Open Journal of Civil Engineering

Vol.2 No.1(2012), Article ID:17809,6 pages DOI:10.4236/ojce.2012.21003

Application of the Combined Method for Evaluating the Compressive Strength of Concrete on Site

Civil Engineering Department, Faculty of Engineering Sciences, University Mentouri, Constantine, Algeria

Email: {samia.hannachi, mnguetteche}@yahoo.fr

Received January 12, 2012; revised February 18, 2012; accepted February 28, 2012

Keywords: Nondestructive Testing; Rebound Hammer; Ultrasonic Pulse Velocity; Combined Method; Compressive Strength; Specimen Samples; Cores; Regression Analysis

ABSTRACT

Ultrasonic pulse velocity (UPV) and rebound hammer (RH) tests are often used for assessing the quality of concrete and estimation of its compressive strength. Several parameters influence this property of concrete as the type and size of aggregates, cement content, the implementation of concrete, etc. To account for these factors, both of the two tests are combined and their measurements are calibrated with the results of mechanical tests on cylindrical specimens cast on site and on cores taken from the existing structure in work progress at the new-city Massinissa El-Khroub Constantine in Algeria. In this study; the two tests cited above have been used to determine the concrete quality by applying regression analysis models between compressive strength of in situ concrete on existing structure and the nondestructive tests values, the combined method is used, equations are derived using statistical analysis (simple and multiple regression) to estimate compressive strength of concrete on site and the reliability of the technique for prediction of the strength is discussed for this case study.

1. Introduction

Evaluation of concrete properties is of great interest, whether to detect altered areasor to control the concrete quality and estimate its compressive strength [1].

The standard methods used to assess the quality of concrete in concrete structures on specimens cannot be considered. The disadvantage is that results are not immediately known, the number of specimens or samples is insufficient for an economic reason, still does not reflect the reality of the structure [2].

The main advantage of nondestructive testing method is to avoid the concrete damage on the performance of building structural components. Additionally, their usage is simple and quick. Test results are available on site. Concrete testing in structures is demanding in which the cores cannot be drilled, where the use of less expensive equipments is required [3].

Several nondestructive evaluation methods have been developed; based on the fact that some physical properties of concrete can be related to the compressive strength of concrete. The Schmidt rebound hammer (SRH) and the ultrasonic pulse velocity (UPV) tests, are combined to develop correlation between hammer/ultrasonic pulse velocity readings and the compressive strength of the concrete. These non-destructive measurements have proved to be an effective tool for inspection of concrete quality concrete.

2. Evaluation of Concrete Structures by Nondestructive Methods

The nondestructive testing of concrete has a great technical and useful importance. These techniques have been grown during recent years especially in the case of construction assessment.

All available methods for evaluating in-situ concrete are limited, their reliability is often questioned, and the combination of two or more techniques is emerging as an answer to all these problems [4].

The combination of several techniques of nondestructive testing is often implemented empirically, combining two techniques most often used to enhance the reliability of the estimate compressive strength of concrete; the principle is based on correlations between observed measurements and the desired property [5].

The compressive strength of concrete is usually the most sought after property. This is leads to the development of a method that combines index rebound hammer and the ultrasonic pulse velocity UPV [1].

The objective of the combined tests is to evaluate the compressive strength of concrete in situ; the best approach is generally to develop a relationship of correlation between the upv/the index of rebound hammer and the compressive strength of standardized laboratory specimen, in some cases specimen are not available, then a number of cores must be taken to establish this relationship [6]. The standardized combined method the most widely used is SonReb method developed by RILEM [7], first born and established in Romania then developed in Australia and in Europe. The improvement in the reliability of the measures is explained by taking into account the contradictory effect of variability factors of some properties for each of the two techniques (ultrasonic pulse velocity/rebound hammer).

2.1. Rebound Hammer (RH) Test EN12504-2

The rebound (Schmidt) hammer is one of the oldest and best known methods. It is usually used in comparing the concrete in various parts of a structure and indirectly assessing concrete strength. The hammer weighs about 1.8 kg and is suitable for use both in a laboratory and in the field. The rebound of an elastic mass depends on the hardness of the surface against which its mass strikes.

The test is described in ASTM C805 and EN12504- 2:2001. The results of rebound hammer are significantly influenced by several factors [4,6] such as: smoothness of test surface; size, shape, and rigidity of the specimens; age of the specimen; surface and internal moisture conditions of the concrete; type of coarse aggregate; type of cement; carbonation of concrete surface.

