Journal of Minerals and Materials Characterization and Engineering

Vol.02 No.06(2014), Article ID:51161,8 pages

10.4236/jmmce.2014.26056

Enhanced High-Temperature Cycling Stability of LiMn2O4 by Coating LiNi0.5Mn1.5O4

Jing Yan1, Wei Liu2,3, Yuelei Wang1, Xinxin Zhao1, Yiming Mi1, Haohan Liu2,3*

1College of Chemistry and Chemical Engineering, Shanghai University of Engineering Science, Shanghai, China

2Shanghai Nanotechnology Promotion Center, Shanghai, China

3Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences, Shanghai, China

Email: *biluo1873@163.com

Academic Editor: Jiann-Yang (Jim) Hwang, Michigan Technological University, USA

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 25 August 2014; revised 17 October 2014; accepted 28 October 2014

ABSTRACT

To enhance the electrochemical performances of LiMn2O4 at elevated temperature (55˚C), we proposed a sol-gel method to synthesize LiNi0.5Mn1.5O4 modified LiMn2O4. The physical and electrochemical performances of pristine and LiNi0.5Mn1.5O4-coated LiMn2O4 cathode materials were investigated by X-ray diffraction, scanning electron microscopy, transmission electron microscopy, X-ray photoelectron spectroscopy and electrochemical measurements, respectively. The results indicated that about 4 - 5 nm thick layer of LiNi0.5Mn1.5O4 was formed on the surface of the LiMn2O4 powders. The modified LiMn2O4 exhibited excellent storage performance at 55˚C compared to the pristine one, which was attributed to the suppression of electrolyte decomposition and the reduction of Mn dissolution.

Keywords:

LiMn2O4, Sol-Gel Method, Surface Coating, Electrochemical Performance

1. Introduction

With the advantages of abundant, nontoxic, and inexpensive, spinel lithium manganese oxide (LiMn2O4) is a promising candidate of the layered cathode materials such as LiCoO2 [1] [2] . Especially, the good stability of LiMn2O4 may ensure its large-scale usage in the batteries for electric vehicle or energy storage [3] . However, LiMn2O4 shows obvious capacity fade when cycling at high temperature [4] -[6] . It was reported that the capacity fading mechanism at high temperature was related to the Jahn-Teller distortion and dissolution of Mn3+ ions [7] [8] . Mn dissolution is induced by HF acid, which is generated by secondary chemical reactions from temperature-enhanced electrolyte decomposition.

In order to solve this problem, earlier studies have been focused on a chemical modification of LiMn2O4 by a partial substitution of Mn with some metal ions to obtain LiMxMn2-xO4 (M = Co, Mg, Cr, Ni, Fe, Al, Ti and Zn) [9] -[12] . These results indicated that the substitution of Mn with metal ions significantly improved the cycle performance of LiMn2O4. However, the partial substitutions decrease the capacity of LiMn2O4. Another effective way is surface coating on LiMn2O4 by oxide with high thermal and structural stability. ZrO2 [13] , Al2O3 [14] , SiO2 [15] and MgO [16] have been used to coat LiMn2O4 by some chemical processes. However, the aforementioned oxides with non-spinel structure are hard to grow on the surface of LiMn2O4. With a similar structure to LiMn2O4, LiNi0.5Mn1.5O4 can grow more easily on LiMn2O4 than other alien phase and form a more close-contacted protective covering layer, which may suppress the dissolution of Mn. Therefore, it is expected that the modified LiMn2O4 will show an excellent cycle performance at elevated temperature. In this study, we proposed an approach to synthesize LiNi0.5Mn1.5O4 on the surface of spinel LiMn2O4. The effect of LiNi0.5Mn1.5O4 layer on the morphology and electrochemical performances of LiMn2O4 cathode materials were examined in detail.

