Paper Menu >>

Journal Menu >>

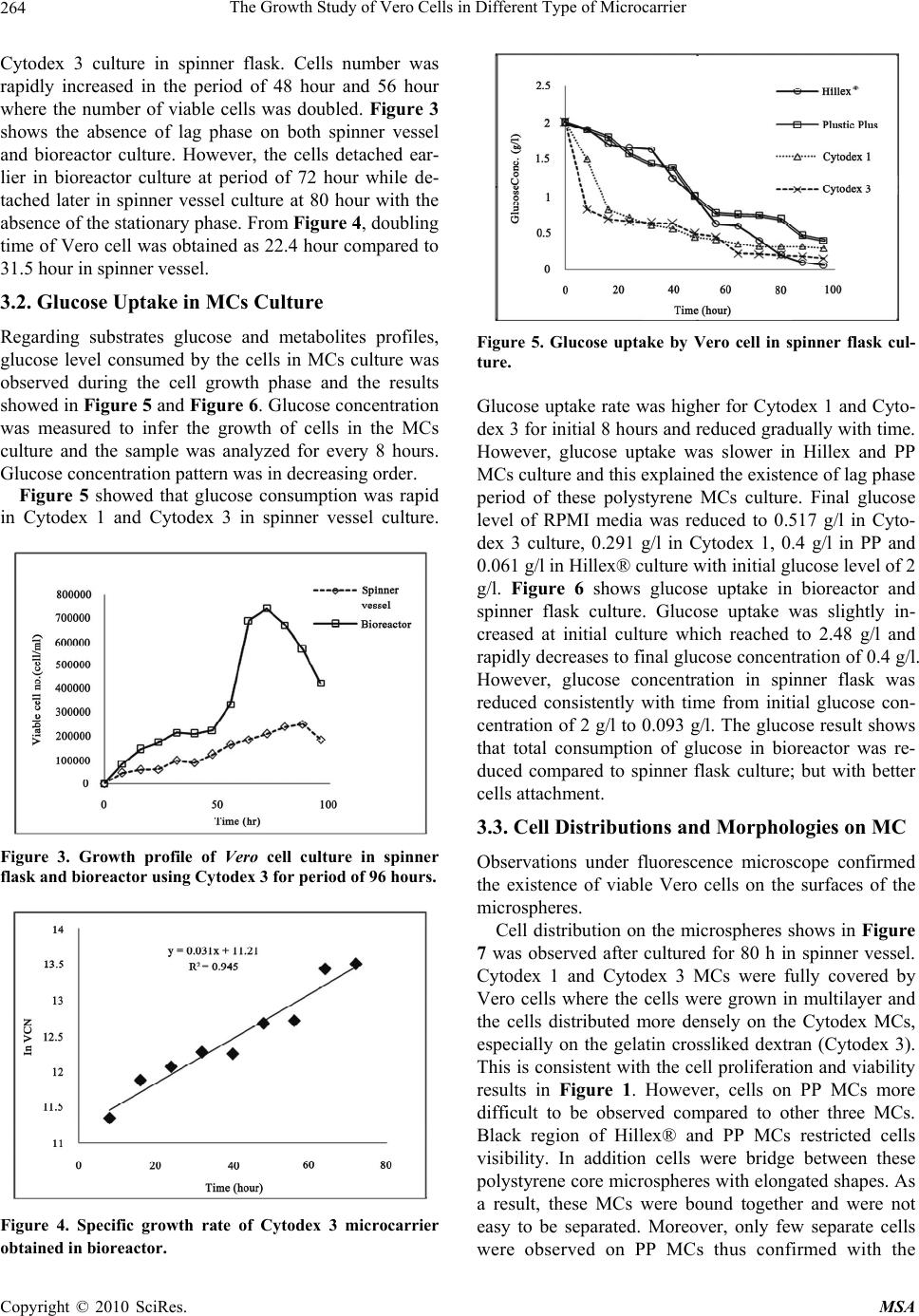

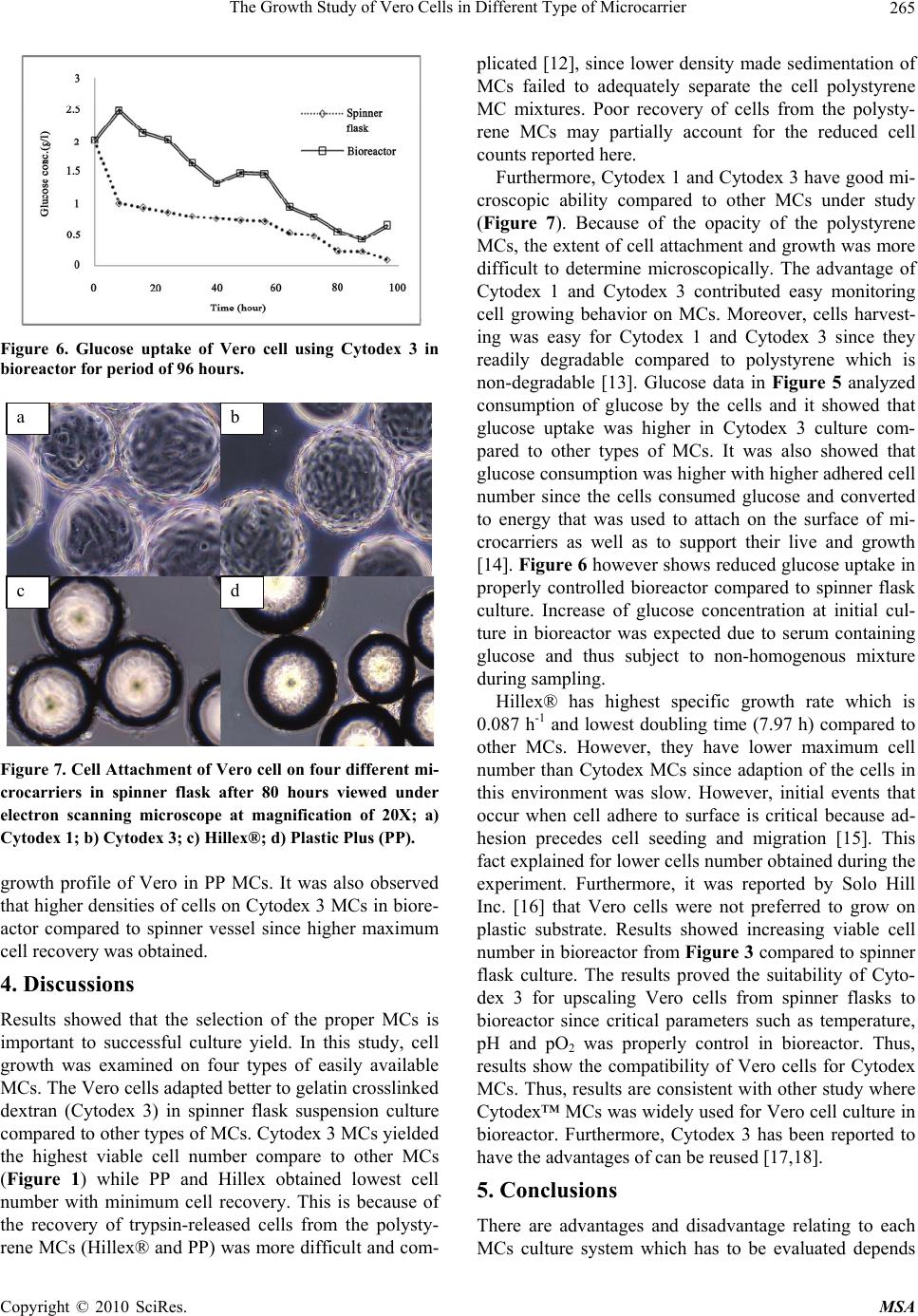

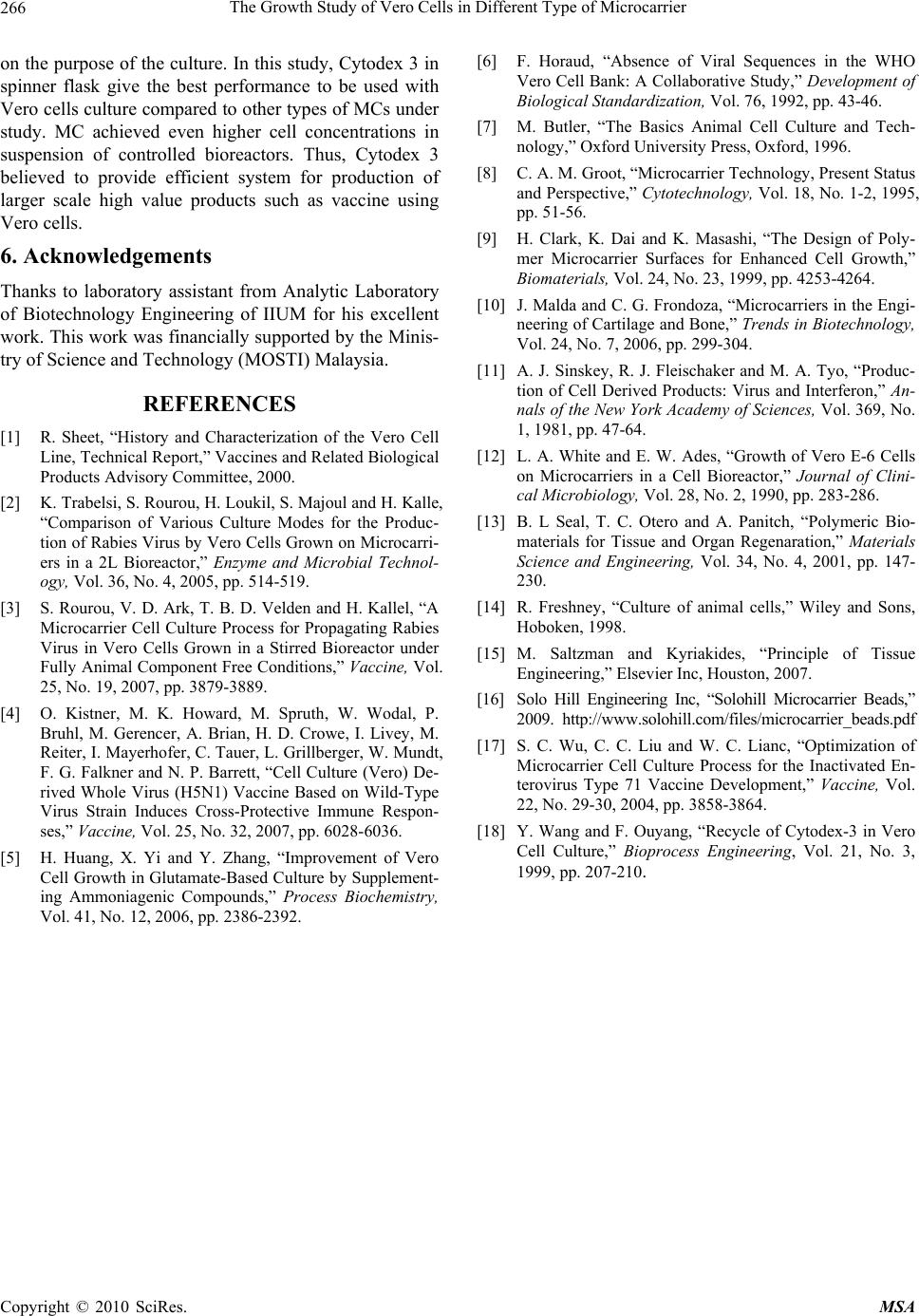

Materials Sciences and Applications, 2010, 1, 261-266 doi:10.4236/msa.2010.15038 Published Online November 2010 (http://www.SciRP.org/journal/msa) Copyright © 2010 SciRes. MSA 261 The Growth Study of Vero Cells in Different Type of Microcarrier Yusilawati Ahmad Nor1, Nurul Hafizah Sulong1, Maizirwan Mel1, Hamzah Mohd Salleh2, Iis Sopyan3 1Bioprocess and Molecular Engineering Research Unit; 2Halal Industry Research Centre; 3Biomedical Engineering Research Group, International Islamic University Malaysia, Kuala Lumpur. Email: maizirwan@iiu.edu.my Received June 10th, 2010; revised October 4th, 2010; accepted October 5th, 2010. ABSTRACT The fact of microcarrier (MC) culture introduces new possibilities and makes possible the practical high-yield culture of anchorage-dependent cells has generated a considerable focus in this study. The objective of this research was to study the comparison of Vero cell growth on different types of commercial microcarriers; Cytodex-1, Cytodex-3, Hillex® II and Plastic Plus in spinner vessel and two liters bioreactor cultured for 96 hours. Biological performance of the microcarrier in RPMI media showed the preference of Vero cell grew on Cytodex 3 microcarriers with highest maximum viable cell number (2.4 × 105 cells/ml) followed by Cytodex 1, Hillex and Plustic Plus. Vero cell on Cyto- dex-3 data in spinner flask was compared in bioreactor and result showed higher viable cell number in biorector. Thus, this dextran-crosslink gelatin microcarrier (Cytodex 3) provided the best surface for cell attachment and fast prolifera- tion. At the end of this cell growth improvement will be used for virus transfection producing a vaccine in bioreactor. Keywords: Cytodex 3, Microcarrier, Spinner Flask, Vero Cells, Vaccines 1. Introduction Vero cell line was derived from the kidney of a normal, adult, African green monkey (Cercopithecus) [1]. Vero cells have been extensively used for producing viral vac- cines [2-4] and for evaluating the performance of animal cell in bioreactors with modified condition [5]. This cell line also has been used extensively for virus replication studies and plaque assays [1]. Moreover, Vero cells do not disturb human health when used as substrate for bio- logical product since they are free from oncogenic prop- erty [2,6]. However, Vero cells are anchorage dependent cells which required solid substrate to attach and grow. Thus, Vero cells can be used in microcarrier and suspen- sion cultures for large scale production in bioreactors. The interaction between the cells and the substrate sur- face is critical where cell adhesion occurs by divalent cation and basic protein which occur between the solid surface and the cell membrane [7]. Under proper condi- tions, cells attach and spread onto the carriers and gradu- ally grow out to a