Advances in Chemical Engineering and Science

Vol.3 No.4(2013), Article ID:37615,9 pages DOI:10.4236/aces.2013.34029

Evaluation of Methane Yield on Mesophilic-Dry Anaerobic Digestion of Piggery Manure Mixed with Chaff for Agricultural Area

1Department of Environmental and Chemical Engineering, Seonam University, Namwon, Republic of Korea

2Department of Environmental Engineering, Chonbuk National University, Jeonju, Republic of Korea

3Yoyo Korea Agricultural Association, Jeongehb, Republic of Korea

4Clinical Trial Center for Functional Foods, Chonbuk National University Hospital, Jeonju, Republic of Korea

5Department of Medical Nutrition Therapy, Chonbuk National University, Medical School, Jeonju, Republic of Korea

Email: *swchae@jbctc.org

Copyright © 2013 Dong-Heui Kwak et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received June 4, 2013; revised July 4, 2013; accepted July 14, 2013

Keywords: Anaerobic Digestion; Methane; Chaff; Biogas; Piggery Manure

ABSTRACT

A mesophilic-dry anaerobic digestion process is valid in treating high-concentration substrates containing low moisture content. It has merits of lower wastewater discharge and lower heat capacity required in maintaining reactor temperature as compared with a thermophilic-wet anaerobic digestion process. In fact, chaff can be easily obtained in farming areas and used as a mixture substrate as one of bulking agents for controlling moisture and supplying carbon. For this reason, this study applies the chaff to improve livestock manure, which contains high moisture content and is discharged from domestic pig farms. This study aims at verifying its feasibility for improving methane production efficiency on a basis of BMP (Biochemical Methane Potential) assay obtained through a series of experiments. Finding results were methane gas production and gas production per volatile solid (VS) added, and methane gas production among biogas production were increased as the chaff added in the piggery manure was increased. According to experimental results for improving the methane production efficiency, mixture of the chaff and the piggery manure played an important role in controlling the moisture content and improving the methane gas production rate, and also verified its feasibility in the mesophilic-dry anaerobic digestion process indicating relatively less difficulty for operation and management.

1. Introduction

A methane fermentation process has an advantage in treating organic contaminants for preventing environmental pollution when comparing a conventional aerobic treatment process. Naturally, the methane fermentation process has a combination limit of processes but it is relatively useful in aspects of energy production and resource collection. The methane fermentation process such as an anaerobic digestion process is a skill studied and used for a long time and is recently being magnified in a situation as an international concern focusing on climate change control and renewable energy demand. Especially, a biogas plant, one of the methane fermentation skills, has been used in many countries and known as one of effective strategy techniques for bio-fuel production [1].

Domestic livestock manure emission classified by livestock types has a component ratio as follows; 57.6% piggery manure (740,000 m3/d) and 42.4% cow manure (540,000 m3/d) [2], and dairy cow manure of the cow manure is emitted in the overcrowded area such as farms but few Korean native cattle are raised in small farmers and there are many bad cases in collecting and in treating Korean native cattle manure. The organic content is a raw matter to produce the methane and exists in the piggery manure as low as 2% to 5%. Thus, utilization of the piggery manure as a substrate is low and also it is known well that a stable operation of an anaerobic digestion tank is difficult because a fluctuation range of the organic content is large periodically and the moisture content is high enough [3].

The anaerobic digestion process is divided into a wet process and a dry process according to solid content or moisture content of the substrate used. Until the mid- 1980s, the wet process has been mainly applied in the field using waste matters within 10% solid content as the substrate. With EU as the center rapidly from the 1990s, however, the dry process has been developed to digest organic waste matters containing the solid content over 20% [4]. In treating the high-concentration substrate having low moisture content, the dry process requires low heat capacity to maintain the reactor temperature and discharges low wastewater after treatment [5]. However, it is not valid to put the livestock manure into the dry process directly because the livestock manure emitted from domestic piggery farms contains a great deal of moisture and the solid content of the livestock manure is very low. Meanwhile, the bulking agents such as rice straws, chaff, dead leaves fragments, sawdust, etc. are easy to obtain in the farm area and such agricultural byproducts have been used as the bulking agent for composing manure from old times and also as the carbon supplement for maintaining the proper C/N ratio. Practically, most of domestic livestock farms are located in the farming settlement that is producing a great deal of the bulking agent. In adopting the biogas plant in the domestic farming areas, the dry anaerobic digestion process is in a more advantageous situation than the wet process when considering realistic conditions, In Europe recently, studies on the dry digestion operation for the municipal organic solid waste are actively proceeding to reduce waste amounts for landfill and to produce the bio-energy [6,7]. However, previous studies mainly present that the operation results for high temperature (50˚C - 60˚C) conditions and continuous operation cases are also pretty rare [8].

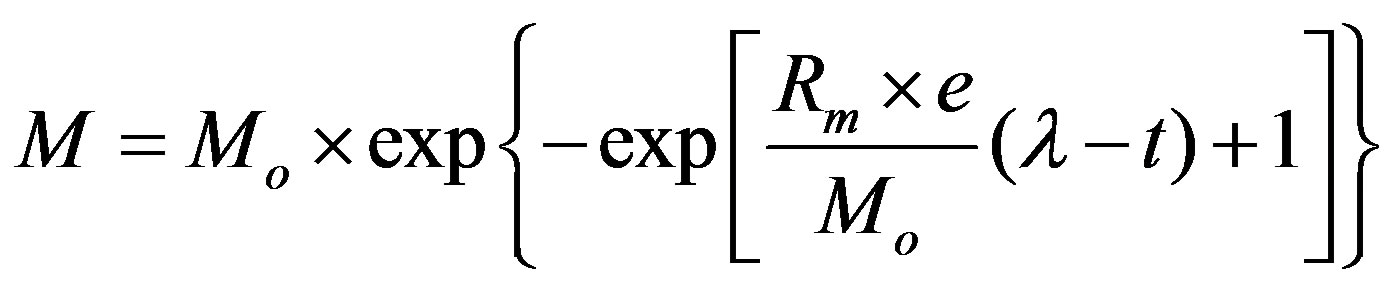

To analyze the ultimate methane production rate (mL/gVSadded) caused by organic matters as the substrate for the anaerobic digestion process, it measures the methane amounts produced during the anaerobic batch incubation period and cumulative methane formula can be used to determine the methane production yield based on the observed data. Representative models such as Modified Gompertz model or Exponential model are used to analyze experiment data obtained through the methane production potential test [9,10]. Using those models described in Equations (1) and (2) as below, comparative studies are variously proceeding to determine the ultimate methane production yield of the substrates related to diverse components [11,12].

Modified Gompertz Model Equation [13]:

(1)

(1)

where, M: cumulative methane production yield (mLCH4/g-VS)

t: incubation time of an anaerobic digestion tank (days)

Mo: ultimate methane production yield (mL-CH4/g-VS)

Rm: maximum methane production rate (mL-CH4/gVS·day)

e: exp (1) = 2.71828182

λ: lag phase, days Exponential Model Equation:

(2)

(2)

where, B: cumulative methane production yield (mLCH4/g-VS)

t: incubation time of an anaerobic digestion tank (days)

Bo: ultimate methane production yield (mL-CH4/g-VS)

k: 1st order reaction rate constant (day−1).

With the purpose of energy resource recovery through the methane production due to the piggery manure in the farming area, this study conducts a series of experiments with the dry anaerobic digestion using the chaff. The chaff is easily obtained in the farming area as one of the byproducts and as the substrate to mix with the manure as well as to control the moisture. The anaerobic digestion has been conducted in the single-phase mesophilic condition, BMP (biochemical methane potential) assay has been applied to estimate the methane production potential due to the several mixture ratios between the piggery manure and the chaff based on the experimental results, and this study has been accomplished to find a way to improve the methane production efficiency.

2. Materials and Methods

2.1. Experimental Equipments and Operation Conditions

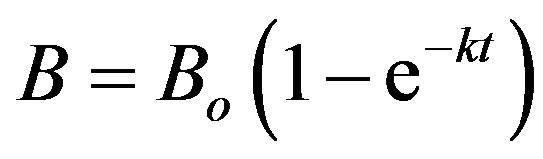

In experiments, a batchwise reactor of methane yield is prepared for single-phase anaerobic digestion as shown in Figure 1. For a dry methane production process of livestock manure as a main substrate, typical experimental conditions were adopted to examine gas production yield and responses characteristics. Experiments were set up to control pH if necessary and to incubate for 40 days as controlling to keep typical temperature for mesophilic digestion in a range of 35˚C ± 1˚C [14], and an additional agitator was excluded in the experiments.

Figure 1 describes a schematic diagram of a batchwise single phase digester for methane yield. 0.5 L serum bottles were set up to an incubator at a constant temperature. Operation conditions were monitored for every serum bottle in different mix proportions between piggery manure as a main substrate and chaff as a mixture substrate to control the moisture. Major items such as pH change and the gas production yield from the serum bottle were monitored due to each condition. The operator also

Figure 1. Schematic diagram of batchwise single phase digester for methane yield.

measured generating-capacity and methane content in gas collected in a teflon bag through an exhaust pipe in the middle of a gas-tight rubber stopper of the serum bottle at a constant time interval, every 3 days. Additionally, taking small amounts from all of samples and putting them into each 50 mL-tube, the operator measured its weight per VS (volatile solid) changed with operating under the same conditions.

