Paper Menu >>

Journal Menu >>

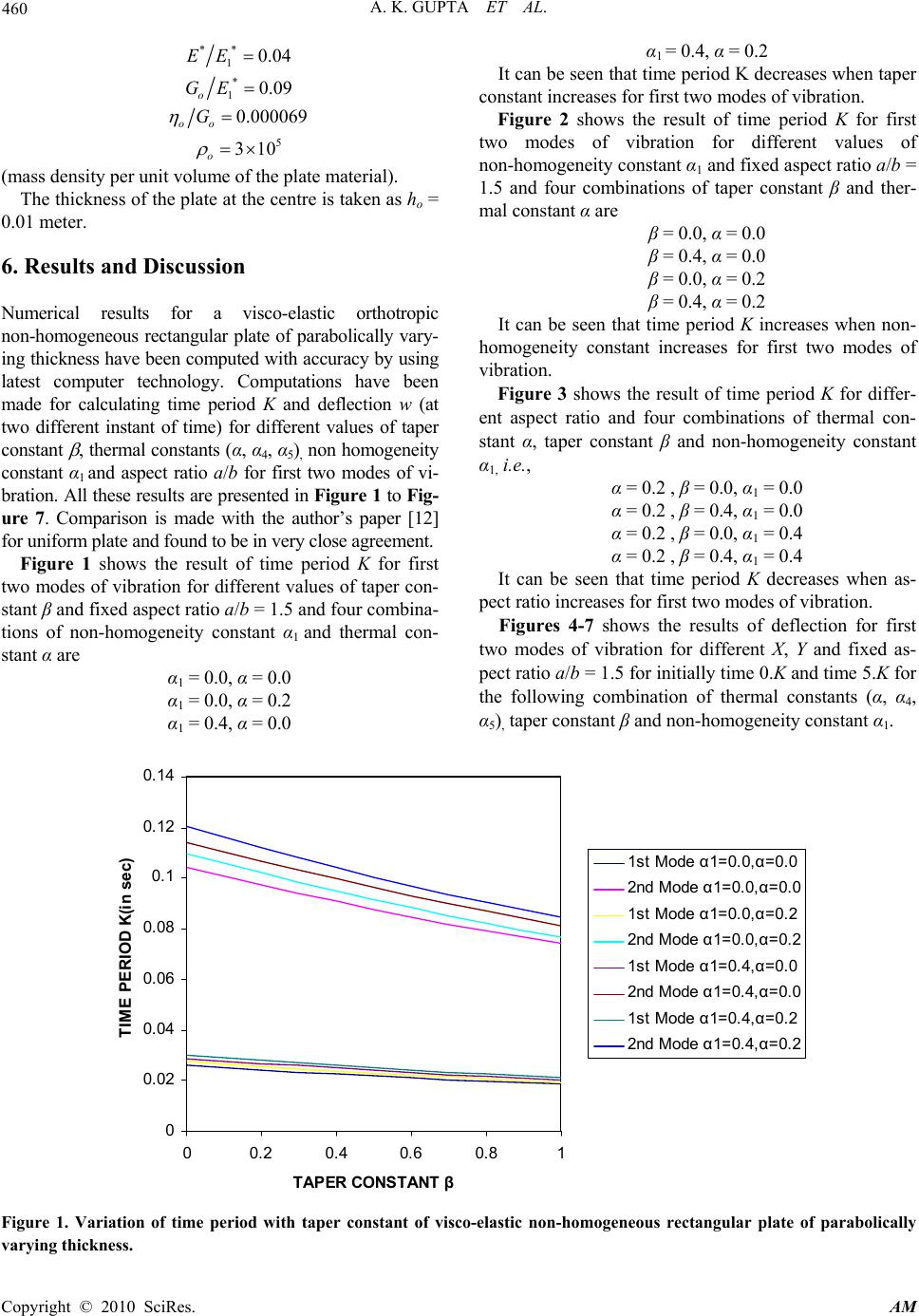

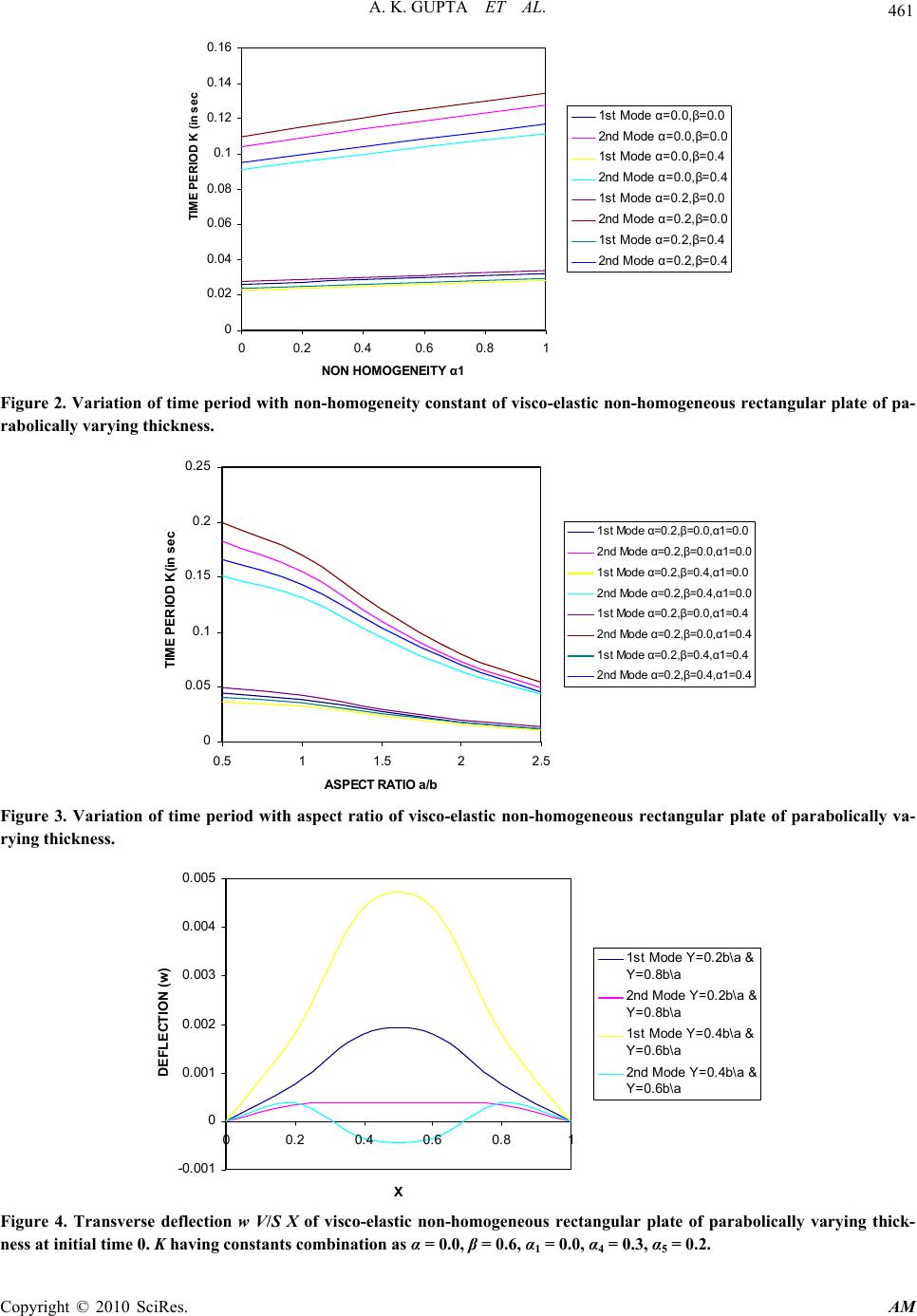

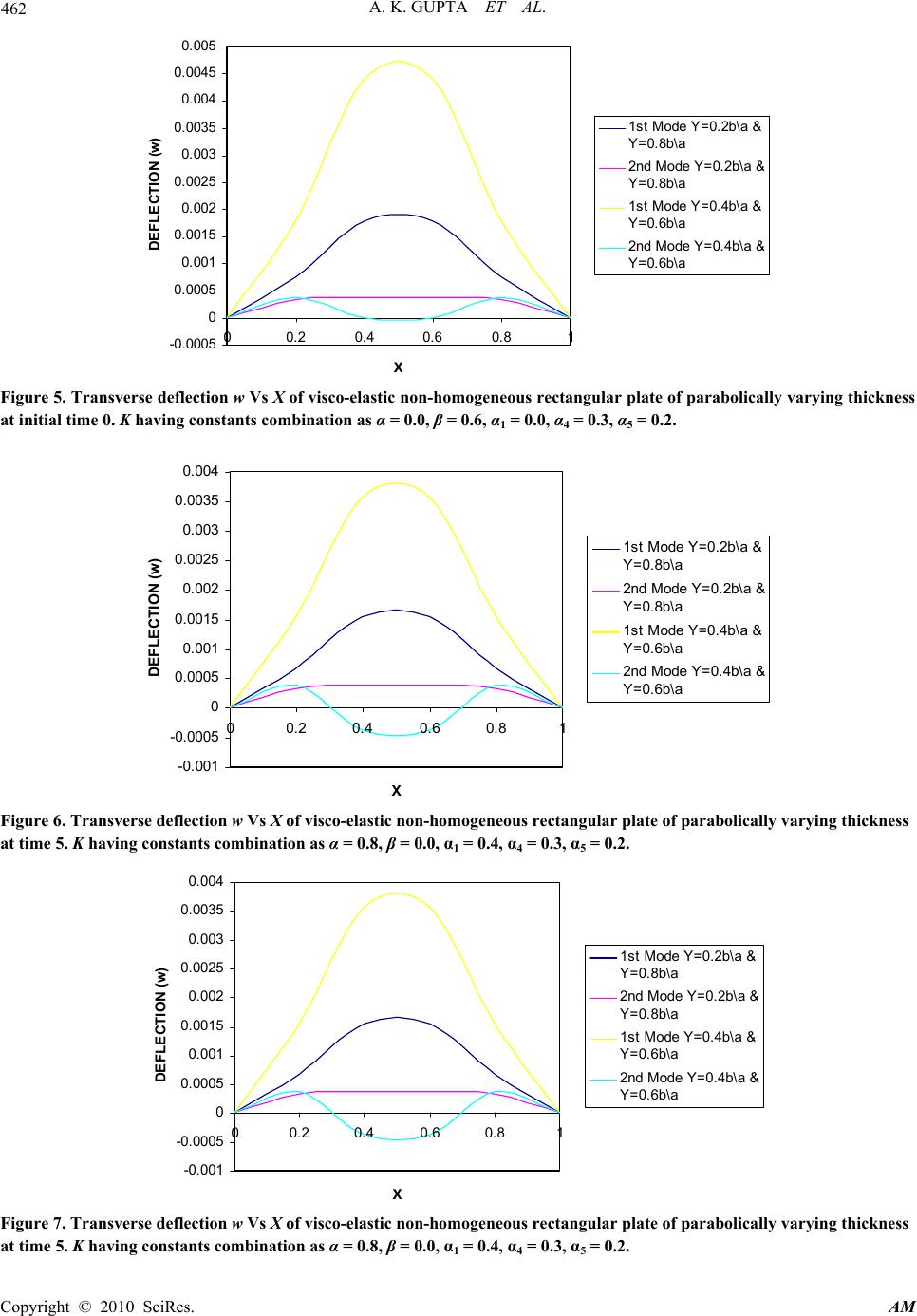

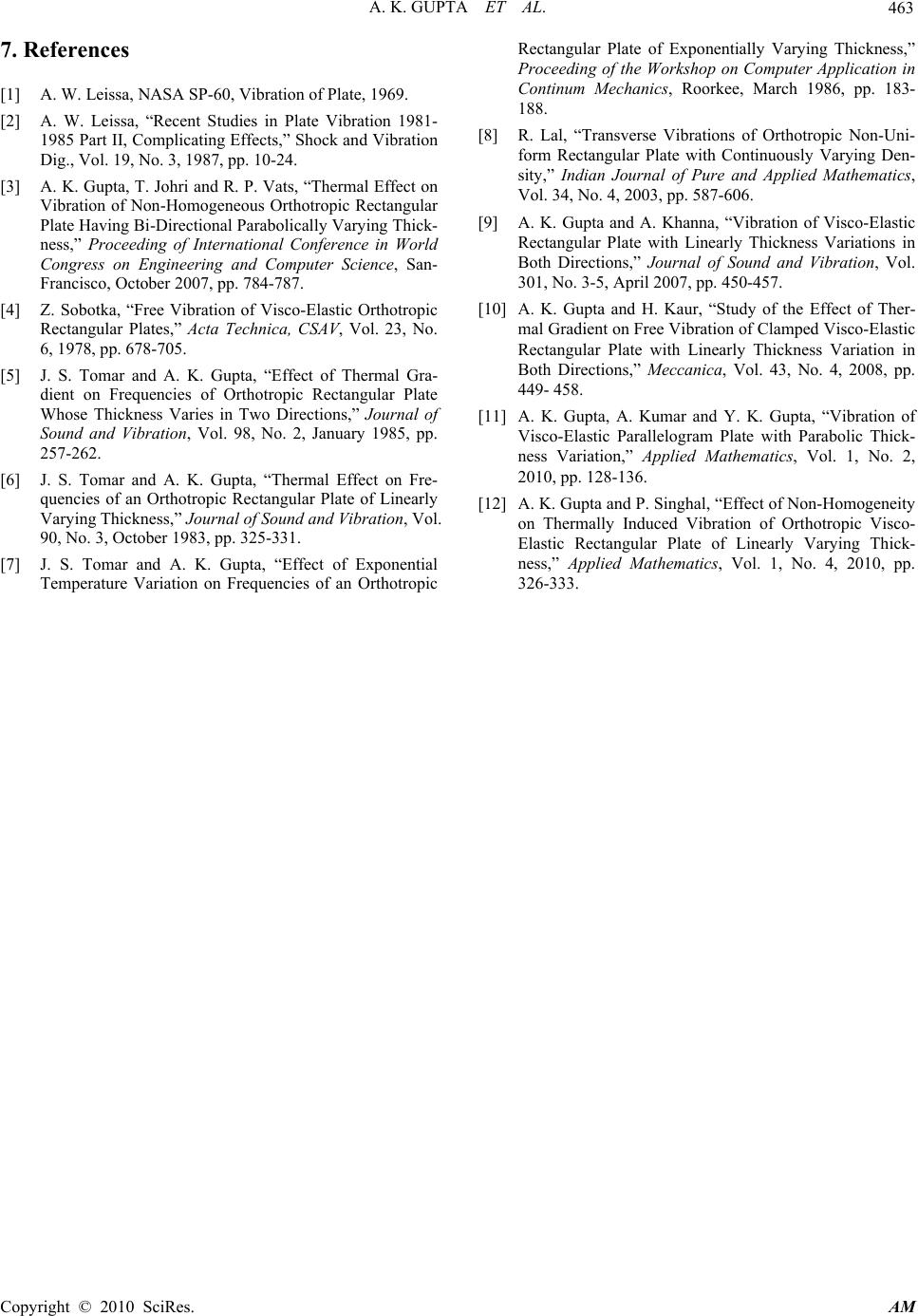

Applied Mathematics, 2010, 1, 456-463 doi:10.4236/am.2010.16060 Published Online December 2010 (http://www.SciRP.org/journal/am) Copyright © 2010 SciRes. AM Thermal Effect on Free Vibration of Non-Homogeneous Orthotropic Visco-Elastic Rectangular Plate of Parabolically Varying Thickness Arun Kumar Gupta, Pooja Singhal Department of Mathematics, M. S. College, Saharanpur, India E-mail: gupta_arunnitin@yahoo.co.in, poojaacad@yahoo.in Received August 31, 2010; revised September 17, 2010; accepted September 21, 2010 Abstract A simple model presented here is to study the thermal effect on vibration of non-homogeneous orthotropic visco-elastic rectangular plate of parabolically varying thickness having clamped boundary conditions on all the four edges. For non-homogeneity of the plate material, density is assumed to vary linearly in one direc- tion. Using the separation of variables method, the governing differential equation has been solved for vibra- tion of non-homogeneous orthotropic visco-elastic rectangular plate. An approximate frequency equation is derived by using Rayleigh-Ritz technique with a two-term deflection function. Results are calculated for time period and deflection at different points, for the first two modes of vibration, for various values of tempera- ture gradients, non-homogeneity constant, taper constant and aspect ratio and shown by graphs. Keywords: Thermal Gradient, Vibration, Non-Homogeneous, Orthotropic, Visco-Elastic, Rectangular Plate, Variable Thickness 1. Introduction In modern technology an interest towards the effect of high temperatures on non-homogeneous plates of varia- ble thickness is developed due to applications in various engineering branches such as nuclear, power plants, aero-nautical, chemical etc. where metals and their alloys exhibits visco-elastic behavior. Therefore for these changes the structures are exposed to high intensity, heat fluxes and material properties undergo significant changes. The materials are being developed, depending upon the requirement and durability, so that these can be used to give better strength, flexibility, weight effectiveness and efficiency. So some new materials and alloys are utilized in making structural parts of equipment used in modern technological industries like space craft, jet en- gine, earth quake resistance structures, telephone indus- try etc. Applications of such materials are due to reduc- tion of weight and size, low expenses and enhancement in effectiveness and strength. It