confluent monolayer [8]. Microcarrier culture comprises the cultivation of an- chorage dependent cells on small solid substrate sus- pended in growth medium and thus can be cultured in larger scale. By using microcarriers in simple suspension culture systems, it is possible to achieve yields of several million cells per milliliter [9]. The microcarrier bioreac- tor culture system offers an attractive method for cell amplification and enhancement of phenotype expression. Besides serving as substrates for the propagation of an- chorage-dependent cells, microcarriers can also be used to deliver the expanded undifferentiated or differentiated cells to the site of the defect [10]. Microcarrier culture also provides a method for rapid scaling-up with mini- mum number subculture steps [11]. However, cell differs in their attachment requirements, and thus a range of microcarriers should be assessed for suitability. There are various kinds of microcarriers based on material that were used. 2. Experimental Details 2.1. Cell lines Vero cells (African green monkey kidney cells) were obtained from ATTC (CCL-81™) Cells were kept cryo- preserved in liquid nitrogen until further use. 2.2. Culture Media and Chemicals RPMI (Cat.no 50-020-PB) and RPMI without phenol red  The Growth Study of Vero Cells in Different Type of Microcarrier Copyright © 2010 SciRes. MSA 262 (Cat.no 90-022-PB) were supplied by Cellgrow. Fetal Bovine Serum (FBS) (Cat. no 10270-098) obtained from Invitrogen and Accutase (Cat. no AT104) from Innova- tive Cell Technologies. Four different commercial mi- crocarrier (MCs) were used which are Hillex® (Model no H112-170) and Plustic Plus (Model no PP102-1521) from Solohill (Michigan, USA); Cytodex 1 and Cytodex 3 from Amersham Biosciences (Uppsala, Sweeden). MCs were prepared for use as recommended by the ma- nufacturers. All other chemicals were obtained from Sigma (St. Louis, USA). 2.3. Preparation of Microcarrier (MCs) Cytodex 1, Cytodex 3, Hillex® and Plustic Plus micro- carriers were prepared and sterilized according to manu- facturer’s instructions. For Cytodex 1 and Cytodex 3 with each 3 g/l, the microcarriers were swollen with Ca2+, Mg2+-free PBS twice and autoclaved at 115oC for 15 minutes while Hillex® (14 g/l) and Plustic Plus (20 g/l) microcarrier were washed with deionized water and autoclaved at 121oC for 30 minutes. All microcarriers where incubated with the RPMI media before used. 2.4. Cell Dissociation Media was discarded and cells were washed twice with phosphate buffer saline (PBS), 2 ml Accutase enzyme were added to a 75 cm2 flask and cells were incubated for 2 minutes at 37oC. Dislodged cells were then pooled with RPMI media contained 10% serum and transferred into inoculums flasks. 2.5. Spinner Flask Culture Cultures were carried out in 250 ml spinner flasks (Bellco Biotechnology, U.S.A) containing 200 ml of cul- tured cells, at 37oC in a 5% CO2 incubator. The stirring speed was maintained at 30 rpm at initial pH of the me- dia adjusted to 7. The spinners were inoculated with 2 × 105 cells/ml. The experiments were carried for 96 hours and sampling was done every 8 hours. 