Paper Menu >>

Journal Menu >>

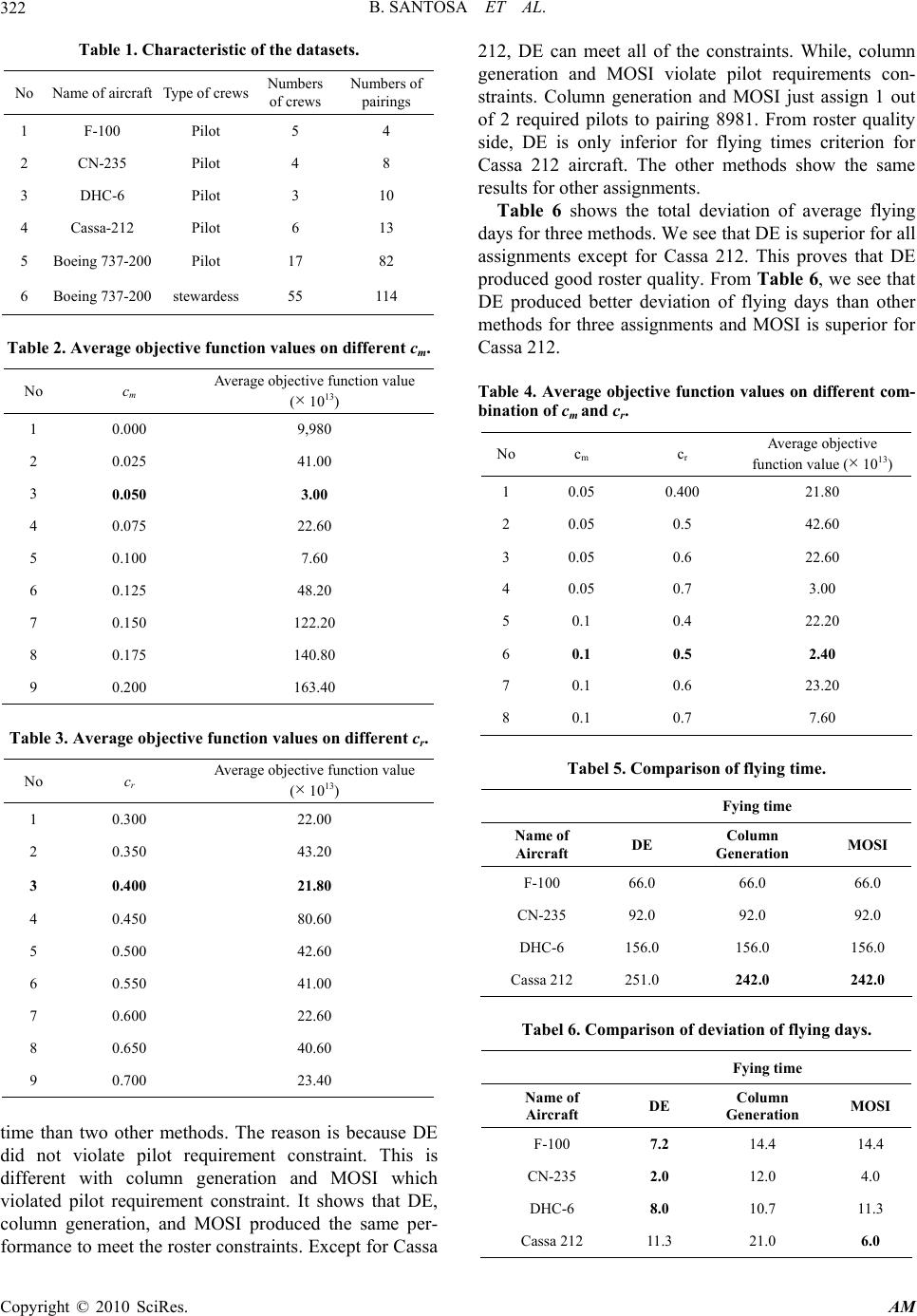

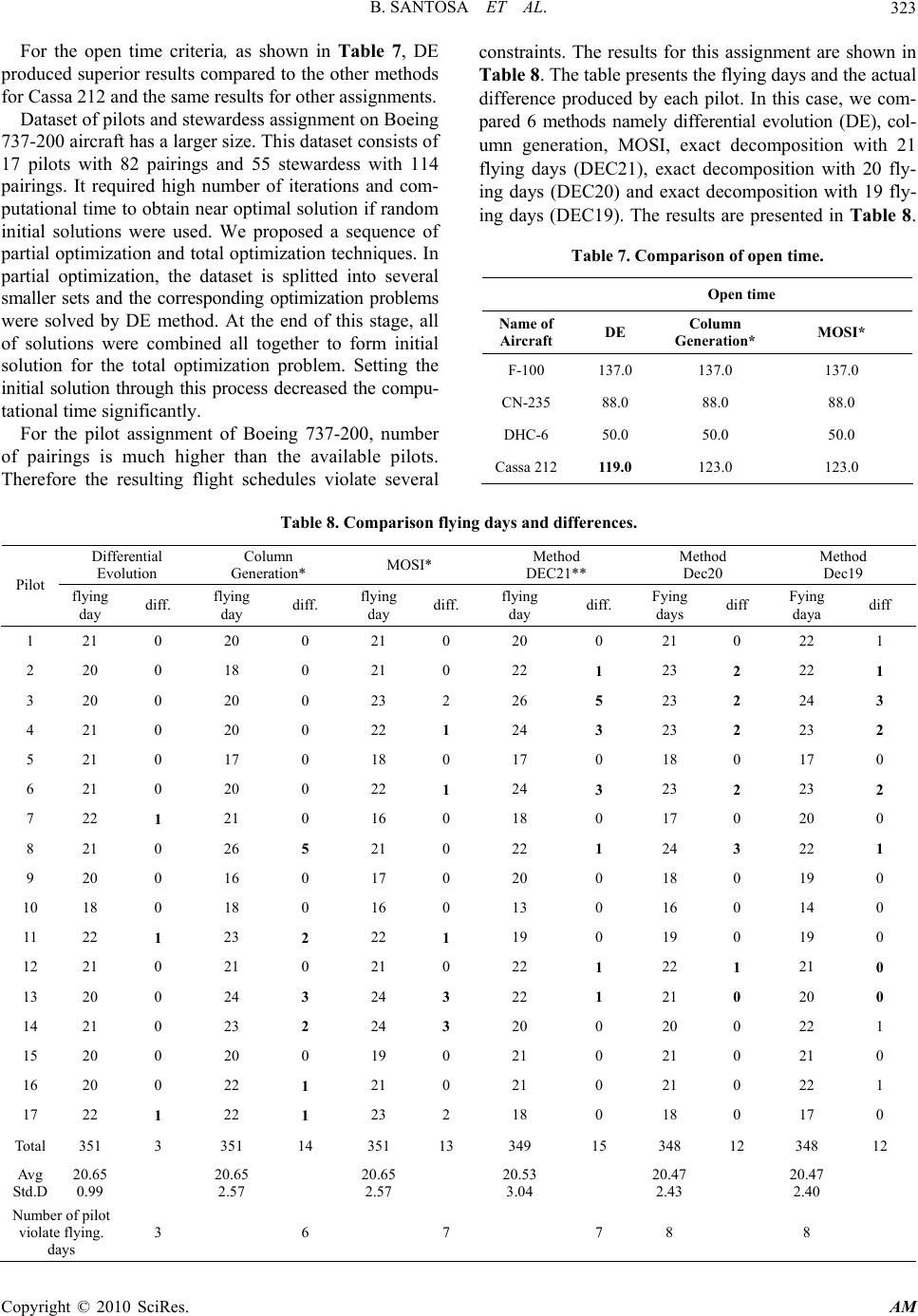

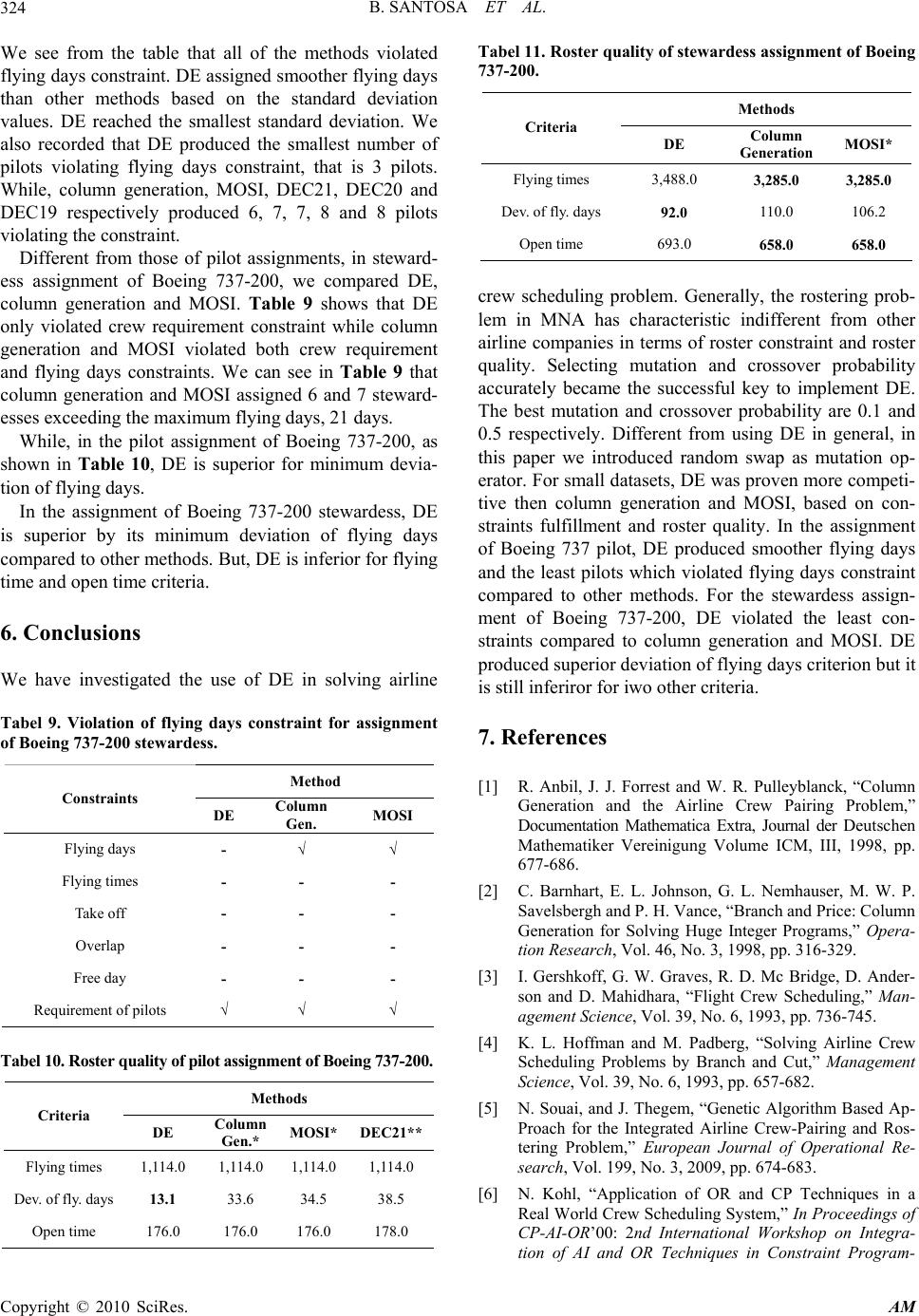

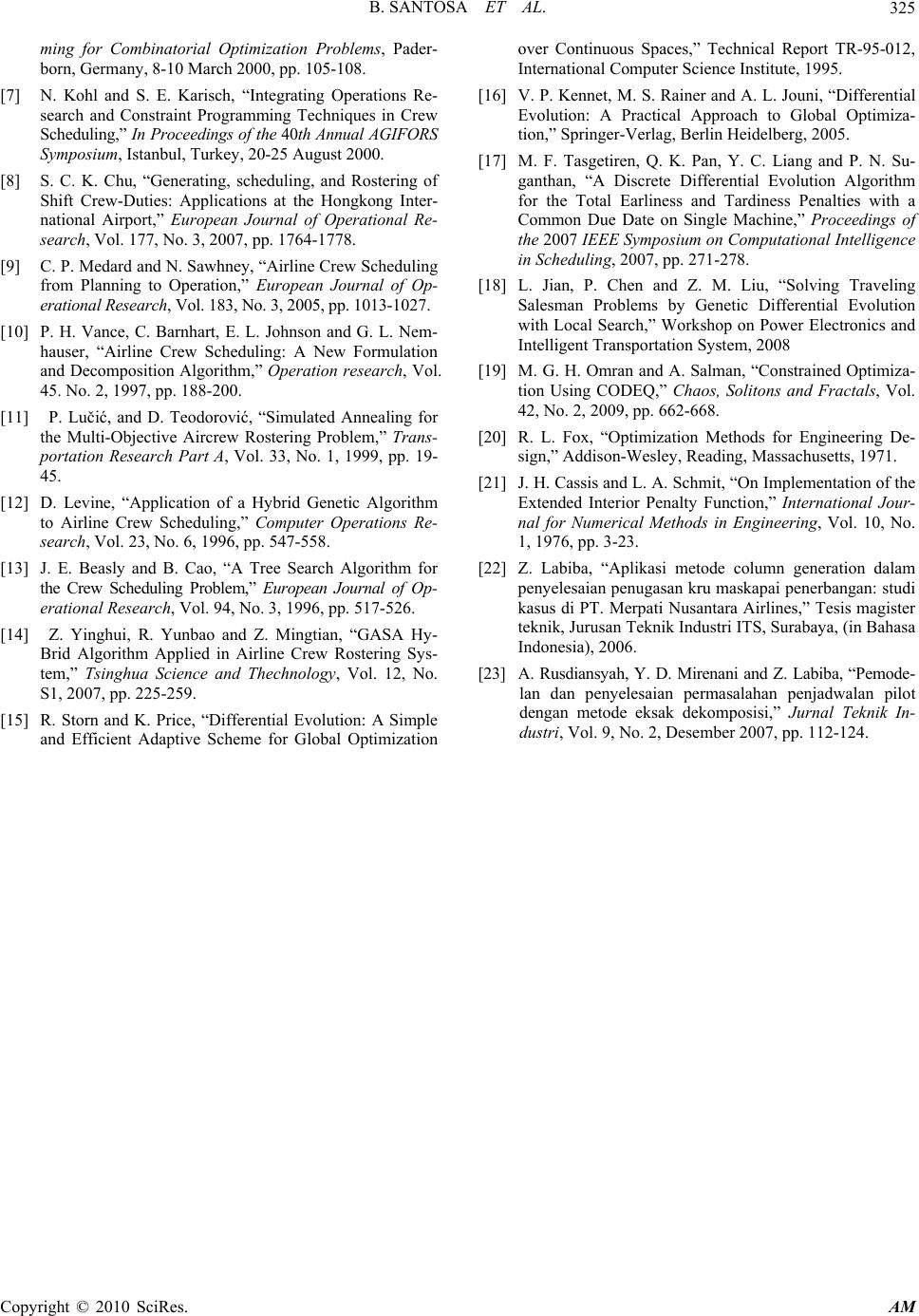

Applied Mathematics, 2010, 1, 316-325 doi:10.4236/am.2010.14042 Published Online October 2010 (http://www.SciRP.org/journal/am) Copyright © 2010 SciRes. AM Using Differential Evolution Method to Solve Crew Rostering Problem Budi Santosa, Andiek Sunarto, Arief Rahman Indusrial Engineering, Institut Teknologi Sepuluh Nopember,Kampus ITS Sukolilo Surabaya, Indonesia E-mail: budi_s@ie.its.ac.id Received April 19, 2010; revised August 24, 2010; accepted August 27, 2010 Abstract Airline crew rostering is the assignment problem of crew members to planned rotations/pairings for certain month. Airline companies have the monthly task of constructing personalized monthly schedules (roster) for crew members. This problem became more complex and difficult while the aspirations/criterias to assess the quality of roster grew and the constraints increased excessively. This paper proposed the differential evolution (DE) method to solve the airline rostering problem. Different from the common DE, this paper presented random swap as mutation operator. The DE algorithm is proven to be able to find the near optimal solution accurately for the optimization problem. Through numerical experiments with some real datasets, DE showed more competitive results than two other methods, column generation and MOSI (the one used by the Airline). DE produced good results for small and medium datasets, but it still showed reasonable results for large dataset. For large crew rostering problem, we proposed decomposition procedure to solve it in more efficient manner using DE. Keywords: Differential Evolution, Crew Scheduling, Pairing, Rostering 1. Introduction Development of crews rostering plan which be able to produce the high utility of crews become the priority in human resources department in airline industry. It is estimated that the use of optimization software for airline could save more than US $20 million per year [1]. Saving 1% in crew utilization can save cost largerly. Though airline crews scheduling became attention in many operation research literature such as [1-7] but air- line crews scheduling remains to become the main atten- tion for many researchers due to its level of complexity and difficulty to solve. Therefore, methods and approa- ches which are used to solve it are continuously develo- ped to get better result both in optimality side and speed of computational time. Generally, solving airline crew scheduling is done by decomposition approach [8-10]), it devides problem into crew pairing and crew rostering. Crew pairing is done to get initial feasible solution, that is sequence of flight which begin and end at the same home base. Crew rostering assigns pairings which were arranged for the certain month to set of crews based on individual calender. Decomposition approach is very effective to solve the difficult and complex problem but this method loss the global treatment since crew pairing and crew rostering done separately. Some other researchers developed the integrated approach to overcome obstacle, such as Souai and Thegem [5], where crew pairing and rostering were done simultantly to get a better optimality level. Many optimization methods have been developed to solve crew scheduling to increase roster quality and to improve computational time such as simulated annealing [11], genetic algorithm [5], tree search algorithm [12], hybrid genetic algorithm [13] and GASA hybrid algori- thm [14]. This research focused on developing differential evo- lution algorithm applied on intelligent airline crew ros- tering system. This paper is organized as follows. The second section reviews differential evolution (DE). Sec- tion 3 describes the problem statement. In Section 4, we describe our methodology. Section 5 explaines the ex- perimental setting and the results. Section 6 concludes the results. 