According to EN13791:2003 standard rebound hammer test with calibration by means of cores test may be used for assessment of in situ concrete strength. In situ strength can be estimated using a basic relationship with a determined factor for shifting the basic relationship curve to take into account of the specific concrete and production procedure [6].

2.2. Ultrasonic Pulse Velocity (UPV) EN 12504-4(a) Rebound Hardness Test

The method consists of measuring the ultrasonic pulse velocity through the concrete with a generator and a receiver. The tests can be performed on samples in the laboratory or on-site. Many factors affect the results, the surface and the maturity of concrete, the travel distance of the wave, the presence of reinforcement, mixture proportion, aggregate type and size, age of concrete, moisture content, etc., furthermore some factors significantly affecting UPV might have little influence on concrete strength [8].

The test is described in ASTM C597, EN12504-4:2004, a critical comparison of several standards from different countries is given in a review paper by Komlos [9].

2.3. Core Sampling in Situ EN12504-1

Coring is a direct measure of the in-situ strength of concrete. It is mainly used to provide a calibration of an indirect method and rarely used for determining the rate of strength gain.

Core sampling is a destructive test which is used to evaluate the suspicious concrete. At least 3 core samples should be taken from each area. The height of core cylinder is 2.0 diameters and maximum size of aggregate is 1/4 diameter or less.

Due to unknown effects of reinforcing bars in the samples and also in order to keep the integrity of structure, it is better to provide bar detection process before coring and to remove the bars from samples before putting them in compression machine. Any visual defect of concrete should be recorded before compression test and should be applied in analysis [10].

3. Experimental Methodology

In this study data from destructive testing and nondestructive testing are provided by the laboratory—CTC-Constantine (Algeria body control) for monitoring and quality control of structures in work progress.

The objective of this work is to study the reliability of these nondestructive techniques and identify factors that affect the interpretation of their results.

The interpretation of results is given through a combination of correlations between nondestructive techniques and those of mechanical tests.

Correlations between compressive strength at 28-day specimens (16/32) cast on site for a concrete proportioned to 350 kg/m3 and stored in air and measures of non-destructive testing in case the hammer and ultrasonic Correlations between compressive strength of cores from the concrete structure (Cores with a diameter of 6.5 cm and a height of 13 cm.

