World Journal of Engineering and Technology

Vol.02 No.03(2014), Article ID:48473,7 pages

10.4236/wjet.2014.23020

Preparation of KOH/CaO/C Supported Biodiesel Catalyst and Application Process

Jianwei Zhang, Qingming Meng

Provincial Key Laboratory of Oil and Gas Chemical Technology, College of Chemistry and Chemical Engineering, Northeast Petroleum University, Daqing, China

Email: benbenbao@163.com, qingmingmeng@163.com

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 25 May 2014; revised 12 July 2014; accepted 16 July 2014

ABSTRACT

KOH/CaO/C supported catalyst was prepared via incipient wetness impregnation and used in synthesis of biodiesel. First, the effects of carrier/active components mass ratio, calcination temperature and calcination time on catalytic activity were investigated aiming at biodiesel yield, and the optimal process conditions for preparation of KOH/CaO/C catalysts were: mass ratio of C/CaO was 4:6; KOH solution (mass concentration) was 25%; impregnation time was 24 h; drying temperature was 105˚C and time was 4 h; calcination temperature was 500˚C and time was 5 h. Then the complex catalysts prepared under the optimal conditions were applied to synthesize biodiesel, and the effects of dose of catalyst, reaction temperature, and reaction time on the yield of biodiesel were investigated. At last, the optimal process conditions for synthesis of biodiesel were concluded: methanol-oil ratio was 10:1; catalyst dose was 2% of that of soybean oil; reaction temperature was 65˚C; reaction time was 5 h. The yield of as-prepared biodiesel could be 98%.

Keywords:

Solid Base Catalyst, Biodiesel, Transesterification, Blending Impregnation

1. Introduction

Hydrogenation energy consumption has been intensified along with the rapid economic development worldwide. The reduction of oil resources and the increasing demands for oil have subjected economic development to severe pressures. The resulting energy shortage diverts people to seeking renewable and environmental fuels and replacing petroleum resources. Biomass energy, solar energy and other renewable energy will substitute petroleum and coals and thus gradually become the major energy sources. Biodiesel deserves special attention owing to the high combustion performance, heat value, combustion stability, low-temperature start-up lubrication, renewability and environmental friendliness [1] . Thus, successful development and utilization of biodiesel will alleviate oil crisis and promote economic development. The traditional biodiesel production processes utilize liquid acids (e.g. H2SO4, HCl, H3PO4 and HF) or bases (e.g. KOH, NaOH, and sodium alkoxide) as catalysts, which will result in abundant waste liquid [2] -[7] . Moreover, the application of these processes is largely limited by the worldwide proposal of green chemical industry. Nevertheless, solid base catalysts with high activity and recyclability became popular in the academic circles [8] -[14] .

In this paper, KOH/CaO/C supported biodiesel catalyst was prepared using blending impregnation. First, CaO was supported on activated carbon and then impregnated with KOH. The catalyst of CaO impregnated with KOH was highly active and renewable. Besides, the activated carbon as the carrier was featured by large specific surface area, easy separation from the products, and high intensity after calcination.

2. Experimental

2.1. Materials

The materials were anhydrous methanol, KOH, CaO, anhydrous NaCO3, HCl, anhydrous ethanol, and 95% ethanol, which were all chemically pure.

2.2. Experimental Methods

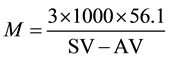

Acid value (AV) of raw oil was measured using the hot ethanol method as per Animal and Vegetable Fats and Oils-Determination of Acid Value and Acidity (GB/T5530-2005). Saponification value (SV) of raw oil was measured as per Animal and Vegetable Fats and Oils-Determination of Saponification Value (GB/T5534-2008). The average molar mass of raw oil was computed as follows:

(1)

(1)

where, SV is saponification value [mg KOH/g oil]; AV is acid value [mg KOH/g oil].

KOH/CaO/C supported catalyst was prepared via incipient wetness impregnation: the ground CaO powder and activated carbon at a preset ratio were fully mixed and then impregnated with KOH solution at room temperature, dried and calcinated at last.