is well known that first few frequencies of structure should be known before finalizing the design of a structure. The study of vibra- tion of plate structures is important in a wide variety of applications in engineering design. Elastic plates are widely employed nowadays in civil, aeronautical and marine structures designs. Complex shapes with variety of thickness variation are sometimes incorporated to re- duce costly material, lighten the loads, and provide ven- tilation and to alter the resonant frequencies of the struc- tures. Dynamic behavior of these structures is strongly dependent on boundary conditions, geometric shapes, material properties etc. As technology develops new discoveries day by day like in jet engine, field of spacecraft and nuclear power plants etc., the time dependent behavior of materials has become of great importance. Thus, the need of the study of vibration of visco-elastic plates (it may be rectangular, circular, elliptical etc.) of certain aspect ratios with some simple boundary conditions has been increased rapidly. Vibration phenomenon, common in mechanical de- vices and structures, is undesirable in many cases, such as machine tools. But this phenomenon is not always unwanted; for example, vibration is needed in the opera- tion of vibration screens. In the course of time, engineers have become increa- singly conscious of the importance of an elastic behavior of many materials and mathematical formulations have  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 457 been attempted and applied to practical problems. Since plastics and new materials are widely used in the con- struction of equipment and structures, so the develop- ment of the application of visco-elasticity is needed to permit rational design. Leissa’s monograph [1] contains an excellent discus- sion of the subject of vibrating plates with elastic edge support. Leissa [2] has given the solution for rectangular plate of variable thickness. Gupta, Johri and Vats [3] have discussed the thermal effect on vibration of non- homo- geneous orthotropic rectangular plate having bi- direc- tional parabolically varying thickness. Sobotka [4] dis- cussed the free vibration of visco-elastic orthotropic rec- tangular plates were discussed. Tomar and Gupta [5-7] solved the vibration problem of orthotropic rectangular plate of varying thickness subjected to a thermal gradient. Lal [8] has studied the transverse vibrations of ortho- tropic non-uniform rectangular plates with continuously varying density. Visco-elasticity, as its name implies, is a generaliza- tion of elasticity and viscosity. The ideal linear elastic element is the spring. When a tensile force is applied