Paper Menu >>

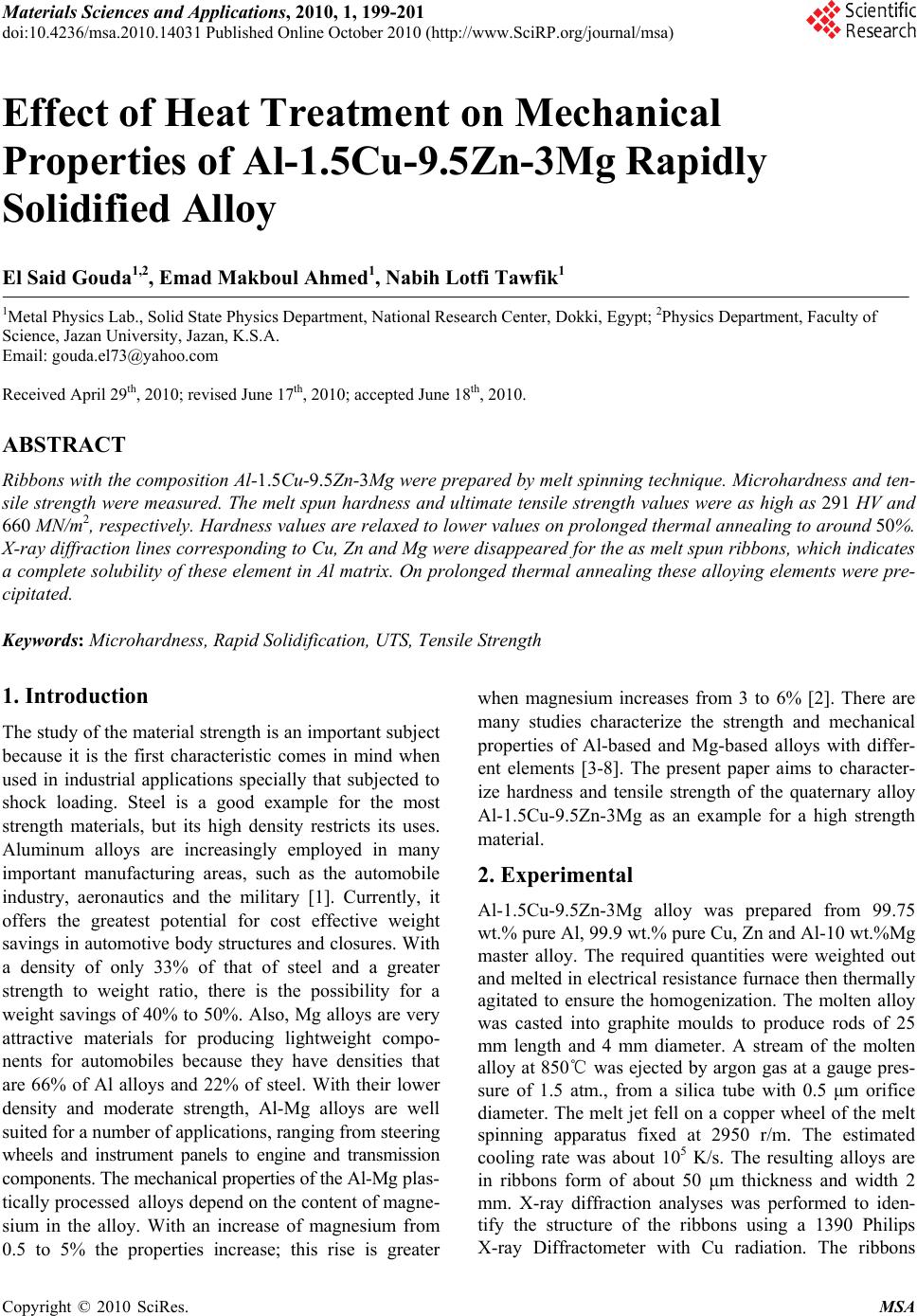

Journal Menu >>

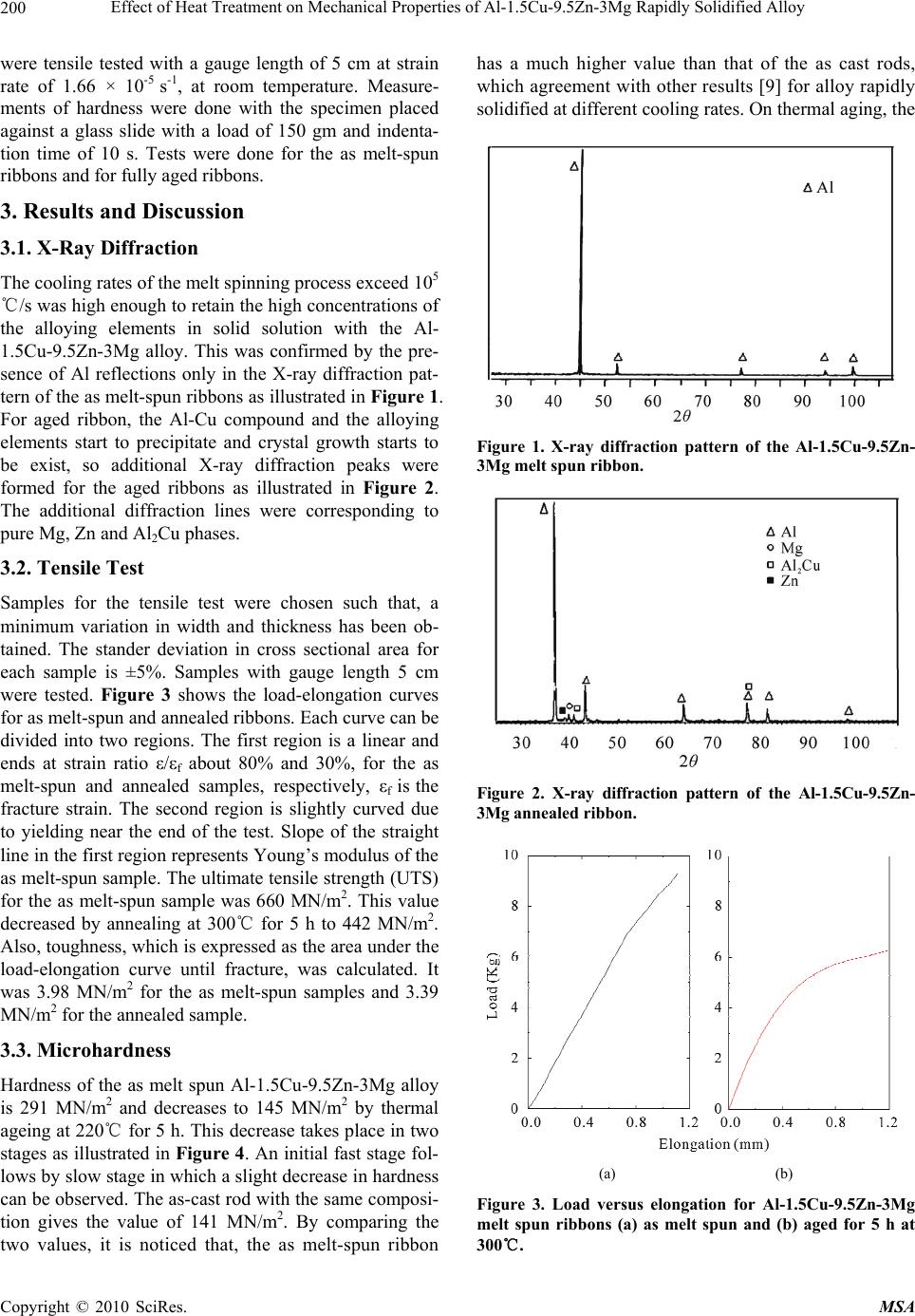

Materials Sciences and Applications, 2010, 1, 199-201 doi:10.4236/msa.2010.14031 Published Online October 2010 (http://www.SciRP.org/journal/msa) Copyright © 2010 SciRes. MSA 199 Effect of Heat Treatment on Mechanical Properties of Al-1.5Cu-9.5Zn-3Mg Rapidly Solidified Alloy El Said Gouda1,2, Emad Makboul Ahmed1, Nabih Lotfi Tawfik1 1Metal Physics Lab., Solid State Physics Department, National Research Center, Dokki, Egypt; 2Physics Department, Faculty of Science, Jazan University, Jazan, K.S.A. Email: gouda.el73@yahoo.com Received April 29th, 2010; revised June 17th, 2010; accepted June 18th, 2010. ABSTRACT Ribbons with the composition Al-1.5Cu-9.5Zn-3Mg were prepared by melt spinning technique. Microhardness and ten- sile strength were measured. The melt spun hardness and ultimate tensile strength values were as high as 291 HV and 660 MN/m2, respectively. Hardness values are relaxed to lower values on prolonged thermal annealing to around 50%. X-ray diffraction lines corresponding to Cu, Zn and Mg were disappeared for the as melt spun ribbons, which indicates a complete solubility of these element in Al matrix. On prolonged thermal annealing these alloying elements were pre- cipitated. Keywords: Microhardness, Rapid Solidification, UTS, Tensile Strength 1. Introduction The study of the material strength is an important subject because it is the first characteristic comes in mind when used in industrial applications specially that subjected to shock loading. Steel is a good example for the most strength materials, but its high density restricts its uses. Aluminum alloys are increasingly employed in many important manufacturing areas, such as the automobile industry, aeronautics and the military [1]. Currently, it offers the greatest potential for cost effective weight savings in automotive body structures and closures. With a density of only 33% of that of steel and a greater strength to weight ratio, there is the possibility for a weight savings of 40% to 50%. Also, Mg alloys are very attractive materials for producing lightweight compo- nents for automobiles because they have densities that are 66% of Al alloys and 22% of steel. With their lower density and moderate strength, Al-Mg alloys are well suited for a number of applications, ranging from steering wheels and instrument panels to engine and transmission components. The mechanical properties of the Al-Mg plas- tically processed alloys depend on the content of magne- sium in the alloy. With an increase of magnesium from 0.5 to 5% the properties increase; this rise is greater when magnesium increases from 3 to 6% [2]. There are many studies characterize the strength and mechanical properties of Al-based and Mg-based alloys with differ- ent elements [3-8]. The present paper aims to character- ize hardness and tensile strength of the quaternary alloy Al-1.5Cu-9.5Zn-3Mg as an example for a high strength material. 