Open Journal of Composite Materials

Vol.3 No.2A(2013), Article ID:30682,5 pages DOI:10.4236/ojcm.2013.32A003

Laser Synthesis of Metal Oxide Crystals with the Use of Carbon Nanotubes

![]()

Department of Physics and Applied Mathematics, Vladimir State University, Vladimir, Russia.

Email: *awraam@mail.ru

Copyright © 2013 Dmitrii V. Abramov et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received February 27th, 2013; revised March 28th, 2013; accepted April 18th, 2013

Keywords: Laser Synthesis; Titanium Oxide; Aluminum Oxide; Carbon Nanotubes; Whiskers

ABSTRACT

The results of experimental studies in the direction of the laser forming of nanostructured arrays of metal oxide crystals are presented in this paper. Laser synthesis of crystals of titanium oxide and aluminum oxide was investigated. Carbon nanotubes have been used to control the process of crystal growth. Formation of structures was carried out under the action of CW ytterbium fiber laser with intensity on the order 105 W/cm2. Laser irradiation of the initial target occurred with applying an external accelerating electric field. Various forms of metal oxide crystals were obtained. Whiskers with cross dimensions on the order of 100 nm have been found among the formed structures.

1. Introduction

Synthesis of low-dimensional oxide materials is now intensively developing scientific field. Such attention to nanostructures of metal oxides is due to new prospects of their use in various fields of science, technology and industrial applications: microelectronics, chemical catalysis, material science engineering and energy conversion [1].

Titanium oxide is one of the most prevalent of oxygen with metals. This material is well researched and used in many practical applications (from the cosmetics industry to the production of photochemical battery). Nanostructuring of this material opens up new opportunities [2]. Aluminum oxide is also very interesting material. It is used in all branches of industry. This is caused its physical properties and availability of raw materials. Corundum, sapphire, mullite and other modifications of aluminum oxide used at the production of ceramics, microelectronic and photonic devices, production of engineering and etc. At present, special attention is focused on nanostructured alumina. This material proved itself perfectly as a dielectric base of optoelectronics systems and reinforcing element of various types of ceramics. Whiskers of aluminum oxide are especially promising in the last case. This is determined primarily by their high elastic-strength properties and heat resistance. Strength of alumina whiskers is 40 GPa and their elasticity modulus is 400 - 2300 GPa [3].

The most common approach to the creation of nanostructures is their synthesis from gases or vapors. Its variants differ only in the methods of obtaining of required medium and material deposition conditions. Experimental studies have shown that metal oxide whiskers are effectively synthesized from the products of laser ablation of the materials [4]. This approach is very promising for such a refractory material as aluminum oxide. Obviously, this approach may also be used for the formation of titanium oxide crystals. Addition of carbon nanotubes into the irradiated area changes the conditions of interaction of laser radiation with the surface of the target and character of oxide crystal growth. In this paper we present the experimental results which were obtained in the Vladimir State University in the direction of development of the laser methods for formation of nanostructured metal oxide crystal (titanium oxide and aluminum oxide).

