Geomaterials

Vol.3 No.2(2013), Article ID:30868,6 pages DOI:10.4236/gm.2013.32008

Prospects of Low Cost Housing in India

School of Mechanical and Building Sciences, VIT University, Vellore, India

Email: swaptikchowdhury16@gmail.com, donna.roycutiepie@gmail.com

Copyright © 2013 Swaptik Chowdhury, Sangeeta Roy. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received January 21, 2013; revised February 25, 2013; accepted March 12, 2013

Keywords: Low-Cost Housing; Building Materials; Sustainability

ABSTRACT

The paper presents work on low-cost and sustainable alternative building materials having advantages on areas such as India where concrete or steel housing is expensive. The project addresses the challenges and stereotypes of using these materials as a structural component for low-cost housing and their same capacity for adaptation to the broad spectrum of factors—physical, ecological, social, economic and technical—through different products developed which can dictate the production of the construction environment.

1. Introduction

Managing the response to the ever increasing housing needs of Indian population expanding by 1.3% every year, has long been a problem for its government. Providing affordable housing remains a major concern of the government as 37% of its population remains below the International poverty line (US $1.5 a day). In India, the maximum affordability of household was defined to be 5.1 times the household’s total gross income as compared to the developed countries (In US it is 0.3 times or less of a household’s gross annual income). Based on the development index of a location the average cost per square meter is about $130 in semi urban areas, $130 - $173 in B class cities whereas in metro cities it increases to $173 - $258. So, majority of Indians have per capita space equivalent to or less than a 3 meter × 3 meter room for their housing needs like living, sleeping, cooking, washing etc. Whereas according to conventional norms, the average is 10 square meters per person in rural areas and 11 square meters per person in urban areas.

The use of natural materials like straw, bamboo, fibres (jute, coir), earth etc. is a centuries’ old practice in India. These materials apart from being locally available have easy workability and speedy construction hence reducing costs. Also industrial wastes like fly ash and rice husk possess pozzoloanic properties which can act as excellent substitute material. This paper aims to bring together the studies of these materials keeping in mind their affordability.

2. Low Cost Housing Materials

Low cost Housing materials can be broadly classified into natural materials and manmade materials according to the source of the building materials.

2.1. Natural Materials

2.1.1. Bamboo

After China, India is the second largest in bamboo production. Coupled with China, it holds 50% of the world’s total share of bamboo production [1]. Of the total 136 species of bamboo occurring in India, 58 species spread out over 10 genera are endemic to the north eastern part of India alone (Sharma, 1987) [2]. The forest area, over which bamboos occur in India, on a conservative estimate, is about 9.57 million hectares, which constitutes about 12.8% of the total area under forests (Bahadur and Verma, 1980) [3]. Its widespread availability and rapid growth in areas of China, Japan and India has made this grass an interesting structural material due to its affordability, easy assembly and relatively long durability. The salient point regarding bamboo is the design specification and concept selection of bamboo structures which are controlled by Young’s Modulus (i.e. its flexibility), and tensile strength (i.e. its resistance of a material to a tearing force). Also it has been seen that bamboo fibre has almost similar tensile strength as that of steel (650 MPa compared to steel’s lying in the range 500 - 1000 MPa). It has much higher flexibility as determined by its lower Young’s Modulus value (~50 GPa compared to steel’s ~200 GPa) [4]. A bamboo hut was constructed in 1955 which was treated with 4 percent CCa and since it has no deterioration [3]. But bamboo culms offer some disadvantage like Bamboo [5] has a circular profile which makes it inherently difficult to connect other members. Also Bamboo has no support in the middle as it is hollow there, hence it cannot be subjected to high compressive forces perpendicular to the culms face.

Some ongoing bamboo product are:

Corrugated Bamboo Roofing Sheet: A successful roofing material with a development of traditional material comes from Bamboo Board. It is eco-friendly, lightweight, strong and durable and has minimal fire hazard when compared to thatch and other roofing materials. These sheets can be used for roofing, walling, door and window shutters and other components in building construction.

2.1.2. Earth

Earth is the oldest building material known to mankind. But its widespread use is hindered due to the limitations like water penetration, erosion of walls at level by splashing of water from ground surfaces, attack by termites and pests, high maintenance requirements etc. These limitations can be overcome by using compressed earths block and non-erodible mud plaster.

