Engineering

Vol. 4 No. 12A (2012) , Article ID: 26070 , 6 pages DOI:10.4236/eng.2012.412A119

Effect of the Weaving Density of Aramid Fabrics on Their Resistance to Ballistic Impacts

1R&D Center, LG Hausys, Anyang City, Korea

2Kolon Central Research Park, Kolon Industries Inc., Cumi-Si, Korea

Email: *staach@dreamwiz.com

Received August 14, 2012; revised September 16, 2012; accepted September 30, 2012

Keywords: Aramid Fiber; Fabrics/Textiles; Impact Behavior

ABSTRACT

Two Heracron® woven fabrics, HT600-1 and HT600-2, were fabricated with different weaving densities and their resistance to ballistic impact was investigated. While HT600-1 was inherently stronger along the weft than HT600-2, the latter exhibited a higher tensile strength along the warp. Crimp values indicate that HT600-1, which possesses a relatively larger weft weaving density, induces an excess in the warp crimp ratio, thereby weakening the fabric along the warp. The dimensionless fiber property U*, which is defined as the product of the specific fiber toughness and the strain wave velocity, was calculated for each fabric. The U* values of HT600-1 were lower than those of HT600-2; U* values along the warp of HT600-1 were extremely low. These analyses show that HT600-2 exhibited improved ballistic properties over those of HT600-1. These findings further indicate the existence of an optimal weave that would minimize damage to both yarn and fabric. Establishing these optimal conditions can be crucial in implementing better ballistic properties into fabrics.

1. Introduction

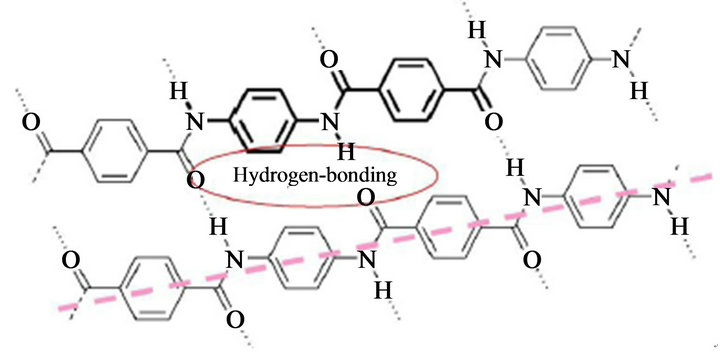

Aramid [poly(p-phenylene terephthalamide), PPTA] consists of relatively rigid polymer chains with linked benzene rings and amide bonds. This structure affords aramid fibers high tenacity, high modulus, and toughness [1-3]. Based on these merits, aramid fibers are used as ballistic materials. Figure 1 represents the chemical structure of aramid fibers.

Generally, ballistic materials can be divided into hard and soft armors [4-7]. Unlike traditional structural composites, hard armors, also known as armor-grade composites, contain only 20% by weight matrix and are made to readily delaminate. Conversely, soft armors consist of multilayered, woven textiles and are used to protect against various types of bullets.

The ability of a woven fabric to protect against bullets depends primarily on the mechanical properties of the yarn such as tenacity, tensile modulus, and toughness. However, Laible [8] demonstrated that “the relationship between the mechanical properties of a yarn and the ballistic resistance of a plied fabric from such yarn has never been established.” In other words, other factors exist that may influence ballistic performance.

Generally, the energy absorption mechanism of a fabric armor depends on several additional factors such as the weave pattern, the number of fabric plies, and weave density. Weave patterns used in ballistic applications are usually plain and basket weaves. Fabrics with unbalanced weaves typically yield inferior ballistic performance [9]. Lim et al. [10] investigated ballistic impacts on multiply systems to characterize the reinforcement effect of multiple layers. They concluded that inter-ply friction inhibited the sideways motion of the yarns, resulting in an increased resistance to ballistic penetration. Weave density, which refers to the number of yarns per unit dimension along the principal yarn directions, affects the areal density of the fabric and the crimp. Shockey et al. [11] concluded that the energy absorbed by a fabric was proportional to the fabric’s areal density. Yarn crimp refers to the degree of yarn undulation and is a property of the weave. Tan et al. [12] compared two methods of modeling crimp using empirical results. They concluded that accounting for crimp by modeling the linear elements in a zigzag manner yielded more accurate results than trying to account for crimp as a constitutive property.