to it, the increase in distance between its two ends is propor- tional to the force. The ideal linear viscous element is the dashpot. The plate type structural components in aircraft and rockets have to operate under elevated temperatures that cause non-homogeneity in the plate material, i.e., elastic constants of the materials becomes functions of space variables. In an up-to-date survey of literature, authors have come across various models to account for non- homogeneity of plate materials proposed by researchers dealing with vibration but none of them consider non-homogeneity with thermal effect on visco-elastic plates. Gupta and Khanna [9] have studied the effect of li- nearly varying thickness in both directions on vibration of visco-elastic rectangular plate. Gupta and Kaur [10] studied the effect of thermal on vibration of clamped viscoelastic rectangular plate with linearly thickness in both directions. Gupta, Kumar and Gupta [11] have con- sidered the vibration of visco-elastic parallelogram plate with parabolic thickness variation. Recently, Gupta and Singhal [12] discussed the effect of non-homogeneity on thermally induced vibration of orthotropic visco-elastic rectangular plate of linearly varying thickness. The object of the present study is to determine the thermal effect on vibration of non-homogeneous ortho- tropic visco-elastic rectangular plate of parabolically varying thickness. It is clamped supported on all the four edges. The assumption of small deflection and linear orthotropic visco-elastic properties are made. It is further assumed that the visco-elastic properties of the plates are of the Kelvin type. Time period and deflection for the first two modes of vibration are calculated for the various values of thermal gradients, non-homogeneity constant, aspect ratio and taper constant. 2. Analysis The equation of motion of a visco-elastic rectangular plate of variable thickness is [12]: 44 4 4422 333 22 3 2 2 2 322 32222 2 2' 2' 22 2 11 22 22 2 222 0 2 4 xy x yy x xy WW W DD H xyxy D HW HWW xyx xyx yxhp W DD D WWW yyxxyy D DD WW W xy xy xy yx (1) and .. ~ 20TpDT (2) where Equations (1) and (2) are the differential equations of motion for orthotropic plate of variable thickness and time function for visco-elastic orthotropic plate for free vibration respectively. Here p2 is a constant and ' 12 x y H DD , 3 12 1 x x x y Eh Dvv , is called the flexural rigidity of the plate in x-direction, 3 12 1 y y x y Eh Dvv , is called the flexural rigidity of the plate in y-direction, 3 12 xy xy Gh D, is called the torsion rigidity, ' 1 x yyx DvD vD , ~ D is Rheological operator and & x y EE are the modules of elasticity in x- and y-direction respectively, x