2. Differential Evolution Differential evolution is an evolutionary population-based  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 317 algorithm proposed by Storn and Price [15,16]. Since its initiation in 1995, DE has shown its performance as a very effective global optimizer. DE originated with Ge- netic Annealing (GA) Algorithm. Since GA was very slow and effective control parameters were hard to de- termine, the modification of the GA algorithm were made. DE uses a floating-point instead of bit-string encoding and arithmatic operations instead of logical ones. DE differs significantly from the evolutionary algorithms in the sense that distance and direction information from the current population is used to guide the search proc- ess. DE uses the differences between two randomly cho- sen vectors (individuals) as the base to form a third vec- tor (individual), referred to as the target vector. Trial solutions are generated by adding weighted difference vectors to the target vector. This process is referred to as the mutation operator where the target vector is mutated. The next step is recombination or crossover which is applied to produce an offspring. This new individual is accepted only if it improves on the fitness of the parent individual. The basic DE algorithm is described in more detail below [16]. 2.1. Initialization In this step, a set of initial solutions are genereted rando- mly. A random number generator assigns each variable of each vector value from within specified range, lower bound, bL, and upper bound, bU. For example the initial value (g = 0) of the jth variable of ith vector is: ,,, ,, rand0,1 . j 0 xbbb j ijUjLjL (1) where, randj (0,1), returns a uniformly distributed random number from within the range [0,1]. 2.2. Mutation DE mutates and recombines the population to produce a population of N-trial vectors. In particular, differential mutation adds a scaled, randomly sampled, vector dif- rence of third vector. To combine three different ran- mly chosen vectors to create the mutant vector, vi,g, the following equation is used: ,,, +. , 012 vxFx x igrgr grg (2) where the scale factor, F (0, 1+) is a positive real number that control the rate at which the population evolve. The vector index, r0, r1, and r2, can be chosen randomly and meet r0 r1 r2 i. 2.3. Crossover DE employs the uniformly crossover. Crossover builds trial vectors out of parameter value that have been copied from two different vectors. In particular, DE crosses each vector with a mutant vector to creat ui,g. ,, ,,, ,, ,((0,1) ,max , j vifrand Crorjj xotherwise jig ig jig jig uu (3) The crosover probability, Cr ∊ [0,1], is user-defined value that controls the fraction of parameter value that are copied from the mutant. 2.4. Selection If the trial vector, ui,g, has an equal or lower objective function value (better fitness value) than that of its target vector, xi,g, it replaces the target vector in the next generation; otherwise, the target retains its place in the population at least one more generation. ,,, ,1 , ,()() , ig ig iff ufx otherwise ig ig ig u xx (4) Once the new population created, the process of mutation, recombination, and selection are repeated until the optimum solution is achieved or prespesified termina-- tion criterion is satisfied, e.g., the number of generations reaches preset maximum, gmax. DE has been applied in many field successfully. In 1995, DE has been used by Ken to solve 5-dimension Chebyshev model. By the time, Ken modified genetic annealing algorithm with differential mutation operator. Different from genetic annealing, DE has not found some difficulty to find the coefficient even 33-dimension Chebyshev. Tasgetiren [15] used a discrete differential evolution (DDE) algorithm to solve the single machine total earli- ss and tardiness penalties with a common due date. A new binary swap mutation operator called Bswap is pre- nted. In addition, the DDE algorithm is hybridized with a local search algorithm to further improve the perform- ance of the DDE algorithm. The performance of the proposed DDE algorithm is tested on 280 benchmark in- stances ranging from 10 to 1000 jobs from the OR Li- brary. The computational experiments showed that the proposed DDE algorithm has generated better results than those in the literature in terms of both solution qual- ity and computational time. A genetic differential evolution (GDE) was derived from the differential evolution (DE) and incorporated with the genetic reproduction mechanisms, namely cross- over and mutation used to solve traveling salesman pro- blems (TSP). The Greedy Subtour Crossover (GSX) was employed to generate an offspring to denote the differ- ence of the parents. A modified ordered crossover (MOX)  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 318 was employed to perform mutation to generate trial vec- tor with a user defined parameter, the parameter were used to control the rates of the target vector components and the mutated vector components in the trial vector. Moreover, a 2-opt local search was implemented to en- hance local search