Journal of Intelligent Learning Systems and Applications

Vol.6 No.1(2014), Article ID:42867,14 pages DOI:10.4236/jilsa.2014.61003

Simulation and Optimization Techniques for Sawmill Yard Operations—A Literature Review

1Department of Computer Engineering, Dalarna University, Borlänge, Sweden; 2Department of Information Technology, Örebro University, Örebro, Sweden.

Email: aus@du.se, sye@du.se, mdo@du.se

Copyright © 2014 Asif Rahman et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In accordance of the Creative Commons Attribution License all Copyrights © 2014 are reserved for SCIRP and the owner of the intellectual property Asif Rahman et al. All Copyright © 2014 are guarded by law and by SCIRP as a guardian.

Received August 16th, 2013; revised September 16th, 2013; accepted September 21st, 2013

KEYWORDS

Sawmill Yard; Logistics; Timber Tucks; Log Stackers; Simulation and Optimization

ABSTRACT

Increasing costs and competitive business strategies are pushing sawmill enterprises to make an effort for optimization of their process management. Organizational decisions mainly concentrate on performance and reduction of operational costs in order to maintain profit margins. Although many efforts have been made, effective utilization of resources, optimal planning and maximum productivity in sawmill are still challenging to sawmill industries. Many researchers proposed the simulation models in combination with optimization techniques to address problems of integrated logistics optimization. The combination of simulation and optimization technique identifies the optimal strategy by simulating all complex behaviours of the system under consideration including objectives and constraints. During the past decade, an enormous number of studies were conducted to simulate operational inefficiencies in order to find optimal solutions. This paper gives a review on recent developments and challenges associated with simulation and optimization techniques. It was believed that the review would provide a perfect ground to the authors in pursuing further work in optimizing sawmill yard operations.

1. Introduction

The optimization problems in any domain are specific concern for managers and decision makers. Even though there are technological developments in the field of optimization techniques, the need for more efficient techniques which can solve such problems will always exist. With increasing competitiveness in real world scenarios, mathematical models of such problems are getting more and more complex. In order to deal with such problems, sophisticated tools and techniques are needed which can efficiently solve such problems. In recent years, many researches have focussed on combinatorial optimization problems using simulations and optimization techniques to improve profits and performance. Accordingly, many areas of supply chain management have adapted optimization techniques to improve and optimize their resources efficiently.

The supply chain logistics is considered as an integrated process in which a group of several organizations, such as suppliers, producers, distributors and retailers, work together [1]. One of the most important problems in supply chain logistics is the optimizations of resources and it is a very complex problem that deals with the planning, handling and control, for the storage of raw material between arrival and production [2]. Further, supply chain management includes logistics transportation, resource allocations, storage bin arrangements, scheduling and routing. Several areas of logistics transportation, resource allocation and arrangements (storage area/containers etc.) within organization demand proper planning and optimization techniques in order to attain significant reduction in operational costs. This review is an attempt to gain a better understanding of the techniques or methodologies used in supply chain management and to provide a basis for research in sawmill yard operations. In most of the sawmill industries, efficient planning and optimization of resources are key factors for successful reduction in operational costs. Storage bins in sawmill yard have a significant impact on the resources and production supply, whereas, resources are essential equipment for transportation, loading and unloading of logs from one place to another within sawmill yard. Inefficient utilization of resources results in unnecessary operational costs. In order to attain significant reduction in operational costs, a comprehensive and systematic approach for optimization of operations in sawmill yard is required. There isn’t enough of literature available on the problems encountered in the sawmill yard, i.e. between arrival and production, whereas problems encountered in sawmill production line, automatic debarking and grading have been investigated in the past. However, the problems in sawmill yard are rather similar to most of the problems encountered in supply chain logistics. Therefore, we try to map the literature, which are immediately relevant to current area of investigation and study.

Most of the researchers are focussing towards developing new methodologies and techniques which can not only provide reasonable good solutions but are also computationally fast. Existing researches in supply chain domain using various Artificial Intelligence, Simulations and Mathematical optimization techniques have been investigated. AI techniques are one of the most popular and fascinating tools to solve the real world optimization problems. Further, they are more feasible to solve complex optimization problems compared to traditional techniques.

The aim of this paper is, therefore, to make a review of the work carried out thus far on operational optimization using various optimization and simulation techniques. As an enormous amount of literature available in domain of optimisation, we will focus mainly on techniques used for decision making within the organisation that improves overall performance. The main issues to address include: what are the main problems within operational routines that have been investigated using combinatorial optimization (CO) and discrete event simulation (DES) techniques? What optimization techniques have been employed? What are the main findings and achievements up to date? And finally, discussion concerning the possible use of such techniques in current areas of investigation is presented for further research directions. Only the classified techniques that are immediately relevant to the area were covered in this review, due to the wide scope of the subject.

This paper is organised in five sections. Subsequent to the introduction in Section 1, the review methodology is mentioned in Section 2. AI and optimization techniques are briefed in Section 3. Section 4 describes the current area of investigation and examines the research of applying AI and DES techniques to various optimization problems in sawmill. Then key findings are concluded. Finally, a summary of existing research and a discussion on the future research directions are provided in Section 5.

2. Review Methodology

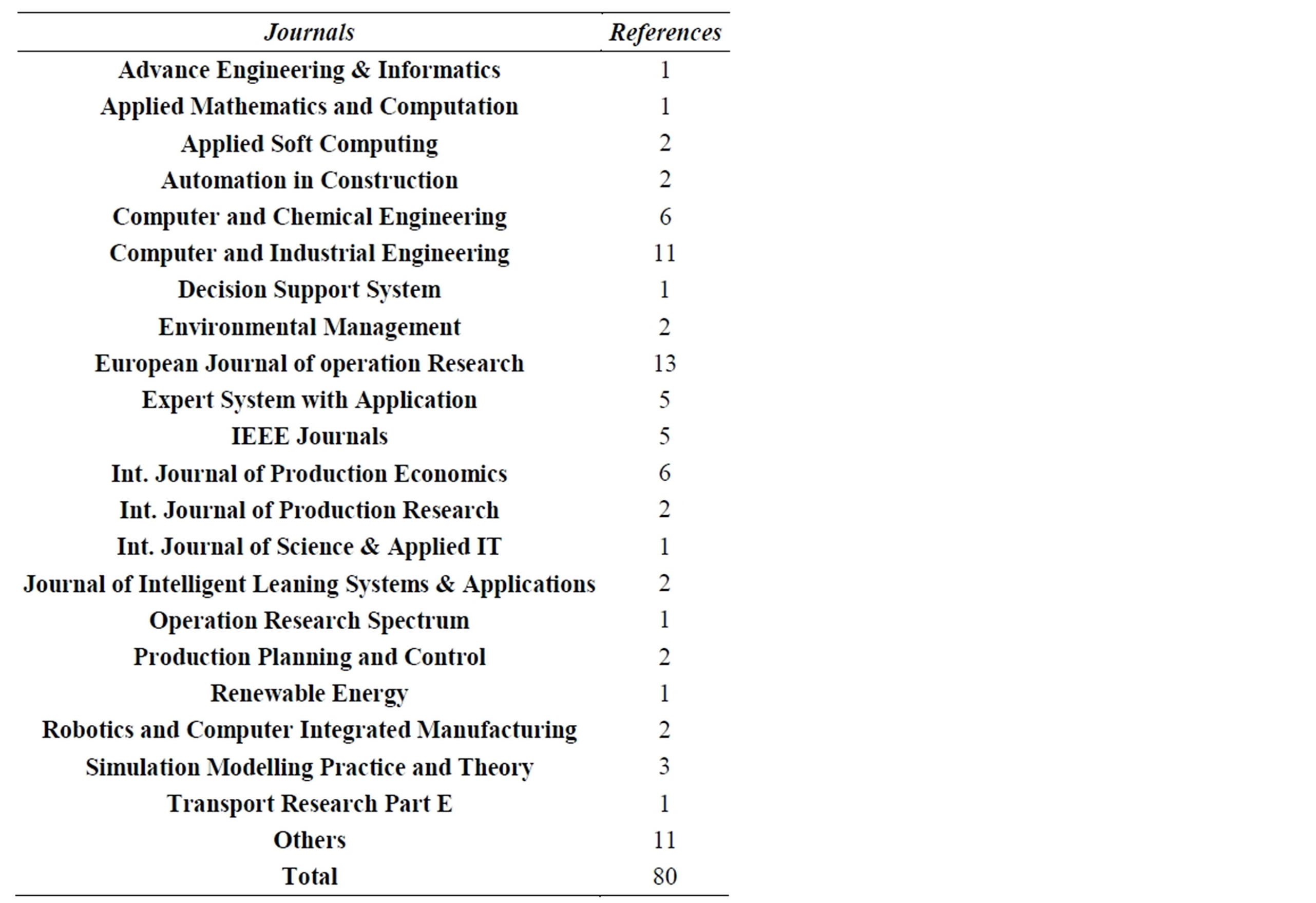

The search process was carried out with scientific databases. The review papers were sorted out from more than 30 journals (Table 1) such as European Journal of Operation Research, International Journal of Production economics, Computers & Industrial Engineering, IEEE journals and Expert systems with Applications etc. Given the specific interest on how Optimization and Artificial Intelligence techniques were used in combination with simulation models to optimize the supply chain logistics operations. More than 100 papers including the journals, conference, book chapters and books were reviewed for this study.

