S. PALANTI

Copyright © 2013 SciRes. 69

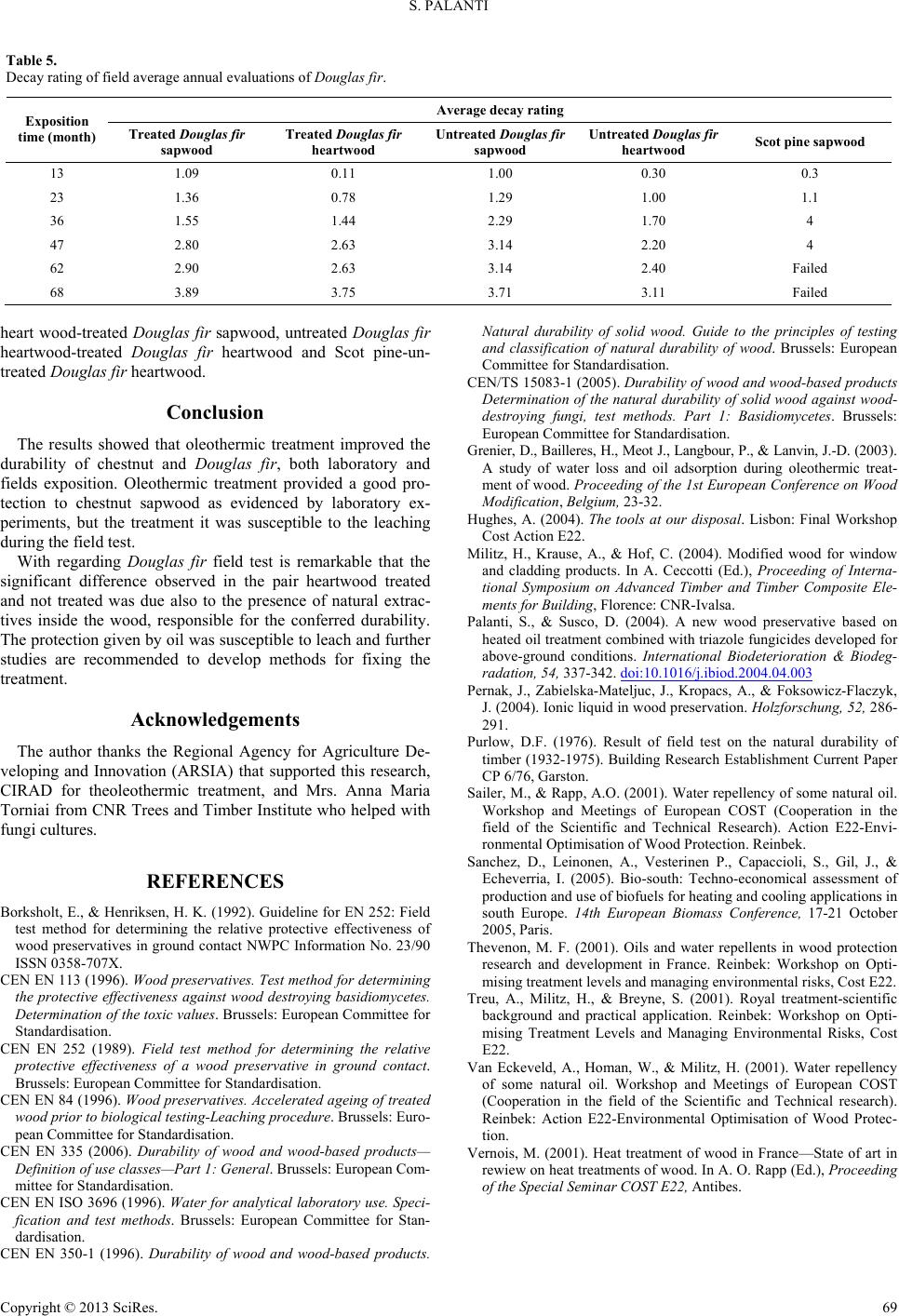

Table 5.

Decay rating of field average annual evaluations of Douglas fir.

Average decay rati ng

Exposition

time (m on th ) Trea ted Douglas fir

sapwood Treated Douglas fir

heartwood Untreated Douglas fir

sapwood Untreated Douglas fir

heartwood Scot pine sapwood

13 1.09 0.11 1.00 0.30 0.3

23 1.36 0.78 1.29 1.00 1.1

36 1.55 1.44 2.29 1.70 4

47 2.80 2.63 3.14 2.20 4

62 2.90 2.63 3.14 2.40 Failed

68 3.89 3.75 3.71 3.11 Failed

heart wood-treated Douglas fir sapwood, untreated Douglas fir

heartwood-treated Douglas fir heartwood and Scot pine-un-

treated Douglas fir heartwood.

Conclusion

The results showed that oleothermic treatment improved the

durability of chestnut and Douglas fir, both laboratory and

fields exposition. Oleothermic treatment provided a good pro-

tection to chestnut sapwood as evidenced by laboratory ex-

periments, but the treatment it was susceptible to the leaching

during the field test.