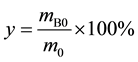

With methanol and soybean oil as raw materials, biodiesel was prepared in a 3-neck flask via transesterification, the hot crude products were filtered immediately, and then the catalyst was removed. The liquid phase was transferred to a separating funnel, and put still until it was separated. The upper layer in the funnel was collected and the lower layer of glycerol phase was discharged. 1/2 volume of water at 50˚C was added into the biodiesel, and then it was shaken, and put still for separation. Then the lower layer of glycerol-water phase was discharged. The remaining solution was washed 3 times. The biodiesel phase was reserved and added with anhydrous CaCl2 for 24 h of drying. The drying agent was filtered out to obtain biodiesel, which was weighed. The yield y of biodiesel was computed as follows:

(2)

(2)

where, mB0 is the weight of biodiesel [g]; m0 is the weight of the raw oil [g].

3. Results and Discussion

3.1. Preparation of KOH/CaO/C Supported Catalyst

C/CaO at different mass ratios were mixed, and then impregnated for 20 h in a 25% KOH solution (mass percentage concentration), followed by drying at 105˚C for 3 h and calcination at 500˚C for 5 h. Catalysts were prepared under different conditions and applied to synthesize biodiesel. The synthesis conditions were: methanol-oil ratio was 9:1, catalyst dose was 1% of that of soybean oil, reaction temperature was 60˚C, reaction time was 4 h. The effects of C/CaO mass ratio on biodiesel yield were investigated and the results were listed in Figure 1. Clearly, the biodiesel yield first increases and then declines with the rising C/CaO ratio, and is maximized to be 93.0% at the ratio of 4:6 (Figure 1). This is because the carrier provided less specific surface area and less active components when C/CaO ratio is too small; and the amount of active components decreases at too large C/CaO ratio, which leads to lower catalytic activity.

Activated carbon and CaO (4:6) were mixed and impregnated at room temperature in KOH solutions with varying concentration for 20 h, followed by drying at 105˚C for 3 h and calcination at 500˚C for 5 h. The effects of impregnated amounts of active components on reactivity were investigated and the results were listed in Figure 2 (conditions for synthesis of biodiesel were the same as in section

Figure 1. Effects of C-CaO ratio on the yield.

Figure 2. Effects of KOH concentration on the yield.

3.1.3. Impregnation Time

At C/CaO ratio 4:6, KOH concentration 25%, drying at 105˚C for 3 h, and calcination at 500˚C for 5 h, the impregnation time was changed and its effects on reactivity were investigated. The results were listed in Figure 3 (conditions for synthesis of biodiesel were the same as in section

At C/CaO ratio 4:6, KOH concentration 25%, impregnation at room temperature for 24 h, drying at 105˚C for 3 h, and calcination for 5 h, the calcination temperature was changed and its effects on reactivity were investigated. The results were listed in Figure 4 (conditions for synthesis of biodiesel were the same as in section

Figure 3. Effects of impregnation time on the yield.

Figure 4. Effects of calcination temperature on the yield.

3.1.5. Calcination Time

At C/CaO ratio 4:6, KOH concentration 25%, impregnation at room temperature for 24 h, drying at 105˚C for 3 h, and calcination temperature 500˚C, the calcination time was changed and its effects on reactivity were investigated. The results were listed in Figure 5 (conditions for synthesis of biodiesel were the same as in section

3.2. Synthesis of Biodiesel

The as-prepared KOH/CaO/C supported catalysts were applied into synthesis of biodiesel and the optimal conditions were determined at last.

At methanol-oil molar ratio 9:1, catalyst dose 1% of that of soybean oil, and reaction time 4 h, the reaction temperature was changed and its effects on biodiesel yield were explored. The results were showed in Figure 6. Clearly, biodiesel yield is small at low temperature, and increases with the rising temperature, maximized at 65˚C, and then declines. The reason is that transesterification is a reversible endothermic process, and the reaction rate is quickened by raising temperature first, but the amount of by-products increase and the products become darker at too high temperature, thus the yield and quality of final products are reduced. Thus, the optimal reaction temperature is 65˚C.