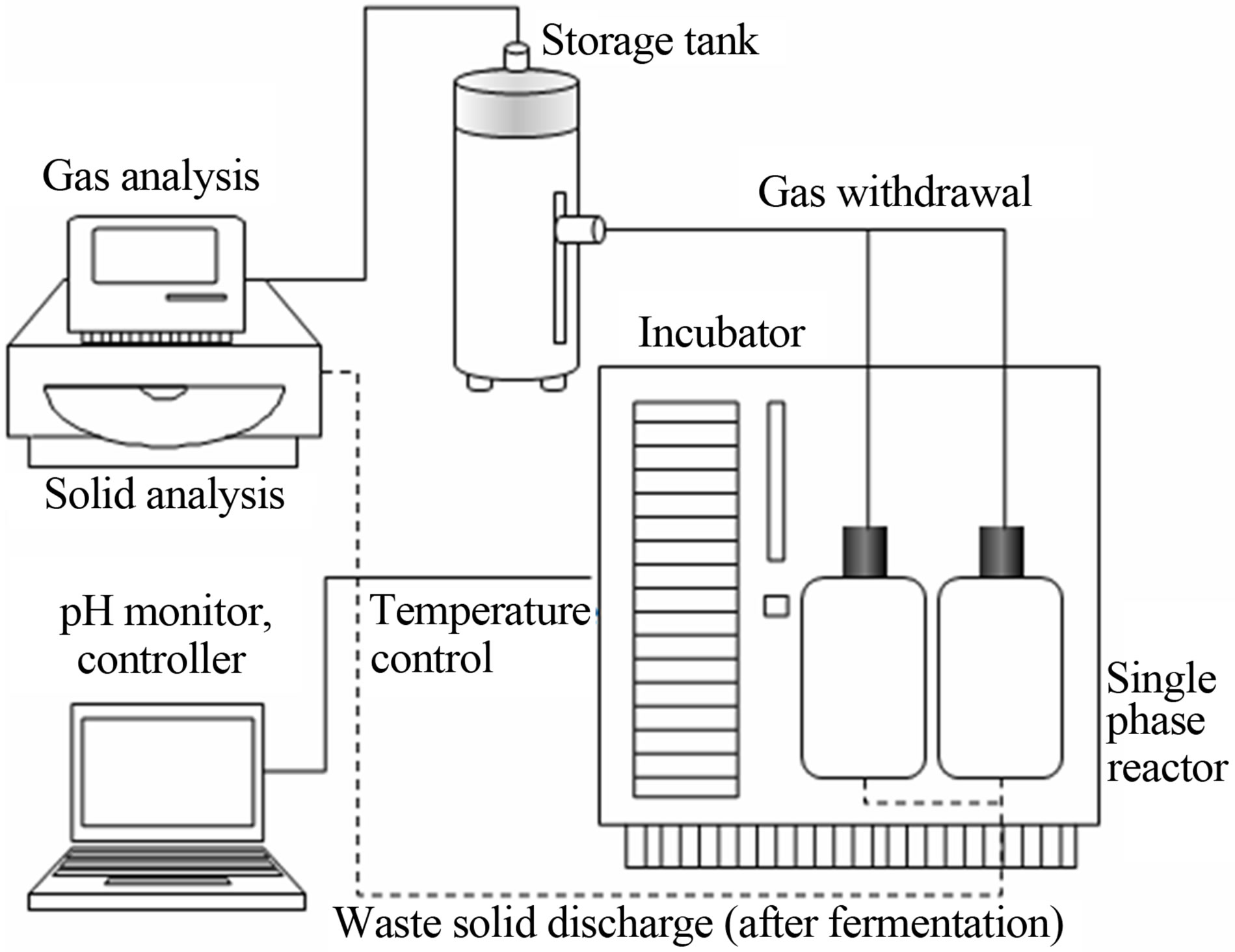

Table 1 presents operation conditions and a substrate composition in the single phase digester. For two operation parameters such as the substrate concentration and the solid content, the methane production was estimated in different mixing ratios between the piggery manure and the chaff. All samples except a control group (marked as Run 1) were added trace elements in order to minimize unstable effects of microbial growth due to lack of essential elements in the anaerobic digester.