2.6. Bioreactor Culture The cultures were performed in a two liters bioreactor (Labfors 3, Switzerland) containing one liter total work- ing volume, equipped with a marine impeller. For start- ing the microcarrier cultures, RPMI media was mixed with 3 g/l Cytodex 3 in the bioreactor and incubated for 3 hours with starting volume of 900ml. Vero cells were detached from T-flasks using PBS and Accutase enzyme and 10% percent inoculums was added to the bioreactor culture. The culture was seeded with 2.5 × 105 cells/ml and was continuously agitated at 70 rpm. During cell culture proliferation step, the following conditions were applied: pH set at 7.2; pO2 maintained at 30% air-satura- tion by injecting air or pure oxygen when required, tem- perature at 37oC and agitation rate at 70 rpm. The ex- periments were carried for 96 hours and sampling was done every 8 hours. 2.7. Viable Cell Number (VCN) Counting Two milliliters of Vero cell culture were washed twice with PBS containing 0.02% (w/v) EDTA at pH7.6. PBS was replaced with 0.25% (w/v) trypsin in Ca2+, Mg2+-free PBS and EDTA (0.02%, w/v) and the tube was incubated at 37°C for 15 minutes with occasional agitation. Two mililiter culture medium containing 5% serum was added to the microcarriers and centrifuged at 300 g and 4°C for 5 minutes. The supernatant is discarded and the pellet is re-suspended in 2 ml Ca2+, Mg2+-free PBS containing 0.05% (w/v) tryphan blue. The concentration of cells in the suspension is counted using haemocytometer. 2.8. Calculation The specific growth rate μ (h−1) calculation was esti- mated by the following equation: n1 1 Inln n nn X X tt (1) where μ (day−1) corresponds to the value of specific growth rate at any given time point, t (hours) the culture time and X (cells) the value of viable cell number for a specific t. The doubling time, td (hour) calculation was estimated by the following equation: In 2 d t (2) 2.9. Monitoring Microcarrier Samples of Vero cells culture were examined micro- scopically using an inverted light microscope (Olympus, Japan). Five mililiters Vero culture was transferred into petri dish and was examined at three different micro- scopic fields per sample. 2.10. Substrate Analysis Sample was centrifuged at 28,000 rpm and 4oC for 15 minutes to remove cells and other contaminant. Super- natant was collected and filtered using 0.45 micron filter to remove any remaining particles. Glucose concentra- tions were monitored by High Performance Liquid Chromatography (HPLC) using SUPELCOGEL C-610H column equipped with a refractive index and 210 nm UV detector. Separation was done at 30oC, eluted at 0.5 ml/min using 0.1% H3PO4 and each sample was analyzed for 30 minutes.  