2. Experimental

LiMn2O4 powder was purchased from Heibei Strong-Power Li-ion Battery Tecnology Co. Ltd (D98, China). To coat LiMn2O4 with LiNi0.5Mn1.5O4, LiCH3COO∙2H2O (0.558 g), Mn (CH3COO)2∙4H2O (2.011 g) and Ni (CH3COO)2∙4H2O (0.68 g) with a stoichiometric ratio (2:1:3) were dissolved in distilled water to form a clear solution. An aqueous solution of ethylene glycol and citric acid as a chelating agent was added to the mixtures. pH value at 6.5 - 7.0 was achieved by Ammonium hydroxide. Then the LiMn2O4 powders (50 g) were slowly added to the sol and vigorously stirred at 85˚C for 8 h. As the evaporation of water proceeding, the sol was turned into a viscous transparent gel. After drying and sieving, the powder was sintering in air at 400˚C for 10 h and 750˚C for 3 h to obtain LiNi0.5Mn1.5O4-coated LiMn2O4. For a comparison, pristine LiMn2O4 was also heat- treated in the same condition.

2.1. Structure and Morphology Characterization

X-ray diffraction patterns were recorded on a DX-2700 diffractometer (Siemens D-5000, Mac Science MXP 18) equipped with Cu Kα radiation of λ = 0.154145 nm. The diffraction patterns were recorded between scattering angles of 15˚ and 80˚ at a step of 4˚/min. The morphology was studied by a scanning electron microscopy (S4700, Hitachi) and transmission electron microscope (JEOL-1200EX). X-ray photoelectron spectroscopy (Kratos AXIS Ultra DLD) was employed to probe the surface for Mn Valence states. Inductively coupled plasma atomic emission spectrometry analysis was conducted on IRIS Intrepid П XSP inductively coupled plasma emission spectrometer (THERMO).

2.2. Electrochemical and Thermal Characteristics

To obtain working electrodes, 85 wt% active materials, 9 wt% acetylene black and 6 wt% polyvinylidene fluoride were homogeneously mixed in N-methyl-pyrroline. Then the resluting slurry was spread on an aluminum foil and thoroughly dried. The electrodes were punched in the form of 14 mm diameter disks, and the typical active material mass loading was about 6 mg/cm2. The electrolyte was 1 M LiPF6 dissolved in a mixture of ethylene carbonate and dimethylene carbonate with the volume ratio of 1:1. The assembly process was conducted in an argon-filled glove-box with the content of H2O and O2 less than 1 ppm.

Before electrochemical tests, the batteries were aged for 24 h to ensure good soakage. The cells were charged and discharged on a battery tester (CT-3008W, NEWARE) between 3.3 and 4.35 V at the rate of 2C at elevated temperatures (55˚C ± 2˚C). Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) investigations were performed on an electrochemical workstation (PGSTAT302N, Autolab) at 25˚C ± 2˚C. The CV curves were recorded between 3.3 and 4.35 V at a scan rate of 0.1 mV・s−1. The EIS measurements were performed over a frequency range from 10 kHz to 0.1 Hz.