Scope

The concept of simulation optimization has been analysed by many researchers from various perspectives. However, it is beyond the scope of this paper to address all problems in detail. In an attempt to provide a more intensive review of existing papers in this area, this paper mainly focuses on problems which are immediately relevant to problems in sawmill yard logistics. The problems

Table 1. List of journals reviewed.

related to automatic grading, production scheduling and efficient debarking techniques will not be discussed in this paper.

3. Optimization Techniques

According to [3] optimization models are used to quantitatively tackle many emerging logistics challenges. The challenges in supply chain design problem comprises the decisions regarding the number and location of production facilities, the amount of capacity at each facility, the assignment of each market region to one or more locations, and supplier selection for sub-assemblies, components and materials [4]. The supply chain design is related to the definition of the structure of the chain, i.e. the sequential links between different sourcing, production and distribution activities or processes [5]. Enormous amount of literature can be found on supply chain logistics with different objectives and using various methodologies. However, the goal of each methodology is to optimize the supply chain process. The different factors which have been considered, namely: costs, location, allocation, capacity, routing, agility and transportation.

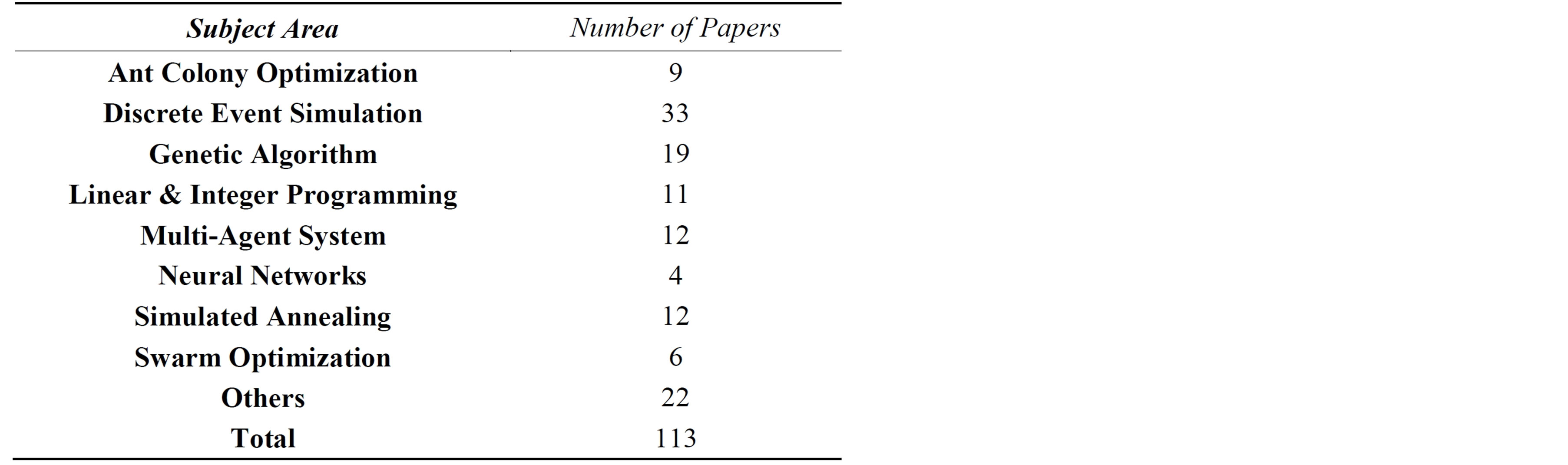

An efficient algorithm to optimize complex real world problems has been a challenge to researches over the years in different domains. Simulation-optimization methods have proved to be powerful tool to reduce operational costs and facilitate effective design operations for optimization problems, and have become an area of extensive investigation over the past decade [6]. Optimization problems are normally expensive and time-consuming. It is then important to develop tools that can help identify the most cost-efficient ways of implementing and solving optimization problems. Simulation models, when used alone, cannot guarantee that the design strategy is optimal. They can handle what-if scenarios/questions, but are weak in seeking answers to which one is the best [7]. The optimization techniques can be categorised into three groups: 1) Linear and Integer Programming; 2) Artificial Intelligence based methods; and 3) Discrete event simulations incorporating optimization techniques (Table 2).

3.1. Linear and Integer Programming

Mathematical programing has been used in a number of supply chain optimization and management problems. Ryu et al. [8] presented a bi-level modelling approach comprising two linear programming models, one for production planning and one for distribution planning. Ozgur and Fusun [9] provided a probabilistic linear programming model to make strategic resource planning decisions in supply chain. Oh and Karimi [10] put forward a linear programming model that integrates production and distribution planning for a multinational firm in

Table 2. Field of Study.

the chemical sector. Yue Wu [11] studied a time staged linear programming model for modelling production loading problem with import quota limits, where, decision regarding quantities of used resources, machines, labour, initial quotas, inventory and outsourcing levels were considered. Jung et al. [12] compared linear programming models for centralized and decentralized production and transport planning environments. Kanyalkar and Adil [13] used a linear programming model for aggregated and detailed production and dynamic distribution planning in a multiproduct and multi-plant supply chain. Kallrath [14] presented a mixed integer linear programming model for production, distribution and sales planning with different time scales for business and production aspects. Silke et al. [15] presents a linear mixedinteger modelling approach for basic components in a biomass supply chain. The main focus of this work was to represent the relationship between moisture and energy content of different kinds of biomass and to handle long-term processes in the optimization like passive drying effects. Yavuz et al. [16] introduced a generalized mixed integer programming (MIP) formulation that allows iterative interaction with a simulation model by taking into account the impact of uncertainty on the objective function value of previous solutions. Talluri and Baker [17] used a multi-phase mathematical programming approach for effective supply chain network design to meet the constantly changing needs of customers at low cost, high quality, short lead times and high verity. Panagiotis and Lazaros [18] proposed an integrated model based on a detailed mathematical programming formulation that addresses some of the complex issues related to the design and operations of global supply chain networks.

The above mentioned studies used Linear or Integer programming algorithms for dealing supply chain optimizations problems. Most of the authors focused on financial and tactical operational aspects within the organization taking into account production operations, distribution efficiency, resource planning, operational costs, customer satisfaction and product quality etc.

3.2. AI Based Methods

Artificial Intelligence is basically a branch of computer science concerned with making computers behave like humans or emulation of human behaviour (McCarthy, 1956). AI is nothing but the ability of a computer program to evaluate information and make a decision according to pre-established criteria. Recently, there has been a growing interest in using artificial intelligence techniques to solve optimization problems. This is mainly because the challenge existing in the solution process that usually requires incorporating complex simulation models into optimization framework. This leads to the difficulty in seeking the globally optimal solution with conventional non-linear optimization algorithms [6].

AI techniques are suitable in addressing the qualitative aspects of decision support system, which are not adequately captured when using analytical models [19]. AI techniques has been used in different fields, however, this paper focuses on the problems related to supply chain logistics and transportation. The artificial intelligence techniques, in particular Genetic Algorithm (GA), Ant Colony optimization (ACO), Particle Swarm Optimization (PSO), Simulated Annealing (SA), Neural Networks (NN) and Multi-agent systems has been analysed to solve optimization problems in supply chain logistics for reduction in operational costs and increase efficiency.

3.2.1. Genetic Algorithm

Genetic algorithm (GA) is a stochastic searching method that mimics natural evolution and is based on the concept of “survival of the fittest”. GA is implemented as a computer simulation in which a population of abstract representation of candidate solution to an optimization problem evolves towards better solutions [20]. Evolutionary algorithms were invented to mimic some of the process observed in natural evolution. Evolution occurs on chromosomes organic devices for encoding the structure of living beings. Processes of natural selection then drive those chromosomes that encode successful structure to reproduce more frequent than those encode failed structures. By using simple encoding and reproduction mechanism, the algorithm can then display complicated behaviour and turn out to solve some extreme difficult problems [21].

Genetic Algorithms (GA) are robust adaptive optimization method based on biological principals, GA is an efficient algorithm to solve combinatorial optimization problems by exploring a large and complex search space in an adaptive way guided by the equivalent biological evolution mechanisms of reproduction, crossover and mutation [22]. The most important advantage of GA is their ability to use accumulative information about the initial unknown search space in order to move the next search into useful spaces [23]. In the past decade, a large number of combinatorial optimization problems and solution methods have been presented in the literature on integrated supply chain management [24].