2.2. Sample and Analysis Method

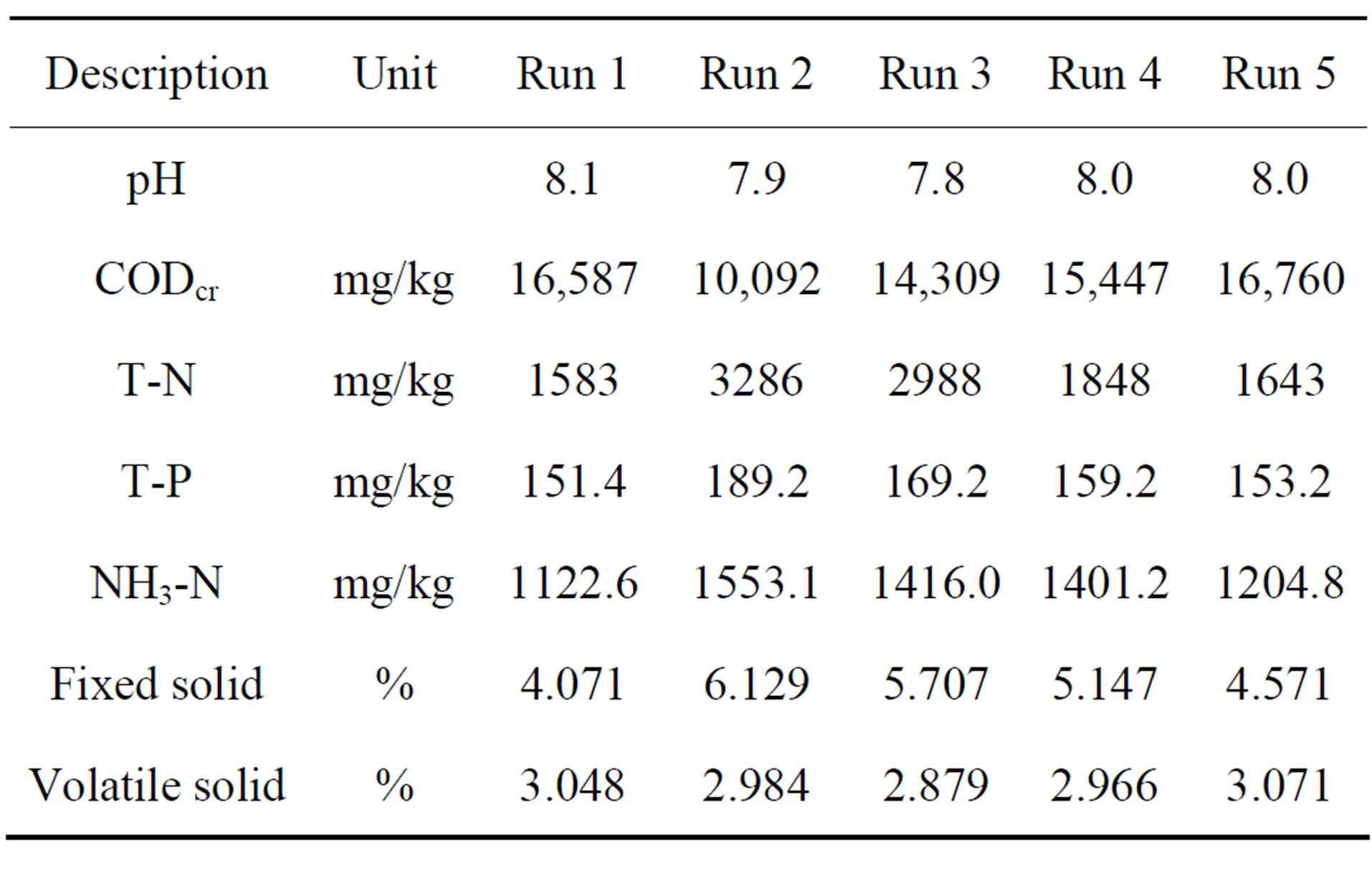

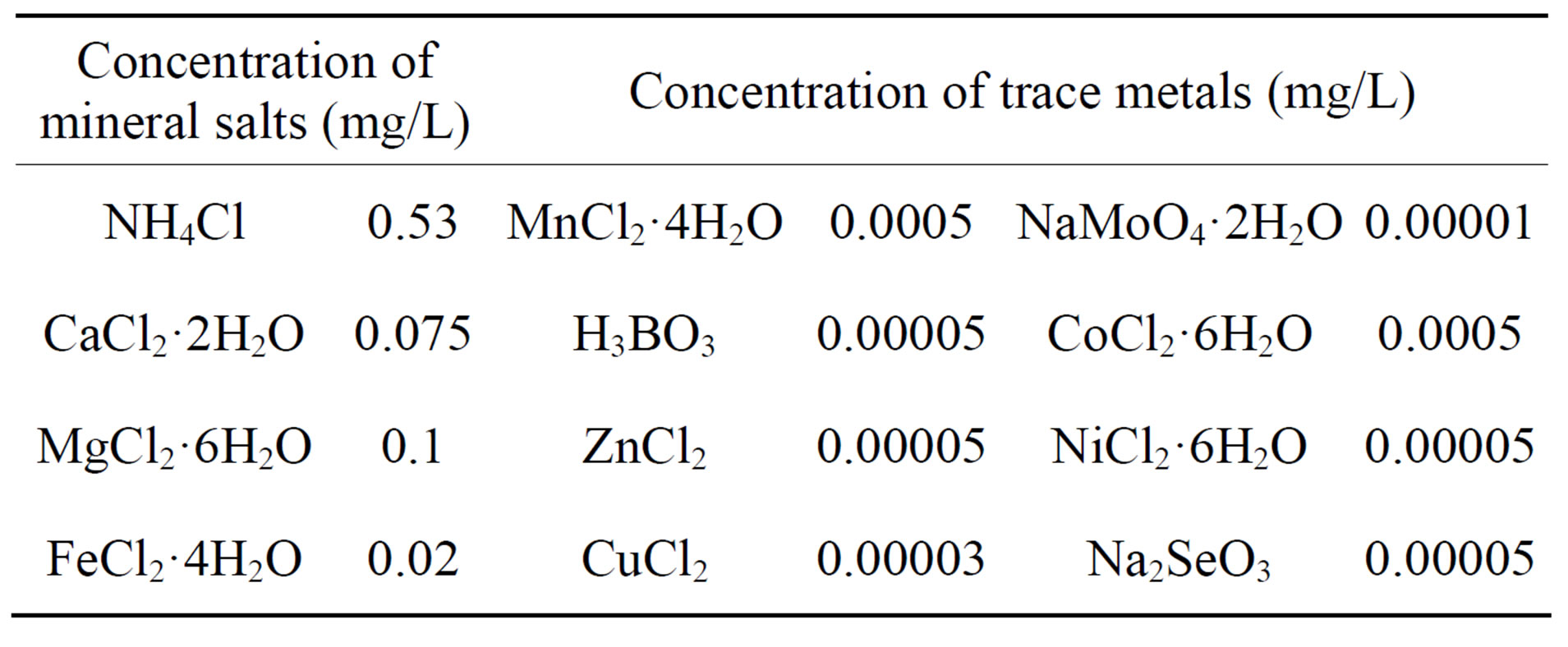

Livestock manure has been concerned in domestic water management as a non-point source. Among the livestock manure, piggery manure is newly applied as a main substrate for methane production. To improve the methane production, chaff in powder form (below than 100 mesh) is also mixed with the piggery manure to control the moisture as well as to improve the methane production. Major properties of the piggery manure are shown in Table 2 and chemical properties of all samples (Run 1 - Run 5) are described in Table 3. Also, Table 4 presents trace elements (mineral salts and trace metals) added for the safe operating condition. Water quality and solid matters were analyzed by the standard method (2005) in this study.

The piggery manure samples were collected in the retaining tank for gathering and mixing the manure of the pigsty before inputting washing water of a pig farm.

Table 1. Operation condition and substrate composition of single phase digester.

Note: *Converted value into concentration.

Table 2. Chemical composition of piggery wastewater used as main substrate in this study.

Table 3. Chemical composition of experimental substrates (mixture of piggery manure and chaff).

Characteristics of target wastewater compiled from the piggery farm were indicated high pH around 8.7 and high alkalinity about 5800 mg/L as CaCO3, which were typical in the livestock wastewater. The wastewater was measured in BOD (2205 mg/L) and TCODCr (2221 mg/L) and contained soluble CODCr ratio around 50.7%. Total solid concentration was 0.92% with 99.1% water content and the solid consisted of VS (35.9%) and inorganic solid (64.1%). Fraction of nutrients compared with the organic was as follows; COD:NH3-N:PO43−-P = 51.7:30.3:1.0.

Table 3 describes chemical compositions of experimental substrates in five different sample groups from Run 1 to Run 5 classified by different mixing ratios between the piggery manure and the chaff at identical conditions. The solid content was ranged from 27.2% to 35.4% and CODcr was distributed from 10.092 mg/L to 16,760 mg/L. Ratios of the organic matter and nutrients (COD:T-N:T-P) for the sample groups (Run 1 - Run 5) were 109.6:10.5:1, 53.3:17.4:1, 84.6: 17.7:1, 97.0:11.6:1, and 109.4:10.7:1, respectively.

2.3. BMP Assay

A BMP (biochemical methane potential) assay was developed by Owen et al. [10] to evaluate potential efficiency for biodegradability of target livestock manure in

Table 4. Composition of mineral salts and trace metals.

an anaerobic process and it was analyzing organic concentration converted into CH4. In this study, a serum bottle was filled with a target sample, covered with a butyl rubber septum, sealed with a reinforced plastic lid, and kept in an incubator at a constant temperature 35˚C to induce anaerobic degradation. Gas producing capacity and its composition were analyzed every time interval and then a methane production rate was recorded. The control group (Run 1) was examined under the same conditions to modify other gas capacity and other effects occurred from the target experimental samples. Unlike the target experimental groups, the control group did not add trace elements consisting of mineral salts and trace metals. The gas producing capacity was measured using a glass syringe in the constant time interval and the methane production rate was analyzed using Gas Chromatography-Mass Spectrometer, GC-MS (6890 N Network GC system).

3. Result and Discussion

3.1. Experimental Result of Dry Mix Digestion

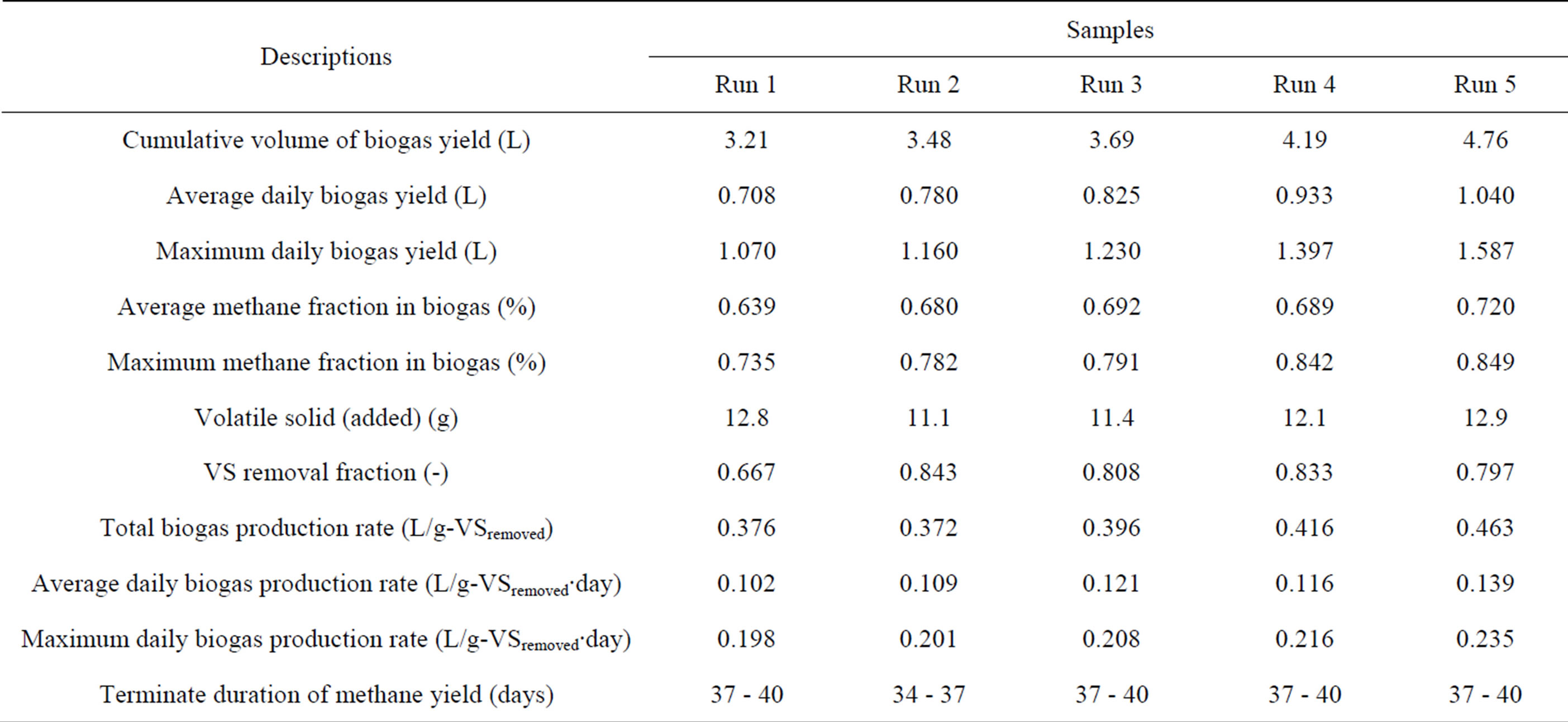

Piggery manure has had a difficult time in proceeding wet anaerobic digestion because of its high moisture content. For improving the anaerobic digestion of the piggery manure, it may be mixed with chaff obtained easily in farming areas. Table 5" target="_self"> Table 5 presents main experimental results of gas production and methane yields through 40 days digestion operating period for five sample groups.

In anaerobic degradation reactions of organic matters, substrate concentrations and physical and chemical compositions can affect on a reaction rate of hydrolysis

Table 5. Experiment results of methane yields for five types of mixed substrates.

and acid formation. Hence, this experiment set an equal amount of the livestock manure for all of samples to prevent the methane production rate from reducing.