3. Results and Discussion

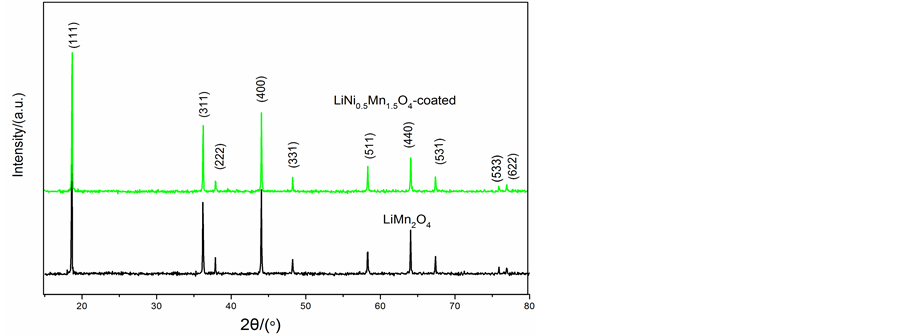

Figure 1 shows the XRD patterns of pristine and LiNi0.5Mn1.5O4-coated LiMn2O4. The peaks of both samples could be indexed to a cubic spinel structure with the space group Fd3m. There is no substantial difference between XRD patterns for pristine and modified LiMn2O4. The crystal lattice parameters were calculated by using the software of Jade, are 8.245 and 8.243 Å for the pristine and LiNi0.5Mn1.5O4-coated LiMn2O4, indicating that the bulk structure of LiMn2O4 unchange after surface modification. The characteristic peaks corresponding to LiNi0.5Mn1.5O4 are not observed because of the low content (about 2.0 wt%).

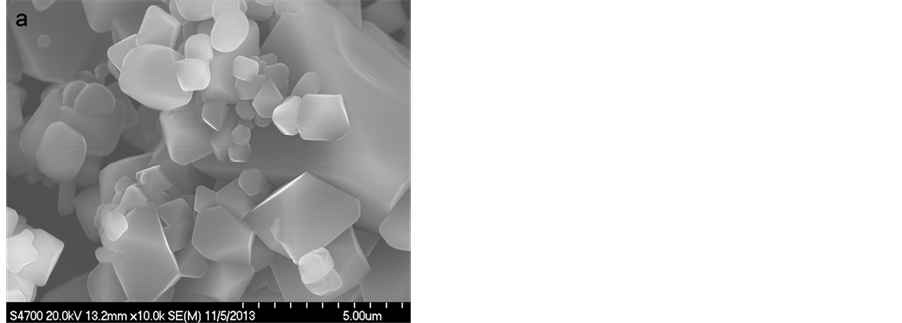

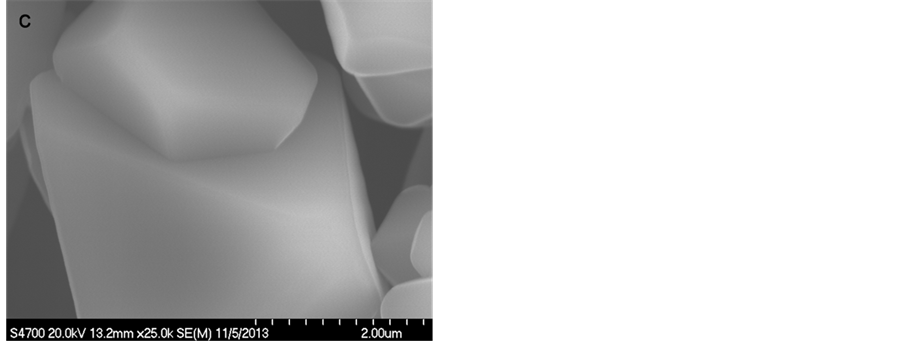

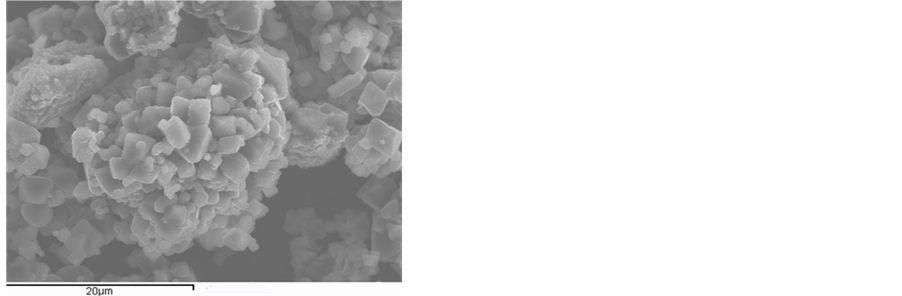

Scanning electron microscopy reveals that the pristine and modified samples present a uniform particle distribution, ranging from 2 to 7 μm. The pristine spinel crystals are smooth with well-defined facets, as observed in Figure 2(a) and Figure 2(c). It can be seen that the morphology and particle diameter of the LiNi0.5Mn1.5O4-

Figure 1. X-ray diffraction patterns of pristine and modified LiMn2O4.