and y are the Poisson ratios & x y G is the shear modulus. Assuming steady one dimensional temperature distribu- tion along the length, i.e., x-direction for the plate as 0 x ττ1a (3)  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 458 where τ denotes the temperature excess above the ref- erence temperature at any point at distance x a and 0 τ denotes the temperature excess above reference temperature at the end, i.e., x=a. Temperature dependence of the modulus of elasticity for most of engineering materials can be expressed in this form 11 x EE , 21 y EE , 01 xy GG (4) Here E1 and E2 are values of the Young’s moduli re- spectively along the x and y axis at the reference temper- ature, i.e., at τ = 0 and γ is the slope of the variation of modulus of elasticity with τ. Thus modulus variation become 111 x Ex Exa , 211 y Ex Exa , 011 xy Gx Gxa (5) where 001 , a parameter ,known as ther- mal gradient. The expression for the strain energy V and Kinetic energy P in the plate are [1]. 2 2 ,, 00 1 2 ab xxx yyy VDWDW 2 1, ,, 24 xx yyxyxy DW WDWdxdy (6) 22 00 1 2 ab PphWdxdy (7) Assuming thickness and density varies parabolically and linearly in the x-direction respectively, therefore one can take 2 01hh xa (8) and 01 1 x a (9) where β is the taper constant and α1 is non-homogeneity constant. 3. Solution and Frequency Equation To find a solution, we use Rayleigh-Ritz technique. This method requires that maximum strain energy must be equal to the maximum kinetic energy. So, it is necessary for the problem under consideration that 0VP (10) for arbitrary variations of W satisfying relevant geome- trical boundary conditions which are 0 x WW at 0, x a 0 y WW at 0,yb (11) and the corresponding two term deflection function is taken as [12]. 2 11Wxaybxayb 12 11 A Axayb xayb (12) The non-dimensional variables are X xa , Yyb , /, /WWahha , ρa (13) * 11 1 x y EE vv, * 22 1 x y EE vv *** 21xy EvE vE By using Equations (5), (8), (9) and (13) in (6) and (7), one gets 2 1/ 25 2 00 11 + 1 2 ba oo Ppha XXWdXdY (14) and 2 3 1/ 2, 00 1 - 11 ba XX VRXX W 2 ** ** ,,, 21 1 2 YYXX YY EE WEEWW 2 *, 1 4XY o GE WdXdY (15) where 3 * 1 112 2o REha (16) On substituting the values of P and V from Equations (14) and (15) in Equation (10), we get 22 11 0VpP (17) 2 3 1/ 2, 100 1 - 11 ba XX VXXW 2 ** ** ,,, 21 1 2 YYXX YY EE WEEWW 2 *, 1 4XY o GE WdXdY (18) 2 1/ 2 11 00 1 + 1 ba PXX WdXdY (19) where 4 2 2 * 1 12 o o a Eh (20) Equation (17) involves the unknown A1 and A2 arising due to the substitution of W(x,y) from Equation (12). These two constants are to be determined from Equation (17) as follows:  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 459 22 11 n VpP0 A where 1, 2n (21) On simplifying (21) we get 112 20 nn bAb A (22) where 1, 2n, bn1, bn2 involves parametric constants and the frequency parameter p. For a non-trivial solution, the determinant of the coefficient of Equation (22) must be zero. So, we get the frequency equation as 11 12 21 22 0 bb bb (23) On solving Equation (23) one gets a quadratic equa- tion in p2, which gives two values of p2. On substituting the value of 11A, by choice, in Equation (12) one get 21112 A bb and hence W becomes: 2 11 aa WXYX Y bb 11 12 111 baa XYX Y bb b (24) 4. Time Functions of Vibration of Viscoelastic Plates Equation (2) is defined as general differential equation of time functions of free vibrations of visco-elastic ortho- tropic plates. It depends on visco-elastic operator ~ D . One has, for Kelvin’s model [12], ~ 1d DGdt (25) where is visco-elastic constant and G is shear modulus. Taking temperature dependence of viscoelastic constant η and shear modulus G is the same form as that of Young’s moduli, we have 01 1GG , 02 1 (26) where G0 is shear modulus and 0 is visco-elastic con- stant at some reference temperature, i.e., at = 0, 1 and 2 are slope variation of with G and respectively. Substituting the value of from Equation (3) and using Equation (13) in Equation (26), one gets: 05 11GG X , where 510 , 5 01 and 04 11 X , where 420 , 4 01 (27) Here 4 and 5 are thermal constants. After using Equation (25) in Equation (2), one obtains 22 0TpkTpT (28) where 04 05 11 11 X kGGX (29) Equation (28) is a differential equation of second order for time function T. Solution of Equation (28) will be 1 1121 cos sin at TteCbt Cbt (30) where 2 12apk (31) 2 112 pk bp (32) and C1 ,C2 are constants which can be determined easily from initial conditions of the plate. Assuming initial conditions as 1T and 0T at 0t (33) Using Equation (33) in Equation (30), one obtains 121 1 1&CCab (34) One has 1 1111 cos sin at Ttebta bbt (35) after using Equation (34) in Equation (30). Thus, deflection of vibrating mode w(x,y,t), which is equal to W(x,y)T(t), may be expressed as 2 11wXYab X Yab 11 12 111bbXY abXYab 1 1111 cos sin at ebtabbt (36) by using Equations (24) & Equation (35). Time period of the vibration of the plate is given by 2 K p (37) where p is the frequency given by Equation (23). 5. Numerical Evaluations The values of time period (K) and deflection (w) (at two different instant of time) for a clamped visco-elastic or- thotropic non-homogeneous rectangular plate for differ- ent values of taper constant , thermal constants (α, α4, α5), non homogeneity constant α1 and aspect ratio a/b at different points for first two modes of vibrations are cal- culated. The following orthotropic material parameters have been taken as [1]. ** 21 0.32EE  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 460 ** 10.04EE * 10.09 o GE 0.000069 oo G 5 310 o (mass density per unit volume of the plate material). The thickness of the plate at the centre is taken as ho = 0.01 meter. 