2. Experimental Al-1.5Cu-9.5Zn-3Mg alloy was prepared from 99.75 wt.% pure Al, 99.9 wt.% pure Cu, Zn and Al-10 wt.%Mg master alloy. The required quantities were weighted out and melted in electrical resistance furnace then thermally agitated to ensure the homogenization. The molten alloy was casted into graphite moulds to produce rods of 25 mm length and 4 mm diameter. A stream of the molten alloy at 850℃ was ejected by argon gas at a gauge pres- sure of 1.5 atm., from a silica tube with 0.5 μm orifice diameter. The melt jet fell on a copper wheel of the melt spinning apparatus fixed at 2950 r/m. The estimated cooling rate was about 105 K/s. The resulting alloys are in ribbons form of about 50 μm thickness and width 2 mm. X-ray diffraction analyses was performed to iden- tify the structure of the ribbons using a 1390 Philips X-ray Diffractometer with Cu radiation. The ribbons  Effect of Heat Treatment on Mechanical Properties of Al-1.5Cu-9.5Zn-3Mg Rapidly Solidified Alloy Copyright © 2010 SciRes. MSA 200 were tensile tested with a gauge length of 5 cm at strain rate of 1.66 × 10-5 s-1, at room temperature. Measure- ments of hardness were done with the specimen placed against a glass slide with a load of 150 gm and indenta- tion time of 10 s. Tests were done for the as melt-spun ribbons and for fully aged ribbons. 3. Results and Discussion 3.1. X-Ray Diffraction The cooling rates of the melt spinning process exceed 105 ℃/s was high enough to retain the high concentrations of the alloying elements in solid solution with the Al- 1.5Cu-9.5Zn-3Mg alloy. This was confirmed by the pre- sence of Al reflections only in the X-ray diffraction pat- tern of the as melt-spun ribbons as illustrated in Figure 1. For aged ribbon, the Al-Cu compound and the alloying elements start to precipitate and crystal growth starts to be exist, so additional X-ray diffraction peaks were formed for the aged ribbons as illustrated in Figure 2. The additional diffraction lines were corresponding to pure Mg, Zn and Al2Cu phases. 