Figure 2. SEM figures of (a), (c) pristine and (b), (d) LiNi0.5Mn1.5O4-coated LiMn2O4.

coated LiMn2O4 powders in Figure 2(b) and Figure 2(d), are similar to the pristine sample. No LiNi0.5Mn1.5O4 agglomerations and obscured facets of spinel LiMn2O4 are observed.

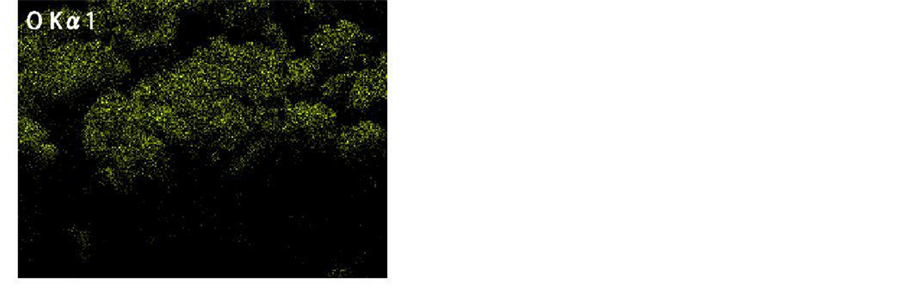

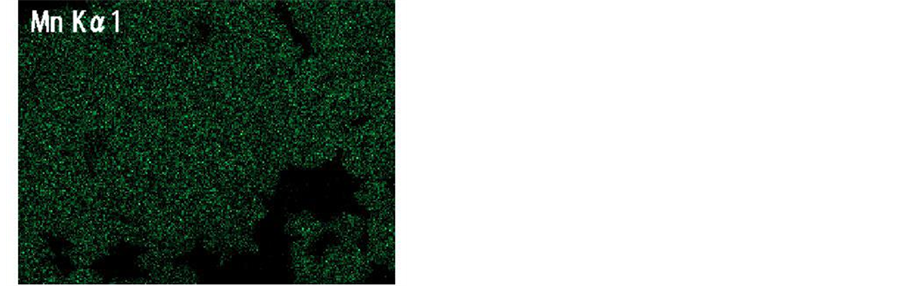

The element composition is determined by EDS analysis. The element mapping of Ni and Mn is displayed in Figure 3. The dense accumulation of Mn spots is attributed to the host material of LiMn2O4 and there is no significant agglomeration of Ni. This indicates that LiNi0.5Mn1.5O4 is homogeneously dispersed on the surface of the LiMn2O4 particles.

TEM micrographs are displayed in Figure 4. Compared to the pristine sample (Figure 4(a)), about 4 - 5 nm

Figure 3. EDS mappings of O, Mn and Ni elements of modified LiMn2O4.

Figure 4. TEM figure of pristine (a) and LiNi0.5Mn1.5O4-coated LiMn2O4 (b).

thick layer of LiNi0.5Mn1.5O4 is uniformly formed on the surface of the LiMn2O4 (Figure 4(b)). The coating layer is clearly distinguishable from the crystalline LiMn2O4. The TEM analysis demonstrates that the sol-gel method is an effective way to coat the LiNi0.5Mn1.5O4 layer on the surface of LiMn2O4.

The oxidation state of manganese ions at the surface was determined from XPS data by the curve fitting of Mn 2p spectral peaks. The experimental peak shape for Mn 2p3/2 was modeled by employing multiple-splitting patterns derived for Mn3+ and Mn4+ at binding energies of 641.6, and 642.8 eV from the standard compounds Mn2O3 and MnO2. Figure 5 shows the fit of the models to the experimental spectra for pristine LiMn2O4 and LiNi0.5Mn1.5O4-coated LiMn2O4 respectively. The surface of the pristine LiMn2O4 sample consists of almost equal amounts of Mn4+ and Mn3+. By contrast, LiNi0.5Mn1.5O4-coated LiMn2O4 exhibited a Mn4+:Mn3+ ratio of 59.4:40.6. The difference of Mn4+:Mn3+ ratio on the surface is due to the formation of LiNi0.5Mn1.5O4, because it has higher valence state of manganese ions. This result is good agreement with the observation of HR-TEM.

