S. BEY ET AL.

34

vigorously stirred to merge the components homogene-

ously and the mixture was casted by a casting knife

(casting thickness 250 µm) on glass plat to induce co-

agulation by immersion precipitation in a water coagula-

tion bath. The experimental conditions of membrane

preparation are reported in Table 1. The prepared mem-

branes were dried in an oven overnight at 60˚C for fur-

ther analysis.

2.2. Scanning Electronic Microscopy

The Scanning Electron Microscopy (FEI QUANTA 200)

at 20 Kv was used to study the morphology of the mem-

branes. For cross section analysis the membrane samples

were freeze fractured in liquid nitrogen. The chemical

composition of the top and bottom surfaces, of the modi-

fied membranes, were analyzed by energy dispersion

X-ray analysis (EDS) instrument (EDAX).

2.3. Thermal Analysis TGA

Thermo-gravimetric analysis (TGA) was carried out for

the polymer and for the modified membranes (polymer

with additives DBP and DEHPA) with SETARAM

TG6DTA92 in nitrogen.

2.4. Extraction of Ni(II) by Supported Liquid

Membrane and Solid-Liquid Systems

The supported liquid membrane is carried out by the im-

pregnation of an asymmetric micro-porous PEEK-WC

membrane by 40% (volume) DEHPA diluted in a mix-

ture of xylene and heptane. The extracting module con-

sists of a two-compartment cell with an effective mem-

brane area of 9 cm2. The procedure of the extraction is th e

same used in our previous work [8]. The flow of the two

solutions was about 5.54 ml/ min (MASTERFLEX pump

7418) and equal volume of samples (0.2 ml) was with-

drawn from both compartments at desired time interval.