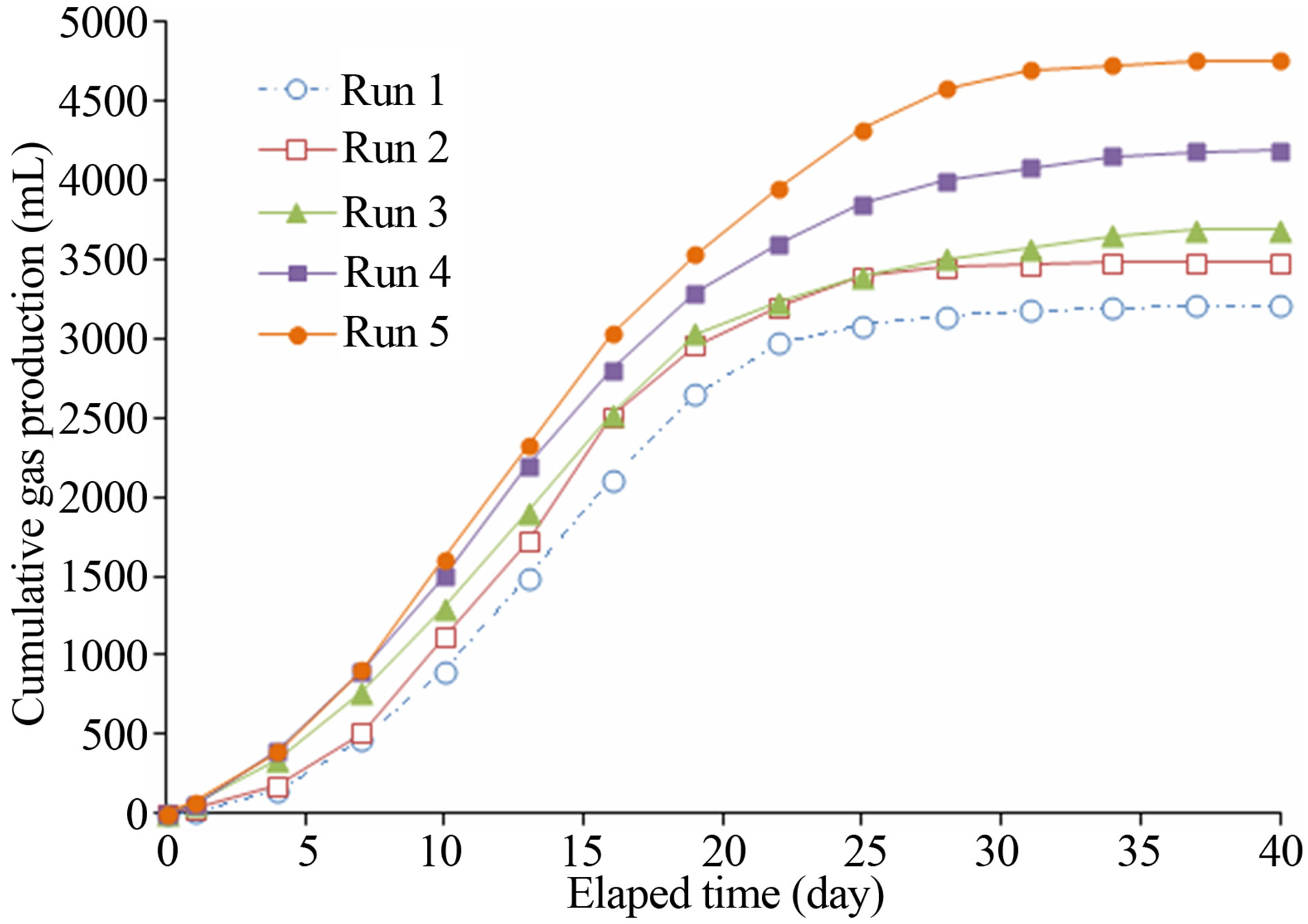

For considering the biogas production as shown in Table 5, total gas production and the gas production yield per VS added were also increased when the more chaff was mixed with the piggery manure. As mentioned above, the methane gas fraction in the biogas swung upward as the more chaff was added in the mixture. The addition of the chaff obviously improved the methane production rate and reduced the moisture content. In Figure 5, Run 1 and Run 2 used the constant mix proportion of the chaff but Run 1 without the trace elements produced less gas amounts compared to Run 2.

VS removal efficiency was estimated depending on measurement results of VS change amounts and was distinct from the change of the gas production yield. Although the VS was measured for the same sample under the identical conditions, in fact, there was a limitation in conforming tiny change of weight when the 0.5 L-serum bottle was measured directly. Thus, it may be possible to have some error because this study has measured a 0.05 L-additional container at the constant time interval.