As shown in Figure 6, the galvanostatic charge-discharge curves under a current rate of 2C were conducted at elevated temperatures (55˚C). It shows two discharge plateaus, which should be attributed to orderly intercalating of lithium ions in the tetrahedral (8a) sites at 4.1 V and disorderly intercalating lithium ions at 3.9 V which substantially maintains the intercalation feature of LiMn2O4 substrate [17] , indicating LiNi0.5Mn1.5O4 surface layer rather than Ni-doped LiMn2O4 because LiMn2O4 with Ni-doped spinel surface showed two ambiguously resolved discharging plateaus. LiNi0.5Mn1.5O4-coated LiMn2O4 shows a lower discharge capacity (104.2 mAh/g) compares to the pristine sample (106.3 mAh/g). The reason of low initial discharge capacity is that LiNi0.5Mn1.5O4 shows no capacity at this voltage range due to its high discharge voltage over 4.35V [18] .

Figure 7 shows the cycling performance of electrodes with and without LiNi0.5Mn1.5O4 coating. After 100 cycles, the discharge capacity of the pristine LiMn2O4 drops from 106.3 to 89.2 mAh/g. In contrast, the discharge capacity of modified sample changes from 104.2 to 98 mAh/g. The capacity retention increases from 84.0% to 94.4% after LiNi0.5Mn1.5O4 coating.

To further verify the effects of surface coating on manganese ions dissolution, the quality of the manganese element was directly determined by using ICP-AES. Li metal anode was washed by dilute hydrochloric acid after 100th cycle at 55˚C ± 2˚C. It can be seen in Table 1, the dissolved quality of Mn2+ ions of the pristine and LiNi0.5Mn1.5O4-coated LiMn2O4 electrode was 20.54 and 12.17 μg/cm2, respectively. It can be concluded that after coating by LiNi0.5Mn1.5O4 layer, the dissolution of the manganese ions was significantly reduced. Therefore, LiNi0.5Mn1.5O4-coated LiMn2O4 electrode had better cycle stability at elevated temperature.

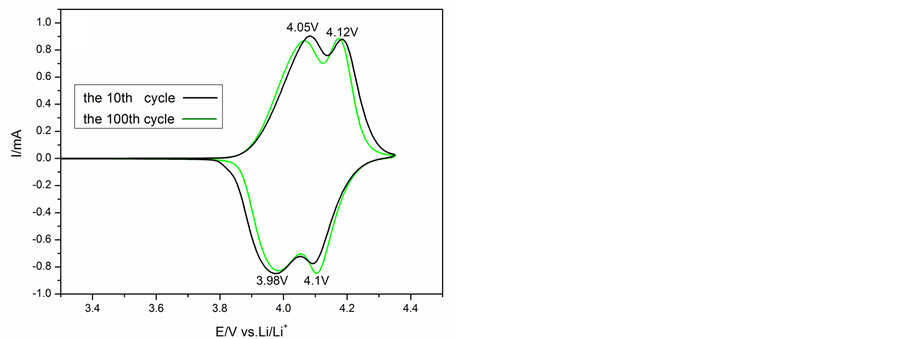

Figure 8 shows the CV profiles of pristine and LiNi0.5Mn1.5O4-coated LiMn2O4 electrodes in the 10th and 100th cycles at the scan rate of 0.1 mV∙s−1. The CV peaks of LiNi0.5Mn1.5O4-coated sample show two symmetrical couples of redox peaks at around 3.98 and 4.1 V respectively (Figure 8(b)), indicating that electrochemical insertion and extraction reactions of Li+ ions are two step processes. It is in agreement with the two plateaus in Figure 6 and demonstrates that LiNi0.5Mn1.5O4 coating does not change the electrochemical reaction mechanism of LiMn2O4. After 10 cycles, two narrow and separate redox peaks appear around at 3.96 and 4.11 V, as shown in Figure 8(a). However, after 100th cycles, due to the dissolution of Mn3+ ions into the electrolyte

Figure 5. XPS spectra of the pristine (a) and LiNi0.5Mn1.5O4-coated LiMn2O4 (b).