performance. GDE was implemented to the well-known TSP with 52, 100 and 200 cities with variable parameters. Based on analysis and discussion on the results, typical values of the parameters were given, with which GDE provided effective and robust perform- ance [18]. Omran and Salman [19] improved Differential evolu- tion by combining with chaotic search, opposition-based learning, and quantum mechanics, called CODEQ, to solve constrained optimization problems. The perform- ance of the proposed approach when applied to five con- strained benchmark problems is investigated and com- pared with other approaches proposed in the literature. The experiments conducted show that CODEQ provides excellent results with the added advantage of no parame- ter tuning. 3. Problem Statement There are two main processes in the airline crew plan- ning. These two process are pairing and rostering. Pair- ing, is the step where the flying activities are created. The flight timetable is used as input to form sequences of flights, known as pairings. The timetable horizon usually covers a period of 4-6 weeks. The main objective of this process is to utilize the minimum number of crew to cover the complete timetable. Rostering is the step where the created pairings are assigned to actual crew (pilot and stewardess), with regard to the qualifications and previ- ously assigned activities, referred to as pre-assignments, of the crew. The objective is to find feasible assignments that minimize costs and match the notion of quality of life for the crew imposed by the airline [9]. In this context, problem of airline crew scheduling generally varies among different countries. Especially in rostering problem since each country may impose different set of regulations, rules and policies. The speed of roster construction is a critical matter in airline crew schedule- ing. In [9], it is stated that for monthly planning, solution should be obtained within 15-20 minutes. While, for shorter horizon planning, such as daily planning, where there are some changes to roster, solutions should be obtained within 1-5 minutes. Therefore, solving optimi- zation problem of airline crew scheduling in time manner become very important. In this paper two main problems are addressed. First, how to mathematically formulate the problem of airline crew scheduling. This formulation includes the construc- tion of objective function and spesific set of constraints which influence the roster quality. We modified the model which is developed by Lučić and Teodorović [11] based on the real condition of rostering in the airline under study. We modified the single crew and single aircraft scheduling model becomes multiple crews and multiple aircrafts model. We also added open time crite- ria to the objective function. Second, how to solve the model using differential evolution approach with consi- dering the simplicity of the model, quality of the resulting roster, and computational time. 3.1. Index k is index for kind of crews k = 1,,K. For example, k = 1 is for Pilot F-100; k = 2 is for Pilot CN-235; and k = 8 is for stewardess and etc. i is index for numbers of crew members (1,,mk). For example m 5 = 17 is the number of crew members for Boeing 737-200, and m8 = 55 is the number of stewardess of Boeing 737-200. j is index rotation/pairing which assigned to crew members (1,,nk). For example n5 = 82, is the number of pairings for Being 737-200. l is number of days in a month (1,,31). 3.2. Parameters djk is length of rotation-j which assigned to crew k. (in hours). 1,ifmember from crew can be assigned to day 0, otherwise ilk i kl p 1,if/ assigned to crew start to day 0, otherwise jlk rotationpairing j kl q dmax,k is maximum flight times crew k for one month; vjk is numbers of take-off rotation j assigned to crew k; vmax,k is maximum take-off in one month; Dmin,jk is minimum of numbers of crews k needed to complete rotation j; tjk is numbers of duty period needed by crew k to com- plete rotation j; tmax,k is maximum of flying day before free day. 1,if rotationoverlap with rotation when assigned to crew 0, otherwise rsk rsk n  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 319 3.3. Objectives Function The objective function of this airline crew rostering is minimizing three terms of criterias. Cost of roster Cost of roster paid by the airline company to crew is variable cost. By assumption that salary per hour is same to all crew, cost of roster can be represented by actual flying hours. 