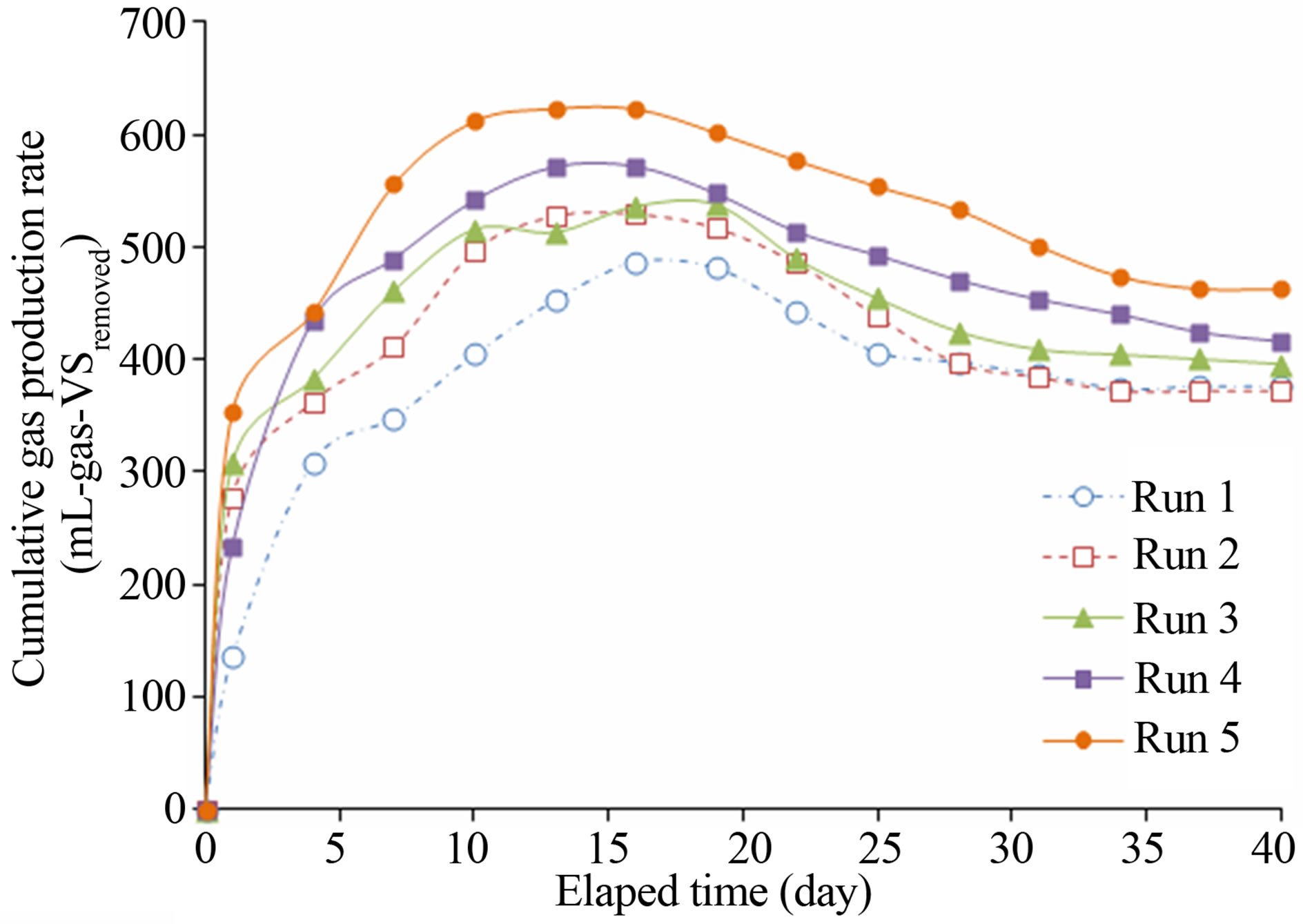

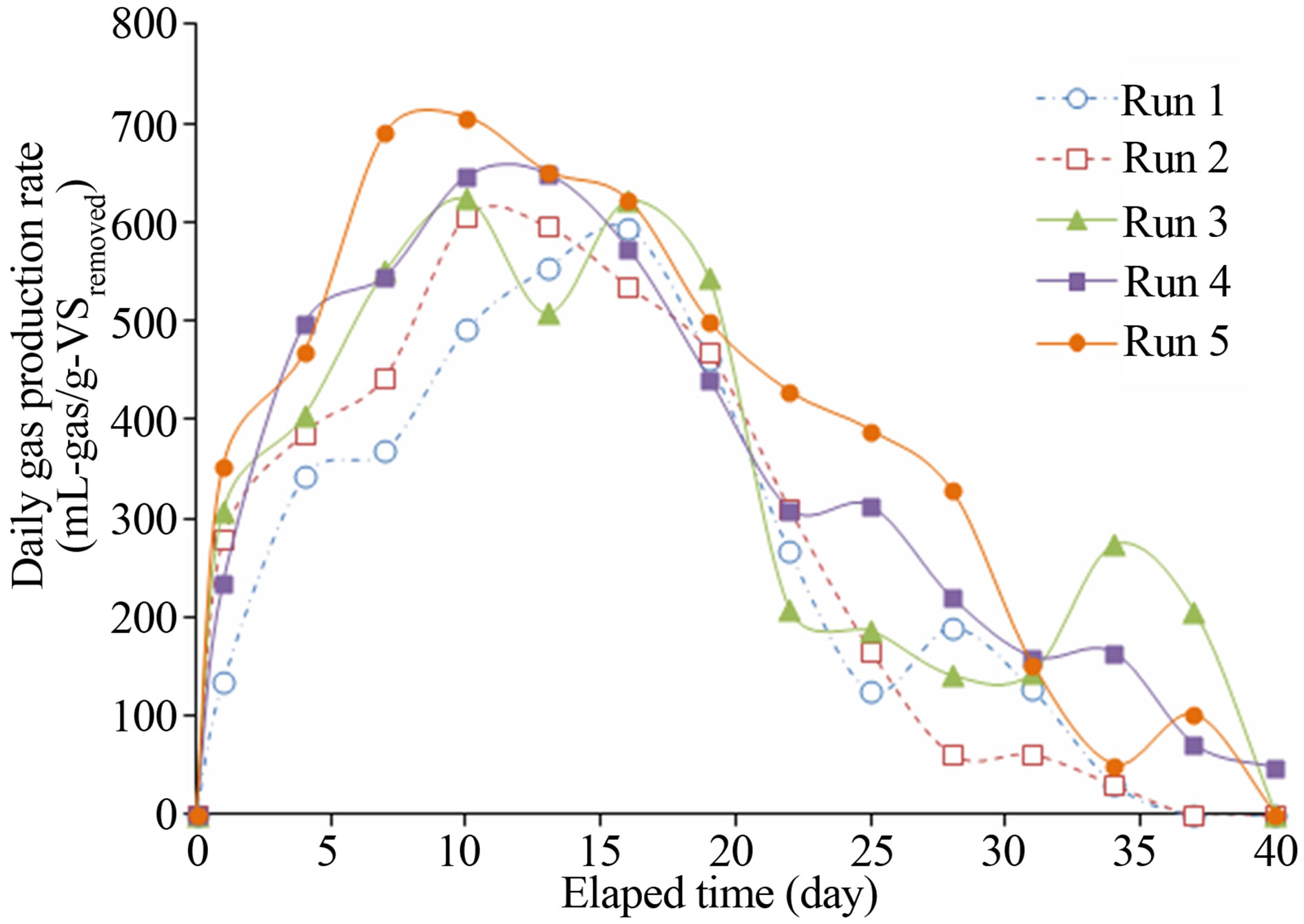

Figure 2 indicates cumulative gas production rates of five sample groups for the digestion period. A large amount of gas was produced when the large amount of the chaff was added. Also, the daily gas production rate was slightly rapid at the sample group with the large amount of the chaff as shown in Figure 3 and a maximum gas production peak was appeared at 10 - 15 days after the digestion was started. Therefore, the sample group with the larger chaff content indicated the more gas production yield and the faster gas production rate, and the earlier maximum gas production peak.

3.2. Ultimate Methane Productivity Evaluation

Theoretical total methane productivities of piggery ma-

Figure 2. Comparison of cumulative gas yield from five types of samples.

(a)

(a) (b)

(b)

Figure 3. Distribution of gas production rate from five types of samples (3 days period). (a) Cumulative gas production rate; (b) Daily gas production rate.

nure (516 L/g-VS by the hog and 530 L/g-VS by the sow) were higher than those of the cow manure (469 L/g-VS). The ultimate methane yield was in order as follows; 356 L/g-VS by the hog, 275 L/g-VS by the sow, and 148 L/g-VS by the milk cow. Also, the straw and the chaff were known to have much more methane yields as compared with the animal manure [15].