However, little has been reported regarding correlations between ballistic properties and the weave pattern of aramid woven fabrics. Furthermore, a comparative study of ballistic performance has not been carried out that accounts for both fabric properties and individual yarn properties. In the current study, two types of aramid

Figure 1. The chemical structure of aramid fibers.

woven fabrics, each with a different weave density, were prepared, and the influence of weave density on their fabric properties and ballistic behavior were ascertained. This study provides fundamental information on how weave density regulates fabric properties and the ballistic behavior of aramid woven fabrics.

2. Experimental

2.1. Materials

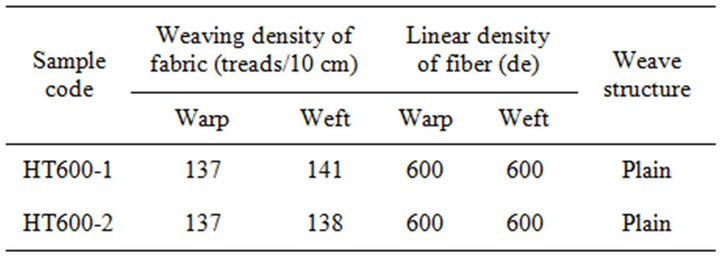

Aramid fibers (trademark Heracron®) were produced by Kolon Inc. (Kwach’on, Korea) with a fiber fineness of 600 denier. Table 1 shows some of the basic properties of Heracron® filament fibers, each composed of 665 mono-fibers. Two types of Heracron® fabrics, HT600-1 and HT600-2, were woven for ballistic tests; the physical characteristics of these fabrics are given in Table 2. While the two fabrics had the same weave structure and fiber fineness, the weaving densities were different. Relative to HT600-2, HT600-1 was woven using more weft fiber, resulting in a much higher areal density. Detailed fabric properties are discussed below.

2.2. Analysis

Filament fiber tests were performed in accordance with ASTM Standard D2256-97(ASTM 2000). Each fiber specimen had an initial length of 50 cm. At the start of the test, the middle 25 cm of the fiber spanned between the instrument grips. The crosshead separation rate was maintained at 2 mm/s and the specimen was elongated until rupture. All of the specimens were twisted at a rate of 1.2 turns/cm. The data from 20 independent measurements are expressed as an average with a single standard deviation.

Fabric tests were performed in accordance with ISO 13934-1. All sample fabrics were created from the HT600 fabrics using the ravel strip method. Each sample had an initial length of 1.2 m and a width of 50 cm. A 50 mm length at each end of each sample was clamped into

Table 1. Physical properties of Heracron® filament fibers.

Table 2. Heracron® fabric (HT600) specifications.

a constant grip. The sample was then wrapped twice around each constant grip. During each test, the load frame crosshead moved at constant rate of 2 mm/s. Samples were pulled until rupture. Twelve samples in total were tested. Six were elongated along the warp, with the weft running along the width. The other six were elongated along the weft, with the warp running along the fabric width. The percent crimp, as defined by ISO 7211- 3, was calculated as k = [(P – L)/L] × 100%, where L is the distance between two ends of the projection of a yarn onto the plane of the fabric and P is the actual length of the yarn.

Ballistic shooting tests were performed on 34-ply samples of each of the two fabrics (HT600-1 and HT600- 2) in accordance with NIJ Standard-0101.06, “Ballistic Resistance of Body Armor, Level 3A Methods.” Tests were performed with 44 Magnum semi-jacketed hollow point (SJHP) bullets with a mass of 15.6 g (240 g) impacted at a velocity of 436 ± 9 m/s (1430 ± 30 ft/s). Six bullets were shot into each sample. After shooting, the depth of the puncture and the back deformation signature (BFS) formed on the backing material were measured. All tests were conducted at H.P. White Laboratory, Inc. (Street, MD, USA).

3 Result and Discussion

3.1. Fiber and Fabric Property

Table 3 summarizes the physical properties of the HT600-1 and HT600-2 fabrics. The thickness of HT600- 1 was greater that that of HT600-2, but the fabric tensile strength, generally considered the most important fabric property, showed unusual characteristics. HT600-1 was stronger than HT600-2 along the weft, which is reasonable since HT600-1 was woven using more weft fiber, as described in the Experimental section. However, HT600- 2 boasts a higher tensile strength along the warp despite having the same warp yarn number as HT600-1.