2. Experimental Technique

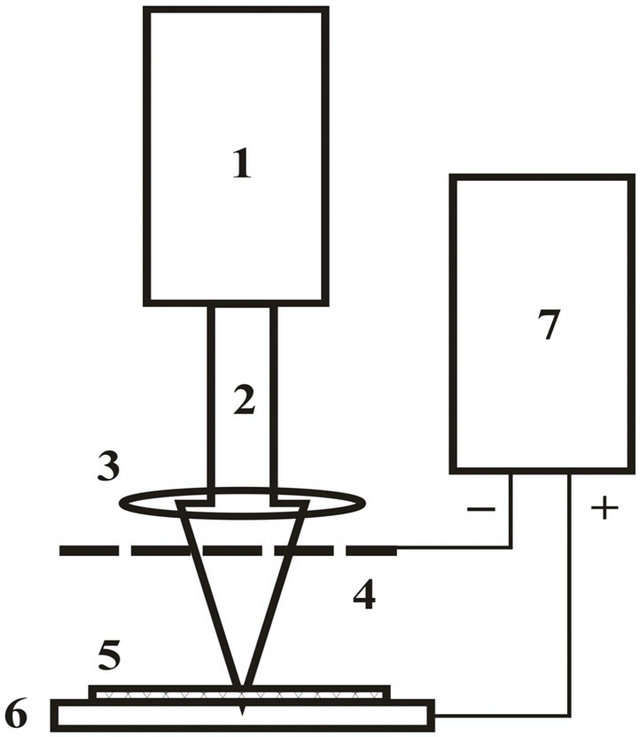

Formation of metal oxide nanocrystals on the samples surface was carried out under action of radiation of CW ytterbium fiber laser LS-02. In the case of the synthesis of titanium oxide the material of irradiated target is titanium alloy VT-9 (Ti—89.9%, Al—5.8%, Mo—2.8%, Zr —0.8%, Si—0.2%, Fe—0.2%, C—0.1%, O—0.15%, other impurities—0.05%). Aluminum oxide was synthesized on the surface of a target from aluminum alloy AD1 (Al—99.3%, Ti—0.05%, Fe—0.3%, Si—0.3%, other impurities—0.05%). Experimental setup is shown in Figure 1.

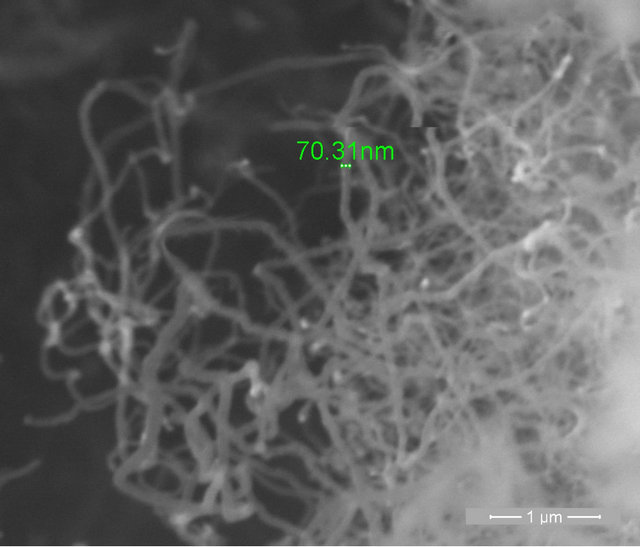

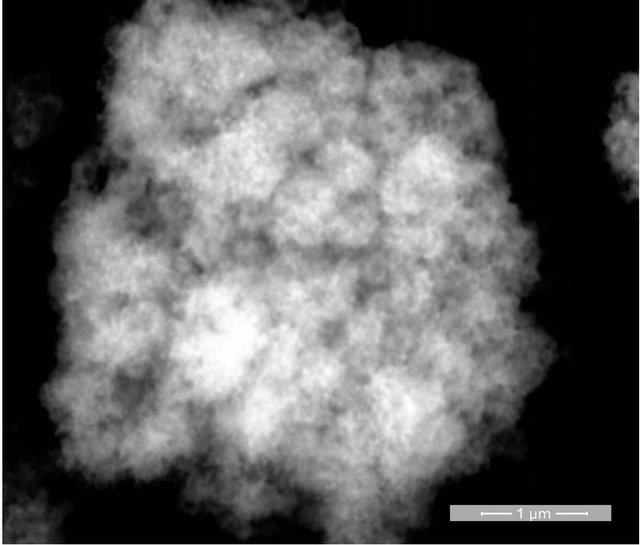

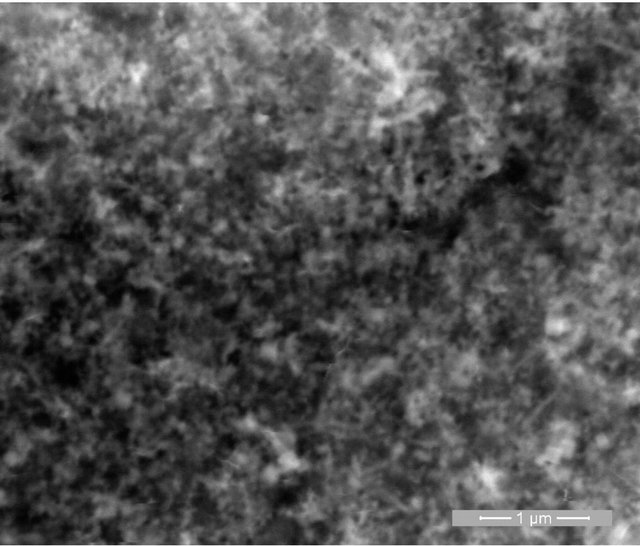

The target (irradiated sample) 6 was installed in working area of the laser 1. Target surface was covered with a layer of carbon nanotubes 5 with thickness 0.5 mm. The average diameter of carbon nanotubes is about 100 nm (Figure 2).