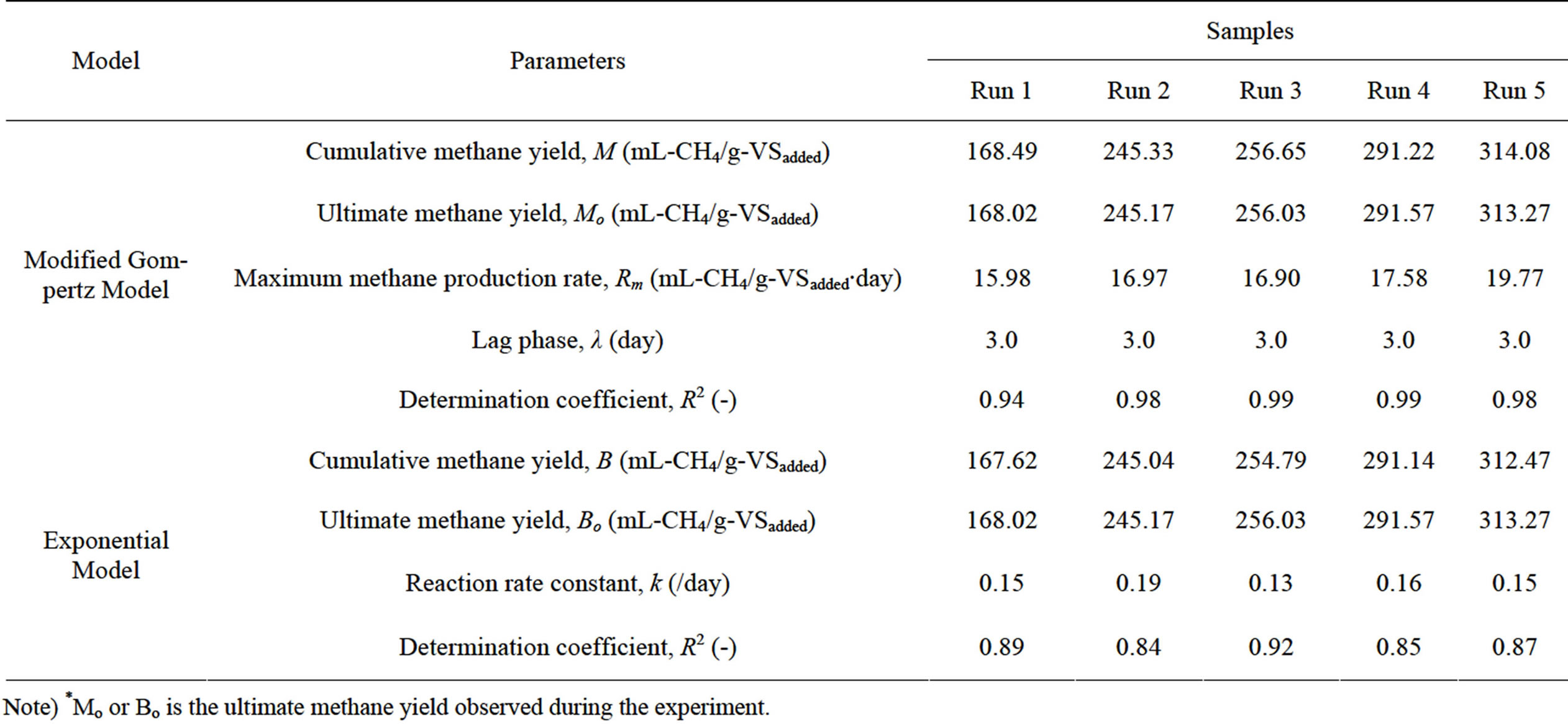

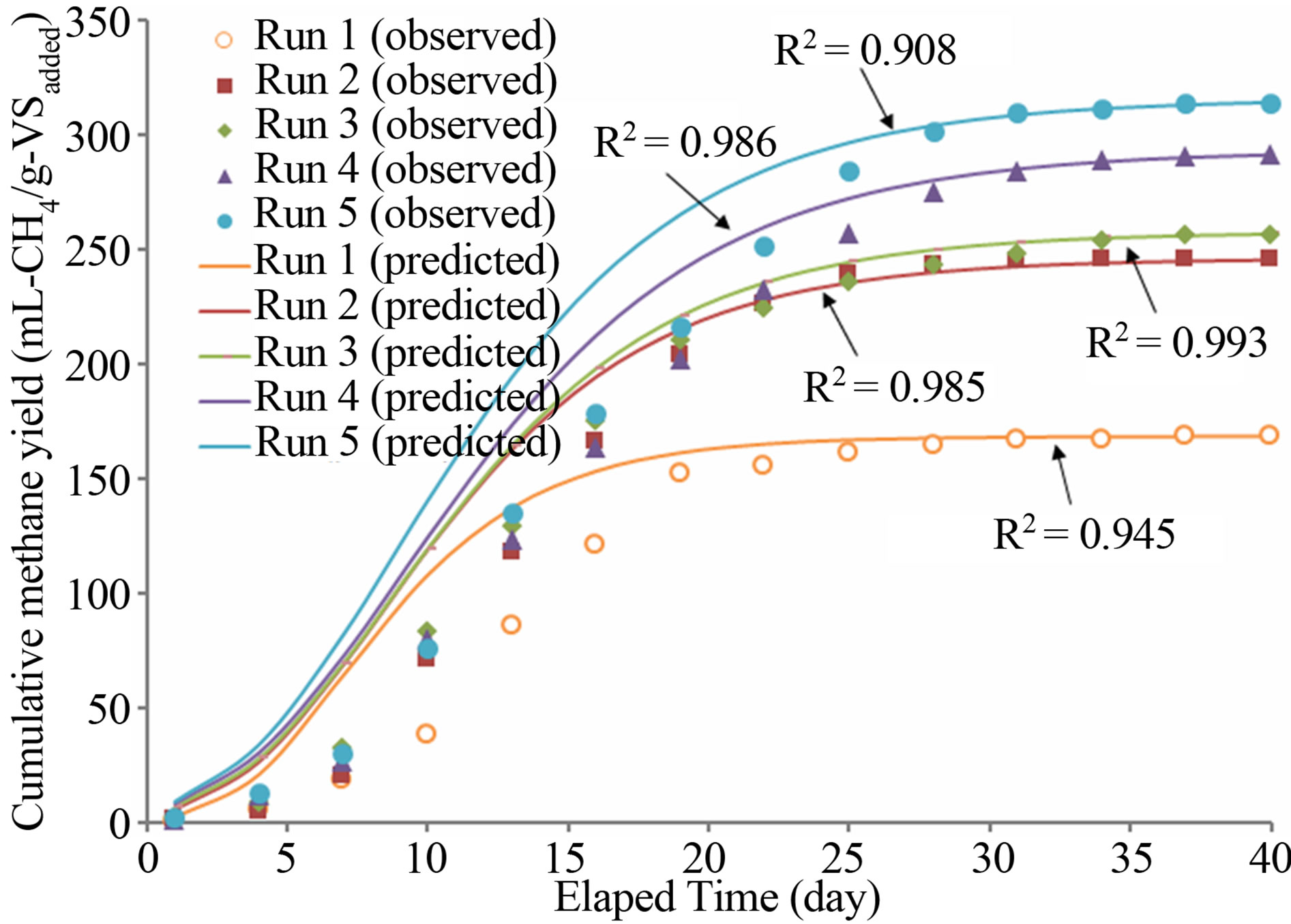

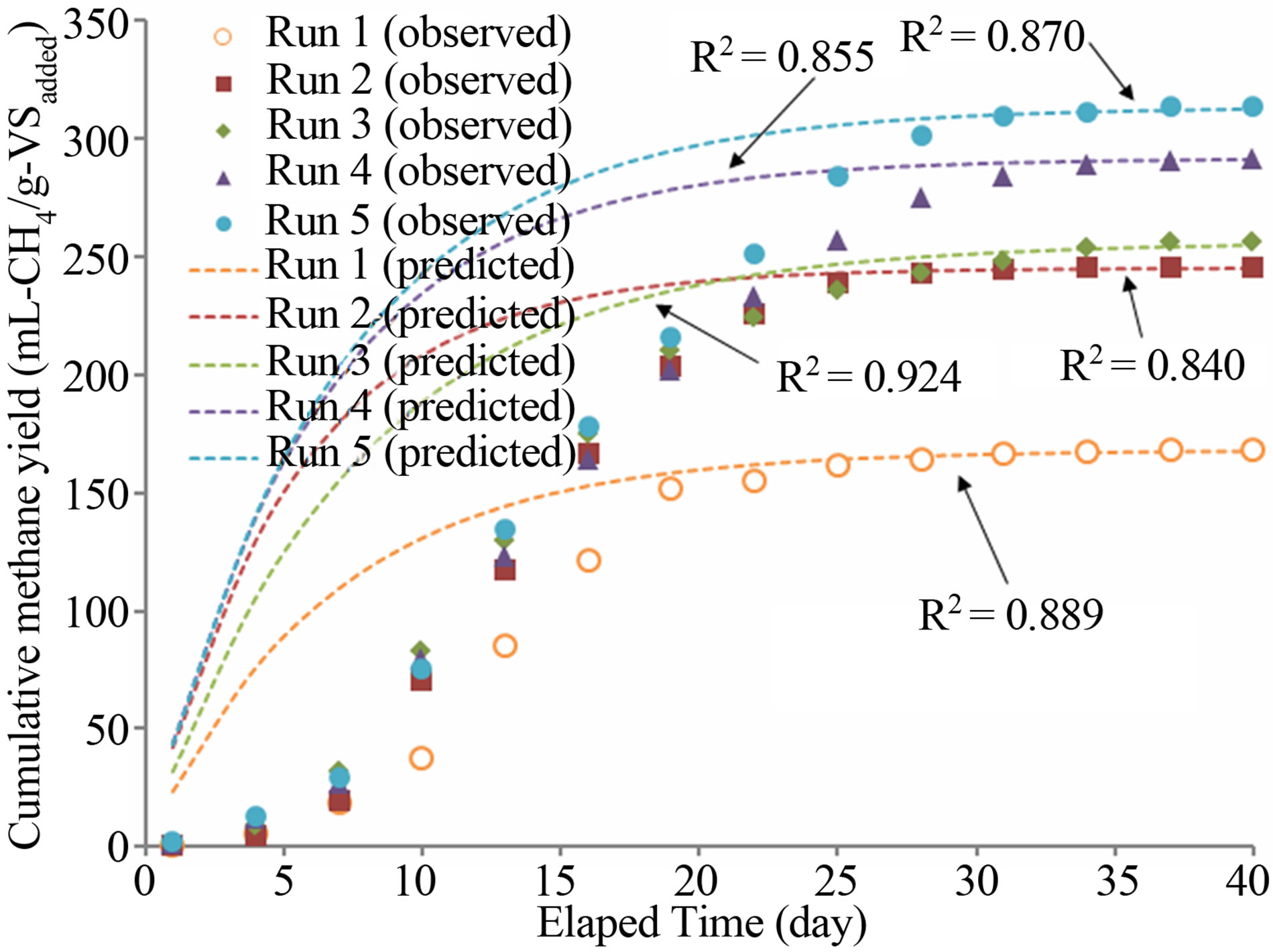

Modified Gompertz Model (MGM) and Exponential Model (EM) were used to evaluate the cumulative methane yield on a basis of the BMP assay operated for 40 days under the experimental conditions for five sample groups. By comparison of the ultimate methane yields (cumulative methane yields at the final time, 40 days) evaluated by two models, MGM (168.39 - 314.08 mLCH4/g-VSadded) determined relatively lower ranges than EM (167.62 - 312.47 mL-CH4/g-VSadded).

In Table 6, for the mesophilic-dry digestion experiment, the ultimate methane yield was observed in the range of 163.02 mL - 313.27 mL-CH4/g-VSadded which was applied in two models as Mo and Bo. The methane yield was also increased when the chaff mixing ratio was

Table 6. Summary of kinetic parameters predicted by two models.

Note) *Mo or Bo is the ultimate methane yield observed during the experiment.

high as shown in the case of total gas production rate. Also, Run 1 without the trace elements indicated the lower cumulative methane yield (77.15 mL-CH4/g-VSadded) than that for Run 2 with the trace elements.

The results of BMP assay simulated by two types of models showed a difference and the modified Gompertz Model was better fit compared with the Exponential Model as shown in Figure 4.

In the experiment, the ultimate methane yield per the inserted VS was distributed in the range of 163.02 mL - 313.27 mL-CH4/g-VSadded. In previous studies, mixture digestion of food waste and livestock manure was tested in the thermophilic-wet digestion process and the ultimate methane yield per the inserted VS was ranged from 313.35 to 377.43 mL-CH4/g-VSadded [16], which was relatively higher than that obtained in this study, and similar to that of the single livestock manure tested at the thermophilic digestion and its result presented as 241 mL/g-VSadded [17]. In addition, typical experimental values obtained from foreign countries were 250 L/g-VS for the cow manure including the straw and 279 L/g-VS [18] for the horse-manure with the straw estimated by the thermophilic-wet anaerobic digestion process, and 318 mL/g-VSadded [19] for sewage sludge in similar. However, comparative evaluation represented little because BMP assay were varied greatly due to the operation conditions such as nutriment component and addition amount, heat, agitation, and so on [20].

According to the evaluation result of the ultimate methane yield, the mixture of the livestock manure and the chaff in the mesophilic anaerobic digestion process has an advantage when comparing with the only livestock manure containing high moisture content at the

(a)

(a) (b)

(b)

Figure 4. Biochemical methane potential assay simulated by two models. a) Modified Gompertz Model; b) Exponential Model.

thermophilic digestion process in common. Also, it is verified that the trace elements are required to add when the chaff to mix with the livestock manure is not sufficient. Therefore, further study is required more detailed research.

3.3. Mixture Ratio of Manure and Chaff

On the domestic side, food waste as a mixture substrate of livestock manure has been mainly used to solve a pending issue and to improve methane production efficiency. Domestic studies related to optimal mixing ratio of the livestock manure and the food waste have been conducted but the study using herbal plants such as chaff and straw is rare. Because rural areas mainly produce the livestock manure and urban areas discharge the food waste mostly, facilities and energy for transportation are required if the food waste is considered as the substrate mixing with the animal manure. The herbal plants like the chaff are easily obtained in the rural area and mostly used to mix with the livestock manure as shown in developed countries having many cases for biogas plants [21].