Gjerdrum et al. [25] proposed a mathematical programming model to reduce operational costs, while maintaining customer order fulfilment at high level of for a supply chain network. Amodeo et al. [26] presents a simulation based multi-objective optimization method for the optimization of inventory policies of supply chains considering total inventory cost and service level. Reza and Mahsa [27], introduced a new model for a distribution network in a three-echelon supply chain, which not only minimizes the total costs but also follows Just-intime distribution purposes in order to better represent the real-world situations. Fulya et al. [28] have used a steadystate genetic algorithm (ssGA) for the single-source multiproduct multi-stage supply chain network design problem, to satisfy the customers demand with minimum costs. D’Souza et al. [29] developed a Genetic Algorithm and Artificial Immune System to tackle the “Pickup and Delivery” problem effectively giving optimal solutions. By using these meta-heuristic methods the authors have optimize overall transport between different destinations leading to better utilization of time and resources. David et al. [30] considered the problem of finding an optimized schedule for the just-in-time production and delivery of ready-mixed concrete. The scheduling algorithm combines a GA and a set of constructive heuristics, which guarantee the determination of a feasible schedule for any given set of requests. Lau et al. [31] uses a stochastic search technique called fuzzy guided genetic algorithm (FLGA) to simultaneously optimize travelling time and travelling distance in a multiple depot vehicle routing problem. Daniels and Parsons [32] proposed the use of hybrid algorithm that combines an agent-based approach with GA global search operator to show that it is both faster and more effective than either a pure GA or a pure agent-based simulation to space arrangement problems. David et al. [33] proposed a hybrid algorithm based on GA and LP to minimize the distribution costs for a pulp producer. GA are the most studied and applied meta-heuristic in the optimization field, because GA are very easy to implement in all sorts of problems, and usually guarantee good solutions, whatever the type of solution space [2].

A variety of problems concerning the simulation based optimization have been widely handled using Genetic Algorithm. One of the promising methods of optimizing problems were performance can be evaluated by a simulation model is the use of GAs [34]. Shin et al. [35] proposed a simulation model incorporating genetic algorithm for optimal hoist planning in building constructions, uses simulation to test the optimal hoist plan whereas GA searches for a set of hoists that optimizes rental costs. Yeh and Lin [36] proposed a GA method to obtain a near optimal solution for hospital emergency department. Further, simulation has been used to evaluate how system is impacted by various nursing schedules. Shin and Iima [37] proposed a GA o find the best classroom seating arrangement based on the questionnaire results and analysis of the observation of behaviour between students. According to authors, the satisfaction of students for the proposed method is higher than the traditional class room seating arrangements.

3.2.2. Simulated Annealing

In traditional problem solving strategies, some of them guarantee finding a global solution, others don’t, but they all share a common pattern. Either they guarantee discovering the global solution, but are too expensive (i.e., too time consuming) for solving typical real world problems, or else they have a tendency of getting stuck in local optima. Since there is no chance to speed up algorithms that guarantee finding the global solution, i.e., there is no chance finding polynomial time algorithm for most real problems as they tend to be NP hard, the other remaining option is to design algorithms that are capable of escaping local optima. After reaching a local optimum, a new starting point is generated and the search is commenced all over again. Two main approaches that we’ll discuss here are based on an additional parameter called (temperature) that changes the probability of moving from one point of search space to another or a memory, which forces the algorithm to explore new area of search space. These two approaches are called Simulated Annealing and Tabu Search. We will focus on Simulated Annealing. It’s a method that simulates the physical process of annealing. Annealing is where a material is heated and then cooled usually for softening and making the material less brittle. Simulate annealing; therefore, exposes a solution to heat and cools producing a more optimal solution [33, 38].

Simulated annealing is the deterministic search approach based on the annealing process of metal. This procedure can be considered a hybrid method of local search and usually employs a downhill algorithm unless probability is decreases to 0. In this situation, uphill moves would be applied for increasing probability [39]. Simulated annealing (SA) is inspired in the physical annealing process. The randomized nature of the procedure permits asymptotic convergence to optimal solution under mild conditions [40]. Vaidyanathan and Anthony [41] studied the applicability of simulated annealing as a very effective and useful solution approach to complex problems involved in supply chain management to reduce costs and improve efficiency. Chibeles-Martins et al. [42] presents a meta-heuristic approach, based on the simulated annealing to optimize the computational burden of supply chain network. Kathryn et al. [43] proposed a hyper heuristic driven simulated annealing approach to minimise the packaging waste by optimizing storage and transportation shipper sizes. Hamid and Keivan [44] uses a simulated annealing approach for optimizing the fleet size and freight car allocation problem wherein car demands and travel times were assumed to be deterministic and unmet demands were backordered. Kathryn et al. [43] developed a simulated annealing based hyper heuristic model for determining shipper sizes for storage and transportation. Allaoui and Artiba [45] considered a multiobjective optimization problem taking into consideration the system constrains. Suman [46] used a Pareto dominated simulated annealing for multi-objective optimization problems where he has made extensive comparisons of multi-objective simulated annealing algorithms. Mahmoud et al. [47] presented a simulated annealing algorithm for solving multi-objective stochastic optimization problem. The algorithm uses hill-climbing feature to escape the local minimalistic trap. A new Pareto set for multi-objective stochastic optimization is also introduced to assist the simulated annealing algorithm attain optimality. Further, simulation is used to estimate the objective function values.

3.2.3. Ant Colony Optimization

Ant colony optimization (ACO) is a technique of problem solving inspired by the behaviour of ants in finding paths from the nest to food and a new search metaphor for solving combinatorial optimization problems, and has been unexpectedly successful in recent years [48,49]. Ant colony optimization is a relatively new optimization technique that has been gaining followers in the past decade, since it is especially suited for problems with dynamic behaviour [48]. The ants cooperate using an indirect form of communication mediated by pheromone trails of scent and find an optimal solution to their tasks guided by both information (exploitation) which has been acquired and search (exploration) of the new route. Therefore the premature convergence probability of the system is lower [50].

Silva et al. [51] proposed an ant colony optimization technique to optimize the different operational activities of generic supply chain. Further, simulation results suggested that new methodology is more efficient than a simple decentralized methodology for different instances of a supply chain. Luis et al. [52] uses a multi-objective ant colony optimization to supply chain design to optimize total supply chain cost while keeping the total lead times within required delivery due dates. Wei and Arun [53] presents a meta-heuristic ant colony optimizations (ACO) approach for solving the logistics problem arising in disaster relief activities, such as planning, dispatching and evacuating. Chaharsooghi and Kermani [54] studied an effective ant colony optimization for multi-objective resource allocation problems in order to minimize the costs of resources and maximize the overall efficiency. Felix and Niraj [55] uses a multiple ant colony optimization (MACO) approach to design a balanced and efficient supply chain network that maintains the best balance of transit time and customers service. Rami et al. [56] proposed an Ant colony optimization algorithm to solve the transportation problem of cross-docking network to minimizing the transportation cost in a network by loading trucks in the supplier locations and then route them either directly to the customers or indirectly to crossdocking facilities so the loads can be consolidated.

Aaron [57] proposed a parametric study of ACO applied to Water Distribution System Optimization. Using the derived parameter guidelines, iteration-best ant system, has been seen to perform extremely competitively when compared with other optimization algorithms.

3.2.4. Particle Swarm Optimization

Particle Swarm Optimization (PSO), an evolutionary computation technique firstly introduced by Kennedy and Eberhart in 1995 [58,59], is based on the collective motion of a flock of particle; the particles swarm. In the simplest version of PSO, each member of the particle swarm is moved through a problem space by two elastic forces. One attracts it with random magnitude towards the best location so far encountered by the particle. The other attracts it with random magnitude towards the best location encountered by any member of the swarm. The position and velocity of each particle are updated at each time step until the swarm as a whole converges to an optimum [60]. The swarm optimization algorithms have been used in different domains, however, only topics immediately relevant to the area of investigation are presented below.

Swarm Optimization (PSO) are increasingly been used in optimization problems related to TSP, VRP, Shortest Path, Resource Allocation, Scheduling and logistics distribution etc. Further, simulations and hybrid algorithms were also used to enhance the results. Wei et al. [61], presents the model of logistics distribution centres location problem considering setup cost, turnover cost and demands of the customers as a combinatorial optimization problems. For the convenience of solving the model, some mathematical properties of the model were also obtained. Further, discrete particle swarm optimization algorithm, tabu search algorithm and sequential quadratic algorithm were integrated to seek the minimum of total cost and assignment plan of the distribution centres. Lie and Fanhua, [62] presented a 4-stage production distribution problem and used the improved PSO algorithm to solve the problem. Further, simulation has also been used to show that the algorithm is effective and efficient in both computation and convergence. Yue-Jiao et al. [63] presents a set-based PSO to solve vehicle routing problem with time windows, the proposed algorithm provides better results than the existing best known results. Yanfang and Hengqing [64] proposed a new method for solving the shortest path problem in stochastic traffic networks. The approach based on combining fluid neural network model with PSO. This algorithm is simple and easy and can find quickly the shortest path without falling into local minimums, which will occur if energy function is used to solve the same problem. Chilukuri et al. [65] have proposed a PSO-based fair Resource allocation and scheduling algorithm for the IEEE 802.16 System. And have compared the results with the static FDMA algorithm and have found it better delay characteristics with increasing number of users while still maintaining the fairness and throughput utilization. This makes the proposed scheme absolutely useful for real-time applications.

3.2.5. Neural Networks

An artificial neural network consists of an interconnected group of artificial neurons. Such a network performs computation and manipulates information based on the connectionist approach in a similar but simpler fashion than the brain would perform [66]. In terms of modelling, remarkable progress has been made in the last few decades to improve artificial neural networks (ANN). Artificial neural networks are strongly interconnected system of so called neurons which have simple behaviour, but when connected they can solve complex problems. Changes may be made further to enhance its performance [67].