With regarding Douglas fir field test is remarkable that the

significant difference observed in the pair heartwood treated

and not treated was due also to the presence of natural extrac-

tives inside the wood, responsible for the conferred durability.

The protection given by oil was susceptible to leach and further

studies are recommended to develop methods for fixing the

treatment.

Acknowledgements

The author thanks the Regional Agency for Agriculture De-

veloping and Innovation (ARSIA) that supported this research,

CIRAD for theoleothermic treatment, and Mrs. Anna Maria

Torniai from CNR Trees and Timber Institute who helped with

fungi cultures.

REFERENCES

Borksholt, E., & Henriksen, H. K. (1992). Guideline for EN 252: Field

test method for determining the relative protective effectiveness of

wood preservatives in ground contact NWPC Information No. 23/90

ISSN 0358-707X.

CEN EN 113 (1996). Wood preservatives. Test method for determining

the protective effectiveness against wood destroying basidiomycetes.

Determination of the toxic values. Brussels: European Committee for

Standardisation.

CEN EN 252 (1989). Field test method for determining the relative

protective effectiveness of a wood preservative in ground contact.

Brussels: European Committee for Standardisation.

CEN EN 84 (1996). Wood preservatives. Accelerated ageing of treated

wood prior to biological testing-Leaching procedure. Brussels: Euro-

pean Committee for Standardisation.

CEN EN 335 (2006). Durability of wood and wood-based products—

Definition of use classes—Part 1: General. Brussels: European Com-

mittee for Standardisation.

CEN EN ISO 3696 (1996). Water for analytical laboratory use. Speci-

fication and test methods. Brussels: European Committee for Stan-

dardisation.

CEN EN 350-1 (1996). Durability of wood and wood-based products.

Natural durability of solid wood. Guide to the principles of testing

and classification of natural durability of wood. Brussels: European

Committee for Standardisation.

CEN/TS 15083-1 (2005). Durability of wood and wood-based products

Determination of the natural durability of solid wood against wood-

destroying fungi, test methods. Part 1: Basidiomycetes. Brussels:

European Committee for Standardisation.

Grenier, D., Bailleres, H., Meot J., Langbour, P., & Lanvin, J.-D. (2003).

A study of water loss and oil adsorption during oleothermic treat-

ment of wood. Proceeding of the 1st European Conference on Wood

Modification, Belgium, 23-32.

Hughes, A. (2004). The tools at our disposal. Lisbon: Final Workshop

Cost Action E22.

Militz, H., Krause, A., & Hof, C. (2004). Modified wood for window

and cladding products. In A. Ceccotti (Ed.), Proceeding of Interna-

tional Symposium on Advanced Timber and Timber Composite Ele-

ments for Building, Florence: CNR-Ivalsa.

Palanti, S., & Susco, D. (2004). A new wood preservative based on

heated oil treatment combined with triazole fungicides developed for

above-ground conditions. International Biodeterioration & Biodeg-

radation, 54, 337-342. doi:10.1016/j.ibiod.2004.04.003

Pernak, J., Zabielska-Mateljuc, J., Kropacs, A., & Foksowicz-Flaczyk,

J. (2004). Ionic liquid in wood preservation. Holzforschung, 52, 286-

291.

Purlow, D.F. (1976). Result of field test on the natural durability of

timber (1932-1975). Building Research Establishment Current Paper

CP 6/76, Garston.

Sailer, M., & Rapp, A.O. (2001). Water repellency of some natural oil.

Workshop and Meetings of European COST (Cooperation in the

field of the Scientific and Technical Research). Action E22-Envi-

ronmental Optimisation of Wood Protection. Reinbek.

Sanchez, D., Leinonen, A., Vesterinen P., Capaccioli, S., Gil, J., &

Echeverria, I. (2005). Bio-south: Techno-economical assessment of

production and use of biofuels for heating and cooling applications in

south Europe. 14th European Biomass Conference, 17-21 October

2005, Paris.

Thevenon, M. F. (2001). Oils and water repellents in wood protection

research and development in France. Reinbek: Workshop on Opti-

mising treatment levels and managing environmental risks, Cost E22.

Treu, A., Militz, H., & Breyne, S. (2001). Royal treatment-scientific

background and practical application. Reinbek: Workshop on Opti-

mising Treatment Levels and Managing Environmental Risks, Cost

E22.

Van Eckeveld, A., Homan, W., & Militz, H. (2001). Water repellency

of some natural oil. Workshop and Meetings of European COST

(Cooperation in the field of the Scientific and Technical research).

Reinbek: Action E22-Environmental Optimisation of Wood Protec-

tion.

Vernois, M. (2001). Heat treatment of wood in France—State of art in

rewiew on heat treatments of wood. In A. O. Rapp (Ed.), Proceeding

of the Special Seminar COST E22, Antibes.