The radiation of the laser was directed to the target perpendicular to the plane of its surface. Power of laser radiation 2 was 20 W. Lens 3 has focal length 50 mm. It focused laser beam on the surface of the sample to a spot with diameter 100 microns. The intensity of the laser radiation on the surface of the metal was 2.5 × 105 W/cm2. Metal net 4 was installed at a distance 40 mm from the target surface. It has no significant effect on the passage of the laser radiation. The target and the grid were connected to the power supply 7 as shown in Figure 1. The accelerating voltage was set in the area of laser action on the sample. Voltage was varied from 1 to 30 V. Time of laser action to a target surface is 10 s. Results of laser pocessing of a samples surface were investigated by means of a scanning electronic microscope Quanta 200 3D.

Figure 1. Experimental setup: 1—ytterbium fiber laser LS- 02; 2—laser radiation; 3—lens; 4—metal net; 5—layer of carbon nanotubes; 6—target; 7—power supply.

Figure 2. Obtained by means of scanning electronic microscope Quanta 200 3D image (SEM image) of carbon nanotubes.

3. Experimental Results

Action of laser radiation does not lead to the destruction of carbon nanotubes. They were removed from the sample surface after laser treatment and could be used in other experiments. Arrays of metal oxide crystals were registered on the cleaned surface of the sample. It should be noted that the surface of the samples does not melted during the laser treatment.

3.1. Synthesis of Titanium Oxide Crystals

The main influence of carbon nanotubes is to change the character of formation of the oxide layer. Titanium oxide is formed not as a compact layer but in the form of an array of crystals. In addition, the obtained results confirmed the theoretical assumptions about the possibility of controlling the characteristics of the crystals by an electric field.

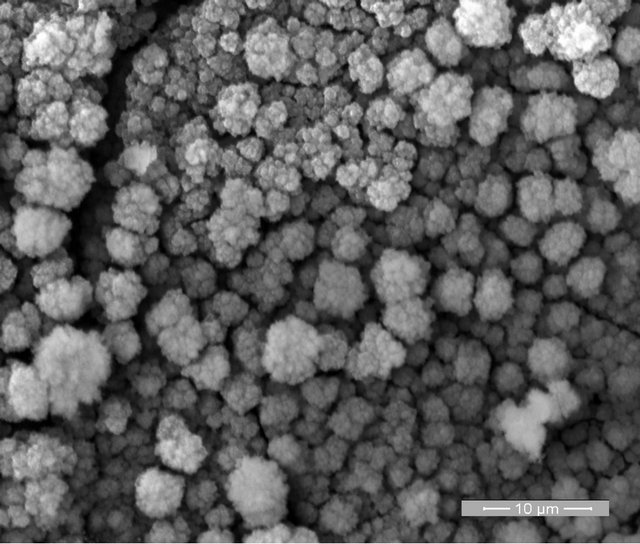

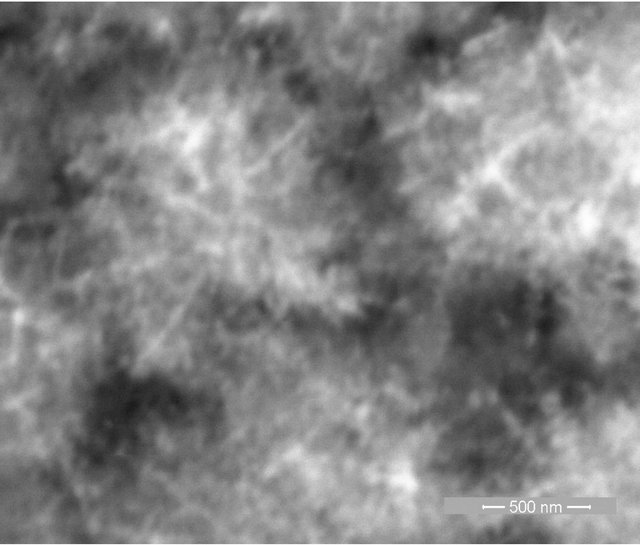

In the absence of the control field the products of laser damage are deposited on the surface in the form of dense spherical structures. These structures are combined into larger formations (conglomerates). Formed conglomerates belong to the type “cauliflower”. Accelerating electric field changes the structure of formed conglomerates. General view of the oxide layer on the surface of titanium sample is shown in Figure 3. This layer was formed under action of laser radiation with power 15 W in the accelerating electrostatic field strength of 375 V/m. Layer consists of conglomerates with a diameter from 1 to 5 micrometers.