11 min1,, kk mn jk ijk ij dx kK (5) Deviation of flying days between crew members Let k t be the average flying days per month for crew member k, then 11 1,, kk mn jk ijk ij k k tx tkK m (6) The deviation of total flying days per month can be formulated as 11 min 1,, kk p mn k jk ijk ij tx tkK (7) where p is positive integer. In this paper we use p = 1. Open time Open time is days when a crew member does not have flying duty. If there are 31 days in a scheduling month, then open time for crew member k can be formulated as 11 min31 1,, kk mn jk ijk ij tx kK (8) 3.4. Constraints There are some constraints which must be satisfied when constructing a roster. The following are the const- raints used: Flight time constraint Maximum flying hours for pilot and co-pilot is 110 hours per month, and for cabin crew is 120 hours per month. So dmax,k = 110 for k = 1,,7 and dmax,k = 120 for k = 8. max, 1 1,...,, 1,, k n jk ijkkk j dxdim kK (9) Duty period constraint Maximum duty period allowed to crew member k is 21 days. 1 21 1,,, 1,, k n jk ijkk j txim kK (10) Numbers of take-off Numbers of maximum take off allowed to pilot is 90, then vmax,k = 90. But, cabin crew have no take off con- straint. max, 1 1,,, 1,, k n jk ijkkk j vxvim kK (11) Numbers of crew reqirement Every rotation needs minimum numbers of crew. min, 1 1,,, 1,, k m ijk jkk i x Dj nkK (12) Free day constraint Every crew member must be given free days after 7 flying days. 7 1 7 1,,, 1,,23, 1,,8 k np jk ijkjklk jlp txqim pk (13) Rotation without free day When crew members complete this rotation not al- lowed to have free day. 1 31 111 1,,, 1,, jk kk lt nn ijkijk jkliskk jjl sl x xqpi mkK (14) No overlap constraint Two rotations in series may not be overlap each other. It means that precedence rotation must be finished when following rotation will start. 1 ()0 1,,, 1,,, 1,, k n ijkjsk isk s kk xxsj imjnkK (15) Airline rostering problem is optimization problem with many constraints. It falls to constrained optimiza- tion problem. To use DE to solve this original problem we have to transform the problem into an unconstrained optimiza- tion problem. We use external penalty function method [20,21] to do this transformation. Basically, this method incurs big penalty while the solution violated any con- straints. The resulting constrained optimization problem is as follows 12 111 1 3 11223344 11 55 6677 88 min 31 kkk k kk p mnm n k jk ijkjk ijk iji j mn jk ijk ij dxtx t t xrCrCrCrC rC rCrCrC (16) where: 2 1max, 11 max0, 1,, kk mn jk ijkk ij CdxdkK  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 320 2 2max, 11 max0, 1,, kk mn jk ijkk ij CvxvkK 2 3min, 11 max0, 1,, kk nm ijk jk ji CxDkK 2 7 4 11 max0,7 1,, kk mn p jk ijkjkl ijlp CtxqkK 2 1 31 5 1111 max0, 1,, jk kkk lt mnn ijkijk jklisk ijjl sl Cxxqp kK 2 1 31 6 1111 min0, 1,, jk kkk lt mnn ijkijk jklisk ijjl sl Cxxqp kK 2 7 11 max0,() 1,, kk mn ijkjsk isk is CxxsjkK 2 8 11 1 min0,() 1,, kk k mn n ijkjsk isk ij s CxxsjkK where β1, β2, and β3 are weight coeficients of the objec- tive function, r1,…,r8 are penalties which are given since model violate any constraints where r1,…,r8 → ∞ will assure that algorithm will satisfy constraint early before considering objective function. Equation (16) becomes the fitness function of DE method. If we assume cost of roster more important than cost of deviation of flying day and more important than open time, then β1, β2, and β3 are selected carefully where β1 β2 β3 and assure followed inequality is true : 12 111 1 3 11 31 kkkk kk p mnm n k jk ijkjk ijk iji j mn jk ijk ij dxtxt tx (17) Term (17) will assure hirarchical ordering of solving iteratively by DE. 4. Solving the Model Using DE In this paper we applied this model on a real case taken from MNA (Merpati Nusantara Airlines), Ltd., a private airline company based in Indonesia [22,23]. To solve the above problem we pursue the following steps of DE. 4.1. Initialization Initial solution xijk is defined by generating n_pop binary random numbers (0 or 1) of dimension nk × mk. Let Xnp,0 be the initial solution population np, then ,0 [0;1] 1..., np np X randnpn pop (18) Randnp[0;1] is binary random 0 or 1 of population np. 4.2. Mutation Different from those which usually used as a mutation operator in DE as indicated in Equation (2), this paper introduce a random swap as a mutation operator. Let r0 be random number between 0 and 1 with nk × mk dimen- sion for each population np, and vnp,r0,g be element of solution V at column r0 at generation g. If Wnp,g-1 is the best population for generation g-1 and wnp,r0,g-1 is the element at column r0 of Wnp,g-1, then mutant of generation g is defined as ,0, 