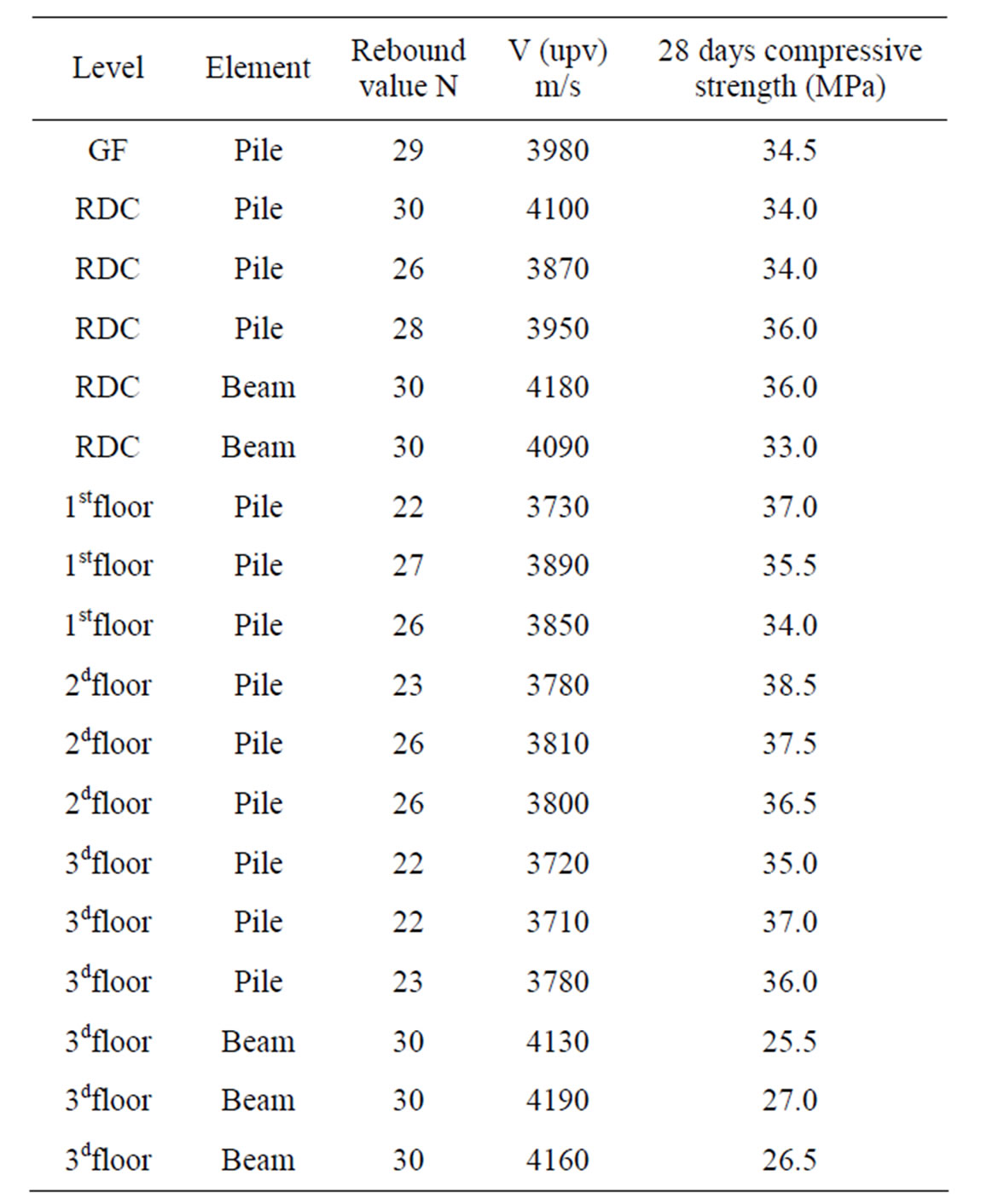

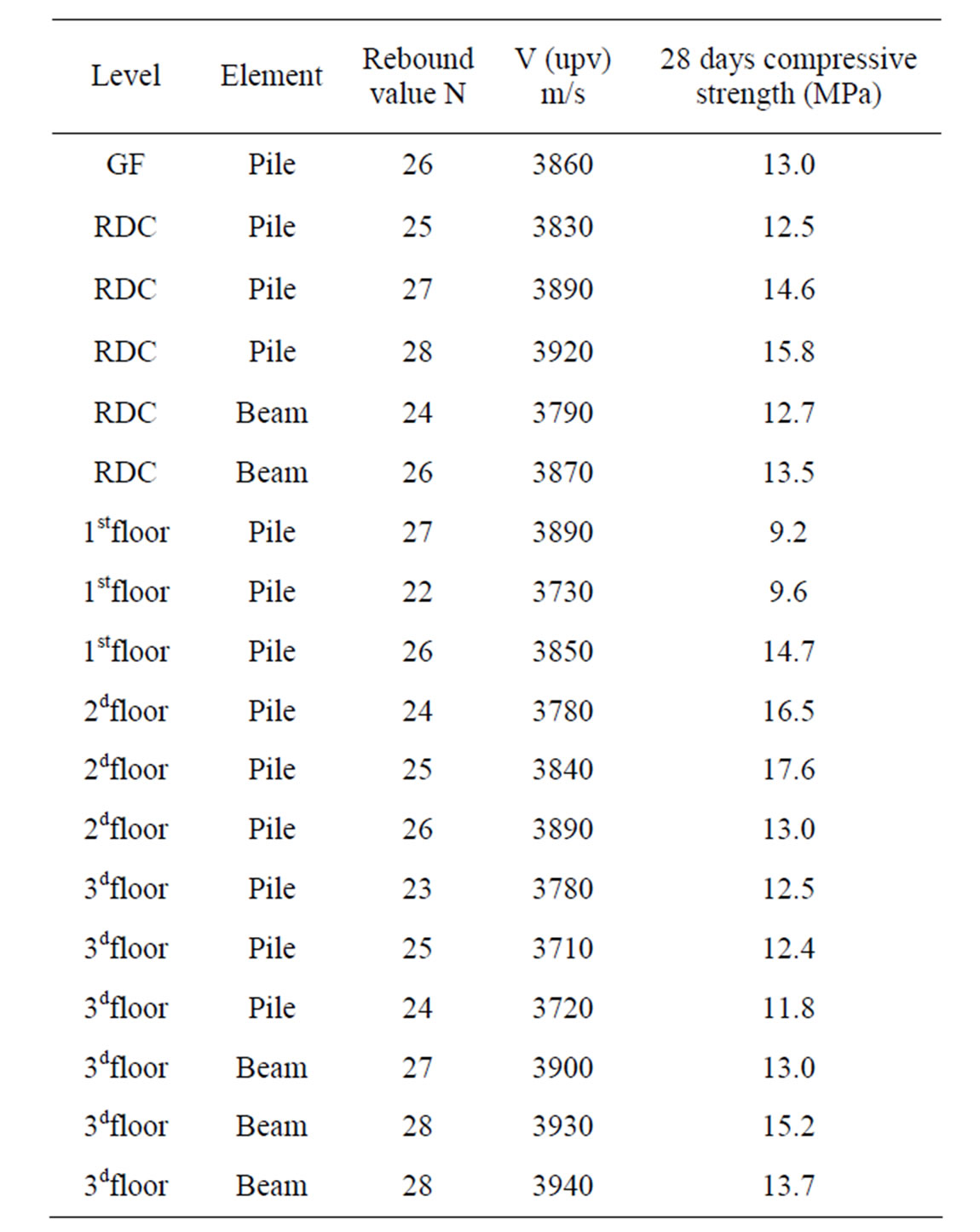

All data from both destructive tests and nondestructive test are resumed in Tables 1 and 2.

4. Combined Method

The reduction of the influence of several factors affecting rebound hammer test and UPV method could be partially achieved by using both methods together. A classical example of this application is the SONREB method, developed mostly by the effort of RILEM Technical Committees 7 NDT and TC-43 CND [7] and widely adopted in Romania [11]. The relationship between UPV, rebound hammer and concrete compressive strength are there given in the form of a monogram.

The improvement of the accuracy of the strength prediction according to Facaoaru [11] is achieved by the use of correction factors taking into account the influence of cement type, cement content, petrologic aggregate type,

Table 1. Test data for specimens.

Table 2. Test data for cores.

fine aggregate fraction, and aggregate maximum size. The accuracy of the combination of rebound hammer and ultrasonic pulse velocity results in improved accuracy in estimating the compressive strength of concrete.

The interest in using the combined technique is that the variability of certain properties of concrete produce opposite effects for each of its components (hammer and UPV). For example a raise in moisture increases the value of the ultrasonic pulse velocity but decreases the value of the rebound hammer.