This indicates that the fabric tensile strength is not a simple function of weaving density alone. Generally, yarn crimp refers to the degree of yarn undulation due to interlacing in the woven structure. In a plain weave, the degree of crimp is unbalanced; the warp yarns are typically more crimped than the weft. As shown in Table 3, the warp crimps of HT600-1 and HT600-2 were 4.10% and 2.96%, respectively. Increasing yarn crimp in a particular direction generally decreases fabric strength and modulus because the tensile load is initially used to de-crimp the yarn instead of extending it [13]. Thus HT600-1, which possesses a higher weft weaving density, and therefore a higher warp crimp ratio, exhibited a relatively lower tensile strength along the warp.

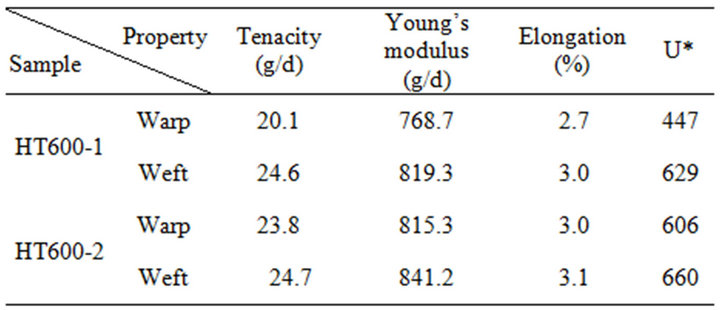

Individual yarn properties were investigated in detail by extracting warp and weft yarns8 from each fabric. Table 4 shows the physical properties of extracted warp and weft from Heracron® fabrics. The warp of HT600-1 exhibited the most damage relative to the other extracted yarns. Despite their high tensile strength, aramid fibers

Table 3. Physical properties of Heracron® woven fabrics.

Table 4. Physical properties of extracted warp and weft yarns from Heracron® fabrics.

consist of highly oriented and ordered crystalline polymer chains, resulting in a rigid structure that does not endure bending. This structural characteristic gives rise to limited lateral cohesion between the molecular chains, such as hydrogen bonds or van der Waals forces [14]. These findings indicate that highly crimped aramid fibers may be significantly weakened due to the innately weak bending properties of the material.

This phenomenon may also be explained by the weaving process used to generate the fabrics. A powerful beating motion is required to obtain the higher weaving density [13], which may damage and consequently weaken the yarn. Therefore, HT600-1, with its relatively denser weave, may absorb a considerable amount of damage during weaving, thereby weakening the fibers and the fabric itself.

The above data were used to calculate the dimensionless fiber property, U*, defined as the product of the specific fiber toughness and strain wave velocity, using the follow equation:

where δ is the fiber ultimate tensile strength, ε is the fiber ultimate tensile strain, E is the Young’s modulus, and ρ is fiber density. U* can be used to qualitatively assess the performance of fibers. Calculated U* values are given in Table 4. Note that the U* values of HT600-1 were lower than those of HT600-2. Moreover, U* along the warp of HT600-1 was extremely low. Cunnif [15] demonstrated that U* may be a major factor that relates ballistic impact performance to fiber mechanical properties, independent of other parameters such as impacting projectile mass, presented area, or armor system areal density. Although the exact relationship between the mechanical properties of a yarn and the ballistic resistance of a plied fabric from such yarn has never been established, the conclusion that the mechanical properties of the yarn would affect a fabric’s ballistic characteristics seems self-evident.