Figure 6. The first Charge-discharge curves of LiNi0.5Mn1.5O4-coated LiMn2O4 at elevated temperature (under 2C rate, 55˚C ± 2˚C).

Figure 7. Cycling behaviours of LiMn2O4 and LiNi0.5Mn1.5O4-coated LiMn2O4 cycled (under 2C rate, 55˚C ± 2˚C).

Table 1. The amount of Mn2+ deposited on Li anode after 100 cycles at 55˚C ± 2˚C.

(Jahn-Teller distortion), both anodic and cathodic peaks become much broader and lower in peaks current. In contrast, the oxidation and reduction peaks relate to LiNi0.5Mn1.5O4-coated LiMn2O4 are much steadier after 100 cycles (Figure 8(b)), which indicated that modified LiMn2O4 has better reversibility and stability than the pristine LiMn2O4.

Electrochemical impedance spectra (EIS) and equivalent circuits are shown in Figure 9. The measurements were carried out with fully charged state (4.35 V). An intercept in the high frequency region of the Zrel axis indicates the ohmic resistance (Rs), the combined resistance of the electrolyte and the contacts of the cell [19] . The semicircle in high-middle frequency region corresponds to the charge transfer (Rct) process on the electrode interface, revealing the lithium transfer rate parameters and the capacitance of the SEI (solid eleteolyte interface) [20] . The inclined line in the lower frequency region represents the Warburg impedance (Zw), which is corresponded to the diffusion of Li+ in LiMn2O4 particles [21] . The plots are fitted and listed in Table 2. As shown in

Figure 8. Typical CV curves of 10th and 100th cycles of pristine (a), and iNi0.5Mn1.5O4-coated LiMn2O4 (b).

Figure 9. EIS of pristine and LiNi0.5Mn1.5O4-coated LiMn2O4 at the end of 10th and 100th cycle

Table 2. The AC impedance fitting data for pristine LiMn2O4 and LiNi0.5Mn1.5O4-coated LiMn2O4.

the table, after 10 cycles, the Rs for LiNi0.5Mn1.5O4-coated LiMn2O4 is slightly larger than the pristine sample, because that the coating layer may slightly increase the elecrolyte and contact resistance. The charge transfer resistance of both samples is approximately the similar (26.82 and 24.4 Ω∙cm2). After 100 cycles, the change in Rs is negligible. However, the Rct value of the LiNi0.5Mn1.5O4-coated electrode (34.8 Ω∙cm2) is two times smaller than that the value pristine electrode (73.8 Ω∙cm2). It attributes to the restraint of structural instability caused by the subsequent Mn dissolution and vacancies formation. This result is also in accordance with the enhanced cycling performance of LiNi0.5Mn1.5O4-coated electrodes.

4. Conclusion

In summary, the surface of LiMn2O4 sample was modified by LiNi0.5Mn1.5O4 using a sol-gel method. TEM and XPS results confirm the existence of LiNi0.5Mn1.5O4 layer. A uniform and dense layer about 4 - 5 nm was coating on the surface of pristine LiMn2O4. The LiNi0.5Mn1.5O4-coated LiMn2O4 sample exhibits much better cycling stability at elevated temperature (55˚C) compared with the pristine sample. The CV tests indicated that the LiNi0.5Mn1.5O4-coated LiMn2O4 electrode has better reversibility and stability. Meanwhile, the charge transfer resistance of the LiNi0.5Mn1.5O4-coated LiMn2O4 was much less than that of pristine sample after 100 cycles, which is ascribed to the better structural stability and restraint of Mn dissolution. These results demonstrated that this is an effective way to improve the high-temperature cyclic performance of spinel LiMn2O4.