10 ,0, ,0, 1 (1) mod(2),if ,otherwise np rgm np rg np rg Wrc vW (19) where cm is mutation probability (0 < cm <1) which represents mutation power imposed to the best popula- tion of previous generation. Term Wnp,r0,g-1 mod(2) means what value left after dividing Wnp,r0,g-1 by 2. The selection of cm must be done carefully because too small cm can cause old solution is difficult to exit from local optimum. While, too big cm causes noise solution such that fast convergence toward global optima can not be achieved. Selecting cm accurately becomes the successful key of implementing this algorithm. As an illustration how this mutation operator works, notice the following example. Suppose we have 3 pilots and 4 pairings, use cm = 0.2. Suppose we have W0 (current solution): 0 1000 11 1 1 1010 W Entry (i,j) = 1 indicates a pilot i be placed in pairing j, entry(i,j) = 0, otherwise. After generating randomly, suppose we got: 0 0,100, 400, 080,70 0,30 0,20 0,90 0,15 0,850,05 0,25 0,55 r To have a new solution, apply Equation (19). By comparing r0 and cm for each corresponding entry in W0 and r0, we have matrix W’0 , where each entry (typed in bold) should be changed since r0 < cm. 0 1000 ' 1111 1010 W  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 321 The changes should be made as follows Cell(1,1) v = (w0 + 1) mod(2) = (1 + 1) mod(2) = 2 mod(2) = 0 Cell(1,3) v = (w0 + 1) mod(2) = (0 + 1) mod(2) = 1 mod(2) = 1 Cell(2,4) v = (w0 + 1) mod(2) = (1 + 1) mod(2) = 2 mod(2) = 0 Cell(3,2) v = (w0 + 1) mod(2) = (0 + 1) mod(2) = 1 mod(2) = 1 The other entries of W0 remains the same as ro ≥ cm,. Therefore, we obtain the new solution 0010 1110 1110 V We follow this process each time the algorithm is on the mutation step. 4.3. Crossover Crossover changes over parent solution Xnp,g by mutant solution Vnp,g to construct a new solution Unp,g. Cross- over is done by defining threshold probability (0 < cr < 1) for mutant to change current solution. Then we gener- ate n_pop random numbers (0,1). If the random number < cr, then the mutant replaces the current solution and otherwise. , , , ,(0,1) , np gnpr np g np g Vif randc UXotherwise (20) 4.4. Selection This process is done by comparing the fitnesses of the parent solution and the new solution which is produced from crossover process. The new population will replace the old population only if the new population has better fitness than that of the old population. The fitness func- tion refers to Equation (16). Then, the solution of the next generation Xnp,g+1 can be obtained from this for- mula: ,, , ,1 , ,( )() , np gnp gnp g np g np g UiffU fX XXotherwise (21) where f(Unp,g) and f(Xnp,g) are the fitness of Unp,g and Xnp,g respectively. The constructed mathematical model consists of some aspirations/criterias as the objective function and some constraints. The objective function includes minimum flying times, deviation of flying days, and open time. Some constraints which are considered when construc- ting a roster include overlap, crew requirement of pairing, free days before seven days of flying days, maximum flying times, and maximum numbers of take off. 5. Experiments and Analysis We used Matlab to implement DE algorithm. The expe- riments were done using the datasets shown in Table 1. The datasets consist of pairings, numbers of crews, type of fleed and rules. Datasets are divided into two catego- ries: small and large datasets. Small dataset consists of assignment of F-100, CN-235, DHC-6, and Cassa 212 pilot. While, large dataset consists of assignment of Boeing 737-200 pilot and stewardess. The experiments aim to assign crew members in which pairings. The results of the experiments on small datasets were compared with column generation [22,23] and MOSI (method used by the company). For large datasets we included exact decomposition as a comparative method [23]. Probability of mutation (cm) and probability of cross- er (cr) are the key succes factors for DE implementation. Therefore, these two parameters should be determined carefully. The precise parameter values will lead to the global optimal solution. In this paper, these parameters settings were done through trial process. The best cm, is determined by using one dataset (Cassa 212) with npop = 50, gmax = 50, cr = 0.7 and the experiments were done with 5 replications. Table 2 shows the objective function values for different cm. The best value is typed in bold. We found that cm = 0.05 is the best one. Using cm = 0.05, the same procedure was done to find the best cr. The results are shown in Table 3. Next, using