3.2. Ballistic Property

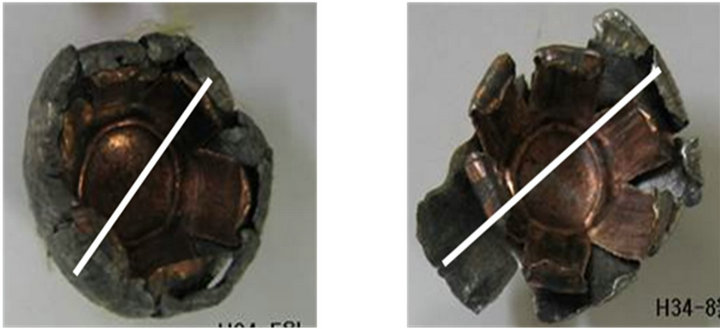

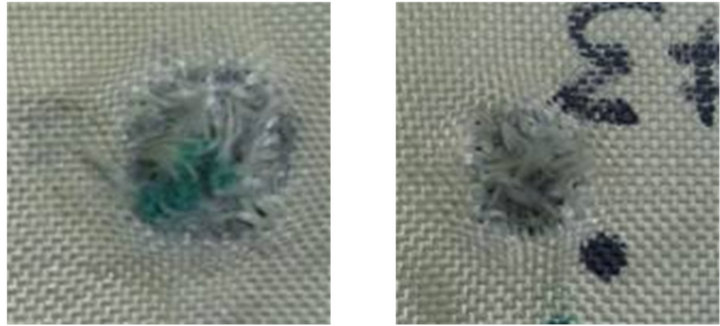

A comparison of ballistic properties can usually be made by analyzing crushed bullets retrieved from the tested fabrics. An increase in bullet diameter at the same ply may be due to a lesser degree of energy propagation and dissipation by the fabric, which would indicate inferior ballistic performance. Figure 2 shows a bottom view of crushed bullets retrieved from the seventh ply the HT600 fabrics. Note that the diameter of the bullet retrieved from HT600-2 was much wider, and the degree of squash much greater, than the bullet retrieved from HT600-1, demonstrating that HT600-2 has a better energy absorp-

tion capability and significantly better ballistic properties than HT600-1.

Figure 3 shows perforated regions in the HT-600 fabrics impacted by the projectile. More yarn was broken in the HT600-1 fabric and the perforation region was larger than that of HT600-2. Upon impaction by a projectile, fabrics generally fail through perforation mechanisms, which reflect both the energy absorption capability and the ballistic performance of the fabric. An increase in the number of broken yarns and an enlargement of perforated regions may indicate that the kinetic energy of the bullet could not be absorbed by the fabric efficiently. The results reported herein show that the kinetic energy of a bullet is more efficiently dissipated in the HT600-2 fabric, resulting in ballistic properties superior to those of HT600-1.

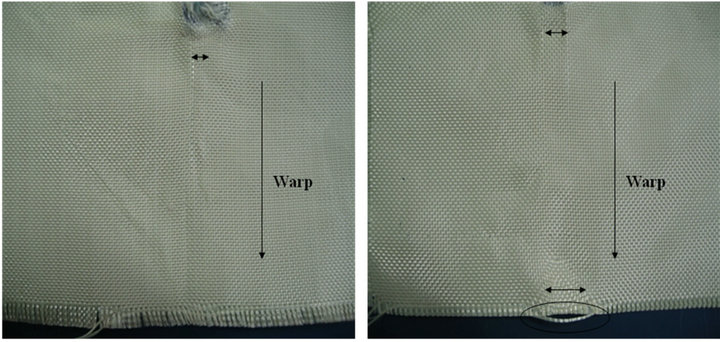

Figure 4 shows a photograph of the third ply removed from each of the HT600 fabrics; the arrow indicates warp yarns that were pulled from the fabric. Relative to HT600-1, the pull-out zone of HT600-2 was both wider and longer. In addition, a greater number of pulled-out yarns can be observed along the bottom edge. Note the more expanded shape of the entire yarn that was pulled out.

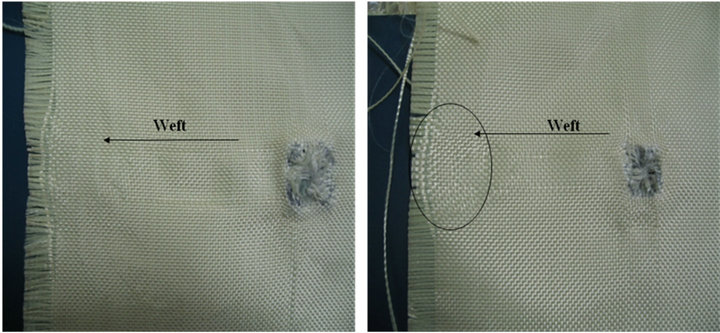

A similar phenomenon is shown along the weft in Figure 5. The pull-out zone of HT600-2, where weft yarns were loaded by the bullet, shows much more distinct shapes than HT600-1. Impact energy is dissipated through yarn pullout, a consequence of yarn stretching. The pullout zone is cross-shaped, the center being the impact point [16]. The high bullet resistance of a fabric is caused by the pulling-out of yarns impacted by the bullet. In these zones, bullet energy is transferred to the fibers and the amount of energy transferred to the fabric layer increases with increasing length and width of the pull-out zone as the bullet decelerates. This indicates that HT600- 2 possesses a higher capacity for impact energy than HT600-1.

When a woven fabric is subjected to a ballistic impact, it is deformed both vertically and horizontally by the kinetic energy of the bullet. The initial deformation at the

(a)HT600-1 (b)HT600-2

Figure 3. Perforated regions of two HT-600 fabrics impacted by the projectile.