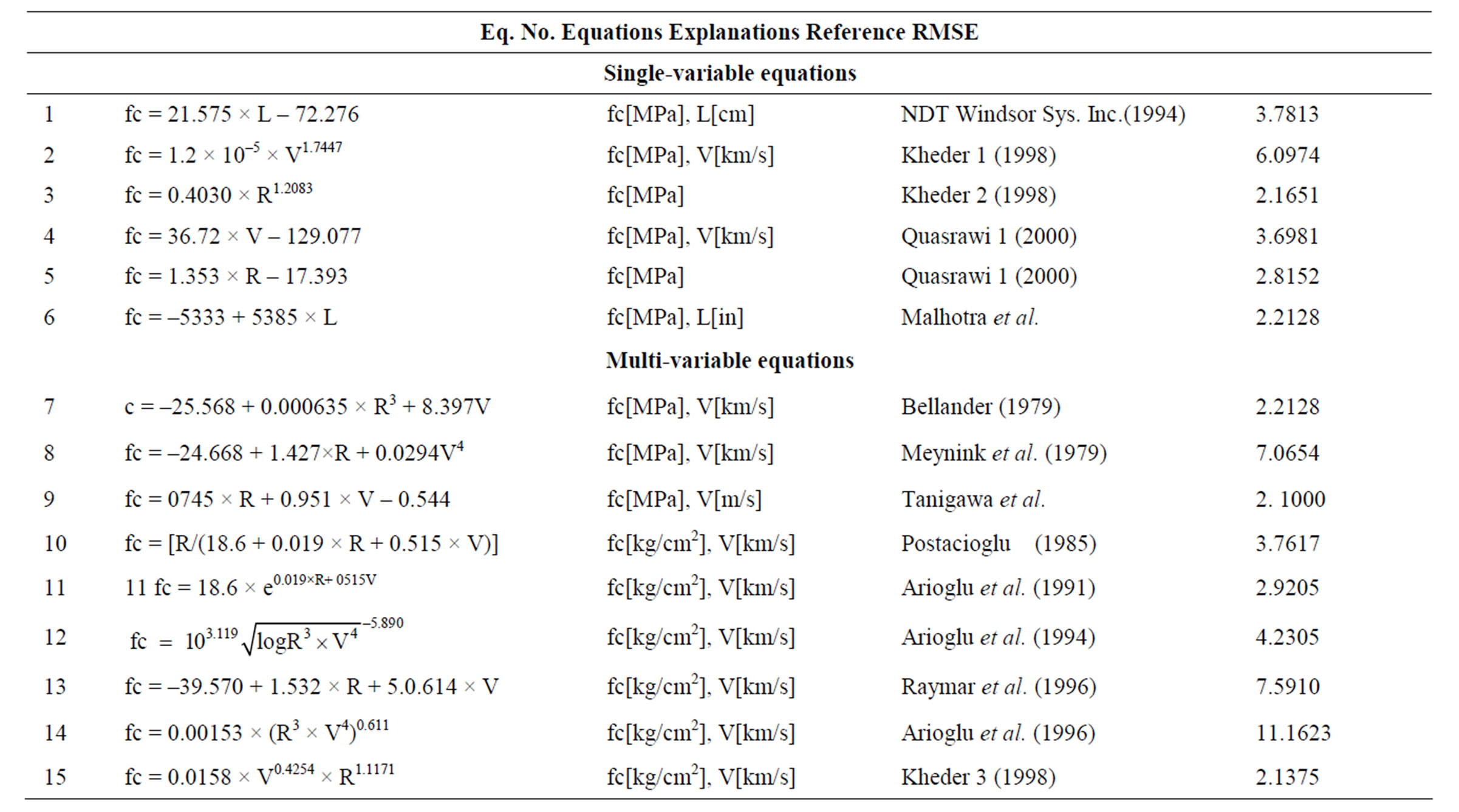

Several linear and nonlinear multiple correlation equations have been developed (Table 3) and are available in literature: Tanigawaand et al. 1984; Malothra and Carino, 1991; Qasrawi, 2000; Ariogluand et al. 2001 [12].

5. Statistical Analysis

All research has shown that petrographic property of aggregates and the composition and means of implementation of concrete significantly influences the values of the rebound hammer and the ultrasonic pulse velocity. To overcome erroneous results and improve the reliability of estimating the compressive strength by nondestructive testing, it is essential to calibrate the measurements from the two trials.

The statistical analysis seems to be the solution to interpret the observed data using the results of mechanical tests on specimens and cores and is needed to calibrate these tests.

In this study, relationships between the results of mechanical testing of specimens and cores and those from non-destructive testing (UPV and RH) are established, the values are plot in graphs, and Matlab is used to extract the curves (regression line), and R2: determination coefficients are obtained for each regression line.

