Paper Menu >>

Journal Menu >>

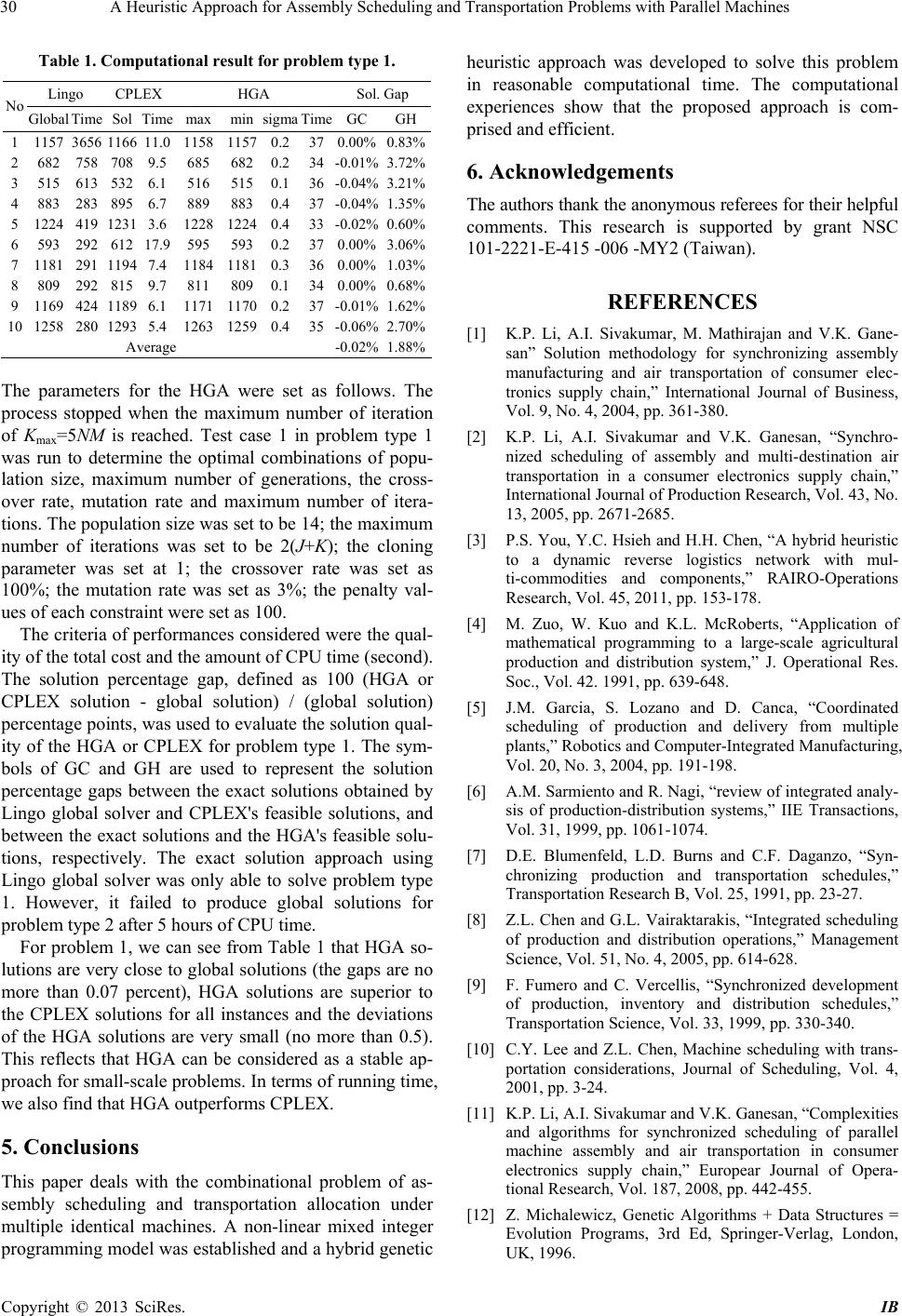

iBusiness, 2013, 5, 27-30 doi:10.4236/ib.2013.51b006 Published Online March 2013 (http://www.scirp.org/journal/ib) 27 A Heuristic Approach for Assembly Scheduling and Transportation Problems with Parallel Machines Peng-Sheng You1, Yi-Chih Hsieh2, Ta-Cheng Chen3, Yung-Cheng Lee4 1Graduate Institute of Marketing and Logistics/Transportation, National Chiayi University, ChiaYi 600; 2Department of Industrial Management, National Formosa University, Yunlin 632; 3Department of Information Management, National Formosa University, Yunlin 632; 4Department of Security Technology and Management, WuFeng University, Chiayi 621. Email: psyuu@mail.ncyu.edu.tw, yhsieh@nfu.edu.tw, tchen@nfu.edu.tw, yclee@wfu.edu.tw Received 2013 ABSTRACT Many firms have to deal with the problems of scheduling and transportation allocation. The problems of assembly scheduling mainly focus on how to arrange orders in proper sequence on the assembly line with the purpose of mini- mizing the maximum completion time before they are flown to their destinations. Transportation allocation problems arise in how to assign processed orders to transport modes in order to minimize penalties such as earliness and tardiness. The two problems are usually separately discussed due to their complexity. This paper simultaneously deals with these two problems for firms with multiple identical parallel machines. We formulate this problem as a mixed integer pro- gramming model. The problem belongs to the class of NP-complete combinatorial optimization problems. This paper develops a hybrid genetic algorithm to obtain a compromised solution within a reasonable CPU time. We evaluate the performance of the presented heuristic with the well-known GAMS/CPLEX software. The presented approach is shown to perform well compared with well-known commercial software. Keywords: Heuristic Approach; Scheduling; Transportation 1. Introduction Assembly scheduling and transportation allocation are two practical problems that industries usually face. Li et al. [1,2] indicated that components in the PC industry are usually stored in warehouses. When receiving orders from customers, PC companies must arrange their orders’ processing sequence on the assembly line to assemble the components for products. Then, an order is ready to be shipped to the customer after assembly process is com- pleted. Since each order has a due date, orders’ process- ing sequence and transportation allocation decisions have significant impact on whether the orders can be shipped to their customers on time so as to reduce inventory holding cost, and earliness and tardiness penalties. In other words, in order to minimize overall costs, the manufacturer must consider the following two problems simultaneously: (1) production scheduling, which de- scribes the orders’ processing sequence, and (2) trans- portation allocation, which describes the allocation of orders to various transport modes in the scheduling pe- riod. A number of production scheduling and transporta- tion allocation works have been separately studied [3-5]. Regarding the production scheduling problem, the pur- pose of this research is similar to previous ones. On the other hand, regarding the transportation allocation prob- lem, this paper focuses on the issue of how to allocate processed orders to transport modes. Researches on the integration of production and distribution have received much attention. Sarmiento and Nagi [6] provided a lit- erature review on this area. Moreover, synchronization of production and road transportation with emphasis on ve- hicle routing problem also has studied by many research- ers (Blumenfeld et al. [7], Chen and Vairaktaraki [8], Fumero and Vercellis [9], Lee and Chen [10]). However, limited works have studied the problem