1) Compressed Earth Block The compressed earth block is the developed form of moulded earth block, more commonly known as the adobe block [4]. This technology offers an economic, environment friendly masonry. Stabilized earth blocks are manufactured by compacting raw material earth mixed with a stabilizer such as cement or lime using manual soil press [4].

2) Nonerodable Mud Plaster Central Building Research Institute, India has developed an economical but effective process to protect mud walls by applying non-erodible mud plaster. Non-erodible mud is prepared by mixing bitumen cutback (Bitumen & Kerosene oil mixture) with a specified mud plaste. Non-erodible mud plastered walls are resistant to water erosion. Centre for Science for Villages, Wardha India has developed a technique of providing potter made tile lining to mud-walls protecting them from rain and moisture [6].

2.1.3. Straw

Straw is basically an agricultural by-product which comprises only of the plant stalks (mostly cereals) after removal of grain and chaff. Rice straw has the highest silica content making it the toughest amongst all other cereal straws [7].Straw is considered as an environmental problem as its burning causes breathing problems. Straw and Straw bale have a huge scope in India as it is one of the largest producers of straw bale. 46% of total land (32, 87,590 sq·km) of India is agricultural land and out of a total population of 1, 17, 09, 38,000 people 58.4% are solely dependent upon agriculture as a means of livelihood. So straw has high potential as an alternate building material. It is also fire resistant as it does not support combustion, is thermally insulated, has sound and moisture insulation and is not toxic.

The following are the profiles of some construction alternatives constructed with straws and straw bales.

Life Extended Thatch Roofing: It is one of the locally available and environment friendly alternative for corrugated sheets. By treating it with copper sulphate solution, its life can be extended by reducing the effect of biodegradability. Additional layer of treatment on the roof surface using phosphorylated spray or CNSL oil imparts water proofing, fire resistance, termite proofing and weathering resistance (Developed by CBRI/RRL-TVM [7]).

Improved Thatch Roofing: In order to decrease the fire hazard of thatch roof and making it water repellent a treatment had been designed by the Central Building Research Institute. It essentials the thatch layers are plastered with specified mud plasters making it durable and fire resistant [7].

2.1.4. Fiber Cement Composites

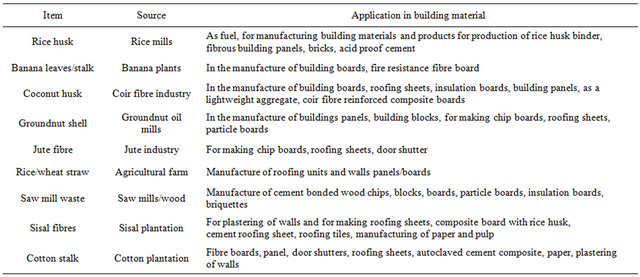

From centuries, mankind has used the various natural fibres for a wide spectrum of applications ranging from consumption to housing. In recent days many researchers have explored the possibilities of using the natural fibre obtained from different plants, which includes bagasse, cereal straw, corn stalk, cotton stalk, kenaf, rice husk/rice straw etc as an alternative building material. Due to the light weight, high strength to weight ratio, corrosion resistance and other advantages, natural fibre based composites are becoming important alternatives for building materials for use in civil engineering fields. A few of the important composites are summarized as under: Table 1.

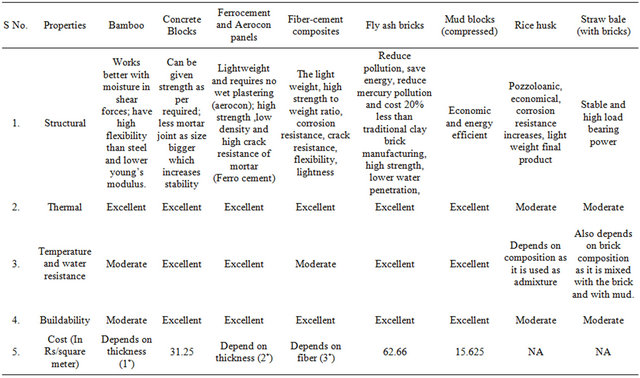

Cement fibre composites are found to have superior properties as compared to concrete blocks. This is mainly due to addition of fibres [9]. The superior properties comprise of better workability, resistance to cracking, lighter weight, high fracture toughness and a higher degree of flexibility. These properties make it a suitable material for use in low cost construction. The performance profiles of some important fibres produced in India are as Table 2.