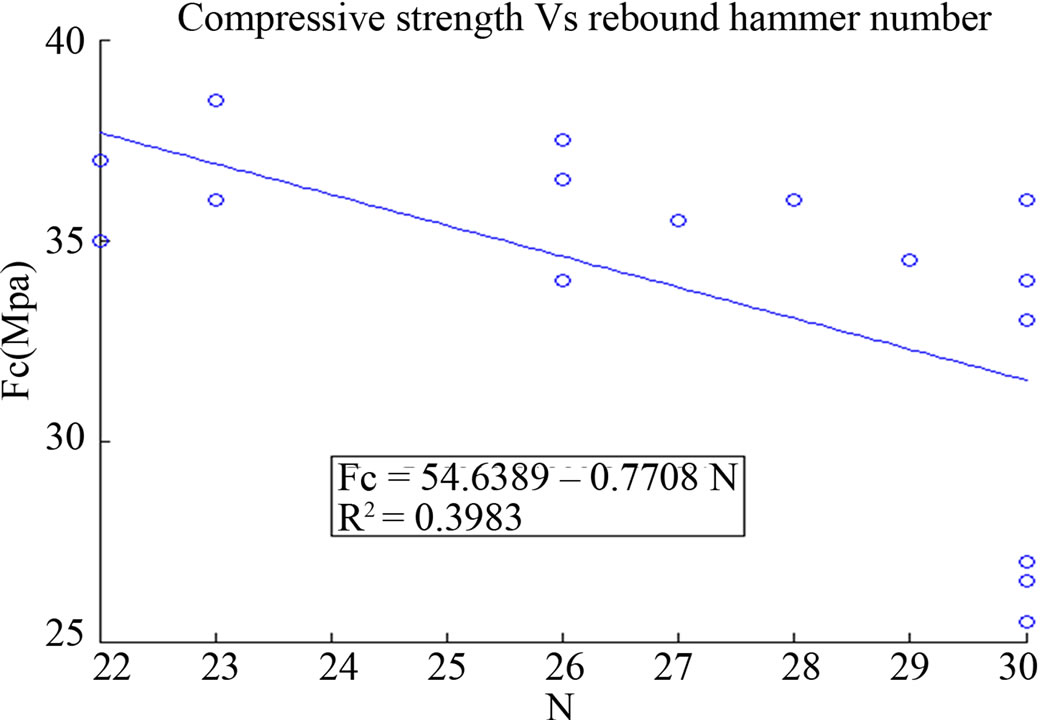

Simple linear regression is adopted to obtain the correlations below: Figures 1-6.

Resistance RES (dependent variable)-vs-N; hammer index (independent variable).

Resistance RES (dependent variable)-vs-V; ultrasonic velocity (independent variable).

Multiple linear regressions is adopted to find correlations Resistance RES (dependent variable)-vs-Index hammer and ultrasonic velocity (N, V) (independent variables).

In parallel with the statistical analysis; other procedures are needed to analyze the results of correlations; standards and specifications are developed [4,13] an none has achieved consensus as hoped.

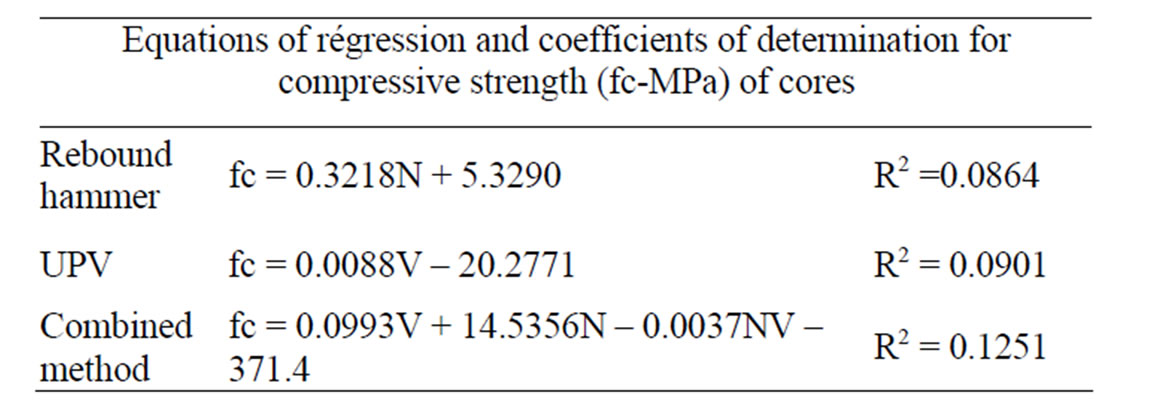

Tables 4 and 5 summarize regression equations and the values of determination coefficients for both the correlations made for cylindrical specimen and cores.

6. Conclusions and Discussion

Based on this study, it appears that using more than one

Table 3. Equations of existing relationship used for compressive strength estimation of concrete [12].

Figure 1. Correlation: compressive strength-rebound number (cylindrical specimens).

Figure 2. Correlation: compressive strength-ultrasonic pulse velocity (cylindrical specimens).