(a)HT600-1 (b)HT600-2

Figure 4. Photograph of the third layer taken out of the two HT600 fabrics (warp direction).

(a)HT600-1 (b)HT600-2

Figure 5. Photograph of the third layer taken out of the two HT600 fabrics (weft direction).

site of impact spreads outward as long as the bullet’s speed is not sufficient to allow penetration of the fabric. Under these circumstances, the kinetic energy of the bullet will be completely absorbed by the fabric. However, at a high enough velocity, the bullet will pass through the fabric. Differences in the tension of warp and weft yarns during the weaving process result in different crimp values for the warp and weft [13]. Consequently, the weft crimp is generally lower than the warp crimp.

The yarn crimp of a fabric is important in impact loading since the initial stage of fabric deformation is the straightening of crimped yarns. Weft yarns typically break preferentially during ballistic impacts since warp yarns require more time to de-crimp and elongate prior to failure [17]. Therefore, ideal fabrics for ballistics applications would be manufactured with equal crimp in the weft and warp such that yarns in both directions are equally loaded during projectile impact, resulting in a higher energy-absorption capability. The two types of HT600 fabrics evaluated herein were woven with the same weave structure and fiber fineness, differing only with regard to fabric density. The difference in crimp between the warp and weft is much less in HT600-2, allowing more uniform deformation along the warp and weft, a higher degree of energy absorption, and more efficient dispersion of kinetic energy during ballistic impacts. This conclusion is consistent with the perforated regions discussed above. Figure 6 shows a mimetic diagram of this phenomenon.

Table 5 summarizes the ballistic properties of the two Heracron® woven fabrics. Generally, the deformation of a ballistic armor during impact can be assessed by measuring the back deformation signature (BFS) [18]. Note that the thickness of HT600-1 is greater than that of HT600-2, even with the same ply number. This may be attributable to the high crimp of HT600-1, which results in a coarser, thicker fabric. Fabrics for ballistic applications generally require multiple plies, which are in contact with one another to achieve the desired level of ballistic resistance; additional plies increase the capacity for impact energy absorption. In addition, the areal density of HT600-1 is greater than that of HT600-2. Therefore, HT600-1 was expected to have a lower BFS value than HT600-2. However, the data in Table 5 show that the BFS of HT600-1 was deeper than that of HT600-2, indicating that the kinetic energy of the bullet was not efficiently propagated over a large area of the fabric.

Table 5. Ballistic properties of Heracron® woven fabrics.

(a)HT600-1 (b)HT600-2

Figure 6. Mimetic diagrams of kinetic energy absorption and dispersion by a fabric.

The energy absorption characteristics of a fabric system under ballistic impact depends on many factors, including the material properties of the constituent fibers, the woven structure of the fabric, the projectile geometry, the impact velocity, the number of plies, and the far-field boundary conditions. In the current study, all of these parameters were held constant with the exception of woven density. Increasing the fabric thickness and areal density was observed to enhance the ballistic properties of the fabric, while increasing the dimensionless fiber property, U*, and the crimp ratio yielded lower impact resistance due to the extreme weaving conditions and the innate properties of the aramid fibers. The results given herein suggest that the lower ballistic resistance of HT600-1 may be interpreted as interplay between the latter two parameters, which more strongly affect ballistic performance than the thickness and the areal density. In summary, an optimal weave exists that will minimize damage to both yarn and fabric during a ballistic impact. Establishing this optimal weave is the key to optimizing the ballistic properties of any given fabric.

4. Conclusions

Two Heracron® woven fabrics with different weaving densities were assessed for their resistance to ballistic impact. The results may be summarized as follows:

a) HT600-1 was stronger along the weft than HT600-2. In contrast, HT600-2 exhibited a higher tensile strength along the warp. HT600-1, which possessed a greater weft weaving density, also exhibited a higher warp crimp that resulted in a deterioration of tensile strength along the warp.

b) Values of U*, a dimensionless product of the specific fiber toughness and strain wave velocity, were lower for HT600-1 than for HT600-2, especially along the warp HT600-1.

c) HT600-2 exhibited enhanced ballistic properties over those of HT600-1. In addition, the results given in the present study suggest the existence of an optimal weave that would minimize damage to both yarn and fabric during a ballistic impact.

REFERENCES

- H. H. Yang and K. A. Fiber, “Aramid Fiber,” John Wiley & Sons Ltd., Chichester, 1993.