The Growth Study of Vero Cells in Different Type of Microcarrier Copyright © 2010 SciRes. MSA 263 3. Results 3.1. Growth Kinetic of Vero Cells in Spinner Flask and Bioreactor Culture There were four runs in this experiment. Four types of different commercial microcarriers (MCs) were used as the substrate in this study which was Cytodex1, Cyto- dex3, Hillex® and Plastic Plus (PP). Figure 1 below showed growth profile of Vero cells in spinner flask on different MCs while Figure 2 determined percentage viability of the cells in the culture. The highest cell den- sity was obtained at hour 88 and was equal to 2.4 × 105cells/ml for 3 g/l Cytodex 3. Cells showed an expo- nential growth for the period of 88 hour for Cytodex 3 and viable cells number decreased at hour 96. Cytodex 1 with the amount of 3 g/l was still increased at the end of 96 hour period with absence of lag phase for both Cyto- dex 1 and Cytodex 3. Cytodex 1 reached the highest vi- able cell number of 1.5 × 105 cells/ml followed by Hillex® which reached 1.35 × 105 cells/ml and PP reached maxi- mum cell number of 8.0 × 104 cells/ml, respectively. Vero- Figure 1. Comparison viable cell numbers of Vero cell har- vested from four types of MCs in spinner flask for 96 hour period using RPMI growth medium supplemented with 10% FBS. Figure 2. Percentage of cell viability in spinner vessel cul- ture adhered slower to Plastic plus (PP) and Hillex® MCs with the existence of lag phase at initial 8 hours. Besides that, the cells was easily detached from these polystyrene core substrate (Hillex® and PP) after 80 hours in Hillex® MCs culture and reached stationary phase before dropped in cells number at 88 hour. From Figure 2 above, percentage of viability of each MC was calculated. It was observed that average per- centage of viability is 70 ± 30 for all MCs. Data for per- centage viability for each MC was summarized in Table 1. Cells viability was highest in Cytodex 3 culture and lower in Hillex and PP culture. However, the range of viability indicated the viability is more that 50%. Thus, this indicates the suitability of the condition parameter in spinner vessel for the cells to grow. Calculation of specific growth rate and doubling time for four different MCs in spinner flasks was obtained using Equations (1) and (2). Average specific growth (µ) rate was determined at acceleration phase and Hillex® has the highest specific growth rate which is 0.087h-1 and lowest doubling time; 7.97 hour followed by PP (µ = 0.046 h-1, td = 15.1 hour), Cytodex 3 (µ = 0.022 h-1; td = 31.5 hour) and Cytodex 1 (µ = 0.022 h-1; td = 31.5 hour). The results for Vero cells growth kinetic on each MC are summarized in Table 2. From the data, Cytodex 3 was used for scaling up Vero cell to two liters bioreactor and the performance of the bioreactor was compared to spin- ner vessel culture. Although Hillex® MC obtained the lowest doubling time which is 7.97 hour; it was not se- lected since the attachment of cells is slower and suscep- tible to cells detachment. Cell started to grow immediately after bioreactor in- oculation. The