of synchronizing production and transportation allocation. Li et al. [1] in- vestigated a single destination’s air- transportation as- signment problem with a single machine production floor shop. Later, this work was extended by Li et al. [2] to a cases with multiple destinations and by Li et al. [11] to a case with parallel machines in assembly. Since the prob- lem has been shown to be NP-hard [2], Li et al. [11] dealt with the problems by decomposing it into two subprob- lems. In the first subproblem, they solved the transporta- tion allocation problem by determining the transportation departure time for each order and meeting it with the as- sembly. In the second subproblem, they dealt with the Copyright © 2013 SciRes. IB  A Heuristic Approach for Assembly Scheduling and Transportation Problems with Parallel Machines 28 assembly scheduling problem, where they scheduled the orders in the assembly to meet the delivery requirements of transportation. You and Hsieh [3] dealt with an assem- bly and transportation allocation problem with a single machine. The objective o this paper is to simultaneously develop the decisions for production scheduling and transportation allocation under multiple parallel machines so as to minimize overall costs. 2. Model Description A make-to-order manufacturer receives N orders from distinct customers. Among these orders, order-i’s ship- ping destination, order due date and order size are denote by Gi, di and Qi, respectively. Before being transported to their destinations, these orders need to be processed by assembling components on one of Gi parallel machines. The assembly sequence and release time of these N or- ders have a direct impact on the inventory holding cost and the selections of transportation. Inventory holding cost incurs when there is waiting time before the com- pleted order can be shipped to its destination. We use the symbol hi to denote the holding cost of order i per unit time. For each completed order, an order can be split and allocated to more than one carriage and delivered sepa- rately to its destination. Let F be the total number of car- riages and Df be the departure time of carriage f. The transportation cost per unit product, when allocated to carriage f is denoted by cf. In addition to the transporta- tion cost, an delivery earliness penalty cost exists if the arrival time of an order reaches its destination airport before its order due date, and a delivery tardiness penalty cost if the order reaches its destination airport beyond its order due date. The delivery earliness penalty cost per unit product per unit time for order-i is denoted by αi. The purpose is to minimize total cost, which consists of inventory holding cost, the transportation cost of orders allocated into carriages, delivery earliness penalty costs, and delivery tardiness penalty. In addition to the previous assumptions, we further make the following assumptions: (1) The time and cost taken of transporting a completed order by local transportation from the manufacturer to an airport, together with the assembly setup time and cost of each order, are included in the assembly time and cost. (2) The total assembly processing time of an order is directly proportional to its quantity. (3) Business processing time and cost, together with load time and load cost of each carriage, are included in the transportation time and transportation cost. (4) Order fulfillment is considered to be achieved when the order reaches its destination on time. The combined model aims to minimize the overall cost by determining the orders' assembly sequence and allo- cating orders to existing carriages. The factors which are taken into account in the model include: (a) the number of available carriages for the planning horizon, (b) the departure and arrival time of the carriages, (c) the