- P. J. de Lang, P. G. Akker, E. Mäder, S. L. Gao, W. Prasithphol and R. J. Young, “Controlled Interfacial Adhesion of Twaron® Aramid Fibers in Composites by the Finish Formulation,” Composites Science and Technology, Vol. 67, 2007, pp. 2027-2035. doi:10.1016/j.compscitech.2006.11.018

- Y. Rao, A. J. Waddon and R. J. Farris, “The Evaluation of Structure and Properties in Poly(p-phenylene terephthalamide) Fibers,” Polymer, Vol. 42, No. 13, 2001, pp. 5925-5935. doi:10.1016/S0032-3861(00)00906-X

- C. Y. Yue and K. Padmanabhan, “Interfacial Studies on Surface Modified Kevlar Fibre/Epoxy Matrix Composites, ” Composite Part B, Vol. 30, No. 2, 1999, pp. 205- 217. doi:10.1016/S1359-8368(98)00053-5

- T. K. Lin, S. J. Wu, J. S. Lai and S. S. Shyu, “The Effect of Chemical Treatment on Reinforcement/Matrix Interaction in Kevlar-Fiber/Bismaleide Composites,” Composites Science and Technology, Vol. 60, 2000, pp. 1873- 1878. doi:10.1016/S0266-3538(00)00074-9

- M. Kawagoe, M. Takeshima, M. Nomiya, J. Qiu, M. Morita, W. Mizuno and H. Kitano, “Microspectroscopic Evaluations of the Interfacial Degradation by Absorbed Water in a Model Composite of an Aramid Fibre and Unsaturated Polyester,” Polymer, Vol. 40, No. 6, 1999, pp. 1373-1380. doi:10.1016/S0032-3861(98)00371-1

- R. Park and J. S. Jang, “Impact Behavior of Aramid Fiber/ Glass Fiber Hybrid Composites: The Effect of Staking Sequence,” Colloid & Polymer, Vol. 22, 2001, pp. 80-89. doi:10.1002/pc.10519

- R. C. Laible, “Fibrous Armor,” In: R. C. Laible, Ed., Ballistic Materials and Penetration Mechanics, Elsevier Scientific Publishing Co., New York, 1980. doi:10.1016/B978-0-444-41928-6.50009-0

- P. M. Cunniff, “An Analysis of the System Effects in Woven Fabrics under Ballistic Impact,” Textile Research Journal, Vol. 62, No. 9, 1992, pp. 495-509.

- C. T. Lim, V. B. C. Tan and C. H. Cheong, “Perforation of High-Strength Double-Ply Fabric System by Varying Shaped Projectiles,” International Journal of Impact Engineering, Vol. 27, 2002, pp. 577-591. doi:10.1016/S0734-743X(02)00004-0

- D. A. Shockey, D. C. Erlich and J. W. Simons, “Improved Barriers to Turbine Engine Fragments: Interim Report III,” Report No. DOT/FAA/AR- 99/8, III, 2004.

- V. C. Tan, V. P. W. Shim and X. Zeng, “Modeling Crimp in Woven Fabrics Subjected to Ballistic Impact,” International Journal of Impact Engineering, Vol. 32, 2005, pp. 561-574. doi:10.1016/j.ijimpeng.2005.06.008

- S. Adanur, “Handbook of Weaving,” CRC Press, Boca Raton, 2001.

- M. G. Dobb, D. J. Johnson and B. P. Saville, “Compressional Behaviour of Kevlar Fibres,” Polymer, Vol. 22, 1981, pp. 960-965. doi:10.1016/0032-3861(81)90276-7

- P. M. Cunniff, “Dimensionless Parameters for Optimization of Textile-Based Body Armor Systems,” Proceedings of the 18th International Symposium on Ballistics, San Antonio, 1999, pp. 1303-1310.

- S. Bazhennov, “Dissipation of Energy by Bullet Proof Aramid Fabric,” Journal of Materials Science, Vol. 32, No. 15, 1997, pp. 4167-4173. doi:10.1023/A:1018674528993

- A. Tabiei and G. Nilakantan, “Ballistic Impact of Dry Woven Fabric Composites: A Review,” Applied Mechanics Reviews, Vol. 61, No. 1, 2008, pp. 4567-4582. doi:10.1115/1.2821711

- H. L. Gower, D. S. Cronin and A. Plumtree, “Ballistic Impact Response of Laminated Composite Panels,” International Journal of Impact Engineering, Vol. 35, 2008, pp. 1000-1008.

NOTES

*Corresponding author.