maximal cell density level in bioreactor was equal to 7.5 × 105cells/ml and was reached at 72 hour after the start of the culture and the average specific growth rate increased and equal to 0.031 h−1 compared to Table 1. Summarized percentage (%) cell viability in spin- ner vessel culture. MCs Cytodex 1 Cytodex 3 Hillex® PP Percentage Viability 85 ± 8 90 ± 6 77 ± 15 77 ± 11 Table 2. Growth study of four different MCs in spinner flask. Responses Cytodex 1Cytodex 3 Hillex® Plastic Plus (PP) Maximum Cell no (cell/ml) 1.55 × 105 2.40 × 105 1.35 × 105 8.0 × 104 Avg. Specific growth rate (µ), h-1 0.022 0.022 0.087 0.046 doubling time (td), hour 31.5 31.5 7.97 15.1  The Growth Study of Vero Cells in Different Type of Microcarrier Copyright © 2010 SciRes. MSA 264 Cytodex 3 culture in spinner flask. Cells number was rapidly increased in the period of 48 hour and 56 hour where the number of viable cells was doubled. Figure 3 shows the absence of lag phase on both spinner vessel and bioreactor culture. However, the cells detached ear- lier in bioreactor culture at period of 72 hour while de- tached later in spinner vessel culture at 80 hour with the absence of the stationary phase. From Figure 4, doubling time of Vero cell was obtained as 22.4 hour compared to 31.5 hour in spinner vessel. 3.2. Glucose Uptake in MCs Culture Regarding substrates glucose and metabolites profiles, glucose level consumed by the cells in MCs culture was observed during the cell growth phase and the results showed in Figure 5 and Figure 6. Glucose concentration was measured to infer the growth of cells in the MCs culture and the sample was analyzed for every 8 hours. Glucose concentration pattern was in decreasing order. Figure 5 showed that glucose consumption was rapid in Cytodex 1 and Cytodex 3 in spinner vessel culture. Figure 3. Growth profile of Vero cell culture in spinner flask and bioreactor using Cytodex 3 for period of 96 hours. Figure 4. Specific growth rate of Cytodex 3 microcarrier obtained in bioreactor. Figure 5. Glucose uptake by Vero cell in spinner flask cul- ture. Glucose uptake rate was higher for Cytodex 1 and Cyto- dex 3 for initial 8 hours and reduced gradually with time. However, glucose uptake was slower in Hillex and PP MCs culture and this explained the existence of lag phase period of these polystyrene MCs culture. Final glucose level of RPMI media was reduced to 0.517 g/l in Cyto- dex 3 culture, 0.291 g/l in Cytodex 1, 0.4 g/l in PP and 0.061 g/l in Hillex® culture with initial glucose level of 2 g/l. Figure 6 shows glucose uptake in bioreactor and spinner flask culture. Glucose uptake was slightly in- creased at initial culture which reached to 2.48 g/l and rapidly decreases to final glucose concentration of 0.4 g/l. However, glucose concentration in spinner flask was reduced consistently with time from initial glucose con- centration of 2 g/l to 0.093 g/l. The glucose result shows that total consumption of glucose in bioreactor was re- duced compared to spinner flask culture; but with better cells attachment. 