Time Controller,” Ameri-

can Control Conference, Baltimore, 30 June-2 July 2010,

PP. 5037-5042.

[13] M. J. Atkins and C. R. Koch, “A Well-to-Wheel Com-

parison of Several Powertrain Technologies,” SAE Ad-

vanced Hybrid Vehicle Powertrains, 2003, pp. 1-9.

doi:10.4271/2003-01-0081

[14] H. Ogawa, M. Matsuki and T. Eguchi, “Development of a

Powertrain for the Hybrid Automobile—The Civic Hy-

brid,” SAE Advanced Hybrid Vehicle Powertrains, 2003,

pp. 11-22. doi:10.4271/2003-01-0083

[15] D. G. Evans, M. E. Polom, S. G. Poulos, K. D. Van Maanen

and T. H. Zarger, “Powertrain Architecture and Controls

Integration for GM’s Hybrid Full-Size Pickup Truck,”

SAE Advanced Hybrid Vehicle Powertrains, 2003, pp.

33-44.

[16] C. Liang, W. Weihua and W. Qingnian, “Energy Man-

agement Strategy and Parametric Design for Hybrid Elec-

tric Military Vehicle,” SAE Advanced Hybrid Vehicle

Powertrains, 2003, pp. 45-50. doi:10.4271/2003-01-0086

[17] M. Zaher, “Real Time Energy Management Control Stra-

tegies for Hybrid Powertrains,” Ph.D. Thesis, University

of Illinois at Chicago, Chicago, 2013.

[18] F Croce, “Optimal Design of Powertrain and Hydraulic

Implement Systems for Construction Equipment Applica-

tions,” Ph.D. Thesis, University of Illinois at Chicago,

Chicago, 2010.

[19] M. Ehsani, et al., “Modern Electric, Hybrid Electric, and

Fuel Cell Vehicles: Fundamentals, Theory, and Design

Second Edition,” CRC Press, Taylor and Francis Group,

Boca Raton, London, 2010.

Copyright © 2013 SciRes. EPE