Enlarged images of conglomerates titanium oxide are shown in Figure 4. Conglomerates consist of elements with size from 200 to 600 nanometers. Their surface is formed by fibers with a transverse size about 50 nm (Figure 4(b)). The Figure 4(a) shows that in conditions of the carried out experiment the titanium oxide layer on the sample surface is not continuous. There are gaps between conglomerates width to 1.5 micrometer. Two ap-

Figure 3. General view of the oxide layer.

(a)

(a) (b)

(b)

Figure 4. SEM images of some part of the titanium oxide layer: (a) Increase 20,000×; (b) Increase 40,000×.

proaches can be used to elimination of these gaps. First, the laser power can be increased. This will increase the concentration of the products of destruction. Consequently, the rate of the formation of the oxide layer will increase too. In the second, the exposure time can be increased. Then conglomerates gradually gathered together and the gaps will be eliminated. As a result, continuity of the oxide layer will be restored. Additional energy costs are a negative consequence of both approaches.

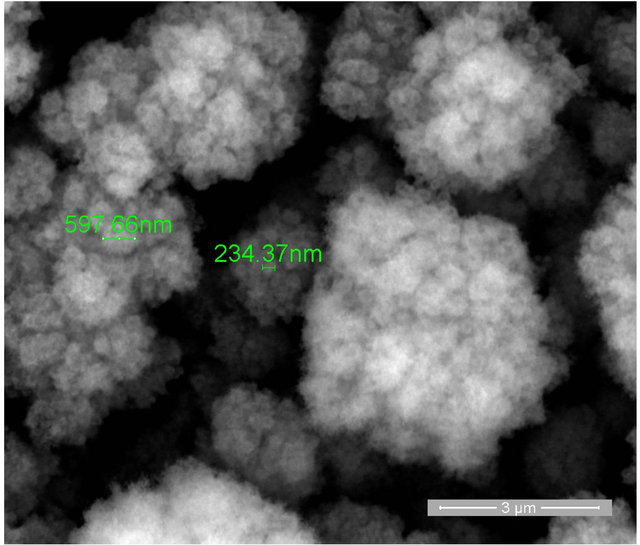

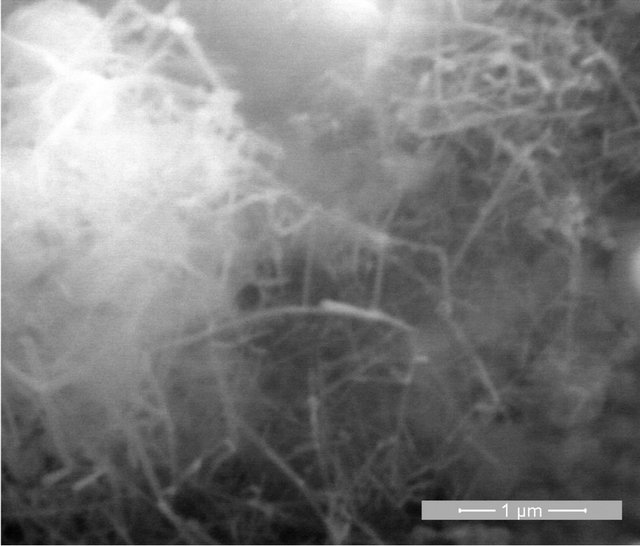

Studies have shown that increasing the voltage of the electric field results in a significant change in the form of structures that form a layer of titanium oxide. SEM images of nanostructured titanium oxide layer witch are formed under action of laser radiation with power 15 W in the accelerating electrostatic field with strength 625 V/m are shown in Figure 5. Laser exposure time is the same as in the previous experiment (10 s). Result of changes in the conditions of laser action was the forma-

(a)

(a) (b)

(b)

Figure 5. Layer of branched structures of titanium oxide: (a) General view (increase 20,000×); (b) Part of layer (increase 80,000×).

tion of a titanium oxide layer in the form of an array of branched structures. Size registered branched structures of titanium oxide from 1 to 3 micrometers. Branches of structures are filamentary crystals (whiskers). The transverse size of these crystals is less than 50 nm (Figure 5(b)). Structures close and even overlap. A slight number of gaps between conglomerates with a width of about 100 nanometers are observed.