Combinatorial optimization problems are NP-complete and have received lot of interest from (Artificial Neural Networks) ANN researchers, many researchers have tried to solve it, but no method can solve it completely. As a result, a number of neural networks have been developed to solve wide range of optimization problems. The majority of the existing studies are based on Hopfield networks or its extensions. This may be partly due to successful applications of Hopfield network to the Travelling Salesman Problem (TSP) and other optimization problems [68]. It can be shown that usually among existing ANNs techniques, Hopfield neural networks and SOM have applied for optimization problems. Some of the many ANN applications have been reported for optimization problems include Assignment Problems, clustering Problems, Scheduling Problems and Travelling Salesman Problem (TSP) [69].

3.2.6. Multi-Agent System

Intelligent agents are able to perceive their environment and respond in a timely fashion, exhibit goal directed behaviour by taking the initiative, and capable of interacting with other agents, in order to satisfy their design objectives. Intelligent agents are autonomous, smart and active. They decide themselves whether or not to reform an action on request from another agent. Agents are different form objects, you order objects to do things, but you request agents to cooperate. The objects don’t have any of the behaviours either. A multi agent system is inherently multi-threaded and each agent is assumed to have at least one thread of active control [70].

Multi Agent systems (MAS) are increasingly been used in complex problems related to logistic planning, air traffic control, military demining, financial portfolio management, among others [71]. Multi agent systems offer such a useful feature as parallelism, robustness and scalability. They are highly applicable in domains and problems, where centralized approaches meet their limits. Multi agent based approaches are well suited for domains, which require the integration and interaction of multiple source of knowledge, the resolution of interest and goal conflicts or time bounded processing of data [72].

Multi-agent technologies start to penetrate into transportation and logistics domain only recently. Intelligent agent represents the organizations within the logistics domain; model their logistics functions, processes, expertise and interaction with other organizations. Due to similarity in characteristics between intelligent agents and organizations, agent technology is an appropriate choice of modelling organization in the logistics domain [73]. Multi-agent or agent based systems that mainly are used to solve typical problems in the transportations and logistics domain such as decision support system, logistics planning system, and simulation and modelling system, which support both decision-making and planning, where experts can make their decisions [74].

The problems in which agent technologies have been applied within transport logistics are planning, scheduling, management etc. Many researchers have focused on the field of multi agent systems. A number of significance advances have been made in both the design and implementation of autonomous agents. Neagu et al. [75] have reported Agent-Based system design to solve the Pickup and Delivery Problem with Time Windows (PDPTW) using constraint satisfaction techniques (CST). Kazami et al. [76] solves a production and distribution planning problem and compare the results through the use of genetic algorithm to the ones coming from employing a multi agent decision support. Vita and Janis [74] proposed an overview of the problem solving methods in transportation and logistics domain. Two different multi-agent architectures has been worked out and used in the real life problem within the transportation and logistics domain. This architecture support both decision making and planning. Persson et al. [77] analyses the strengths and weakness of agent-based approaches and mathematical optimizations techniques. According to the author’s qualitative evaluation, agent-based approaches tend to be preferable when, the problem domain is large, probability of node or link failures is high, time scale of the domain is short, sensitive information that should be kept locally, and mathematical optimization techniques when, the cost of communication is high, the domain is monolithic in nature, quality of solution can be guaranteed, it is important that a system optimal or near optimal solution is found. Combining the approaches into a hybrid approach can be a promising way.

The potential of agent technology is also suitable for modelling practical supply chain management problems, where analytic or optimization results cannot be easily applied or global information sharing and central coordination are difficult to achieve [78]. Liang and Huang [79] developed a multi-agent system to simulate a supply chain, where agents represent the different actors within a supply chain. Agents are coordinated to control inventory and minimize the total cost by sharing information and forecasting knowledge. Ahn & Lee [78] present a practical collaboration framework for supply chain management wherein multi-agent systems form dynamic information network and co-ordinate their production and order planning according to synchronised estimation of market demand. Caridi and Cavalieri [80] provide a critical analysis of agent based approaches applied to supply chain management domain, pointing out the lack of real world applications and the low maturity level of agent based manufacturing technology. Akanle and Zhang [19] proposed an Agent based model for optimizing supply chain configurations to meet customers demand with minimum costs.

3.3. Simulation Techniques

Supply chain simulation is often carried out in general purpose simulation software as reported in [81] or using special purpose analysing tools as reported in [82]. Simulation, as a generic technique, has been identified as a suitable tool for the analysis of complex and dynamics systems such as supply networks [83]. Computer simulation and simulation models can be used to model complex supply networks close to real systems, execute those models, and observe system behaviour. Simulation also provides the ability to simulate the effect of particular events on supply network performance and experimenting with different scenarios without huge investments (time and money) and process disruption [84]. Simulation can be defined as the process of designing an abstract model of a real system and conducting experiments with this model for the purpose of either understanding system behaviour or evaluating various strategies within the limits imposed by a set of criteria for the operation of the system [85]. Simulation enables managers to study and evaluate alternative solutions to analyse the effect of process or operation modification [86].

The simulation based approaches to assess the operational routines within the domain and the impact of logistics is not a new concept. Many simulations models are increasingly being used for optimization and decision making purposes in most of the organizations. The commercially available simulation packages have also being increased. Many newer simulation packages now offer object-oriented modelling architecture; therefore the simulation applications are more portable and scalable than before [87]. Simulation models have been successfully used in different domains, such as, berth planning, resources optimization and resource allocation at container terminal [88,89], manufacturing activities in an automobile supply chain, automotive industry [90,91], fright transportation analysis [92], optimization of supply chain network, management and demand uncertainty [93-100]. Xiatao et al. [101] and Amalia & Marianthi [102] emergency department in health care [36,103] water resource management [104], multiple performance measures [105], scheduling system, production line in industry and flexible transport services [106-108].

Discrete Event Simulations

Discrete event simulation can be particularly useful in non-stable environments such as supply networks that are characterized by a high degree of interdependences and where logistic processes play important role, and also there is a need for process optimization [109]. However, as a descriptive method, discrete event simulations can only be used to perform optimization through “what if” case studies involving the comparison of several cases or scenarios [101]. Simulations are often developed to check the validity of the model or to evaluate its efficiency. It permits examination of the behaviour of real world system by developing simplified models of real system. It can be used to explore the behaviour of artificial systems in order to predict what might happen should such a system come into existence in the real world [110]. Simulation allows researchers to study processes in ways nature prohibits, given that it can be run many times with the values of the model parameters modified in each run and changes observed in outputs. According to, computer simulation can be applied for different purposes, namely prediction, performance, entertainment, training, education, confirmation and discovery [111].

Recently, other techniques have been combined with discrete event simulations techniques in supply chain domain. Jaroslav and Pavel [96] proposed an integer based simulation optimization, where, local search algorithm minimizes the number of evaluations and simulation optimizes the objective function. Carvalho et al. [97] presents a supply chain simulation study for an automotive supply chain. The study was to evaluate alternative supply chain scenarios for improving supply chain resilience to a disturbance and understanding how mitigation strategies affect each supply chain entity performance. Taejong et al. [98] proposed a hybrid algorithm for discrete event simulation to reduce the computational load and to improve the efficiency of supply chain. Tu Hoang et al. [99] combines Integer programming and GA to produce supply chain configuration design. Moreover, a reference model of supply chain has been established based on distributed simulation and business process modelling techniques [100]. Xiatao et al. [101] presents an extension to the simulation-based optimization framework for optimizing supply chains under uncertainty. Amalia and Marianthi [102] proposed a hybrid simulation optimization approach, where, combination of mathematical programming and agent based simulation model has been investigated to minimize the summation of production cost, transportation cost, inventory holding and shortage costs, subject to capacity and inventory balance constraints in a supply chain management. Further, Georgiana [112] presents a use of simulation and multiple linear regressions to improve operational inefficiencies of a small scale process industry. Ye et al. [113] proposed a simulation-optimization approach to improve clinical supply chain management including patient demand and demand scenario forecast. Young et al. [114] proposed a combined discrete and continuous simulation model for evaluating and optimizing supply chains as supply chain systems are neither completely discrete nor continuous. Fengli et al. [115] describes the development of a simulation model for biofuel supply chain, where harvesting or processing, transportation and storage were the key activities in the model in order to minimize feedstock cost, energy consumption and GHG emissions.

4. Sawmill Yard Operations

4.1. Bergkvist Insjön AB—A Case Study

Bergkvist Insjön AB1 is one of the large privately owned sawmills in Sweden with an annual production volume of around 400,000 cubic meters. A brief description of the work routine has been provided to the sake of clarity. Typical operations at the Bergkvist Insjön AB begin with the arrival of logs. Trucks loaded with timber arrive at sawmill where they are unloaded by a log stacker. Unloaded timber is allowed to pass through a measuring station in which a human inspector checks for the quality of the timber. Further the timber passes through a 3-D scanner that will determine the type and dimension of the wood. Depending upon the type and dimensions, timber gets placed into appropriate storage bins which are ranged alongside a long transport band. Depending on the production requirements, timber from specific storage area or storage bins are emptied and fed to the saw mill with the aid of a second log stacker. Timber is then passed through a second 3-D scanner. The role of the second scanner is to double check that the right type and dimension of timber is being selected for production. Lack of proper control at this stage seriously compromises quality of the end product. Timber that is rejected by the second scanner is sent back to the measurement station. Such timber are reassigned a new (timber) class and appropriate storage bins as per the new grade and the process continues. Upon acceptance, the logs are processed and are directed to further stages of production.