1. Bagasse Bagasse is the fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juice. Since bagasse is a by-product of the cane sugar industry, the quantity of production in each country is similar to the quantity of sugarcane produced. India has just over 500 sugar mills. With nine states (Uttar Pradesh, BiharTable 1. Availability of natural fibre in India and its applications in building materials [8].

Table 2. The properties of building materials in consideration.

Punjab and Haryana in the northern region; Maharashtra & Gujarat in the western region and Andhra Pradesh, Tamil Nadu and Karnataka in the southern region) holding 95% of them.

Some ongoing products are:

1) Bagasse-Cement Boards and Panels: The developed product is eco friendly and the process utilizes sugar cane bagasse and ordinary Portland cement [10]. The physico-mechanical behaviour of the developed building board passes most of the requirements of general purposes high density board and is cost effective too.

2) Bagasse-PVC Boards: This building board uses sugarcane bagasse and PVC as binder [10]. PVC is the most widely used resin in making different articles for building applications such as door shutters, sanitary fixtures, pipes, cables, cabinets, etc. due to its inherent self extinguishing characteristic and affordable cost.

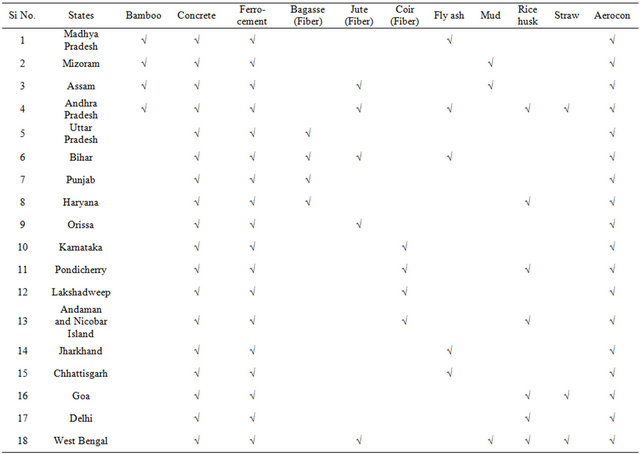

2. Jute and Coir Jute cultivation has been in practise in India for as far as 800 BC. Production of jute is mainly concentrated in West Bengal, Orissa, Bihar, Assam, Meghalaya and Andhra Pradesh. There are 33 odd districts spanning all over West Bengal, Bihar, Assam and Orissa which accounts for 98.41% of total area under jute cultivations and 98.45% total raw jute production in India. Historically, the coir industry started and flourished in Kerala which has a long coast line, lakes, lagoons and backwaters providing natural conditions required for retting. However, with the expansion of coconut cultivation, coir industry has picked up in the States of Tamil Nadu, Karnataka, Andhra Pradesh, Orissa, West Bengal, Assam, Tripura, Pondicherry and the Union Territories of Lakshadweep and Andaman & Nicobar Islands through the efforts of Coir Board. India accounts for more than two-thirds of the world production of coir and coir products. So as India is a leading producer of jute and coir, they can be used as a solution for low cost housing and has been implemented in following ways (Table 3).

1) Coir-CNSL Board: The Coir-CNSL Board is a wood alternative which can be used for surfacing, door and window shutters, partitioning, false ceiling, panelling, furniture, cabinets, packaging, etc. It is a single layer flat pressed class Medium Density Fibre (MDF) Board. It has low water absorption, negligible change in dimensions due to water absorption, workable with normal wood working tools, paintable, pre-laminable, and nailable and screw able [10].

2) Coir-CNSL Thermal Insulation Board: This is a composite material, which utilizes the coconut fibres as re-enforcing material and CNSL as the natural binder [10]. The density of the board is kept low and therefore is suitable for moderate temperature insulation.