Thus, the continuity of the titanium oxide layer on the surface of the sample is improved. This is determined by a higher rate of growth of filamentary structures in comparison with the formation of spheres. The homogeneity of the layer as defined by the possibility of penetration of branched structures in each other. It is principle impossible at the formation of conglomerates with a solid surface. It should be noted that the character of the formation of the registered structures different from the growth of zinc oxide whisker [4]. Series connection of spherical elements with a diameter about 10 nm is registered in the filamentary structures of titanium oxide, whereas crystals of zinc oxide are linear and rather flat. Overall fractal character of growth of branched structures is preserved.

Separate clearly expressed whiskers registered on modified by laser radiation surface. They can be divided into two types. First, it is rods with the transverse size of up to 200 nm (Figure 6(a)) similar whiskers which were obtained on the surface of brass [4]. Second, the structures having the form of five-way druses are registered on the irradiated surface (Figure 6(b)). They can be complete or defective (in the form of unformed for some reason individual rays). The transverse size of druses rays does not exceed 200 nm. Length of rays may be up to 3 micrometers or more. Spherical formations are formed on the ends of the rays. The diameter of the spheres is usually in three times more than the transverse size of rays. However, the large ratio of the diameter sphere to the transverse size of ray is also registered. This

(a)

(a) (b)

(b)

Figure 6. SEM images of arrays of titanium oxide whiskers: (a) Nanorods; (b) A five-way druses.

is typical for very thin whiskers. Large locally based whiskers of titanium oxide and their arrays are registered on surface of the treated by laser radiation sample in small quantities. Apparently, the seed of their growth are nanoscale droplets of molten material that were captured carbon nanotubes.

3.2. Synthesis of Aluminum Oxide Crystals

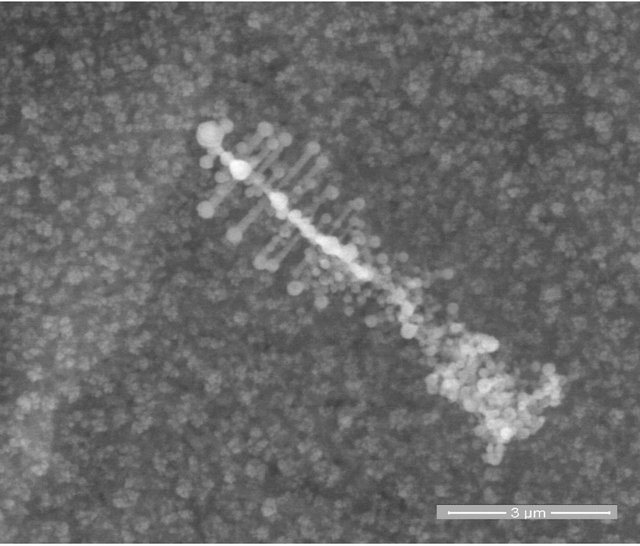

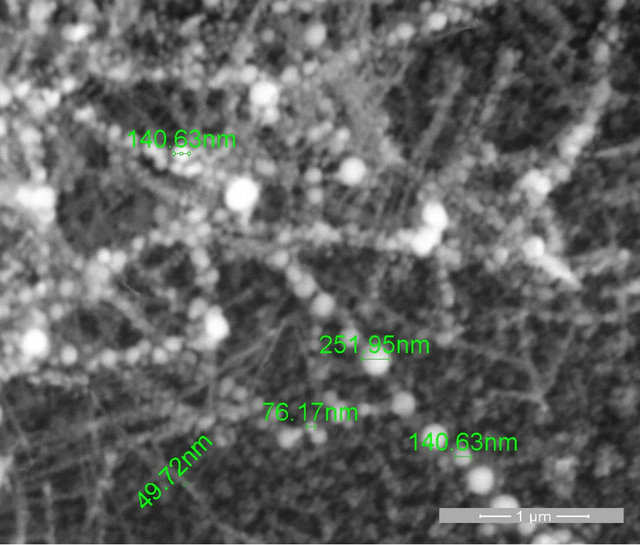

In general, laser synthesis of crystals of aluminum oxide is similar to the formation of the structures of titanium oxide. Products of laser damage form the arrays of conglomerates such as “cauliflower” on the surface of the sample if the control electric field is absent. The influence of the accelerating electric field leads to the formation of a layer of aluminum oxide in the form of branched structures (Figure 7(a)). Size of structure element of alumina is less than 100 nm.