combination of cm and cr we tried to determine the best values of these two parameters. Through experiments, we obtained the best combination between cm and cr are 0.1 and 0.5 as shown in bold in Table 4. Criteria in the objective function are weighted based on their significances. In this paper we put roster cost minimization as the most significance followed by devia- tion of minimum flying days and open time with weights of 104, 102 and 1 respectively. Other parameter needs to set up is pinalty for the constraints. Penalties for overlap and rotation without free day, number of pilot require- ments and day off constraints are 1015, 1013 and 1011 res- pectively based on their signifances.While, the penalties for flying day, flying times, and numbers of take off are set to 106 as these constraints are assumed to be the same important. Experimental results for small datasets are indicated in Table 5. For the flying time criterion, DE spent more  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 322 Table 1. Characteristic of the datasets. No Name of aircraft Type of crews Numbers of crews Numbers of pairings 1 F-100 Pilot 5 4 2 CN-235 Pilot 4 8 3 DHC-6 Pilot 3 10 4 Cassa-212 Pilot 6 13 5 Boeing 737-200 Pilot 17 82 6 Boeing 737-200 stewardess55 114 Table 2. Average objective function values on different cm. No cm Average objective function value (× 1013) 1 0.000 9,980 2 0.025 41.00 3 0.050 3.00 4 0.075 22.60 5 0.100 7.60 6 0.125 48.20 7 0.150 122.20 8 0.175 140.80 9 0.200 163.40 Table 3. Average objective function values on different cr. No cr Average objective function value (× 1013) 1 0.300 22.00 2 0.350 43.20 3 0.400 21.80 4 0.450 80.60 5 0.500 42.60 6 0.550 41.00 7 0.600 22.60 8 0.650 40.60 9 0.700 23.40 time than two other methods. The reason is because DE did not violate pilot requirement constraint. This is different with column generation and MOSI which violated pilot requirement constraint. It shows that DE, column generation, and MOSI produced the same per- formance to meet the roster constraints. Except for Cassa 212, DE can meet all of the constraints. While, column generation and MOSI violate pilot requirements con- straints. Column generation and MOSI just assign 1 out of 2 required pilots to pairing 8981. From roster quality side, DE is only inferior for flying times criterion for Cassa 212 aircraft. The other methods show the same results for other assignments. Table 6 shows the total deviation of average flying days for three methods. We see that DE is superior for all assignments except for Cassa 212. This proves that DE produced good roster quality. From Table 6, we see that DE produced better deviation of flying days than other methods for three assignments and MOSI is superior for Cassa 212. Table 4. Average objective function values on different com- bination of cm and cr. No cm c r Average objective function value (× 1013) 1 0.05 0.400 21.80 2 0.05 0.5 42.60 3 0.05 0.6 22.60 4 0.05 0.7 3.00 5 0.1 0.4 22.20 6 0.1 0.5 2.40 7 0.1 0.6 23.20 8 0.1 0.7 7.60 Tabel 5. Comparison of flying time. Fying time Name of Aircraft DE Column Generation MOSI F-100 66.0 66.0 66.0 CN-235 92.0 92.0 92.0 DHC-6 156.0 156.0 156.0 Cassa 212 251.0 242.0 242.0 Tabel 6. Comparison of deviation of flying days. Fying time Name of Aircraft DE Column Generation MOSI F-100 7.2 14.4 14.4 CN-235 2.0 12.0 4.0 DHC-6 8.0 10.7 11.3 Cassa 212 11.3 21.0 6.0  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 323 For the open time criteria, as shown in Table 7, DE produced superior results compared to the other methods for Cassa 212 and the same results for other assignments. Dataset of pilots and stewardess assignment on Boeing 737-200 aircraft has a larger size. This dataset consists of 17 pilots with 82 pairings and 55 stewardess with 114 pairings. It required high number of iterations and com- putational time to obtain near optimal solution if random initial solutions were used. We proposed a sequence of partial optimization and total optimization techniques. In partial optimization, the dataset is splitted into several smaller sets and the corresponding optimization problems were solved by DE method. At the end of this stage, all of solutions were combined all together to form initial solution for the total optimization problem. Setting the initial solution through this process decreased the compu- tational time significantly. For the pilot assignment of Boeing 737-200, number of pairings is much higher than the available pilots. Therefore the resulting flight schedules violate several constraints. The results for