3) Jute-Coir Composites: Jute-coir composite provides an economic alternative to wood for the construction industry. It involves the production of coir-ply boards with oriented jute as face veneer and coir plus waste rubber wood inside [10].

4) Coconut and Wooden Chips Roofing Sheet: Coconut fibre and wooden chips are soaked in water for two hours and then the water is drained off. Later these are mixed with cement and laid over a corrugated mould and kept under pressure for 8 to 10 hours [10]. After demoulding, these are cured and dried before use (Developed by RRL-TVM).

Also use of Cashewnut Shell Flour was a major development as filler [3].

2.2. Man Made Materials

The Industrial Revolution introduced many foreign substances which were the by products of industries like fly ash and rice husk and created problems for their disposal. But on further research into their properties it was observed that these materials possess excellent pozzoloanic properties. Hence these can be used as alternative building materials.

2.2.1. Fly Ash

The mineral residue produced by burning coal and the fine glass powder recovered from its gases is called Fly Ash. The major constituents of fly ash are silica, alumina and iron [11]. Coal fired electricity generating plants are the primary producers of fly ash nowadays. In the first half of the year 2011-2012 out of the sixteen states placed under survey five have generated more than five million tonne of fly ash. The state of UP was the top producer of fly ash producing more than nine million tonnes of fly ash. Fly Ash can be substituted for many constituents in building materials making it the ideal choice for alternate building material. Some of them are discussed as under Fly Ash Brick Fly Ash Brick is a construction material, masonry unit comprising of Class C Fly Ash and water. Due to the high concentration of calcium oxide in Class C Fly Ash, the brick can be described as self-cementing [11]. These properties make fly ash bricks energy efficient, mercury pollution resistant, lower water penetration, light weight, thermal insulation and cost effective (it costs 20% less than traditional clay brick manufacturing). The only major disadvantages of using fly ash brick is that there is very less information on its toxic fume emission. Also it contains many unhealthy elements like silica, aluminium, iron oxides, arsenic, cadmium and mercury. Its mechanical bonding is weak and presents poor outlook.

2.2.2. Aerocon Panels

Aerocon panels are the inorganic bonded sandwich panels made of two fiber reinforced cement sheets engulfing a light-weight core consisting of Portland cement, binders and a mix of silicaceous and micaceous aggregates [12]. The use of Fly ash and its substitution for timber based products makes the panels environmental-friendly.

The property attributes are eco-friendly, faster construction, no wet plastering and on-site curing, light weight, high thermal insulation, fire resistant, excellent sound reduction properties, water and termite and weather resistant, suitable for Seismic and Cyclone prone zones, relocatable, thin walls (space saving), smooth finish, minimum foundation or ground preparation required and easy workability.

Recently in a project called “Mass Housing” under “VALMIKI” scheme sponsored by Govt. of India for improving the living conditions of slum dwellers in Mumbai was completed in a very short span of time using aerocon panels demonstrating its prowess [12].

Table 3. Availability of different materials in India showing feasibility.

2.2.3. Ferro-Cement

Ferro-cement can be defined as a thin walled versatile high strength cement based composite material made of cement mortar reinforced with one or more layers of wire mesh closely bound together to create a stiff structure unit with high performance, lightness of structure and strength. It possesses the property of completely homogeneous material [7]. The only real disadvantage of using Ferro-cement is its high rates of shrinkage and creep when using rich mortars). It can be used for constructing pre cast toilet units, water tanks, cycle sheds etc. As it is pre casted and then manufactured, it can play a major role during post disaster housing requirements which is economical and easy to build.

2.2.4. Cement Concrete Hollow Blocks

Cement Concrete Block is a recently developed masonry unit of concrete. It works on the principal of densification of a lean concrete mix to make a regular shaped, uniform, high performance masonry unit. They are cost affective and better alternative to burnt clay bricks due to their good durability, fire resistance, partial resistance to sound, thermal insulation, small dead load and high speed of construction [13]. And as they are larger in size as a conventional clay bricks, less mortar is required and thus cost reduction in the construction is achieved. The major advantage of concrete blocks is that their strength can be engineered as per specified. Concrete blocks have an excellent thermal property due to the cavities present in them. It is also fire and sound insulated. They are inert and non toxic.