To be able to meet with the production and supply challenges, Bergkvist Insjön AB has been constantly updating its resources (for handling operations) over time. In spite of the adaptive nature, Bergkvist Insjön AB has been facing severe challenges that are threatening the overall efficiency and thereby limiting profit margins of sawmill. A particular challenge concerns the unexpected arrival of trucks loaded with timber. The trucks arriving at sawmill have to be unloaded before they can leave. Further Bergkvist-Insjön AB is bound to pay certain amount of waiting fee to the truck drivers for keeping them waiting beyond certain time limit. Unexpected arrival of several trucks within intervals is imposing enormous amount of pressure on the internal resources (log stackers). Unexpected arrival of trucks is not an internal problem that can be regulated by Bergkvist Insjön AB due to the presence of large number of actor’s such as small enterprises making delivery of timber, truck drivers, timber procurers etc. Informing the truck drivers (prior to their arrival) about possible serving times i.e. the best time that one could come in to avoid delays, could be seen as a way to cope up with the problem. However the ability to provide the drivers with arrival information is largely dependent on the efficiency and predictability of internal operations such as loading and unloading procedures, storage capacity, arrangement of storage bins, number of resources, measuring and processing speed etc.

Bergkvist Insjön is facing difficulties in managing their resources, especially when many trucks (loaded with timber) arrive unexpectedly at the same time. Achieving better routine to carry out internal operations is essential. Hence, the main objective of this review is to investigate and propose a means of optimizing all internal operations at Bergkvist, thereby helping them to improve overall performance and promote efficiency. Finally, it is expected that such an improvement will help the truck drivers in planning better timber delivery routines.

4.2. Future Work

The efficient optimization of sawmill yard operations is a complicated task, involving a variety of factors with storage bin arrangements, unexpected arrivals and rejections. Many traditional solutions based on experiences and empirical analysis, which may not represent optimal strategy at sawmill yard. Simulation and optimization models based on sawmill operational routines is an immediate requirement to examine and evaluate sawmill yard operations, bin arrangements and behaviour of log stackers. The ultimate goal here is to minimize usage of resources and maximize supply of logs to sawmill for production. However, the possibility for accomplishing this goal could be affected by many constraints, and limitations that exit in sawmill yard and its operational routines.

The operational inefficiencies of sawmill yard seriously threatens the overall efficiency and profit margins of sawmill. Several types of optimization techniques and simulation models can be used to investigate problems causing operational inefficiency in sawmill yard. Further, new strategies and behaviors can be adopted to improve the overall performance in sawmill yard. Problems concerning the sawmill yard operations were studied recently using discrete event simulations [116]. Further, discrete event simulation can also be combined with optimization algorithms to improve and optimize the operational routines. As there are several optimization algorithms and each technique have their own benefits, so it is left to uses to make a choice of best suitable technique.

Optimal arrangements of storage a bin is one of most important operational inefficiency among others in sawmill yard. It takes enormous amount of time to simulate all possible arrangements, as n becomes large exhaustive search is computationally infeasible. Therefore, an effective simulation model incorporating Genetic Algorithm (GA) to optimize the arrangement could be a promising alternative, as GA has been used very efficiently by many researchers. Further, agent based simulation model or discrete event simulation can be used in combination with GA.

5. Conclusions

The papers reviewed were from more than 30 different Journals (Table 1); it is due to the fact that optimization problems are application driven. Hence, most of the papers reporting the use of Simulation and AI techniques to solve optimization problems were found to be published in Operation Research Journals and other Journals immediately relevant to the area compared to pure Computing or AI based Journals. The current literature review has been done with the intention of focussing on the latest advancements and trends provided by employing AI techniques to solve operational optimization problems. AI based approaches are the most popular techniques adopted to solve optimization problems, particularly in transportation and logistics domain. Further, simulations are also used in combination with the techniques to solve uncertainty of a system to predict performance under various scenarios. Techniques such as neural networks, multi-agent simulation, genetic algorithm, ant colony algorithm, simulated annealing, discrete event simulation and mathematical programming etc. have been used to handle a variety of problems in supply chain domain.

Identifying the best optimization technique that can be combined with simulation models to solve operational inefficiencies is impossible since all optimization algorithms, which have been used so far exhibits benefits of their own. Therefore it is left to the users to make a choice for the most suitable algorithm that can be incorporated into simulation model. Moreover, selection of appropriate technique depends on the usage, application and complexity of the task. It is hoped that this review provides a good platform for researchers interested in pursuing further work in optimizing sawmill yard operations.

An interesting aspect that has been recognised during the review was that the combinations of AI techniques with simulation models greatly enrich the flexibility of problem solving. Therefore, there may be a great potential for further research either to improve the efficiency and effectiveness of existing practice or to create a new paradigm by integrating more practical algorithms. The operational inefficiencies in different domains have been addressed by Simulation and AI based optimization techniques, there are some specific areas which have not yet been well explored. The in-house operations of sawmill yard logistics, therefore, it is expected that this paper can stimulate more research in the field of sawmill yard operations.

Acknowledgements

The authors would like to thank the anonymous reviewers for their valuable comments that greatly helped us to improve the contents of this paper.

REFERENCES

- M. Josefa, P. David, D. M. Manuel and V. Eduardo, “Mathematical Programming Models for Supply Chain Production and Transport Planning,” European Journal of Operation Research, Vol. 204, No. 3, 2010, pp. 377-390. http://dx.doi.org/10.1016/j.ejor.2009.09.008

- C. A. Silva, J. M. Sousa and T. A. Runkler, “Rescheduling and Optimization of Logistics Process Using GA and ACO,” Journal of Engineering Application of Artificial Intelligence, Vol. 21, No. 3, 2008, pp. 343-352. http://dx.doi.org/10.1016/j.engappai.2007.08.006

- M. C. Aakil, N. Xiaofeng and P. Shaligram, “Optimization Models in Emergency Logistics: A Literature Review,” Journal of Socio-Economic Planning Sciences, Vol. 46, No. 1, 2012, pp. 4-13. http://dx.doi.org/10.1016/j.seps.2011.04.004

- S. Chopra and P. Meindl, “Supply Chain Management: Strategy, Planning, and Operations,” 2nd Edition, Prentice Hall, New York, 2003.

- F. Persson and J Olhager, “Performance Simulation of Supply Chain Designs,” International Journal of Production Economics, Vol. 77, No. 3, 2002, pp. 231-245. http://dx.doi.org/10.1016/S0925-5273(00)00088-8

- X. S. Qin, G. H. Huang and L. He, “Simulation and Optimization Technologies for Petroleum Waste Management and Remediation Process Control,” Journal of Environmental Management, Vol. 90, No. 1, 2009, pp. 54- 76. http://dx.doi.org/10.1016/j.jenvman.2008.07.002

- G. H. Huang and J. Xia, “Barriers to Sustainable WaterQuality Management,” Journal of Environmental Management, Vol. 61, No. 1, 2001, pp. 1-23. http://dx.doi.org/10.1006/jema.2000.0394

- J. H. Ryu, V. Dua and E. N. Pistikopoulos, “A Bi-Level Programming Framework for Enterprise-Wide Process Networks under Uncertainty,” Journal of Computers and Chemical Engineering, Vol. 28, No. 6-7, 2004, pp. 1121- 1129. http://dx.doi.org/10.1016/j.compchemeng.2003.09.021

- K. Ozgur and U. Fusun, “Probabilistic Linear Programming Approach for Supply Chain Networking Decisions,” European Journal of Operation Research, Vol. 209, No. 3, 2011, pp. 253-264. http://dx.doi.org/10.1016/j.ejor.2010.09.025

- H. C. Oh and I. A. Karimi, “Global Multiproduct Production—Distribution Planning with Duty Drawbacks,” AICHE Journal, Vol. 52, No. 2, 2006, pp. 595-610. http://dx.doi.org/10.1002/aic.10669

- W. Yue, “A Time Staged Linear Programming Model for Production Loading Problem with Import Quota Limit in a Global Supply Chain,” Journal of Computers & Industrial Engineering, Vol. 59, No. 4, 2010, pp. 520-529. http://dx.doi.org/10.1016/j.cie.2010.06.007

- H. Jung, B. Jeong and C. G. Lee, “An Order Quantity Negotiation Model for Distributor-Driven Supply Chains,” International Journal of Production Economics, Vol. 111, No. 1, 2008, pp. 147-158. http://dx.doi.org/10.1016/j.ijpe.2006.12.054

- A. P. Kanyalkar and G. K. Adil, “An Integrated Aggregate and Detailed Planning in a Multi-Site Production Environment Using Linear Programming,” International Journal of Production Research, Vol. 43, No. 20, 2005, pp. 4431-4454. http://dx.doi.org/10.1080/00207540500142332

- J. Kallrath, “Combined Strategic and Operational Planning—An MILP Success Story in Chemical Industry,” Journal of Operation Research Spectrum, Vol. 24, No. 3, 2002, pp. 315-341. http://dx.doi.org/10.1007/s00291-002-0102-6