6. Results and Discussion Numerical results for a visco-elastic orthotropic non-homogeneous rectangular plate of parabolically vary- ing thickness have been computed with accuracy by using latest computer technology. Computations have been made for calculating time period K and deflection w (at two different instant of time) for different values of taper constant , thermal constants (α, α4, α5), non homogeneity constant α1 and aspect ratio a/b for first two modes of vi- bration. All these results are presented in Figure 1 to Fig- ure 7. Comparison is made with the author’s paper [12] for uniform plate and found to be in very close agreement. Figure 1 shows the result of time period K for first two modes of vibration for different values of taper con- stant β and fixed aspect ratio a/b = 1.5 and four combina- tions of non-homogeneity constant α1 and thermal con- stant α are α1 = 0.0, α = 0.0 α1 = 0.0, α = 0.2 α1 = 0.4, α = 0.0 α1 = 0.4, α = 0.2 It can be seen that time period K decreases when taper constant increases for first two modes of vibration. Figure 2 shows the result of time period K for first two modes of vibration for different values of non-homogeneity constant α1 and fixed aspect ratio a/b = 1.5 and four combinations of taper constant β and ther- mal constant α are β = 0.0, α = 0.0 β = 0.4, α = 0.0 β = 0.0, α = 0.2 β = 0.4, α = 0.2 It can be seen that time period K increases when non- homogeneity constant increases for first two modes of vibration. Figure 3 shows the result of time period K for differ- ent aspect ratio and four combinations of thermal con- stant α, taper constant β and non-homogeneity constant α1, i.e., α = 0.2 , β = 0.0, α1 = 0.0 α = 0.2 , β = 0.4, α1 = 0.0 α = 0.2 , β = 0.0, α1 = 0.4 α = 0.2 , β = 0.4, α1 = 0.4 It can be seen that time period K decreases when as- pect ratio increases for first two modes of vibration. Figures 4-7 shows the results of deflection for first two modes of vibration for different X, Y and fixed as- pect ratio a/b = 1.5 for initially time 0.K and time 5.K for the following combination of thermal constants (α, α4, α5), taper constant β and non-homogeneity constant α1. 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 00.2 0.40.6 0.81 TAPER CONSTANT β TIME PERIOD K(in sec) 1st Mode α1=0.0,α=0.0 2nd Mode α1=0.0,α=0.0 1st Mode α1=0.0,α=0.2 2nd Mode α1=0.0,α=0.2 1st Mode α1=0.4,α=0.0 2nd Mode α1=0.4,α=0.0 1st Mode α1=0.4,α=0.2 2nd Mode α1=0.4,α=0.2 Figure 1. Variation of time period with taper constant of visco-elastic non-homogeneous rectangular plate of parabolically varying thickness.  