Acknowledgements

This work was supported by National Science Foundation of China (No. 50672026). This work was also supported by Shanghai Nano Technology Promotion (No. 12ZR1448800).

References

- Pitchai, R., Thavasi, V., Mhaisalkar, S.G. and Ramakrishna, S. (2011) Nanostructured Cathode Materials: A Key for Better Performance in Li-Ion Batteries. Journal of Materials Chemistry, 21, 11040-11051. http://dx.doi.org/10.1039/c1jm10857c

- Zhao, S., Bai, Y., Ding, L.H., Wang, B. and Zhang, W.F. (2013) Enhanced Cycling Stability and Thermal Stability of YPO4-Coated LiMn2O4 Cathode Materials for Lithium Ion Batteries. Solid State Ionics, 247, 22-29. http://dx.doi.org/10.1016/j.ssi.2013.05.022

- Kim, W.-K., Han, D.-W., Ryu, W.-H., Lim, S.-J. and Kwon, H.-S. (2012) Al2O3 Coating on LiMn2O4 by Electrostatic Attraction Forces and Its Effects on the High Temperature Cyclic Performance. Electrochimica Acta, 71, 17-21. http://dx.doi.org/10.1016/j.electacta.2012.03.090

- Aoshima, T., Okahara, K., Kiyohara, C. and Shizuka, K. (2001) Mechanisms of Manganese Spinels Dissolution and Capacity Fade at High Temperature. Journal of Power Sources, 97-98, 377-380. http://dx.doi.org/10.1016/S0378-7753(01)00551-1

- Baba, M., Kumagai, N., Fujita, H., Ohta, K., Nishidate, K., Komaba, S., Kaplan, B., Groult, H. and Devilliers, D. (2003) Multi-Layered Li-Ion Rechargeable Batteries for a High-Voltage and High-Current Solid-State Power Source. Journal of Power Sources, 119, 914-917. http://dx.doi.org/10.1016/S0378-7753(03)00223-4

- Kim, D., Park, S., Chae, O.B., Ryu, J.H., Kim, Y.U., Yin, R.Z. and Oh, S.M. (2012) Re-Deposition of Manganese Species on Spinel LiMn2O4 Electrode after Mn Dissolution. Journal of the Electrochemical Society, 159, A193-A197. http://dx.doi.org/10.1149/2.003203jes

- Gummow, R.J., Dekock, A. and Thackeray, M.M. (1994) Improved Capacity Retention in Rechargeable 4 V Lithium/ Lithium-Manganese Oxide (Spinel) Cells. Solid State Ionics, 69, 59-67. http://dx.doi.org/10.1016/0167-2738(94)90450-2

- Jang, D.H., Shin, Y.J. and Oh, S.M. (1996) Dissolution of Spinel Oxides and Capacity Losses in 4V Li/LixMn2O4 Coils. Journal of the Electrochemical Society, 143, 2204-2211. http://dx.doi.org/10.1149/1.1836981

- Wu, X.L. and Kim, S.B. (2002) Improvement of Electrochemical Properties of LiNi0.5Mn1.5O4 Spinel. Journal of Power Sources, 109, 53-57. http://dx.doi.org/10.1016/S0378-7753(02)00034-4

- Tarascon, J.M., Wang, E., Shokoohi, F.K., McKinnon, W.R. and Colson, S. (1991) The Spinel Phase of LiMn2O4 as a Cathode in Secondary Lithium Cells. Journal of the Electrochemical Society, 138, 2859-2864. http://dx.doi.org/10.1149/1.2085330

- Hernan, L., Morales, J., Sanchez, L. and Santos, J. (1999) Use of Li-M-Mn-O [M = Co, Cr, Ti] Spinels Prepared by a Sol-Gel Method as Cathodes in High-Voltage Lithium Batteries. Solid State Ionics, 118, 179-185. http://dx.doi.org/10.1016/S0167-2738(98)00449-4