desig- nated capacity and its corresponding transportation cost, and (d) the possible capacity in each carriage with its corresponding carriage cost. Prior to formulating the ma- thematical model, we introduce some additional notation as follows. Notation: k: the destination index, k =1,2,…,K. Bf: the capacity of carriage f, Gf: the destination of carriage f, Pi: the processing time to assemble order i, Af : the arrival time of carriage f, xif : the quantity of the portion of order-i allocated to carriage f, yim :1 if order-i is assembled on machine m, 0 othewise, Ri: the release time to assemble order i, Ci: the assembly completion time of order i, max ij P: maximum production capacity of manufacturer j for order-i, Zif : 1 if order-i is shipped by flight f, 0 otherwise, PIijm: 1 if the processing sequence of order i precedes processing sequence of order j on machine m, immedi- ately, 0 otherwise. Min 11 (max0, ( r F N iff ii fif i if )) x cdAhD C (1) Subject to Z0,f=0, f (2) ZN+1,f=0, f (3) Zif=(Gi- G f)2 0, i, f (4) 1 1,1 r F if f Z iN (5) (1-Zif)M Af- U i, i, f (6) (1-Zif)M Ci- D f, i, f (7) xif= Z if Qi, i, f (8) 1 , N if f i x Cap f (9) Ci=Ri-Pi, 0iN+1 (10) R1=0 (11) 1 1 N N i i R P N (12) 1 1, 1 M im m yi (13) PIiim=0, 0iN+1, 0mM (14) 1 1 ,1 ,1 N ijm im j PIyiNm M (15) Copyright © 2013 SciRes. IB  A Heuristic Approach for Assembly Scheduling and Transportation Problems with Parallel Machines 29 1 ,1 1,1 N ijm jm j PIyjNm M (16) PIi0m=0, 0iN+1, 0mM (17) PIN+1jm=0, 0jN+1, 0mM (18) Cj-Ci-MPIij Pj-M, 0iN, 0jN (19) Zif1, PIijm {0,1} (20) 3. Research Metholodgy The proposed problem is a mix integer program. Due to the computational complexity of the model, no approach is guaranteed for solving the problem optimally within a polynomial time. To overcome this difficulty, we will develop a solution approach to obtain a compromised solution within a reasonable CPU time. The approach is an iteration method in which the concept of genetic algo- rithm (GA) and mathematical programming are consid- ered. We refer to it as HGA. GAs are a particular class of evolutionary algorithms, which generate exact or ap- proximate solutions to optimization and search problems using techniques inspired by evolutionary biology. For details, readers are referred to the textbook by Michale- wicz [12]. The heuristic approach of HGA is addressed as follows: First, let smn be a n-dimensional vector with n orders processed on machine m and element smn(j) at j-th entry denoting the order corresponding to the j-th job processed on machinem. Note that the processing release time of a job does not necessarily happen immediately after the completion time of its previous job. Let w be a N-dimensional vector with element wj at j-th entry de- noting the idle time between order j’s release time and its proceeding job's completion time. For convenience, let s0=0. Then, the relationship between Csmn(j-1) and Rsmn(j) can be expressed as 1mn jmn jmn j Rs Csws (21) At each iteration of HGA, the values of the assembly sequence smn and the idle times w are determined by GA. The values of smn are used to derived the values of PIijm, and the values of w are used to derived the values of ci and Ri. The derived values satisfy constraints (10) to (19). Solution procedure: (a) Initial population: The processing sequence is codified with N distinct in- teger numbers within the range of [1,N]. Idle time w is codified as a binary string. The first N elements of a chromosome are used to generate assembly sequence on each machine and the remaining represents the idle times. (b) Genetic operators: Four standard genetic operators, namely the Cloning operator, Parent selection, Crossover operator and Muta- tion operator repeatedly performed until the maximum number of iterations Kmax is reached. An elitism strategy and the Roulette-wheel