this assignment are shown in Table 8. The table presents the flying days and the actual difference produced by each pilot. In this case, we com- pared 6 methods namely differential evolution (DE), col- umn generation, MOSI, exact decomposition with 21 flying days (DEC21), exact decomposition with 20 fly- ing days (DEC20) and exact decomposition with 19 fly- ing days (DEC19). The results are presented in Table 8. Table 7. Comparison of open time. Open time Name of Aircraft DE Column Generation* MOSI* F-100 137.0 137.0 137.0 CN-235 88.0 88.0 88.0 DHC-6 50.0 50.0 50.0 Cassa 212119.0 123.0 123.0 Table 8. Comparison flying days and differences. Differential Evolution Column Generation* MOSI* Method DEC21** Method Dec20 Method Dec19 Pilot flying day diff. flying day diff. flying day diff. flying day diff. Fying days diff Fying daya diff 1 21 0 20 0 21 0 20 0 21 0 22 1 2 20 0 18 0 21 0 22 1 23 2 22 1 3 20 0 20 0 23 2 26 5 23 2 24 3 4 21 0 20 0 22 1 24 3 23 2 23 2 5 21 0 17 0 18 0 17 0 18 0 17 0 6 21 0 20 0 22 1 24 3 23 2 23 2 7 22 1 21 0 16 0 18 0 17 0 20 0 8 21 0 26 5 21 0 22 1 24 3 22 1 9 20 0 16 0 17 0 20 0 18 0 19 0 10 18 0 18 0 16 0 13 0 16 0 14 0 11 22 1 23 2 22 1 19 0 19 0 19 0 12 21 0 21 0 21 0 22 1 22 1 21 0 13 20 0 24 3 24 3 22 1 21 0 20 0 14 21 0 23 2 24 3 20 0 20 0 22 1 15 20 0 20 0 19 0 21 0 21 0 21 0 16 20 0 22 1 21 0 21 0 21 0 22 1 17 22 1 22 1 23 2 18 0 18 0 17 0 Total 351 3 351 14 351 13 349 15 348 12 348 12 Avg Std.D 20.65 0.99 20.65 2.57 20.65 2.57 20.53 3.04 20.47 2.43 20.47 2.40 Number of pilot violate flying. days 3 6 7 7 8 8  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 324 We see from the table that all of the methods violated flying days constraint. DE assigned smoother flying days than other methods based on the standard deviation values. DE reached the smallest standard deviation. We also recorded that DE produced the smallest number of pilots violating flying days constraint, that is 3 pilots. While, column generation, MOSI, DEC21, DEC20 and DEC19 respectively produced 6, 7, 7, 8 and 8 pilots violating the constraint. Different from those of pilot assignments, in steward- ess assignment of Boeing 737-200, we compared DE, column generation and MOSI. Table 9 shows that DE only violated crew requirement constraint while column generation and MOSI violated both crew requirement and flying days constraints. We can see in Table 9 that column generation and MOSI assigned 6 and 7 steward- esses exceeding the maximum flying days, 21 days. While, in the pilot assignment of Boeing 737-200, as shown in Table 10, DE is superior for minimum devia- tion of flying days. In the assignment of Boeing 737-200 stewardess, DE is superior by its minimum deviation of flying days compared to other methods. But, DE is inferior for flying time and open time criteria. 6. Conclusions We have investigated the use of DE in solving airline Tabel 9. Violation of flying days constraint for assignment of Boeing 737-200 stewardess. Method Constraints DE Column Gen. MOSI Flying days - √ √ Flying times - - - Take off - - - Overlap - - - Free day - - - Requirement of pilots √ √ √ Tabel 10. Roster quality of pilot assignment of Boeing 737-200. Methods Criteria DE Column Gen.* MOSI* DEC21** Flying times 1,114.0 1,114.0 1,114.0 1,114.0 Dev. of fly. days 13.1 33.6 34.5 38.5 Open time 176.0 176.0 176.0 178.0 Tabel 11. Roster quality of stewardess assignment of Boeing 737-200. Methods Criteria DE Column Generation MOSI* Flying times 3,488.0 3,285.0 3,285.0 Dev. of fly. days 92.0 110.0 106.2 Open time 693.0 658.0 658.0 crew scheduling problem. Generally, the rostering prob- lem in MNA has characteristic indifferent from other airline companies in terms of roster constraint and roster quality. Selecting mutation and crossover probability accurately became the successful key to implement DE. The best mutation and crossover probability are 0.1 and 0.5 respectively. Different from using DE in general, in this paper we introduced random swap as mutation op- erator. For small datasets, DE was proven more competi- tive then column generation and MOSI, based on con- straints fulfillment and roster quality. In the assignment of Boeing 737 pilot, DE produced smoother flying days and the least pilots which violated flying days constraint compared to other methods. For the stewardess assign- ment of Boeing 737-200, DE violated the least con- straints compared to column generation and MOSI. DE produced superior deviation of flying days criterion but it is still inferiror for iwo other criteria. 