3.3. Cell Distributions and Morphologies on MC Observations under fluorescence microscope confirmed the existence of viable Vero cells on the surfaces of the microspheres. Cell distribution on the microspheres shows in Figure 7 was observed after cultured for 80 h in spinner vessel. Cytodex 1 and Cytodex 3 MCs were fully covered by Vero cells where the cells were grown in multilayer and the cells distributed more densely on the Cytodex MCs, especially on the gelatin crossliked dextran (Cytodex 3). This is consistent with the cell proliferation and viability results in Figure 1. However, cells on PP MCs more difficult to be observed compared to other three MCs. Black region of Hillex® and PP MCs restricted cells visibility. In addition cells were bridge between these polystyrene core microspheres with elongated shapes. As a result, these MCs were bound together and were not easy to be separated. Moreover, only few separate cells were observed on PP MCs thus confirmed with the  The Growth Study of Vero Cells in Different Type of Microcarrier Copyright © 2010 SciRes. MSA 265 Figure 6. Glucose uptake of Vero cell using Cytodex 3 in bioreactor for period of 96 hours. b a c d Figure 7. Cell Attachment of Vero cell on four different mi- crocarriers in spinner flask after 80 hours viewed under electron scanning microscope at magnification of 20X; a) Cytodex 1; b) Cytodex 3; c) Hillex®; d) Plastic Plus (PP). growth profile of Vero in PP MCs. It was also observed that higher densities of cells on Cytodex 3 MCs in biore- actor compared to spinner vessel since higher maximum cell recovery was obtained. 4. Discussions Results showed that the selection of the proper MCs is important to successful culture yield. In this study, cell growth was examined on four types of easily available MCs. The Vero cells adapted better to gelatin crosslinked dextran (Cytodex 3) in spinner flask suspension culture compared to other types of MCs. Cytodex 3 MCs yielded the highest viable cell number compare to other MCs (Figure 1) while PP and Hillex obtained lowest cell number with minimum cell recovery. This is because of the recovery of trypsin-released cells from the polysty- rene MCs (Hillex® and PP) was more difficult and com- plicated [12], since lower density made sedimentation of MCs failed to adequately separate the cell polystyrene MC mixtures. Poor recovery of cells from the polysty- rene MCs may partially account for the reduced cell counts reported here. Furthermore, Cytodex 1 and Cytodex 3 have good mi- croscopic ability compared to other MCs under study (Figure 7). Because of the opacity of the polystyrene MCs, the extent of cell attachment and growth was more difficult to determine microscopically. The advantage of Cytodex 1 and Cytodex 3 contributed easy monitoring cell growing behavior on MCs. Moreover, cells harvest- ing was easy for Cytodex 1 and Cytodex 3 since