selection are used in Cloning op- erator and parent selection, respectively. (c) Fitness: Note the value of the first N entries of a chromosome, (uj,…, uN), is used to generate assembly sequence on each machine where uj is the order appearing at the j-th posi- tion in the number sequence. The assignment of orders to machines is according to the following rule. Let '1 j mj j j CP P (22) be the minimum processed time needed to complete jobs 1 to j on machine m. In addition, let mj denote the num- ber of orders assigned to machine m before order u j is assigned. Then, we sequentially assign orders to the ma- chine with minimum value of CP. The sequence of the orders on each machine also determines the values of PIijm. Moreover, according to equation (21) and idle time, we can further determines Ci and Ri. Let us refer to the model obtained by substituting the known variables of PIijm, Ci, Ri, yim into the original model as model-1. Then, solving model-1 by linear programming, we can obtain xif, zif and the objective value. The objective value is viewed as fitness. (d) Solution update: Updating solution once the result obtained in step 3 is smaller than the objective value found up to now. (e) Stopping criteria: Steps (2-4) are executed repeatedly until the stop crite- rion is matched. 4. Experiments The experiments was designed in terms of (K,F,M,N,T). The combination of (3,10,2,10,24) is set. Ten test cases were generated. The destination for each order and each carriage was generated from uniform distribution over [1, F]. The total assembly processing time of order i was set at Pi = Qi. The due date of each order was generated over [Pi+Ti, 6(Pi+Ti,)]. The commercial software GAMS/CPLEX modeling language was adopted for the purpose of feasible solution comparison with the proposed HGA for all problem types. The proposed HGA was coded in Visual C++ 6.0 pro- gramming language. Both HGA and the GAMS/ CPLEX model were implemented on an Intel Core 2 Duo per- sonal computer equipped with a speed of 2.4 GHz and 2GB of memory. For identifying the gaps between the results obtained from CPLEX and HGA for optimal solu- tion, the Lingo global solver was also used to solve prob- lem type 1. For practical concerns, all algorithms were terminated if the execution time exceeded 5 hours. opyright © 2013 SciRes. IB  A Heuristic Approach for Assembly Scheduling and Transportation Problems with Parallel Machines Copyright © 2013 SciRes. IB 30 Table 1. Computational result for problem type 1. Lingo CPLEX HGA Sol. Gap No Global Time Sol Time max min sigma Time GCGH 1 1157 3656 1166 11.0 1158 1157 0.2 37 0.00%0.83% 2 682 758 708 9.5 685 682 0.2 34 -0.01%3.72% 3 515 613 532 6.1 516 515 0.1 36 -0.04%3.21% 4 883 283 895 6.7 889 883 0.4 37 -0.04%1.35% 5 1224 419 1231 3.6 1228 1224 0.4 33 -0.02%0.60% 6 593 292 612 17.9 595 593 0.2 37 0.00%3.06% 7 1181 291 1194 7.4 1184 1181 0.3 36 0.00%1.03% 8 809 292 815 9.7 811 809 0.1 34 0.00%0.68% 9 1169 424 1189 6.1 1171 1170 0.2 37 -0.01%1.62% 10 1258 280 1293 5.4 1263 1259 0.4 35 -0.06%2.70% Average -0.02%1.88% The parameters for the HGA were set as follows. The process stopped when the maximum number of iteration of Kmax=5NM is reached. Test case 1 in problem type 1 was run to determine the optimal combinations of popu- lation size, maximum number of generations, the cross- over rate, mutation rate and maximum number of itera- tions. The population size was set to be 14; the maximum number of iterations was set to be 2(J+K); the cloning parameter was set at 1; the crossover rate was set as 100%; the mutation rate was set as 3%; the penalty val- ues of each constraint were set as 100. The criteria of performances considered were the qual- ity of the total cost and the amount of CPU time (second). The solution percentage gap, defined as 100 (HGA or CPLEX solution - global