Figure 5. Effects of calcination time on the yield.

Figure 6. Effects of reaction temperature on the yield.

3.2.2. Catalyst Dosage

At methanol-oil molar ratio 9:1, reaction temperature 65˚C, and reaction time 4 h, we changed the dosage of catalyst and explored its effects on biodiesel yield. The results were showed in Figure 7. It could be seen that the biodiesel yield first rises and then declines with the increasing dosage of catalyst, and is maximized to be 96.5% at the dosage of 2% (Figure 7). The reason is that with too large dosage, the catalyst hinders the contact between reactants and too many alkaline centers will cause saponification reaction, which decreases the yield at last.

At methanol-oil molar ratio 9:1, catalyst dose 2% of that of soybean oil, and reaction temperature at 65˚C, we changed the reaction time and explored its effects on biodiesel yield. The results were showed in Figure 8. It could be seen that the biodiesel yield first rises and then declines with the prolonged reaction time, and is maximized to be 97.6% at 5 h (Figure 8). The reason is that with enough time, the reaction is complete and biodiesel yield increases, but the amount of by-products increases with too long time and the yield decreases.

3.2.4. Methanol-Oil Ratio

At catalyst dose 2% of that of soybean oil, reaction temperature 65˚C, and reaction time 5 h, we changed the methanol/bean oil ratio and explored its effects on the yield. The results were showed in Figure 9. It could be seen that the biodiesel yield first rises, when the methanol/bean oil ratio is between 9:1 and10:1, the yield rises indistinctively, and is maximized to be 98% at the ratio of 10:1. After the methanol/bean oil ratio is greater than 10:1, the yield declines with the increasing alcohol-oil ratio (Figure 9). The reason is that when methanol-oil ra-

Figure 7. Effects of catalyst dosage on the yield.

Figure 8. Effects of reaction time on the yield.

Figure 9. Effects of methanol-oil ratio on the yield.

tio is too small, little fatty acid methyl ester is generated, indicating low yield. But if the methanol-oil ratio is too large or exceeds the normal level in transesterification, the volume of reaction solution becomes larger, which slightly dilutes the concentrations of reactants, and the amount of catalyst is relatively smaller, leading to less opportunity for contact between catalyst and fatty glyceride. These changes less promote the reaction and enhance the polarity of the solution, which leads to slower reaction and lower biodiesel yield.

4. Conclusions

KOH/CaO/C supported catalysts via blending impregnation were prepared and then were applied to synthesis of biodiesel. The best optimum synthesis conditions were identified according to the biodiesel yield. The conclusions are summarized as follows:

The optimal prepared conditions of KOH/CaO/C supported catalysts are: C/CaO mass ratio is 4:6, mass concentration of KOH solution is 25%, impregnation time is 24 h, drying temperature is 105˚C and drying time is 4 h, calcination temperature is 500˚C and calcination time is 5 h.

Catalysts are prepared under above conditions with methanol and soybean oil as raw materials and then applied to synthesize biodiesel. The optimum synthesis conditions for biodiesel are: alcohol-oil ratio is 10:1, catalyst dose is 2% of that of soybean oil, reaction temperature is 65˚C and reaction time is 5 h. The yield of as- prepared biodiesel could be 98%.

Acknowledgements

The authors are grateful to the Provincial Key Laboratory of Oil and Gas Chemical Technology of Northeast Petroleum University in China for financial support.

References

- Ramachandran, K., Suganya, T., Nagendra, G.N. and Renganathan, S. (2014) Recent Developments for Biodiesel Production by Ultrasonic Assist Transesterification Using Different Heterogeneous Catalyst: A Review. Renewable and Sustainable Energy Reviews, 22, 410-418. http://dx.doi.org/10.1016/j.rser.2013.01.057

- Van Gerpen, J.H. and He, B.B. (2014) Biodiesel and Renewable Diesel Production Methods. In: Advances in Biorefineries, Biomass and Waste Supply Chain Exploitation, 441-475. http://www.sciencedirect.com/science/article/pii/B9780857095213500144