- V. D. Silke, H. B. Bjorn and I. S. Hans, “Linear MixedInteger Models for Biomass Supply Chains with Transport, Storage and Processing,” Journal of Energy, Vol. 35, No. 3, 2010, pp. 1338-1350. http://dx.doi.org/10.1016/j.energy.2009.11.017

- A. Yavuz, N. K. Sukran and M. D. Jamison, “Incorporating Uncertainty in Optimal Decision Making: Integrating Mixed Integer Programming and Simulation to Solve Combinatorial Problems,” Journal of Computers & Industrial Engineering, Vol. 56, No. 1, 2009, pp. 106-112. http://dx.doi.org/10.1016/j.cie.2008.04.003

- S. Talluri and R. C. Baker, “A Multi-Phase Mathematical Programming Approach for Effective Supply Chain Design,” European Journal of Operational Research, Vol. 141, No. 3, 2002, pp.544-558. http://dx.doi.org/10.1016/S0377-2217(01)00277-6

- T. Panagiotis and G. P. Lazaros, “Optimal Production Allocation and Distribution Supply Chain Network,” International Journal of Production Economics, Vol. 111, No. 2, 2008, pp. 468-483. http://dx.doi.org/10.1016/j.ijpe.2007.02.035

- O. M. Akanle and D. Z. Zhang, “Agent Based Model for Optimizing Supplu-Chain Configurations,” International Journal of Production Economics, Vol. 115, No. 2, 2008, pp. 444-460. http://dx.doi.org/10.1016/j.ijpe.2008.02.019

- D. Goldberg, “Genetic Algorithm in Search, Optimization and Machine Learning,” Addison-Wesley, Reading, 1989.

- L. Davis, “Handbook of Genetic Algorithm,” Van Nostrand Reinhold, New York, 1991.

- A. A. Javadi, R. Farmani and T. P. Tan, “A Hybrid Intelligent Genetic Algorithm,” Journal of Advance Engineering Informatics, Vol. 19, No. 4, 2005, pp. 255-262. http://dx.doi.org/10.1016/j.aei.2005.07.003

- H. Ceylan and H. K. Ozturk, “Estimating Energy Demand of Turkey Based on Economic Indicators Using Genetic Algorithm Approach,” Journal of Energy Conversion and Management, Vol. 45, No. 15-16, 2004, pp. 2525-2537.

- L. Songsong and G. P. Lazaros, “Multi-Objective Optimization of Production, Distribution and Capacity Planning of Global Supply Chain in the Process Industry,” Journal of Omega, Vol. 41, No. 2, 2013, pp. 369-382. http://dx.doi.org/10.1016/j.omega.2012.03.007

- J. Gjerdrum, S. Nilay and G. P. Lazaros, “A Combined Optimization and Agent Based Approach to Supply Chain Modelling and Performance Assessment,” Journal of Production Planning and Control, Vol. 12, No. 1, 2001, pp. 81-88.

- L. Amodeo, H. Chen and A. El Hadji, “Multi-Objective Supply Chain Optimization: An Industrial Case Study,” Applications of Evolutionary Computing, Vol. 4448, 2007, pp. 732-741.

- Z. F. Reza and E. Mahsa, “A Genetic Algorithm to Optimize the Total Cost and Service Level for Just-in-Time Distribution in a Supply Chain,” International Journal of Production Economics, Vol. 111, No. 2, 2008, pp. 229- 243. http://dx.doi.org/10.1016/j.ijpe.2006.11.028

- A. Fulya, G. Mitsuo, L. Lin and K. Ismail, “A SteadyState Genetic Algorithm for Multi-Product Supply Chain Network Design,” Journal of Computers and Industrial Engineering, Vol. 56, No. 2, 2009, pp. 521-537 http://dx.doi.org/10.1016/j.cie.2007.05.012

- C. D’souza, S. N. Omkar and J. Senthilnatj, “Pickup and Delivery Problem Using Meta-Heuristic Techniques,” Journal of Expert System with Applications, Vol. 39, No. 1, 2012, pp. 328-334. http://dx.doi.org/10.1016/j.eswa.2011.07.022

- N. David, S. Michele, T. Biagio and K. Uzay, “Genetic Algorithms for Supply-Chain Scheduling: A Case Study in the Distribution of Ready-Mixed Concrete,” European Journal of operation Research, Vol. 177, No. 3, 2007, pp. 2069-2099.

- H. C. W. Lau, T. Chan, W. T. Tsui and W. K. Pang, “Application of Genetic Algorithm to Solve the Multi Depot Vehicle Routing Problem,” IEEE Transactions on Automation Science and Engineering, Vol. 7, No. 2, 2010, pp. 383-392. http://dx.doi.org/10.1109/TASE.2009.2019265

- A. S. Daniels and M. G. Parson, “Development of Hybrid Agent Genetic Algorithm Approach to General Arrangements,” Proceedings of Computer Applications and Information Technology in the Maritime Industries, Cortona, 2007, pp. 197-209.

- B. David, C. Dick and R. Mikael, “A Hybrid Algorithm for Distribution Problems,” IEEE Intelligent Systems, Vol. 20, No. 4, 2005, pp. 19-25. http://dx.doi.org/10.1109/MIS.2005.59

- F. Azadivar and J. Wang, “Facility Layout Optimization Using Simulation and Genetic Algorithm,” International Journal of Production Research, Vol. 38, No. 17, 2000, pp. 4369-4383. http://dx.doi.org/10.1080/00207540050205154

- Y. Shin, H. Cho and K. Kang, “Simulation Model Incorporating Genetic Algorithm for Optimal Temporary Hoist Planning in High-Rise Building Construction,” Automation in Construction, Vol. 20, No. 5, 2011, pp. 550-558. http://dx.doi.org/10.1016/j.autcon.2010.11.021

- J. Y. Yeh and W. S. Lin, “Using Simulation Techniques and Genetic Algorithm to Improve the Quality Care of a Hospital Emergency Department,” Expert System with Applications, Vol. 32, No. 4, 2007, pp. 1073-1083. http://dx.doi.org/10.1016/j.eswa.2006.02.017

- K. Shin-ike and H. Iima, “A Method for Determining Classroom Seating Arrangements by Using Genetic Algorithm,” 2011 Proceedings of SICE Annual Conference, Tokyo, 13-18 September 2011, pp. 161-166.

- L. Davis and M. Steenstrup, “Genetic Algorithm and Simulated Annealing an Overview,” Pitman, 1987.

- Z. Xin, Y. Hongnian and A. Anthony, “An Overview of Simulation in Supply Chains,” Advanced Design and Manufacture to Gain a Competitive Edge, Book Chapter 3, Springer, London, 2008, pp. 407-416.

- C. Reeves, “Modern Heuristic Techniques for Combinatorial Problems,” John Wiley & Sons, Chichester, 1990.

- J. Vaidyanathan and R. Anthony, “A Simulated Annealing Methodology to Distribution Network Design and Management,” European Journal of Operation Research, Vol. 144, No. 3, 2003, pp. 629-645. http://dx.doi.org/10.1016/S0377-2217(02)00153-4

- N. Chibeles-Martins, T. Pinto-Varela, A. P. Barbosa-Povoa and A. Q. Novais, “A Simulated Annealing Algorithm for the Design and Planning of Supply Chains with Economic and Environmental Objectives,” Computer Aided Chemical Engineering, Vol. 30, 2012, pp. 21-25. http://dx.doi.org/10.1016/B978-0-444-59519-5.50005-8

- A. D. Kathryn, S. Eric and B. Edmund, “A Simulated Annealing Based Heuristic for Determining Shipper Sizes for Storage and Transportation,” European Journal of Operation Research, Vol. 179, No. 3, 2007, pp. 759-774. http://dx.doi.org/10.1016/j.ejor.2005.03.058

- R. S. Hamid and G. Keivan, “A Simulated Annealing Approach for Multi-Periodic Rail-Car Fleet Sizing Problem,” Journal of Computers & Operation Research, Vol. 36, No. 6, 2009, pp. 1789-1799. http://dx.doi.org/10.1016/j.cor.2008.05.004

- H. Allaoui and A. Artiba, “Integrating Simulation and Optimization to Schedule a Hybrid Flow Shop with Maintenance Constraints,” Computers & Industrial Engineering, Vol. 47, No. 4, 2004, pp. 431-450. http://dx.doi.org/10.1016/j.cie.2004.09.002

- B. Suman, “Study of Simulated Annealing Based Algorithms for Multiobjective Optimization of a Constrained Problem,” Computers and Chemical Engineering, Vol. 28, No. 9, 2004, pp. 1849-1871. http://dx.doi.org/10.1016/j.compchemeng.2004.02.037

- A. Mahmoud, D. Ali, A. Ameen, A. Raid and F. M. Nishat, “Simulated Annealing for Multi Objective Stochastic Optimization,” International Journal of Science and Applied Information Technology, Vol. 2, No. 2, 2013, pp. 18- 21.

- M. Dorigo and T. Stutzle, “Ant Colony Optimization,” MIT Press, Cambridge, 2004.