7. References [1] R. Anbil, J. J. Forrest and W. R. Pulleyblanck, “Column Generation and the Airline Crew Pairing Problem,” Documentation Mathematica Extra, Journal der Deutschen Mathematiker Vereinigung Volume ICM, III, 1998, pp. 677-686. [2] C. Barnhart, E. L. Johnson, G. L. Nemhauser, M. W. P. Savelsbergh and P. H. Vance, “Branch and Price: Column Generation for Solving Huge Integer Programs,” Opera- tion Research, Vol. 46, No. 3, 1998, pp. 316-329. [3] I. Gershkoff, G. W. Graves, R. D. Mc Bridge, D. Ander- son and D. Mahidhara, “Flight Crew Scheduling,” Man- agement Science, Vol. 39, No. 6, 1993, pp. 736-745. [4] K. L. Hoffman and M. Padberg, “Solving Airline Crew Scheduling Problems by Branch and Cut,” Management Science, Vol. 39, No. 6, 1993, pp. 657-682. [5] N. Souai, and J. Thegem, “Genetic Algorithm Based Ap- Proach for the Integrated Airline Crew-Pairing and Ros- tering Problem,” European Journal of Operational Re- search, Vol. 199, No. 3, 2009, pp. 674-683. [6] N. Kohl, “Application of OR and CP Techniques in a Real World Crew Scheduling System,” In Proceedings of CP-AI-OR’00: 2nd International Workshop on Integra- tion of AI and OR Techniques in Constraint Program-  B. SANTOSA ET AL. Copyright © 2010 SciRes. AM 325 ming for Combinatorial Optimization Problems, Pader- born, Germany, 8-10 March 2000, pp. 105-108. [7] N. Kohl and S. E. Karisch, “Integrating Operations Re- search and Constraint Programming Techniques in Crew Scheduling,” In Proceedings of the 40th Annual AGIFORS Symposium, Istanbul, Turkey, 20-25 August 2000. [8] S. C. K. Chu, “Generating, scheduling, and Rostering of Shift Crew-Duties: Applications at the Hongkong Inter- national Airport,” European Journal of Operational Re- search, Vol. 177, No. 3, 2007, pp. 1764-1778. [9] C. P. Medard and N. Sawhney, “Airline Crew Scheduling from Planning to Operation,” European Journal of Op- erational Research, Vol. 183, No. 3, 2005, pp. 1013-1027. [10] P. H. Vance, C. Barnhart, E. L. Johnson and G. L. Nem- hauser, “Airline Crew Scheduling: A New Formulation and Decomposition Algorithm,” Operation research, Vol. 45. No. 2, 1997, pp. 188-200. [11] P. Lučić, and D. Teodorović, “Simulated Annealing for the Multi-Objective Aircrew Rostering Problem,” Trans- portation Research Part A, Vol. 33, No. 1, 1999, pp. 19- 45. [12] D. Levine, “Application of a Hybrid Genetic Algorithm to Airline Crew Scheduling,” Computer Operations Re- search, Vol. 23, No. 6, 1996, pp. 547-558. [13] J. E. Beasly and B. Cao, “A Tree Search Algorithm for the Crew Scheduling Problem,” European Journal of Op- erational Research, Vol. 94, No. 3, 1996, pp. 517-526. [14] Z. Yinghui, R. Yunbao and Z. Mingtian, “GASA Hy- Brid Algorithm Applied in Airline Crew Rostering Sys- tem,” Tsinghua Science and Thechnology, Vol. 12, No. S1, 2007, pp. 225-259. [15] R. Storn and K. Price, “Differential Evolution: A Simple and Efficient Adaptive Scheme for Global Optimization over Continuous Spaces,” Technical Report TR-95-012, International Computer Science Institute, 1995. [16] V. P. Kennet, M. S. Rainer and A. L. Jouni, “Differential Evolution: A Practical Approach to Global Optimiza- tion,” Springer-Verlag, Berlin Heidelberg, 2005. [17] M. F. Tasgetiren, Q. K. Pan, Y. C. Liang and P. N. Su- ganthan, “A Discrete Differential Evolution Algorithm for the Total Earliness and Tardiness Penalties with a Common Due Date on Single Machine,” Proceedings of the 2007 IEEE Symposium on Computational Intelligence in Scheduling, 2007, pp. 271-278. [18] L. Jian, P. Chen and Z. M. Liu, “Solving Traveling Salesman Problems by Genetic Differential Evolution with Local Search,” Workshop on Power Electronics and Intelligent Transportation System, 2008 [19] M. G. H. Omran and A. Salman, “Constrained Optimiza- tion Using CODEQ,” Chaos, Solitons and Fractals, Vol. 42, No. 2, 2009, pp. 662-668. [20] R. L. Fox, “Optimization Methods for Engineering De- sign,” Addison-Wesley, Reading, Massachusetts, 1971. [21] J. H. Cassis and L. A. Schmit, “On Implementation of the Extended Interior Penalty Function,” International Jour- nal for Numerical Methods in Engineering, Vol. 10, No. 1, 1976, pp. 3-23. [22] Z. Labiba, “Aplikasi metode column generation dalam penyelesaian penugasan kru maskapai penerbangan: studi kasus di PT. Merpati Nusantara Airlines,” Tesis magister teknik, Jurusan Teknik Industri ITS, Surabaya, (in Bahasa Indonesia), 2006. [23] A. Rusdiansyah, Y. D. Mirenani and Z. Labiba, “Pemode- lan dan penyelesaian permasalahan penjadwalan pilot dengan metode eksak dekomposisi,” Jurnal Teknik In- dustri, Vol. 9, No. 2, Desember 2007, pp. 112-124. |