3.2. Tensile Test Samples for the tensile test were chosen such that, a minimum variation in width and thickness has been ob- tained. The stander deviation in cross sectional area for each sample is ±5%. Samples with gauge length 5 cm were tested. Figure 3 shows the load-elongation curves for as melt-spun and annealed ribbons. Each curve can be divided into two regions. The first region is a linear and ends at strain ratio ε/εf about 80% and 30%, for the as melt-spun and annealed samples, respectively, εf is the fracture strain. The second region is slightly curved due to yielding near the end of the test. Slope of the straight line in the first region represents Young’s modulus of the as melt-spun sample. The ultimate tensile strength (UTS) for the as melt-spun sample was 660 MN/m2. This value decreased by annealing at 300℃ for 5 h to 442 MN/m2. Also, toughness, which is expressed as the area under the load-elongation curve until fracture, was calculated. It was 3.98 MN/m2 for the as melt-spun samples and 3.39 MN/m2 for the annealed sample. 3.3. Microhardness Hardness of the as melt spun Al-1.5Cu-9.5Zn-3Mg alloy is 291 MN/m2 and decreases to 145 MN/m2 by thermal ageing at 220℃ for 5 h. This decrease takes place in two stages as illustrated in Figure 4. An initial fast stage fol- lows by slow stage in which a slight decrease in hardness can be observed. The as-cast rod with the same composi- tion gives the value of 141 MN/m2. By comparing the two values, it is noticed that, the as melt-spun ribbon has a much higher value than that of the as cast rods, which agreement with other results [9] for alloy rapidly solidified at different cooling rates. On thermal aging, the Figure 1. X-ray diffraction pattern of the Al-1.5Cu-9.5Zn- 3Mg melt spun ribbon. Figure 2. X-ray diffraction pattern of the Al-1.5Cu-9.5Zn- 3Mg annealed ribbon. (a) (b) Figure 3. Load versus elongation for Al-1.5Cu-9.5Zn-3Mg melt spun ribbons (a) as melt spun and (b) aged for 5 h at 300℃.  Effect of Heat Treatment on Mechanical Properties of Al-1.5Cu-9.5Zn-3Mg Rapidly Solidified Alloy Copyright © 2010 SciRes. MSA 201 Figure 4. Variation of Vickers hardness ratio H (t)/H (0) at 170 and 220℃ with aging time. hardness decreases to reach limiting values of 50% of the as melt-spun values. It was observed that the hardness relaxation during isothermal ageing is much slower than that of resistivity relaxation at the same temperature. This behavior can be explained as that, hardness is closely related to size of precipitates. Also the electrical resistiv- ity is sensitive to point defects which are usually the first properties to recover. On the other hand, the hardness depends more on line imperfection which may require higher temperatures for recovery. So, rapid solidification has a significant effect on increasing the hardness. The higher value of hardness for the as melt spun state can be attributed to the effect of the solute atoms upon the sol- vent lattice and the nature of the lattice forces operative owning to the interaction of different atomic spices. 