J. ESMAILI, M. R. EHSANI

62

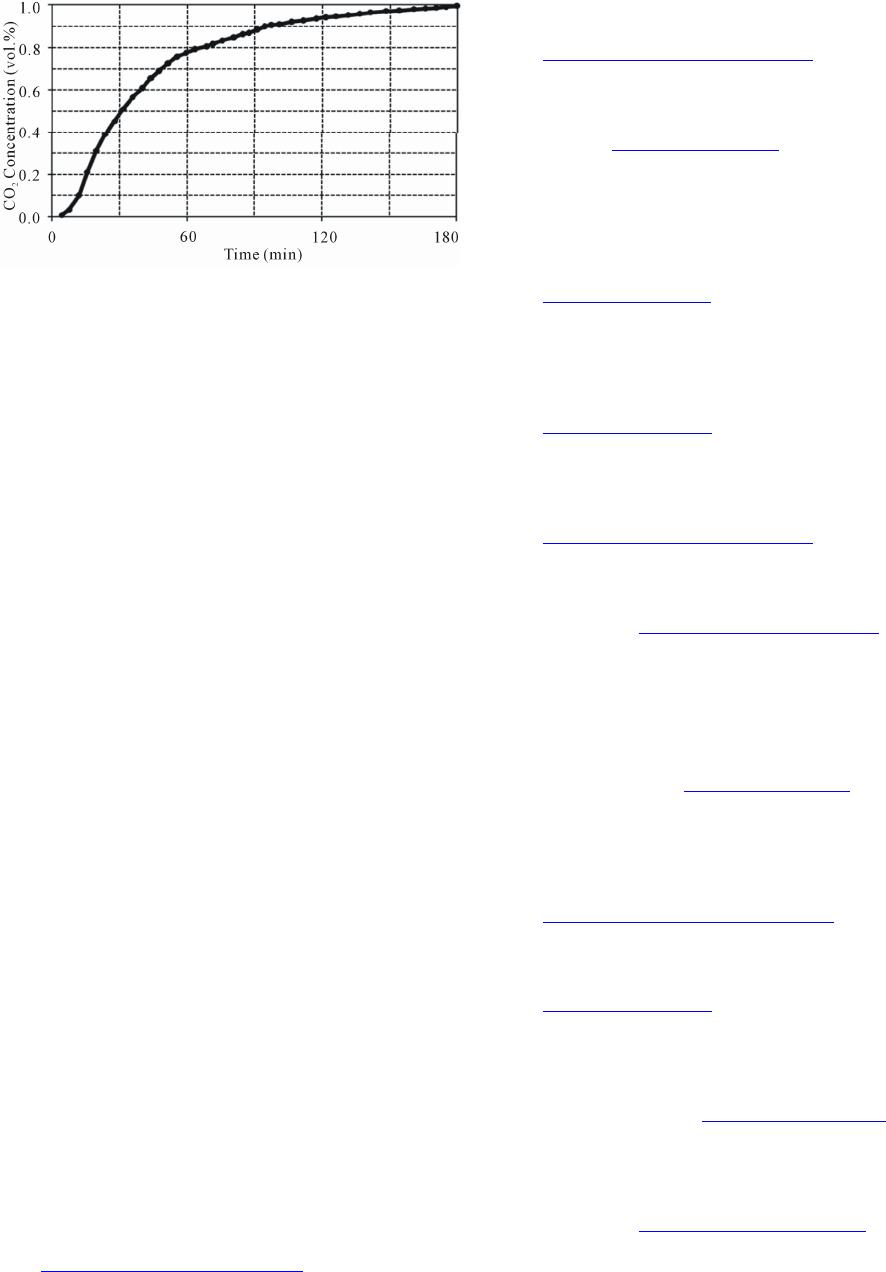

Figure 5. The breakthrough curves of the sorbent prepare

at optimum conditions during CO2 adsorption.

4. Conclusions

The sorbent capacity for carbon dioxide capture from a

gas stream is important for the industrial application of

solid sorbents. The present investigation was carried out

to study combined effects of the initial solution concen-

tration, impregnation time, calcination temperature, and

calcination time on the sorbent capture capacity using a

Box-Behnken design under the Response surface metho-

dology (RSM). The obtained results demonstrate that

sorbent capacity increased with increasing the initial so-

lution concentration and impregnation time. Sorbent ca-

pacity has a maximum point for variation of calcination

temperature and time and further increases of these vari-

ables lead to decrease of sorbent capacity. However,

ANOVA analysis as well as 3D surface plots revealed

that initial solution concentration has the greatest effect

on sorbent capacity. On the basis of the results it can be

concluded that RSM presents an excellent tool which

enables the evaluation of interactions and competitive

effects in multivariable systems and reduces the number

of needed experiments in contrast to the classical method

of changing one variable at a time.

The optimized values obtained for initial solution con-

centration, impregnation time and calcination step tempe-

rature and time were 32.3 wt%, 13.4 hr, 367˚C and 4.1 hr,

respectively, with the predicted maximized response of

sorbent capture capacity (78.66 mg CO2/g sorbent). Stu-

dy on other sorbent characterization such as mechanical

strength require for application of this procedure for pre-

paration of industrial sorbents.