The Ni(II) concentrations were determined by using

analytical kits (Carlo Erba reagent), based on a colori-

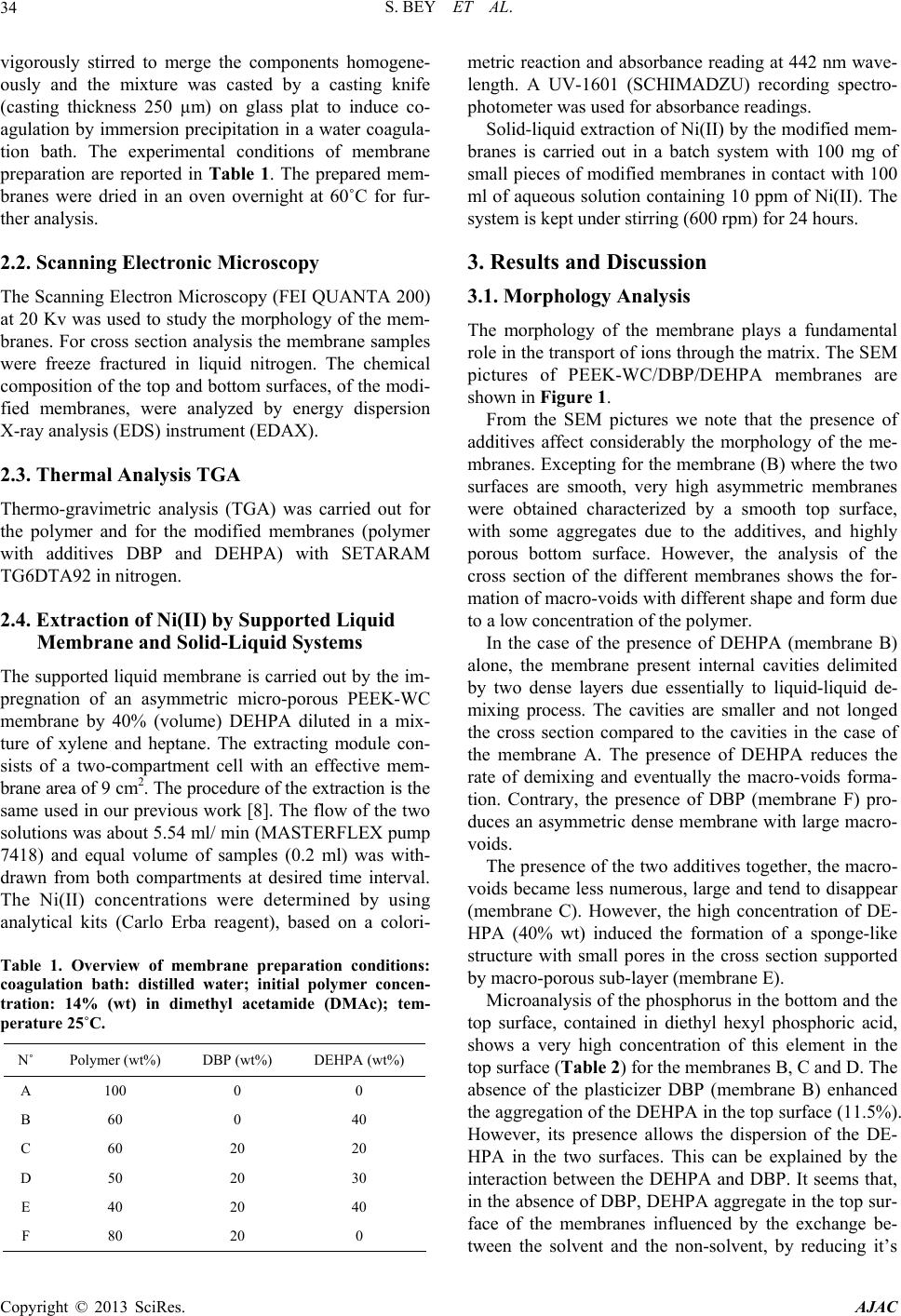

Table 1. Overview of membrane preparation conditions:

coagulation bath: distilled water; initial polymer concen-

tration: 14% (wt) in dimethyl acetamide (DMAc); tem-

perature 25˚C.

N˚ Polymer (wt%) DBP (wt%) DEHPA (wt%)

A 100 0 0

B 60 0 40

C 60 20 20

D 50 20 30

E 40 20 40

F 80 20 0

metric reaction and absorbance reading at 442 nm wave-

length. A UV-1601 (SCHIMADZU) recording spectro-

photometer was used for absorbance readings.

Solid-liquid extraction of Ni(II) by the modified mem-

branes is carried out in a batch system with 100 mg of

small pieces of modified membranes in contact with 100

ml of aqueous solution containing 10 ppm of Ni(II). The

system is kept under stirring (600 rpm) for 24 hours.

3. Results and Discussion

3.1. Morphology Analysis

The morphology of the membrane plays a fundamental

role in the transport of ions through the matrix. The SEM

pictures of PEEK-WC/DBP/DEHPA membranes are

shown in Figure 1.

From the SEM pictures we note that the presence of

additives affect considerably the morphology of the me-

mbranes. Excepting for the membrane (B) where the two

surfaces are smooth, very high asymmetric membranes

were obtained characterized by a smooth top surface,

with some aggregates due to the additives, and highly

porous bottom surface. However, the analysis of the

cross section of the different membranes shows the for-

mation of macro-voids with different shape and form due

to a low concentration of the polymer.

In the case of the presence of DEHPA (membrane B)

alone, the membrane present internal cavities delimited

by two dense layers due essentially to liquid-liquid de-

mixing process. The cavities are smaller and not longed

the cross section compared to the cavities in the case of

the membrane A. The presence of DEHPA reduces the

rate of demixing and eventually the macro-voids forma-

tion. Contrary, the presence of DBP (membrane F) pro-

duces an asymmetric dense membrane with large macro-

voids.

The presence of the two additiv es together, the macro-

voids became less numerous, large and tend to disappear

(membrane C). However, the high concentration of DE-

HPA (40% wt) induced the formation of a sponge-like

structure with small pores in the cross section supported

by macro-porous sub-layer (membrane E).

Microanalysis of the phosphorus in the bottom and the

top surface, contained in diethyl hexyl phosphoric acid,

shows a very high concentration of this element in the

top surface (Table 2) for the membranes B, C and D. The

absence of the plasticizer DBP (membrane B) enhanced

the aggregation of the DEHPA in the top surface (11.5%).

However, its presence allows the dispersion of the DE-

HPA in the two surfaces. This can be explained by the

interaction between the DEHPA and DBP. It seems that,

in the abs ence of DBP, DEHPA aggrega te in the top sur -

face of the membranes influenced by the exchange be-

tween the solvent and the non-solvent, by reducing it’s

Copyright © 2013 SciRes. AJAC