- Bart, J.C.J., Palmeri, N. and Cavallaro, S. (2010) Industrial Process Technology for Biodiesel Production. In: Biodiesel Science and Technology, From Soil to Oil, A Volume in Woodhead Publishing Series in Energy, 462-513. http://www.sciencedirect.com/science/article/pii/B9781845695910500115

- Aransiola, E.F., Ojumu, T.V., Oyekola, O.O. Madzimbamuto, T.F. and Ikhu-Omoregbe, D.I.O. (2014) A Review of Current Technology for Biodiesel Production: State of the Art. Biomass and Bioenergy, 61, 276-297. http://dx.doi.org/10.1016/j.biombioe.2013.11.014

- Abbaszaadeh, A., Ghobadian, B., Reza, M.O. and Najafi, G. (2012) Current Biodiesel Production Technologies: A Comparative Review. Energy Conversion and Management, 63, 138-148. http://dx.doi.org/10.1016/j.enconman.2012.02.027

- Marchetti, J.M. (2012) A Summary of the Available Technologies for Biodiesel Production Based on a Comparison of Different Feedstock’s Properties. Process Safety and Environmental Protection, 90, 157-163. http://dx.doi.org/10.1016/j.psep.2011.06.010

- Takami, K., Goon, L. M., Wada, S. and Nakazato, T. (2014) Production of Biodiesel Fuel from Canola Oil with Dimethyl Carbonate Using an Active Sodium Methoxide Catalyst Prepared by Crystallization. Bioresource Technology, 163, 360-363. http://dx.doi.org/10.1016/j.biortech.2014.04.030

- Takase, M., Chen, Y, Liu, H.Y., Zhao, T., Yang, L.Q. and Wu, X.Y. (2014) Biodiesel Production from Non-Edible Silybum marianum Oil Using Heterogeneous Solid Base Catalyst under Ultrasonication. Ultrasonics Sonochemistry, 21, 1752-1762. http://dx.doi.org/10.1016/j.ultsonch.2014.04.003

- Jeon, H., Kim, D.J. and Kim, J.H. (2014) Synthesis of Mesoporous MgO Catalyst Templated by a PDMS-PEO Comb- Like Copolymer for Biodiesel Production. Fuel Processing Technology, 116, 325-331. http://dx.doi.org/10.1016/j.fuproc.2013.07.013

- Olutoye, M.A. and Hameed, B.H. (2013) Production of Biodiesel Fuel by Transesterification of Different Vegetable Oils with Methanol Using Al2O3 Modified MgZnO Catalyst. Bioresource Technology, 132, 103-108. http://dx.doi.org/10.1016/j.biortech.2012.12.171

- Calero, J., Luna, D., Enrique, D.S., Luna, C., Felipa, M.B., Antonio, A. R., Posadillo, A. and Verdugo, C. (2014) Development of a New Biodiesel That Integrates Glycerol, by Using CaO as Heterogeneous Catalyst, in the Partial Methanolysis of Sunflower Oil. Fuel, 122, 94-102. http://dx.doi.org/10.1016/j.fuel.2014.01.033

- Ofori-Boateng, C. and Lee, K.T. (2013) The Potential of Using Cocoa Pod Husks as Green Solid Base Catalysts for the Transesterification of Soybean Oil into Biodiesel: Effects of Biodiesel on Engine Performance. Chemical Engineering Journal, 220, 395-401. http://dx.doi.org/10.1016/j.cej.2013.01.046

- Kesica, Z., Lukic, I., Zdujic, M., Liu, H. and Skala, D. (2012) Mechanochemically Synthesized CaO ZnO Catalyst for Biodiesel Production. Procedia Engineering, 42, 1169-1178. http://dx.doi.org/10.1016/j.proeng.2012.07.509

- Wang, B.Y., Li, S.F. Tian, S.J., Feng, R.H. and Meng, Y.L. (2013) A New Solid Base Catalyst for the Transesterification of Rapeseed Oil to Biodiesel with Methanol. Fuel, 104, 698-703. http://dx.doi.org/10.1016/j.fuel.2012.08.034