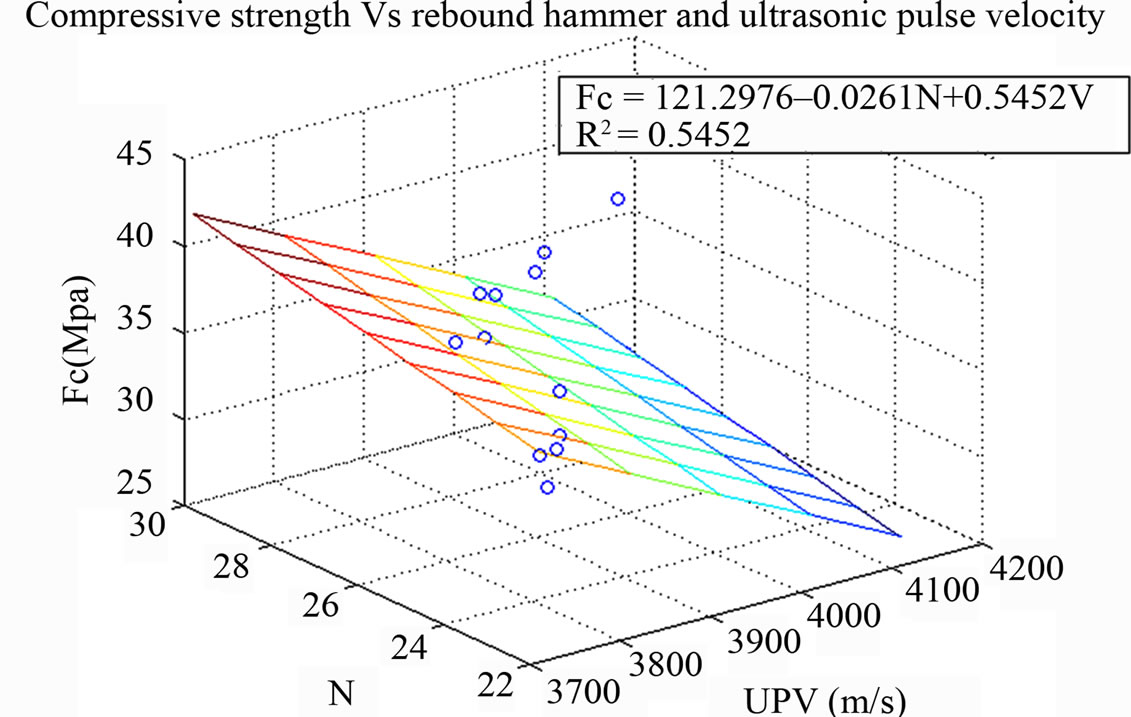

Figure 3. Correlation: compressive strength-rebound number and ultrasonic pulse velocity (cylindrical specimens).

Figure 4. Correlation: compressive strength-rebound number (cores).

Figure 5. Correlation: compressive strength-ultrasonic pulse velocity (cores).

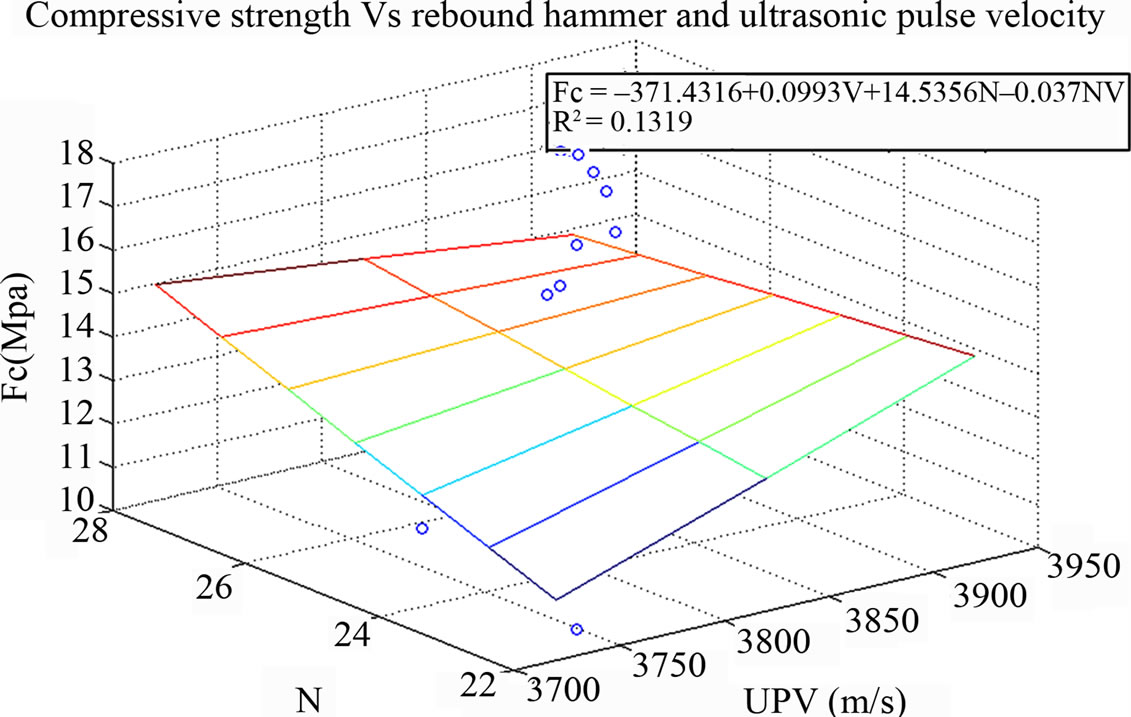

Figure 6. Correlation: compressive strength-rebound number and ultrasonic pulse velocity (cores).