Separate arrays of large whiskers were registered on the background main of the oxide layer. They have the

(a)

(a) (b)

(b)

Figure 7. SEM images of the of aluminum oxide layer: (a) General view of layer; (b) Array of nanorods.

form of branched systems of nanorods (Figure 7(b)). The total size of a single array of nanorods has order 10 micrometers. Whiskers of alumina have smaller transverse dimensions in comparison with the sizes of titanium oxide nanorods. Their average transverse sizes are about 50 nanometers.

The formation of sequences of spherical elements is detected on the whiskers. Their size can be as comparable to the transverse dimension of the rod and signifIcantly exceed of it. The spherical structures with a diameter about 250 nm were registered. Increasing of the sphere diameter may be explained by additional deposition of products of laser damage of the target to the initial structure.

4. Conclusions

The experimental results showed that the use of carbon nanotubes provides laser synthesis of filamentary crystals of titanium oxide and aluminum. Examples of laser synthesis of zinc oxide nanocrystals (including whiskers) with using carbon nanotubes have been presented in earlier works [4,5]. Thus, the described in the article approach may be considered common to the formation of filamentary structures of metal oxides. It is based on ensuring the conditions of crystal growth on the mechanism of “vapor-liquid-solid” [6] within local areas with nanometer dimensions.

However, principally different mechanisms of melt drops to initiate crystal growth are realized when used as a target of pure metals or alloys with a predominant concentration of the oxidized material and alloys with comparable mass proportions of the components. Capture of products of laser material damage by defects of carbon nanotubes occurs in the first case. The phenomenon of local enhancement of the laser field due to the so-called peak effect is used in the second case. In this case melting occurs within domains of phase which has a lower melting point. Thus the melting of zinc in brass is realized while maintaining the copper in the solid state. Domain dimensions and as consequence the melting region correspond to conditions of formation of the nanocrystals. However, the presence of carbon nanotubes is of fundamental importance in both cases.

The electrostatic field is used in the presented experiments as an additional parameter of control of the metal oxides crystals growth. The form and the rate of nanocrystals growth depend on the strength and direction of the electric field. In the absence of an accelerating field the metal oxide crystals are formed in the form of fractal structures with the same probability of the branches growth in all directions and a constant length of their linear segments. The action of the accelerating electric field leads to the growth of long filamentary crystals.

5. Acknowledgements

This study was supported by the Ministry of education and science of Russia. Additional funding was provided within the framework of grants of RFBR (No. 12-02- 97531 and No. 11-02-97516), grant of President of Russian Federation for support of leading scientific schools No. НШ-3088.2012.2 and FTP “Scientific and scientificpedagogical personnel of innovative Russia in 2009- 2013” (agreement No. 14.B37.21.1281).

REFERENCES

- A. Umar and Y.-B. Hahn, “Metal Oxide Nanostructures and Their Applications,” American Scientific Publishers, Stevenson Ranch, 2010.

- D. V. Bavykin and F. C. Walsh, “Titanate and Titania Nanotubes: Synthesis, Properties and Applications,” Royal Society of Chemistry, Cambridge, 2010.

- I. M. Afanasov and B. I. Lazoryak, “High Temperature Ceramic Fibers,” Moscow State University, Moscow, 2010.

- D. V. Abramov, S. V. Zhirnova, I. M. Loginova, S. A. Makov and V. G. Prokoshev, “Formation of Microand Nano-Structured Arrays of Zinc Oxide Crystals under Laser Irradiation,” Proceedings of the Vladimir State University, Vol. 5, 2010, pp. 16-20.

- D. V. Abramov, T. N. Gorudko, A. N. Koblov, D. S. Nogtev and O. A. Novikova, “Laser Forming of Structures of Zinc Oxide on a Surface of Products from Copper Alloys,” Physics Procedia, Vol. 5, 2010, pp. 211-214. doi:10.1016/j.phpro.2010.08.046

- R. S. Wagner and W. C. Ellis, “Vapor-Liquid-Solid Mechanism of Single Crystal Growth,” Applied Physics Letters, Vol. 4, No. 5, 1964, pp. 89-90. doi:10.1063/1.1753975

NOTES

*Corresponding author.