solution) / (global solution) percentage points, was used to evaluate the solution qual- ity of the HGA or CPLEX for problem type 1. The sym- bols of GC and GH are used to represent the solution percentage gaps between the exact solutions obtained by Lingo global solver and CPLEX's feasible solutions, and between the exact solutions and the HGA's feasible solu- tions, respectively. The exact solution approach using Lingo global solver was only able to solve problem type 1. However, it failed to produce global solutions for problem type 2 after 5 hours of CPU time. For problem 1, we can see from Table 1 that HGA so- lutions are very close to global solutions (the gaps are no more than 0.07 percent), HGA solutions are superior to the CPLEX solutions for all instances and the deviations of the HGA solutions are very small (no more than 0.5). This reflects that HGA can be considered as a stable ap- proach for small-scale problems. In terms of running time, we also find that HGA outperforms CPLEX. 5. Conclusions This paper deals with the combinational problem of as- sembly scheduling and transportation allocation under multiple identical machines. A non-linear mixed integer programming model was established and a hybrid genetic heuristic approach was developed to solve this problem in reasonable computational time. The computational experiences show that the proposed approach is com- prised and efficient. 6. Acknowledgements The authors thank the anonymous referees for their helpful comments. This research is supported by grant NSC 101-2221-E-415 -006 -MY2 (Taiwan). REFERENCES [1] K.P. Li, A.I. Sivakumar, M. Mathirajan and V.K. Gane- san” Solution methodology for synchronizing assembly manufacturing and air transportation of consumer elec- tronics supply chain,” International Journal of Business, Vol. 9, No. 4, 2004, pp. 361-380. [2] K.P. Li, A.I. Sivakumar and V.K. Ganesan, “Synchro- nized scheduling of assembly and multi-destination air transportation in a consumer electronics supply chain,” International Journal of Production Research, Vol. 43, No. 13, 2005, pp. 2671-2685. [3] P.S. You, Y.C. Hsieh and H.H. Chen, “A hybrid heuristic to a dynamic reverse logistics network with mul- ti-commodities and components,” RAIRO-Operations Research, Vol. 45, 2011, pp. 153-178. [4] M. Zuo, W. Kuo and K.L. McRoberts, “Application of mathematical programming to a large-scale agricultural production and distribution system,” J. Operational Res. Soc., Vol. 42. 1991, pp. 639-648. [5] J.M. Garcia, S. Lozano and D. Canca, “Coordinated scheduling of production and delivery from multiple plants,” Robotics and Computer-Integrated Manufacturing, Vol. 20, No. 3, 2004, pp. 191-198. [6] A.M. Sarmiento and R. Nagi, “review of integrated analy- sis of production-distribution systems,” IIE Transactions, Vol. 31, 1999, pp. 1061-1074. [7] D.E. Blumenfeld, L.D. Burns and C.F. Daganzo, “Syn- chronizing production and transportation schedules,” Transportation Research B, Vol. 25, 1991, pp. 23-27. [8] Z.L. Chen and G.L. Vairaktarakis, “Integrated scheduling of production and distribution operations,” Management Science, Vol. 51, No. 4, 2005, pp. 614-628. [9] F. Fumero and C. Vercellis, “Synchronized development of production, inventory and distribution schedules,” Transportation Science, Vol. 33, 1999, pp. 330-340. [10] C.Y. Lee and Z.L. Chen, Machine scheduling with trans- portation considerations, Journal of Scheduling, Vol. 4, 2001, pp. 3-24. [11] K.P. Li, A.I. Sivakumar and V.K. Ganesan, “Complexities and algorithms for synchronized scheduling of parallel machine assembly and air transportation in consumer electronics supply chain,” Europear Journal of Opera- tional Research, Vol. 187, 2008, pp. 442-455. [12] Z. Michalewicz, Genetic Algorithms + Data Structures = Evolution Programs, 3rd Ed, Springer-Verlag, London, UK, 1996. |