2.2.5. Rice Husk

India is one of the world’s largest producers of white rice contributing about 20% of world’s total rice production. The state of West Bengal ranks first in terms of area under production whereas Punjab has the highest productivity in the country. The major rice growing states are West Bengal, Uttar Pradesh, Andhra Pradesh, Punjab, Tamil Nadu, Orissa, Bihar and Chhattisgarh. Rice mills generate a by-product known as husk (it surrounds the paddy grain). During milling of paddy about 78% of weight is received as rice, broken rice and bran, but rest 22% of the weight is collected as husk. The husk contains about 75% organic volatile matter and the balance 25% of the weight of this husk is converted into ash during the firing process, which is known as rice husk ash (RHA). RHA contains about 85% to 90% amorphous silica. About 20 million tonnes of RHA is produced annually. This RHA is a great environment threat causing damage to the land and the surrounding area on which it is dumped. So products are being developed to use it as an alternative building material:

1) Low Cost Sandcrete Block The rice husk ash produced using charcoal from rice husk is pozzoloanic and therefore is suitable for use in block making. The compressive strength of the blocks for all mixes increases with age at curing and decreases as the RHA content increases. The optimum replacement level of OPC with RHA is 20% and the water requirement increases with increase in ash content in the paste (OPC/RHA) [14].

2) In Concrete The rice husk ash is a highly siliceous material that can be used as an admixture in concrete if the rice husk isburnt in a specific manner. The characteristics of the ash depend on the components, temperature and time of burning (Hwang, 185). But the silica must be kept at a non crystalline state in order to generate an ash with high pozzoloanicactivity. RHA imparts corrosion resistance and compactibility to the concrete.

3. Summary and Conclusions

In this study, alternate construction materials were studied and the potential of these materials to be used as alternate building materials is brought out. Depending on the availability of the materials in a particular region, these materials can be selected as transportation consists of approximately 30% of total construction budget. In most developing countries, the challenge is to organize and initiate measures that promote these materials as well as train local artisans and masons in the construction techniques involving these materials. There have been several attempts at local levels to make use of bamboo, mud or natural fibers but it still lacks scientific precisions and proper techniques to be used precisely. Also the usage of industrial wastes still needs study on their better usage toxicity. These materials if studied and developed properly hold the key to address the current housing needs.

REFERENCES

- http://www.fao.org/docrep/007/ad871e/ad871e10.htm

- Building Materials in India: 50 Years, TN Gupta, bmtpc, 253-254.

- Building Materials in India: 50 Years, TN Gupta, bmtpc, 270-271.

- L. Dinachandran Singh, “Low Cost Housing Using Stabilized Mud Blocks,” 2007.

- G. Leake, K. Toole, P. Divis and C. Torres, “Sánchez Bamboo as a Solution for Low-Cost Housing and Storage in Pabal (India),” 19 February 2010.

- P. Bhattarai, “Straw Bale in Building Construction and Its Future in India,” International Journal for Modern Engineering Research, Vol. 2, No. 2, 2012, pp. 422-426.

- R. Sarkar, “Post Earthquake Housing Construction Using Low Cost Building Materials,” 4th International Conference on Earthquake Engineering, Taipei, 14-15 October 2006

- A. Rai and C. N. Jha, “Natural Fibre Composites and Its Potential as Building Materials,” 2004.

- A. L. Moslemi, “Technology and Market Consideration for Fiber Cement Composite,” 11th International Inorganic Bonded Fiber Composite Conference, Madrid, 4-7 November 2008.

- Science Tech Entrepreneur, “Green Building Materials for Low Cost Housing,” 2009.

- Fly Ash Brick. www.wikipedia.com

- J. Sunu, “Eco-Friendly Inorganic Bonded Sandwich Panels (Aerocon Panels): Production Properties and Applications,” 11th Inorganic Bonded Fiber Composite Conference, Madrid, 4-7 November 2008

- http://besharp.archidev.org/IMG/pdf/solid-hollow_concrete_blocks.pdf

- E. B. Oyetola and M. Abdullah, “The Use of Rice Husk Ash in Low Cost Sandcrete Block,” Leonardo Electronic Journal of Practices and Technologies, Vol. 8, 2006, pp. 58-70.