With that background, this study verified that the methane production rate was varied due to the amount of the chaff mixed with the livestock manure. As the amount of the chaff was enlarged to expand biogas production and to increase methane production efficiency, it was naturally converted to the dry anaerobic digestion process caused by the lower moisture content and it had little regard for wastewater emission. Coverse et al. studied on the methane production using the high rate of organic loading as inserting carbohydrate mixture compounds [22]. According to their study, the maximum methane production rate was high at the thermophilic digestion but overall methane production yield was larger at the mesophilic digestion. A previous study applied the straw as the mixture substance had reported the most methane production was yielded from the mixture sample of 3% straw and the livestock manure containing 5% solid [23].

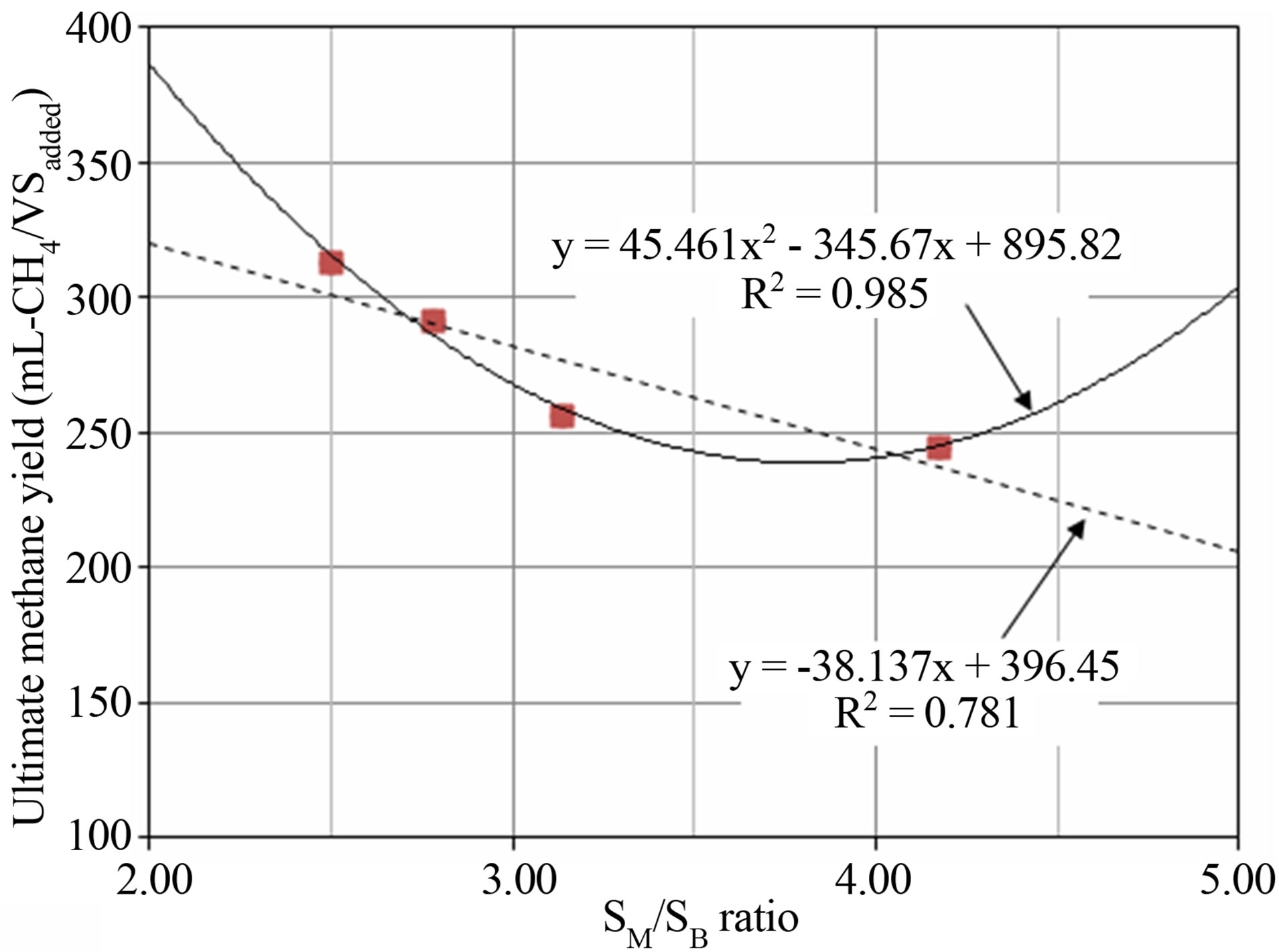

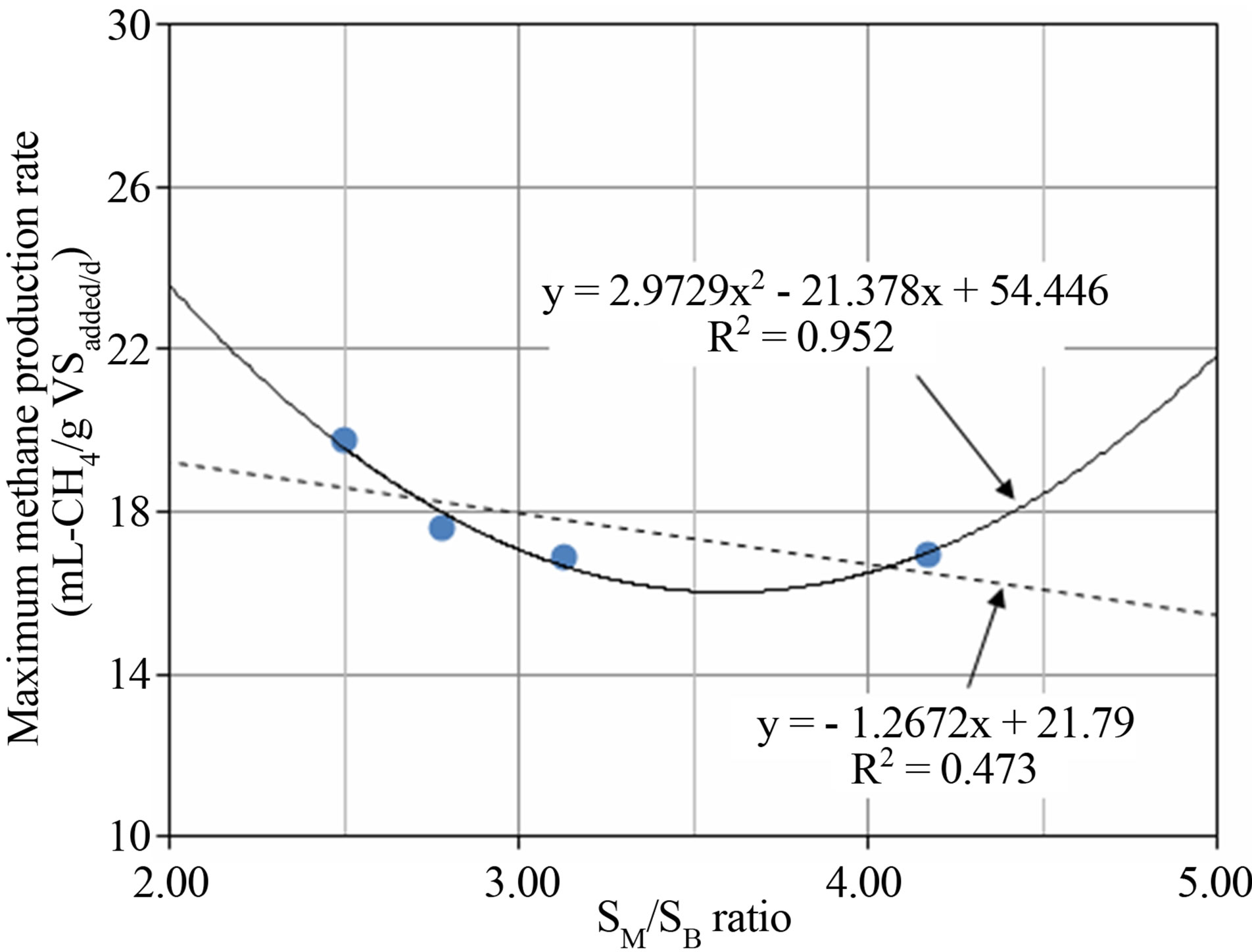

To verify the optimal mixing ratio of the piggery manure (SM) as the main compound and the chaff (SB) as the additional mixing compound in this study, the ultimate methane production yield and the maximum production rate due to SM/SB ratio are presented in Figure 5. As shown in Figure 5(a), the ultimate methane production yield and the maximum methane production rate were increased less than 3.5 of SM/SB ratio. The SM/SB ratio is remarkably varied due to the livestock manure composition changed by the stock farmers and the discharging season (or time) and its role may be slightly changed due to the type of the chaff and the condition of the chaff. Therefore, it is necessary to develop a standard model using the more accurate SM/SB ratio examined by several parameters such as solid content, livestock ma-

(a)

(a) (b)

(b)

Figure 5. Change of methane yield coefficients in terms of M/H ratio. a) Ultimate methane yield; b) Maximum methane production rate.

nure types, chaff types, dry conditions of the chaff including moisture content and woody presence, and so on.