- Thackeray, M.M., Johnson, C.S., Kim, J.S., Lauzze, K.C., Vaughey, J.T., Dietz, N., Abraham, D., Hackney, S.A., Zelt- ner, W. and Anderson, M.A. (2003) ZrO2- and Li2ZrO3-Stabilized Spinel and Layered Electrodes for Lithium Batteries. Electrochemistry Communications, 5, 752-758. http://dx.doi.org/10.1016/S1388-2481(03)00179-6

- Cho, J., Kim, Y.J., Kim, T.J. and Park, B. (2001) Enhanced Structural Stability of O-LiMnO2 by Sol-Gel Coating of Al2O3. Chemistry of Materials, 13, 18-20.http://dx.doi.org/10.1021/cm000759+

- Zheng, Z.H., Tang, Z.L., Zhang, Z.T., Shen, W.C. and Lin, Y.H. (2002) Surface Modification of Li1.03Mn1.97O4 Spinels for Improved Capacity Retention. Solid State Ionics, 148, 317-321. http://dx.doi.org/10.1016/S0167-2738(02)00068-1

- Gnanaraj, J.S., Pol, V.G., Gedanken, A. and Aurbach, D. (2003) Improving the High-Temperature Performance of LiMn2O4 Spinel Electrodes by Coating the Active Mass with MgO via a Sonochemical Method. Electrochemistry Communications, 5, 940-945. http://dx.doi.org/10.1016/j.elecom.2003.08.012

- Wu, F., Wang, M., Su, Y.F., Chen, S. and Xu, B. (2009) Effect of TiO2-Coating on the Electrochemical Performances of LiCo1/3Ni1/3Mn1/3O2. Journal of Power Sources, 191, 628-632. http://dx.doi.org/10.1016/j.jpowsour.2009.02.063

- He, X.M., Li, J.J., Cai, Y., Wang, Y.W., Ying, J.R., Jiang, C.Y. and Wan, C.R. (2005) Preparation of Co-Doped Sphe- rical Spinel LiMn2O4 Cathode Materials for Li-Ion Batteries. Journal of Power Sources, 150, 216-222. http://dx.doi.org/10.1016/j.jpowsour.2005.02.029

- Myung, S.T., Izumi, K., Komaba, S., Sun, Y.K., Yashiro, H. and Kumagai, N. (2005) Role of Alumina Coating on Li- Ni-Co-Mn-O Particles as Positive Electrode Material for Lithium-Ion Batteries. Chemistry of Materials, 17, 3695-3704. http://dx.doi.org/10.1021/cm050566s

- Jang, S.B., Kang, S.H., Amine, K., Bae, Y.C. and Sun, Y.K. (2005) Synthesis and Improved Electrochemical Performance of Al (OH)3-Coated Li[Ni1/3Mn1/3Co1/3]O2 Cathode Materials at Elevated Temperature. Electrochimica Acta, 50, 4168-4173. http://dx.doi.org/10.1016/j.electacta.2005.01.037

- Levi, M.D., Gamolsky, K., Aurbach, D., Heider, U. and Oesten, R. (2000) On Electrochemical Impedance Measurements of LixCo0.2Ni0.8O2 and LixNiO2 Intercalation Electrodes. Electrochimica Acta, 45, 1781-1789. http://dx.doi.org/10.1016/S0013-4686(99)00402-8

- Fey, G.T.K., Lu, C.Z. and Kumar, T.P. (2003) Preparation and Electrochemical Properties of High-Voltage Cathode Materials, LiMyNi0.5-yMn1.5O4 (M = Fe, Cu, Al, Mg; y = 0.0 - 0.4). Journal of Power Sources, 115, 332-345. http://dx.doi.org/10.1016/S0378-7753(03)00010-7

NOTES

*Corresponding author.