- S. C. Zhan, J. Xu and J. Wu, “The Optimization Selection on the Parameters of the Ant Colony Algorithm,” Bulletin of Science and Technology, Vol. 19, No. 5, 2013, pp. 381- 386. http://dx.doi.org/10.1007/b99492

- J. Yang and Y. Zhuang, “An Improved Ant Colony Optimization for Solving Complex Combinatorial Optimization Problem,” Applied Soft Computing, Vol. 10, No. 2, 2010, pp. 653-660. http://dx.doi.org/10.1016/j.asoc.2009.08.040

- C. A. Silva, J. M. C. Sousa, T. A. Runkler and J. M. G. Sa da Costa, “Distributed Supply Chain Management Using Ant Colony Optimization,” European Journal of Operation Research, Vol. 199, No. 2, 2009, pp. 349-358. http://dx.doi.org/10.1016/j.ejor.2008.11.021

- A. Luis, M. Moncayo and Z. Z. David, “Multi-Objective Ant Colony Optimization: A Meta-Heuristic Approach to Supply Chain Design,” International Journal of Production Economics, Vol. 131, No. 1, 2011, pp. 407-420. http://dx.doi.org/10.1016/j.ijpe.2010.11.026

- Y. Wei and K. Arun, “Ant Colony Optimization for Disaster Relief Operations,” Transportation Research Part E, Vol. 43, No. 6, 2007, pp. 660-672. http://dx.doi.org/10.1016/j.tre.2006.05.004

- S. K. Chaharsooghi and A. H. M. Kermani, “An Effective Ant Colony Optimization Algorithm for Multi-Objective Resource Allocation Problem,” Journal of Applied Mathematics and Computation, Vol. 200, No. 1, 2008, pp. 167-177. http://dx.doi.org/10.1016/j.amc.2007.09.070

- T. S. C. Felix and K. Niraj, “Effective Allocation of Customers to Distribution Centres: A Multiple Ant Colony Optimization Approach,” Robotics and Computer-Integrated Manufacturing, Vol. 25, No. 1, 2009, pp. 1-12. http://dx.doi.org/10.1016/j.rcim.2007.05.002

- M. Remi, A. Jean-Paul and J. Hosang, “Ant Colony Optimization Algorithm to Solve for the Transportation Problem of Cross-Docking Network,” Computers & Industrial Engineering, Vol. 59, No. 1, 2010, pp. 85-92. http://dx.doi.org/10.1016/j.cie.2010.03.002

- A. C. Zecchin, A. R. Simpson, H. R. Maier and J. B. Nixon, “Parametric Study of an Ant Algorithm Applied to Water Distribution System Optimization,” IEEE Transactions on Evolutionary Computation, Vol. 9, No. 2, 2005, pp. 175- 191. http://dx.doi.org/10.1109/TEVC.2005.844168

- J. Kennedy and R. C. Eberhart, “Particle Swarm Optimization,” Proceedings of IEEE International Conference on Neural Networks, Perth, 27 November-1 December 1995, pp. 1942-1948. http://dx.doi.org/10.1109/ICNN.1995.488968

- K. Andreas and D. Andreas, “Facility Location Models for Distribution System Design,” European Journal of Operational Research, Vol. 162, No. 1, 2005, pp. 4-29. http://dx.doi.org/10.1016/j.ejor.2003.10.031

- W. B. Langdon and R. Poli, “Evolving Problems to Learn about Particle Swarm Optimizers and Other Search Algorithms,” IEEE Transactions on Evolutionary Computation, Vol. 11, No. 5, 2007, pp. 561-578. http://dx.doi.org/10.1109/TEVC.2006.886448

- G. Wei, K. S. Huang and Y. C. Guan, “Automation and Logistics,” IEEE International Conference on Digital Object Identifier, 2007, pp. 2830-2835.

- W. Lei and M. Fanhua, “Natural Computation,” ICNC 4th International Conference on Natural Computation, Vol. 7, Jinan, 18-20 October 2008, pp. 659-663.

- Y. J. Gong, J. Zhang, O. Liu, R. Z. Huang, H. S. H. Chung and Y. H. Shi, “Optimizing the Vehicle Routing Problem with Time Windows: A Discrete Particle Swarm Optimization Approach,” IEEE Transactions on, Systems, Man and Cybernetics-Part C: Applications and Reviews, Vol. 42, No. 2, 2012, PP. 254-267.

- Y. f. Deng and H. Q. Tong, “Dynamic Shortest Path Algorithm in Stochastic Traffic Networks Using PSO Based on Fluid Neural Network,” Journal of Intelligent Learning Systems and Applications, Vol. 3, No. 1, 2011, pp. 11-16. http://dx.doi.org/10.4236/jilsa.2011.31002

- K. C. Chilukuri and R. Prasad, “Particle Swarm Optimization Based Approach for Resource Allocation and Scheduling in OFDMA Systems,” International Journal of Communications, Network and System Sciences, Vol. 3, No. 5, 2010, pp. 466-471. http://dx.doi.org/10.4236/ijcns.2010.35062

- N. S. Fadi, I. H. Hafsa, M. N. Raja, D. Salima and S. Shaikha, “Iris Recognition Using Artificial Neural Network,” Journal of Expert System with Applications, Vol. 38, No. 5, 2011, pp. 5940-5946. http://dx.doi.org/10.1016/j.eswa.2010.11.029

- K. Mark, T. Ashutosh and M. Jörn, “A Review of Soft Computing Applications in Supply Chain Management,” Journal of Applied Soft Computing, Vol. 10, No. 3, 2010, pp. 661- 674. http://dx.doi.org/10.1016/j.asoc.2009.09.004

- S. Ihsan and G. Burckaan, “A Neural Network Model for Scheduling Problems,” European Journal of Operation Research, Vol. 93, No. 2, 1996, pp. 288-299. http://dx.doi.org/10.1016/0377-2217(96)00041-0

- A. R. Soroush, I. N. Kamal-Abadi and A. Bahreininejad, “Review on Applications of Artificial Neural Networks in Supply Chain Management and Its Future,” Journal of World Applied Sciences, Vol. 6, No. 1, 2009, pp. 12-18.

- N. Nikotan, J. Han and M. Behesthi, “Software Project Scheduling Using a Multi-Agent System,” Proceedings of 2011 8th International Conference on Information Technology: New Generations, Las Vegas, 11-13 April 2011, pp. 212-213.

- R. C. Cavalcante, I. I. Bittencourt, A. P. Da Silva, M. Silva, E. Costa and R. Santos, “A Survey of Security in Multi Agent Systems,” Journal of Expert System with Applications, Vol. 39, No. 5, 2012, pp. 4835-4846.

- K. Kyoungmin and K. Kyong Ju, “Multi-Agent-Based Simulation System for Construction Operations with Congested Flow,” Journal of Automation in Construction, Vol. 19, No. 7, 2010, pp. 867-874. http://dx.doi.org/10.1016/j.autcon.2010.05.005

- D. Perugini, S. Wark, A. Zschorn, D. Lambert, L. Sterling and A. Pearce, “Agent in Logistics Planning-Experiences with the Coalition Agent Experiment Project,” 2nd International Joint Conference on Autonomous Agents and Multi-agent Systems (AAMAS 2003), Melbourne, 14-18 July 2003.

- G. Vita and G. Janis, “Technologies and Multi-Agent System Architecture for Transportation and Logistics Support: An Overview,” International Conference on Computer Systems and Technologies-CompSysTech’ 2005, Varna, 16-17 June 2005, pp. IIIA.6-1-IIIA.6.6.

- N. Neagu, K. Dorer and M. Calisti, “Solving Distributed Delivery Problems with Agent-Based Technologies and Constraint Satisfaction Problems,” 2006.

- A. Kazemi, M. H. Fazel and S. M. Husseini, “A MultiAgent System to solve the Production-Distribution Planning Problem for Supply Chain: A Genetic Algorithm Approach,” International Journal of Advance Manufacturing Technology, Vol. 44, No. 1-2, 2009, pp. 180-193.

- J. A. Persson, P. Davidsson, S. J. Jhansson and F. Werenstedt, “Agent-Based Approaches and Classical Optimization Techniques for Dynamic Distributed Resource Allocation: A Preliminary Study,” 2003.

- H. Ahn and H. Lee, “Agent Based Dynamic Network for Supply Chain Management,” BT Technology Journal, Vol. 22, No. 2, 2004, pp. 18-27. http://dx.doi.org/10.1023/B:BTTJ.0000033467.83300.c0

- W. Y. Liang and C. C. Huang, “Agent-Based Demand Forecasting in Multi-Echelon Supply Chain,” Journal of Decision Support Systems, Vol. 42, No. 1, 2006, pp. 390- 407.

- M. Caridi and S. Cavalieri, “Multi-Agent System in Production Planning and Control: An Overview,” Journal of Production Planning and Control, Vol. 15, No. 2, 2004, pp. 106-118. http://dx.doi.org/10.1080/09537280410001662556

- F. Person, “Supply Chain Simulation: Experiences from Two Case Studies,” In: A. Verbraeck and V. Hlupic, Eds., Proceedings from the 15th European Simulation Symposium, Delft, 26-29 October 2003, pp. 399- 404.

- J. Dong, H. Ding, C. Ren and W. Wang, “IBM Mart SCORA SCOR Based Supply Chain Transformation Platform through Simulation and Optimisation Techniques,” Proceedings of the 2006 Winter Simulation Conference, California, 3-6 December 2006, pp. 650-659.