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 461 0 0. 02 0. 04 0. 06 0. 08 0. 1 0. 12 0. 14 0. 16 00.20.40.6 0.81 NON HOMOGENEITY α1 TIME PERIOD K (in sec ) 1st Mode α=0.0,β=0.0 2nd Mode α=0.0,β=0.0 1st Mode α=0.0,β=0.4 2nd Mode α=0.0,β=0.4 1st Mode α=0.2,β=0.0 2nd Mode α=0.2,β=0.0 1st Mode α=0.2,β=0.4 2nd Mode α=0.2,β=0.4 Figure 2. Variation of time period with non-homogeneity constant of visco-elastic non-homogeneous rectangular plate of pa- rabolically varying thickness. 0 0.05 0.1 0.15 0.2 0.25 0.511.522.5 ASPECT RATIO a/b TIME PERIOD K(in sec ) 1st Mode α=0.2,β=0.0,α1=0.0 2nd Mode α=0.2,β=0.0,α1=0.0 1st Mode α=0.2,β=0.4,α1=0.0 2nd Mode α=0.2,β=0.4,α1=0.0 1st Mode α=0.2,β=0.0,α1=0.4 2nd Mode α=0.2,β=0.0,α1=0.4 1st Mode α=0.2,β=0.4,α1=0.4 2nd Mode α=0.2,β=0.4,α1=0.4 Figure 3. Variation of time period with aspect ratio of visco-elastic non-homogeneous rectangular plate of parabolically va- rying thickness. -0.0 01 0 0. 00 1 0. 00 2 0. 00 3 0. 00 4 0. 00 5 00.20.4 0.60.81 X DEFLECTION (w) 1st Mode Y=0.2b\a & Y=0.8b\a 2nd Mode Y=0.2b\a & Y=0.8b\a 1st Mode Y=0.4b\a & Y=0.6b\a 2nd Mode Y=0.4b\a & Y=0.6b\a Figure 4. Transverse deflection w V/S X of visco-elastic non-homogeneous rectangular plate of parabolically varying thick- ness at initial time 0. K having constants combination as α = 0.0, β = 0.6, α1 = 0.0, α4 = 0.3, α5 = 0.2.  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 462 -0.0005 0 0.0005 0.001 0.0015 0.002 0.0025 0.003 0.0035 0.004 0.0045 0.005 00.20.40.6 0.81 X DEFLECTION (w) 1st Mode Y=0.2b\a & Y=0.8b\a 2nd Mode Y=0.2b\a & Y=0.8b\a 1st Mode Y=0.4b\a & Y=0.6b\a 2nd Mode Y=0.4b\a & Y=0.6b\a Figure 5. Transverse deflection w Vs X of visco-elastic non-homogeneous rectangular plate of parabolically varying thickness at initial time 0. K having constants combination as α = 0.0, β = 0.6, α1 = 0.0, α4 = 0.3, α5 = 0.2. -0.001 -0.0005 0 0. 0005 0. 001 0. 0015 0. 002 0. 0025 0. 003 0. 0035 0. 004 00.20.40.6 0.81 X DEFLECTION (w) 1st Mode Y=0.2b\a & Y =0.8b\a 2nd Mode Y=0.2b\a & Y =0.8b\a 1st Mode Y=0.4b\a & Y =0.6b\a 2nd Mode Y=0.4b\a & Y =0.6b\a Figure 6. Transverse deflection w Vs X of visco-elastic non-homogeneous rectangular plate of parabolically varying thickness at time 5. K having constants combination as α = 0.8, β = 0.0, α1 = 0.4, α4 = 0.3, α5 = 0.2. -0.001 -0.0005 0 0.0005 0. 001 0.0015 0. 002 0.0025 0. 003 0.0035 0. 