4. Conclusions

Considering domestic waste and natural water management, piggery manure is mostly required to be treated among non-point sources of the stock raising system and can also be a main compound of methane production. With that background, this study performed a series of experiments on mesophilic-dry anaerobic digestion of the main compound, piggery manure, mixed with chaff, a mixture compound or substrate, for supplying carbon and controlling moisture. Also, this study conducted comparative evaluation of methane production potential produced from the anaerobic digestion process due to a mixing ratio of the piggery manure and the chaff, and obtained following conclusions after the careful consideration and emphasis on the reasonable mixing ratio:

1) The larger amounts of the chaff resulted in the larger methane production yields as well as the larger gas production yields per volatile solid (VS) inserted. The methane ratio in the produced biogas was also increased as the amount of the chaff was increased.

2) When using the same mixture ratio of the chaff, the gas production from the sample without trace elements was less than that from the sample with trace elements. Therefore, one can say that the trace elements are important when producing the methane from the mixture compounds of the piggery manure and the chaff.

3) For the mesophilic-dry digestion, the cumulative methane production yield per the inserted VS was ranged in 163.02 mL - 313.27 mL-CH4/g-VSadded. Similar to the measurement result of total gas production yield, the methane production yield was increased with the higher mixture ratio of the chaff.

4) For the comparative evaluation of the BMP assay, the ultimate methane yield using Modified Gompertz Model was calculated as 168.39 - 314.08 mL-CH4/gVSadded. It was slightly lower than that in the thermophilic-wet digestion process for the mixture of the domestic food waste and livestock manure and similar to that in the thermophilic-wet digestion process of the sewage activated sludge.

5) When the optimal mixture ratio (SM/SB) between the piggery manure (SM) and the chaff (SB) was less than 3.5, the ultimate methane production yield (Mo) and the maximum production rate (Rm) were decreased.

In conclusion, the mixture of the chaff to the piggery manure controls the moisture content and improves the methane production rate. Also, this study verifies the feasibility of the mesophilic-dry anaerobic digestion process, which is less difficult in operating and maintaining.

5. Acknowledgements

This study was supported by a grant (CUHBRI-2012-0 2-007) of the CNUH-BRI as the project, Development of Future Oriented Healthcare Model and Fundamental Technology for Agro-Medical System, and partly supported by a grant (2013 research project) of Jeonbuk Green Environment Center. Also, we appreciate to Dr. Kyung-Yub Hwang (Research Fellow Emeritus) in Korea Institute of Science and Technology who gives us professional advice to complete this paper and experiments.

REFERENCES

- P. Börjesson and B. Mattiasson, “Biogas as a ResourceEfficient Vehicle Fuel,” Trends Biotechnology, Vol. 26, No. 1, 2008, pp. 7-13. http://dx.doi.org/10.1016/j.tibtech.2007.09.007

- H. J. Park, M. K. Song and C. K. Na, “Pretreatment Efficiency of Piggery Wastewater Using Coagulation-MAP Sedimentation,” Journal of Korea Society of Waste Management, Vol. 27, 2010, pp. 457-466.

- Y. M. Yoon, Y. J. Kim and C. H. Kim, “The Evaluation of Economical Efficiency to Composting and Liquefying Process of Biomass Discharged in Pig Breeding,” Agriculture Economics, Vol. 31, 2009, pp. 39-62.

- D. Bolzonella, L. Innocenti, P. Pavan, P. Traverso and F. Cecchi, “Semi-Dry Thermophilic Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste: Focusing on the Start-Up Phase,” Bioresource Technology, Vol. 86, No. 2, 2003, pp. 123-129. http://dx.doi.org/10.1016/S0960-8524(02)00161-X

- P. Pavan, P. Battistoni and J. Mata-Alvarez, “Performance of Thermophilic Semi-Dry Anaerobic Digestion Process Changing the Feed Biodegradability,” Water Science and Technology, Vol. 41, 2000, pp. 75-81.

- N. Forster-Carneiro, M. Perez and L. I. Romero, “Anaerobic Digestion of Municipal Solid Wastes: Dry Thermophilic Performance,” Bioresource Technology, Vol. 99, No. 17, 2008, pp. 8180-8184. http://dx.doi.org/10.1016/j.biortech.2008.03.021

- B. Montero, J. L. Garcia-Morales, D. Sales and R. Solera, “Analysis of Methanogenic Activity in a Thermophilicdry Anaerobic Reactor: Use of Fluorescent in Situ Hybridization,” Waste Management, Vol. 29, No. 3, 2009, pp. 1144-1151. http://dx.doi.org/10.1016/j.wasman.2008.08.010

- S. E. Oh, M. K. Lee and D. H. Kim, “Continuous Mesophilic-Dry Anaerobic Digestion of organic Solid Waste,” Journal of Korean Society of Environmental Engineers, Vol. 31, 2009, pp. 341-345.

- J. J. Lay, Y. Y. Li and T. Noike, “Development of Bacterial Population and Methanogenic Activity in a Laboratory-Scale Landfill Bioreactor,” Water Research, Vol. 32, No. 12, 1998, pp. 3673-3679. http://dx.doi.org/10.1016/S0043-1354(98)00137-7

- W. F. Owen, D. C. Stuckey, J. B. Healy, L. Y. Young and P. L. McCarty, “Bioassay for Monitoring Biochemical Methane Potential and Anaerobic Toxicity,” Water Research, Vol. 13, No. 6, 1979, pp. 485-492. http://dx.doi.org/10.1016/0043-1354(79)90043-5

- R. S. Daniel and J. M. Tiedje, “General Method for Determining Anaerobic Biodegradation Potential,” Applied and Environmental Microbiology, Vol. 47, 1984, pp. 850-857.

- I. Angelidaki, M. Alves, D. Bolzonella, L. Borzacconi, J. L. Campos, A. J. Guwy, S. Kaalyuzhnyi, P. Jenicek and J. B. van Lier, “Defining the Biomethane Potential (BMP) of Solid Organic Wastes and Energy Crops: A Proposed Protocol for Batch Assays,” Water Science and Technology, Vol. 59, No. 5, 2009, pp. 927-934. http://dx.doi.org/10.2166/wst.2009.040

- M. H. Zwietering, I. Jongenburger, F. M. Rombouts and K. van’t Riet, “Modeling of the Bacterial Growth Curve,” Applied and Environmental Microbiology, Vol. 56, No. 6, 1990, pp. 1875-1881.

- T. L. Hansen, J. E. Schmidt, I. Angelidaki, E. Marca, J. Cour Jansen, H. Mosboek and T. H. Christensen, “Method for Determination of Methane Potentials of Solid Organic Waste,” Waste Management, Vol. 24, No. 4, 2004, pp. 393-400. http://dx.doi.org/10.1016/j.wasman.2003.09.009

- H. B. Møllera, S. G. Sommera and B. K. Ahringb, “Methane Productivity of Manure, Straw and Solid Fractions of Manure,” Biomass and Bioenergy, Vol. 26, No. 5, 2004, pp. 485-495. http://dx.doi.org/10.1016/j.biombioe.2003.08.008

- J. K. Park, S. R. Jeong, J. H. Kang, Y. M. Ahn, H. E. Jin and N. H. Lee, “A Study on Optimization Condition for Anaerobic Co-Digestion of Food Waste with Livestock Wastes,” Journal of Korea Society of Waste Management, Vol. 29, 2012, pp. 356-364.

- S. H. Kim, H. C. Kim, C. H. Kim and Y. M. Yoon, “The Measurement of Biochemical Methane Potential in the Several Organic Waste Resources,” Korean Journal of Soil Science and Fertilizer, Vol. 43, 2010, pp. 356-362.

- S. Aslanzadeh, M. J. Taherzadeh and I. S. Horvath, “Pretreatment of Straw Fraction of Manure for Improved Biogas Production,” Bio-Resources, Vol. 6, 2011, pp. 5193-5205.

- J. G. Lin, Y. S. Ma, A. C. Chao and C. L. Huang, “BMP Tests on Chemically Pretreated Sludge,” Bioresources Technology, Vol. 68, No. 2, 1999, pp. 187-192. http://dx.doi.org/10.1016/S0960-8524(98)00126-6

- P. Shanmugam and N. J. Horan, “Simple and Rapid Methods to Evaluate Methane Potential and Biomass Yield for a Range of Mixed Solid Wastes,” Bioresource Technology, Vol. 100, No. 1, 2008, pp. 471-474. http://dx.doi.org/10.1016/j.biortech.2008.06.027

- D. Jackowiak, D. Bassard, A. Pauss and T. Ribeiro, “Optimization of a Microwave Pretreatment of Wheat Straw for Methane Production,” Bioresource Technology, Vol. 102, No. 12, 2011, pp. 6750-6756. http://dx.doi.org/10.1016/j.biortech.2011.03.107

- J. C Converse, R. E. Graves and G. W. Evans, “Anaerobic Degradation of Dairy Manure under Mesophilic and Thernophilic Temperatures,” Transactions of the ASAE, Vol. 20, 1977, pp. 336-340.

- J. E. Robbins, M. T. Armold and S. L. Lacher, “Methane Production from Cattle Waste and Delignified Strawt,” Infection and Immunity, Vol. 38, 1979, pp. 175-177.

NOTES

*Corresponding author.