they readily degradable compared to polystyrene which is non-degradable [13]. Glucose data in Figure 5 analyzed consumption of glucose by the cells and it showed that glucose uptake was higher in Cytodex 3 culture com- pared to other types of MCs. It was also showed that glucose consumption was higher with higher adhered cell number since the cells consumed glucose and converted to energy that was used to attach on the surface of mi- crocarriers as well as to support their live and growth [14]. Figure 6 however shows reduced glucose uptake in properly controlled bioreactor compared to spinner flask culture. Increase of glucose concentration at initial cul- ture in bioreactor was expected due to serum containing glucose and thus subject to non-homogenous mixture during sampling. Hillex® has highest specific growth rate which is 0.087 h-1 and lowest doubling time (7.97 h) compared to other MCs. However, they have lower maximum cell number than Cytodex MCs since adaption of the cells in this environment was slow. However, initial events that occur when cell adhere to surface is critical because ad- hesion precedes cell seeding and migration [15]. This fact explained for lower cells number obtained during the experiment. Furthermore, it was reported by Solo Hill Inc. [16] that Vero cells were not preferred to grow on plastic substrate. Results showed increasing viable cell number in bioreactor from Figure 3 compared to spinner flask culture. The results proved the suitability of Cyto- dex 3 for upscaling Vero cells from spinner flasks to bioreactor since critical parameters such as temperature, pH and pO2 was properly control in bioreactor. Thus, results show the compatibility of Vero cells for Cytodex MCs. Thus, results are consistent with other study where Cytodex™ MCs was widely used for Vero cell culture in bioreactor. Furthermore, Cytodex 3 has been reported to have the advantages of can be reused [17,18]. 5. Conclusions There are advantages and disadvantage relating to each MCs culture system which has to be evaluated depends  The Growth Study of Vero Cells in Different Type of Microcarrier Copyright © 2010 SciRes. MSA 266 on the purpose of the culture. In this study, Cytodex 3 in spinner flask give the best performance to be used with Vero cells culture compared to other types of MCs under study. MC achieved even higher cell concentrations in suspension of controlled bioreactors. Thus, Cytodex 3 believed to provide efficient system for production of larger scale high value products such as vaccine using Vero cells. 