Table 4. Regressions equations forcylindrical specimens.

Table 5. Regression equations forcores.

non-destructive technique provides a better correlation and in this sense contributes to more reliable strength evaluation of concrete.

The combined method seems more promising to evaluate the compressive strength of concrete in construction. It will also be noted that correlations between destructive testing and non-destructive techniques in our study provide more meaningful results for the specimens cast and stored under the same conditions as the concrete structure than taken cores.

The analysis for cores gives correlations that are not really satisfactory, this is explained by the fact that:

The quality and means of implementation of concrete which are often inadequate, in terms of social housing programs often attributed to small companies without major resources.

The sampling areas of taking cores are not really representative of concrete, since most often taken at random, because hardly feasible.

The core drilling way and conditions can affect the integrity of the cores.

Nevertheless these combined non-destructive methods can inform us about the quality of concrete and it will be better for a good quality-control monitoring of concrete; to establish correlations between mechanical tests on specimens cast and stored in same conditions as the concrete structure rather than using cores that are very difficult to achieve less representative and more expensive to obtain.

In general, the combined method appears more appropriate to conditions on-site measurements, very convenient, fast and with a reasonable cost. Once the correlations are established between the compressive strength values of samples derived from mechanical tests and measurements from non-destructive techniques (the rebound hammer and ultrasonic pulse velocity); the prediction of concrete strength value appears more reliable.

The practical use of this technique is gaining recognition on a large scale; it provides contracting authorities with accurate and objective information for monitoring quality-control of concrete construction.

REFERENCES

- D. Breysse, “Quality of NDT Measurements and Accuracy of Physical Properties,” Concrete NDTCE’09, Nantes, 30 June-3 July, 2009.

- International Atomic Energy Agency, “Guidebook for the Fabrication of Nondestructive Testing Training Course,” Series No. 13, 2001.

- B. Hobbs and K. Tchoketch, “Nondestructive Testing Techniques for the Forensic Engineering Investigation of Reinforced Concrete Buildings,” Forensic Science International, Vol. 167, No. 2-3, 2007, pp. 167-172. doi:10.1016/j.forsciint.2006.06.065

- J. H. Bungey and S. G. Millard, “Testing of Concrete in Structures,” 3rd Edition, Blackie Academic & Professional, London, 1996.

- D. Breysse, “Combining Information, Reliability and Maintenance,” Diagnosis of NEC Works, 2008

- V. M. Malhotra and N. J. Carino, “CRC Handbook on Nondestructive Testing of Concrete,” CRC Press, Boca Raton, 1991.

- Rilem Report TC43-CND, “Draft Recommendation for in Situ Concrete Strength Determination by Combined NonDestructive Methods,” 1983.

- Y. Lin, C. Lai and T. Yen, “Prediction of Ultrasonic Pulse Velocity (UPV) in Concrete,” ACI Materials Journal, Vol. 100, No. 1, 2003, pp. 21-28.

- K. Komlos, S. Popovics, T. Nurnbergerova, B. Babal and J. S. Popovics, “Ultrasonic Pulse Velocity Test of Concrete Properties as Specified in Various Standard,” Cement and Concrete Composites, Vol. 18, No. 5, 1996, pp. 357-364.

- L. Divet, “Techniques for Diagnosing the Condition of Concrete,” LCPC Presentation, Nantes, 2005.

- I. Facaoaru, “Non-Destructive Testing of Concrete in Romania, Symposium on NDT of Concrete and Timber,” Institute of Civil Engineers, London, 1970, pp. 39-49.

- M. Erdal, “Prediction of the Compressive Strength of Vacuum Processed Concretes Using Artificial Neural Network and Regression Techniques,” Scientific Research and Essay, Vol. 4, No. 10, 2009, pp. 1057-1065.

- Hindo and Bergstrom, “Statistical Evaluation of the inPlace Strength of Concrete,” Concrete International, Vol. 7, No. 2, 1985, pp. 44-48.