- D. R. Towill, “Supply Chain Dynamic,” International Journal of Computer Integrated Manufacturing, Vol. 4, No. 4, 1991, pp. 197-208. http://dx.doi.org/10.1080/09511929108944496

- S. Dusan, S. Nenad and B. Radenkovic, “Supply Network Modelling and Simulation Methodology,” Journal of Simulation Modelling and Practice and Theory, Vol. 17, No. 4, 2009, pp. 743-766. http://dx.doi.org/10.1016/j.simpat.2009.01.001

- E. R. Shannon, “Systems Simulation: The Art and Science,” Prentice-Hall, Upper Saddle River, 1975.

- S. G. Bell, “Simulation: A Data-Driven Tool to Lower Costs ASCET,” Vol. 4, Montgomery Research, San Francisco, 2002.

- E. J. Chen, Y. M. Lee and P. L. Selikson, “A Simulation Study on Logistic Activities in a Chemical Plant,” Journal of Simulation Modelling Practice and Theory, Vol. 10, No. 3-4, 2002, pp. 235-245.

- L. Pasquale and M. M. Rina, “Berth Planning and Resource Optimization at a Container Terminal via Discrete Event Simulation,” European Journal of Operational Research, Vol. 133, No. 3, 2001, pp. 537-547. http://dx.doi.org/10.1016/S0377-2217(00)00200-9

- H. Zhang and H. Li, “Simulation-Based Optimization for Dynamic Resource Allocation,” Automation in Constructions, Vol. 13, No. 3, 2004, pp. 409-420.

- P. Henri, B. Romain and C. Christophe, “A Continuous Simulation Approach for Supply Chains in the Automotive Industry,” Simulation Modelling Practice and Theory, Vol. 15, No. 2, 2007, pp. 185-198. http://dx.doi.org/10.1016/j.simpat.2006.09.019

- G. M. Maziar, K. Behrooz and D. Mohammad, “A Simulation Study of Logistics and Manufacturing Activities in an Automobile Supply Chain,” The 41th International Conference on Computer and Industrial Engineering, Los Angeles, 23-25 October 2011, pp. 74-80.

- F. Hanno, “Simulation of Logistics in Food Retailing for Freight Transportation Analysis,” 12th World Conference on Transport Research, Lisbon, 11-15 July 2010.

- K. S. Sanjay, M. K. Tiwari, H. D. Wan and S. Ravi, “Optimization of the Supply Chain Network: Simulation, Taguchi and Psychoclonal Algorithm Embedded Approach,” Computers and Industrial Engineering, Vol. 58, No. 1, 2010, pp. 29-39. http://dx.doi.org/10.1016/j.cie.2009.07.016

- Y. J. June, B. Gary, F. P. Jospeh, V. R. Gintaras and E. David, “A Simulation Based Optimization Approach to Supply Chain Management under Demand Uncertainty,” Computer and Chemical Engineering, Vol. 28, No. 10, 2004, pp. 2087-2106. http://dx.doi.org/10.1016/j.compchemeng.2004.06.006

- P. Dobrila, R. Rajat and P. Radivoj, “Modelling and Simulation of a Supply Chain in an Uncertain Environment,” European Journal of Operational Research, Vol. 109, No. 2, 1998, pp. 299-309. http://dx.doi.org/10.1016/S0377-2217(98)00058-7

- S. Jaroslav and P. Pavel, “Integer Simulation Based Optimization by Local Search,” Journal of Procedia Computer Science, Vol. 1, No. 1, 2010, pp. 1341-1348.

- H. Carvalho, A. P. Barroso, V. H. Machado, S. Azevedo and V. Cruz-Machado, “Supply Chain Redesign for Resilience Using Simulation,” Journal of Computers and Industrial Engineering, Vol. 62, No. 1, 2012, pp. 329-341. http://dx.doi.org/10.1016/j.cie.2011.10.003

- Y. Taejong, C. Hyunbo and Y. Enver, “Hybrid Algorithm for Discrete Event Simulation Based Supply Chain Optimization,” Journal of Expert System with Applications, Vol. 37, No. 3, 2010, pp. 2354-2361. http://dx.doi.org/10.1016/j.eswa.2009.07.039

- T. H. Truong and F. Azadivar, “Simulation Optimization in Manufacturing Analysis: Simulation Based Optimization for Supply Chain Configuration Design,” The 35th Conference on Winter Simulation: Driving Innovation, New Orleans, 7-10 December 2003, pp. 1268-1275.

- M. Rabe, F. W. Jaekel and H. Weinaug, “Reference Models for Supply Chain Design and Configuration,” Proceedings of the 38th Conference on Winter Simulation, Winter Simulation Conference, Monterey, 3-6 December 2006, pp. 1143- 1150.

- W. Xiatao, F. P. Joseph and V. R. Gintaras, “SimulationBased Optimization with Surrogate Models-Application to Supply Chain Management,” Journal of Computers & Chemical Engineering, Vol. 29, No. 6, 2005, pp. 1317- 1328. http://dx.doi.org/10.1016/j.compchemeng.2005.02.018

- N. Amalia and G. L. Marianthi, “Hybrid Simulation Based Optimization Approach for Supply Chain Management,” Journal of Computers & Chemical Engineering, Vol. 47, 2012, pp. 183-193. http://dx.doi.org/10.1016/j.compchemeng.2012.06.045

- A. A. Mohamed and M. A. Talal, “Simulation Optimization for an Emergency Department Healthcare Unit in Kuwait,” European Journal of Operation Research, Vol. 198, No. 3, 2009, pp. 936-942. http://dx.doi.org/10.1016/j.ejor.2008.10.025

- Y. Huang, Y. P. Li., X. Chen, A. M. Bao and M. Zhou, “Simulation-Based Optimization Methods for Water Resources Management in Tarim River Basin, China,” Procedia Environmental Sciences, Vol. 2, 2010, pp. 1451- 1460. http://dx.doi.org/10.1016/j.proenv.2010.10.158

- L. R. Scott, M. H. Catherine and T. T. Mark, “Optimization of Systems with Multiple Performance Measures via Simulation: Survey and Recommendations,” Computers & Industrial Engineering, Vol. 54, No. 2, 2008, pp. 327- 339. http://dx.doi.org/10.1016/j.cie.2007.07.004

- F. Marcus, H. C. N. Amos and M. Philip, “A SimulationBased Scheduling System for Real-Time Optimization and Decision Making Support,” Robotics and ComputerIntegrated Manufacturing, Vol. 27, No. 4, 2011, pp. 696- 705. http://dx.doi.org/10.1016/j.rcim.2010.12.006

- D. Berna, B. Tolga and U. A. Eren, “Simulation Optimization Based DSS Application: A Diamond Tool Production Line in Industry,” Simualtion Modelling Practice and Theory, Vol. 14, No. 3, 2006, pp. 296-312. http://dx.doi.org/10.1016/j.simpat.2005.07.001

- C. Pasquale, M. Daniele, R. Giuseppe and T. Marco, “A Dynamic Simulation Model of a Flexible Transport Services for People in Congested Area,” Procedia-Social and Behavioral Sciences, Vol. 54, No. 4, 2012, pp. 357-364.

- J. Banks, S. Buckley, S. Jain, P. Lendermann and M. Manivannan, “Panel Session: Opportunities for Simulation in Supply Chain Management,” Proceedings of the 2002 Winter Simulation Conference, IEEE, San Diego, 8-11 December 2002, pp. 1652-1658.

- C. Goldspink, “Methodological Implications of Complex Systems Approach to Sociality: Simulation as a Foundation for Knowledge,” Journal of Artificial Societies and Social Simulation, Vol. 5, No. 1, 2002, pp. 1-19.

- V. Albino, N. Carbonara and I. Gainnoccaro, “Supply Chain Cooperation in Industrial Districts: A Simulation Analysis,” European Journal of Operation Research, Vol. 117, No. 1, 2007, pp. 261-280. http://dx.doi.org/10.1016/j.ejor.2005.12.007

- B. Georgiana, “Simulation and Optimization in Supply Chain,” Journal of Procedia Economics and Finance, Vol. 3, 2012, pp. 635-641. http://dx.doi.org/10.1016/S2212-5671(12)00207-9

- C. Ye, M. Linas, O. Seza and V. R. Gintaras, “SimulationOptimization Approach to Clinical Trial Supply Chain Management with Demand Scenario Forecast,” Journal of Computers & Chemical Engineering, Vol. 40, No. 11, 2012, pp. 82-96. http://dx.doi.org/10.1016/j.compchemeng.2012.01.007

- H. L. Young, K. C. Min, J. K. Seo and B. K.Yun, “Supply Chain Simulation with Discrete-Continuous Combined Modelling,” Journal of Computers & Industrial Engineering, Vol. 43, No. 1-2, 2002, pp. 375-392.

- F. L. Zhang, D. M. Johnson and M. A. Johnson, “Development of a Simulation Model of Biomass Supply Chain for Biofuel Production,” Journal of Renewable Energy, Vol. 44, 2012, pp. 380-391. http://dx.doi.org/10.1016/j.renene.2012.02.006

- B. Daniel, L. B. Luc and A. S. Mohamed, “Discrete Event Simulation to Improve Log Yard Operations,” INFOR, Vol. 50, No. 4, 2012, pp. 175-185.

NOTES

1http://www.bergkvist-insjon.se/