6. Acknowledgements Thanks to laboratory assistant from Analytic Laboratory of Biotechnology Engineering of IIUM for his excellent work. This work was financially supported by the Minis- try of Science and Technology (MOSTI) Malaysia. REFERENCES [1] R. Sheet, “History and Characterization of the Vero Cell Line, Technical Report,” Vaccines and Related Biological Products Advisory Committee, 2000. [2] K. Trabelsi, S. Rourou, H. Loukil, S. Majoul and H. Kalle, “Comparison of Various Culture Modes for the Produc- tion of Rabies Virus by Vero Cells Grown on Microcarri- ers in a 2L Bioreactor,” Enzyme and Microbial Technol- ogy, Vol. 36, No. 4, 2005, pp. 514-519. [3] S. Rourou, V. D. Ark, T. B. D. Velden and H. Kallel, “A Microcarrier Cell Culture Process for Propagating Rabies Virus in Vero Cells Grown in a Stirred Bioreactor under Fully Animal Component Free Conditions,” Vaccine, Vol. 25, No. 19, 2007, pp. 3879-3889. [4] O. Kistner, M. K. Howard, M. Spruth, W. Wodal, P. Bruhl, M. Gerencer, A. Brian, H. D. Crowe, I. Livey, M. Reiter, I. Mayerhofer, C. Tauer, L. Grillberger, W. Mundt, F. G. Falkner and N. P. Barrett, “Cell Culture (Vero) De- rived Whole Virus (H5N1) Vaccine Based on Wild-Type Virus Strain Induces Cross-Protective Immune Respon- ses,” Vaccine, Vol. 25, No. 32, 2007, pp. 6028-6036. [5] H. Huang, X. Yi and Y. Zhang, “Improvement of Vero Cell Growth in Glutamate-Based Culture by Supplement- ing Ammoniagenic Compounds,” Process Biochemistry, Vol. 41, No. 12, 2006, pp. 2386-2392. [6] F. Horaud, “Absence of Viral Sequences in the WHO Vero Cell Bank: A Collaborative Study,” Development of Biological Standardization, Vol. 76, 1992, pp. 43-46. [7] M. Butler, “The Basics Animal Cell Culture and Tech- nology,” Oxford University Press, Oxford, 1996. [8] C. A. M. Groot, “Microcarrier Technology, Present Status and Perspective,” Cytotechnology, Vol. 18, No. 1-2, 1995, pp. 51-56. [9] H. Clark, K. Dai and K. Masashi, “The Design of Poly- mer Microcarrier Surfaces for Enhanced Cell Growth,” Biomaterials, Vol. 24, No. 23, 1999, pp. 4253-4264. [10] J. Malda and C. G. Frondoza, “Microcarriers in the Engi- neering of Cartilage and Bone,” Trends in Biotechnology, Vol. 24, No. 7, 2006, pp. 299-304. [11] A. J. Sinskey, R. J. Fleischaker and M. A. Tyo, “Produc- tion of Cell Derived Products: Virus and Interferon,” An- nals of the New York Academy of Sciences, Vol. 369, No. 1, 1981, pp. 47-64. [12] L. A. White and E. W. Ades, “Growth of Vero E-6 Cells on Microcarriers in a Cell Bioreactor,” Journal of Clini- cal Microbiology, Vol. 28, No. 2, 1990, pp. 283-286. [13] B. L Seal, T. C. Otero and A. Panitch, “Polymeric Bio- materials for Tissue and Organ Regenaration,” Materials Science and Engineering, Vol. 34, No. 4, 2001, pp. 147- 230. [14] R. Freshney, “Culture of animal cells,” Wiley and Sons, Hoboken, 1998. [15] M. Saltzman and Kyriakides, “Principle of Tissue Engineering,” Elsevier Inc, Houston, 2007. [16] Solo Hill Engineering Inc, “Solohill Microcarrier Beads,” 2009. http://www.solohill.com/files/microcarrier_beads.pdf [17] S. C. Wu, C. C. Liu and W. C. Lianc, “Optimization of Microcarrier Cell Culture Process for the Inactivated En- terovirus Type 71 Vaccine Development,” Vaccine, Vol. 22, No. 29-30, 2004, pp. 3858-3864. [18] Y. Wang and F. Ouyang, “Recycle of Cytodex-3 in Vero Cell Culture,” Bioprocess Engineering, Vol. 21, No. 3, 1999, pp. 207-210. |