4. Conclusions The effects of rapid solidification and thermal heat treat- ments on the mechanical properties of quaternary Al- 1.5Cu-9.5Zn-3Mg melt spun alloy were studied. A maxi- mum solid solubility value of 9.5 wt.% Zn in α-Al was obtained for the as melt-spun alloy, 3% Mg and 1.5% Cu were also obtained as solid solutions in Al-matrix. The existence of the alloying elements as solid solution in α-Al significantly enhances microhardness, ultimate ten- sile strength U.T.S values. After aging the values relaxed to lower values as a result of the Al2Cu, Zn and Mg pre- cipitations. Hardness and U.T.S were as high as 291 HV and 660 MN/m2, respectively. REFERENCES [1] S. J. Maddox, “Review of Fatigue Assessment Procedures for Welded Aluminum Structures,” International Journal of Fatigue, Vol. 25, No. 12, 2003, pp. 1359-1378. [2] J. R. Davis, “Aluminum and Aluminum Alloys,” ASM International, Materials Park, OH, 1998. [3] C. Zhou, X. Yang and G. Luan, “Investigation of Micro- structures and Fatigue Properties of Friction Stir Welded Al–Mg Alloy,” Journal of Materials Chemistry and Phys- ics, Vol. 98, No. 2-3, 2006, pp. 285-290. [4] B. Grushko E. Kowalska, B. Przepi and M. Surowiec, “An Investigation of the Al-Cu-Cr Phase Diagram: Phase Equilibria at 800-1000℃,” Journal of Alloys and Com- pounds, Vol. 417, No. 1-2, 2006, pp. 121-126. [5] D. R. Fang, Z. F. Zhang, S. D. Wu, C. X. Huang, H. Zhang, N. Q. Zhao and J. Li, “Effect of Equal Channel Angular Pressing on Tensile Properties and Fracture Modes of Casting Al-Cu Alloys,” Journal of Materials Science and Engineering A, Vol. 426, No. 1-2, 2006, pp. 305-313. [6] B. B. Straumal, B. Baretzky, A. A. Mazilkin, F. Phillipp, O. A. Kogtenkova, M. N. Volkov and R. Z. Valiev, “For- mation of Nanograined Structure and Decomposition of Supersaturated Solid Solution during High Pressure Tor- sion of Al-Zn and Al-Mg Alloys,” Journal of Acta Mate- rialia, Vol. 52, No. 15, 2004, pp. 4469-4478. [7] A. Białobrzeski, and E. Czekaj, “An Attempt to Use Alloy Synthesis in Evaluating the Corrosion Behaviour of Al- and Mg-Based Alloys,” Journal of Materials Processing Technology, Vol. 175, No. 1-3, 2006, pp. 27-32. [8] E. M. AbdelHady, N. L. Tawfik and E. S. Gouda, “Me- chanical Properties of Some Al-Based Alloys with Heat Treatment,” Journal of Heat Treatment and Surface En- gineering, Vol. 8, No. 1-2, 2007, pp. 39-45. [9] M. Kamal and E. S. Gouda, “Effect of Cooling Speed on Structure and Properties of Rapidly Solidified Pb-25wt.% Sn Alloy,” Journal of Radiation Effects and Defects in Solids, Vol. 162, No. 9, 2007, pp. 691-696. |