REFERENCES

[1] P. Hagewiesche, S. S. Ashour, H. A. Al-Ghawas and O. C.

Sandall, “Absorption of Carbon Dioxide into Aqueous

Blends of Monoethanolamine and N-Methyldiethanola-

mine,” Chemical Engineering Science, Vol. 50, No. 7,

1995, pp. 1071-1079.

doi:10.1016/0009-2509(94)00489-E

[2] M. Mavroudi, S. P. Kaldis and G. P. Sakellaropoulos,

“Reduction of CO2 Emissions by a Membrane Contacting

Process,” Fuel, Vol. 82, No. 15-17, 2003, pp. 2153-2159.

doi:10.1016/S0016-2361(03)00154-6

[3] R. V. Siriwardane, M. S. Shen, E. P. Fisher and J. A. Po-

ston, “Adsorption of CO2 on Molecular Sieves and Acti-

vated Carbon,” Energy & Fuels, Vol. 15, No. 2, 2001, pp.

279-284. doi:10.1021/ef000241s

[4] H. Hayashi, J. Taniuchi, N. Furuyashiki, S. Sugiyama, S.

Hirano, N. Shigemoto and T. Nonaka, “Efficient Recov-

ery of Carbon Dioxide from Flue Gases of Coal-Fired Po-

wer Plants by Cyclic Fixed-Bed Operations over K2CO3-

on-Carbon,” Industrial and Engineering Chemistry Re-

search, Vol. 37, No. 1, 1998, pp. 185-191.

doi:10.1021/ie9704455

[5] N. Shigemoto, T. Yanagihara, S. Sugiyama and H. Haya-

shi, “Material Balance and Energy Consumption for CO2

Recovery from Moist Flue Gas Employing K2CO3-on-

Activated Carbon and Its Evaluation for Practical Adapta-

tion,” Energy & Fuels, Vol. 20, No. 2, 2006, pp. 721-726.

doi:10.1021/ef058027x

[6] S. C. Lee, B. Y. Choi, S. J. Lee, S. Y. Jung, C. K. Ryu

and J. C. Kim, “CO2 Absorption and Regeneration Using

Na and K Based Sorbents,” Studies in Surface Science

and Catalysis, Vol. 153, No. 1, 2004, pp. 527-530.

doi:10.1016/S0167-2991(04)80307-0

[7] S. C. Lee, B. Y. Choi, C. K. Ryu, Y. S. Ahn and J. C. Kim,

“Absorption and Regeneration of Alkali Metal-Based So-

lid Sorbents,” Catalysis Today, Vol. 111, No. 3-4, 2006,

pp. 385-390. doi:10.1016/j.cattod.2005.10.051

[8] J. S. Hoffman and H. W. Pennline, “Study of Regenerable

Sorbents for CO2 Capture, First National Conference on

Carbon Sequestration, Washington,” 2001.

[9] Y. Liang, D. P. Harrison, R. P. Gupta, D. A. Green and W.

J. McMichael, “Carbon Dioxide Capture Using Dry So-

dium-Based Sorbents,” Energy & Fuels, Vol. 18, No. 2,

2004, pp. 569-575. doi:10.1021/ef030158f

[10] Y. W. Seo, S. H. Jo, C. K. Ryu and C. K. Yi, “Effects of

Water Vapor Pretreatment Time and Reaction Tempera-

ture on CO2 Capture Characteristics of a Sodium-Based

Solid Sorbent in a Bubbling Fluidized-Bed Reactor,”

Chemosphere, Vol. 69, No. 5, 2007, pp. 712-718.

doi:10.1016/j.chemosphere.2007.05.036

[11] C. Zhao, X. Chen and C. Zhao, “CO2 Absorption Using

Dry Potassium-Based Sorbents with Different Supports,”

Energy & Fuels, Vol. 23, No. 9, 2009, pp. 4683-4687.

doi:10.1021/ef900182d

[12] S. Hirano, N. Shigemoto, S. Yamaha and H. Hayashi, Cy-

clic Fixed-Bed Operations over K2CO3-on-Carbon for the

Recovery of Carbon Dioxide under Moist Conditions,”

Bulletin of the Chemical Society of Japan, Vol. 68, No. 3,

1995, pp. 1030-1035. doi:10.1246/bcsj.68.1030

[13] A. G. Okunev, V. E. haronov, Y. I. Aistov and V. N. Parmon,

“Sorption of Carbon Dioxide from Wet Gases by K2CO3-

in-Porous Matrix: Influence of the Matrix Nature,” Reac-

tion Kinetics and Catalysis Letters, Vol. 71, No. 2, 2000,

pp. 355-362. doi:10.1023/A:1010395630719

[14] A. G. Okunev, V. E. Sharonov, A. V. Gubar, I. G. Danilo-

va, E. A. Paukshtis, E. M. Moroz, T. A. Kriger, V. V. Ma-

lakhov and Y. I. Aistov, “Sorption of Carbon Dioxide by

Copyright © 2013 SciRes. JEAS