004 00.2 0.40.6 0.81 X DEFLECTION (w) 1st Mode Y=0.2b\a & Y=0.8b\a 2nd Mode Y=0.2b\a & Y=0.8b\a 1st Mode Y=0.4b\a & Y=0.6b\a 2nd Mode Y=0.4b\a & Y=0.6b\a Figure 7. Transverse deflection w Vs X of visco-elastic non-homogeneous rectangular plate of parabolically varying thickness at time 5. K having constants combination as α = 0.8, β = 0.0, α1 = 0.4, α4 = 0.3, α5 = 0.2.  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 463 7. References [1] A. W. Leissa, NASA SP-60, Vibration of Plate, 1969. [2] A. W. Leissa, “Recent Studies in Plate Vibration 1981- 1985 Part II, Complicating Effects,” Shock and Vibration Dig., Vol. 19, No. 3, 1987, pp. 10-24. [3] A. K. Gupta, T. Johri and R. P. Vats, “Thermal Effect on Vibration of Non-Homogeneous Orthotropic Rectangular Plate Having Bi-Directional Parabolically Varying Thick- ness,” Proceeding of International Conference in World Congress on Engineering and Computer Science, San- Francisco, October 2007, pp. 784-787. [4] Z. Sobotka, “Free Vibration of Visco-Elastic Orthotropic Rectangular Plates,” Acta Technica, CSAV, Vol. 23, No. 6, 1978, pp. 678-705. [5] J. S. Tomar and A. K. Gupta, “Effect of Thermal Gra- dient on Frequencies of Orthotropic Rectangular Plate Whose Thickness Varies in Two Directions,” Journal of Sound and Vibration, Vol. 98, No. 2, January 1985, pp. 257-262. [6] J. S. Tomar and A. K. Gupta, “Thermal Effect on Fre- quencies of an Orthotropic Rectangular Plate of Linearly Varying Thickness,” Journal of Sound and Vibration, Vol. 90, No. 3, October 1983, pp. 325-331. [7] J. S. Tomar and A. K. Gupta, “Effect of Exponential Temperature Variation on Frequencies of an Orthotropic Rectangular Plate of Exponentially Varying Thickness,” Proceeding of the Workshop on Computer Application in Continum Mechanics, Roorkee, March 1986, pp. 183- 188. [8] R. Lal, “Transverse Vibrations of Orthotropic Non-Uni- form Rectangular Plate with Continuously Varying Den- sity,” Indian Journal of Pure and Applied Mathematics, Vol. 34, No. 4, 2003, pp. 587-606. [9] A. K. Gupta and A. Khanna, “Vibration of Visco-Elastic Rectangular Plate with Linearly Thickness Variations in Both Directions,” Journal of Sound and Vibration, Vol. 301, No. 3-5, April 2007, pp. 450-457. [10] A. K. Gupta and H. Kaur, “Study of the Effect of Ther- mal Gradient on Free Vibration of Clamped Visco-Elastic Rectangular Plate with Linearly Thickness Variation in Both Directions,” Meccanica, Vol. 43, No. 4, 2008, pp. 449- 458. [11] A. K. Gupta, A. Kumar and Y. K. Gupta, “Vibration of Visco-Elastic Parallelogram Plate with Parabolic Thick- ness Variation,” Applied Mathematics, Vol. 1, No. 2, 2010, pp. 128-136. [12] A. K. Gupta and P. Singhal, “Effect of Non-Homogeneity on Thermally Induced Vibration of Orthotropic Visco- Elastic Rectangular Plate of Linearly Varying Thick- ness,” Applied Mathematics, Vol. 1, No. 4, 2010, pp. 326-333. |