Paper Menu >>

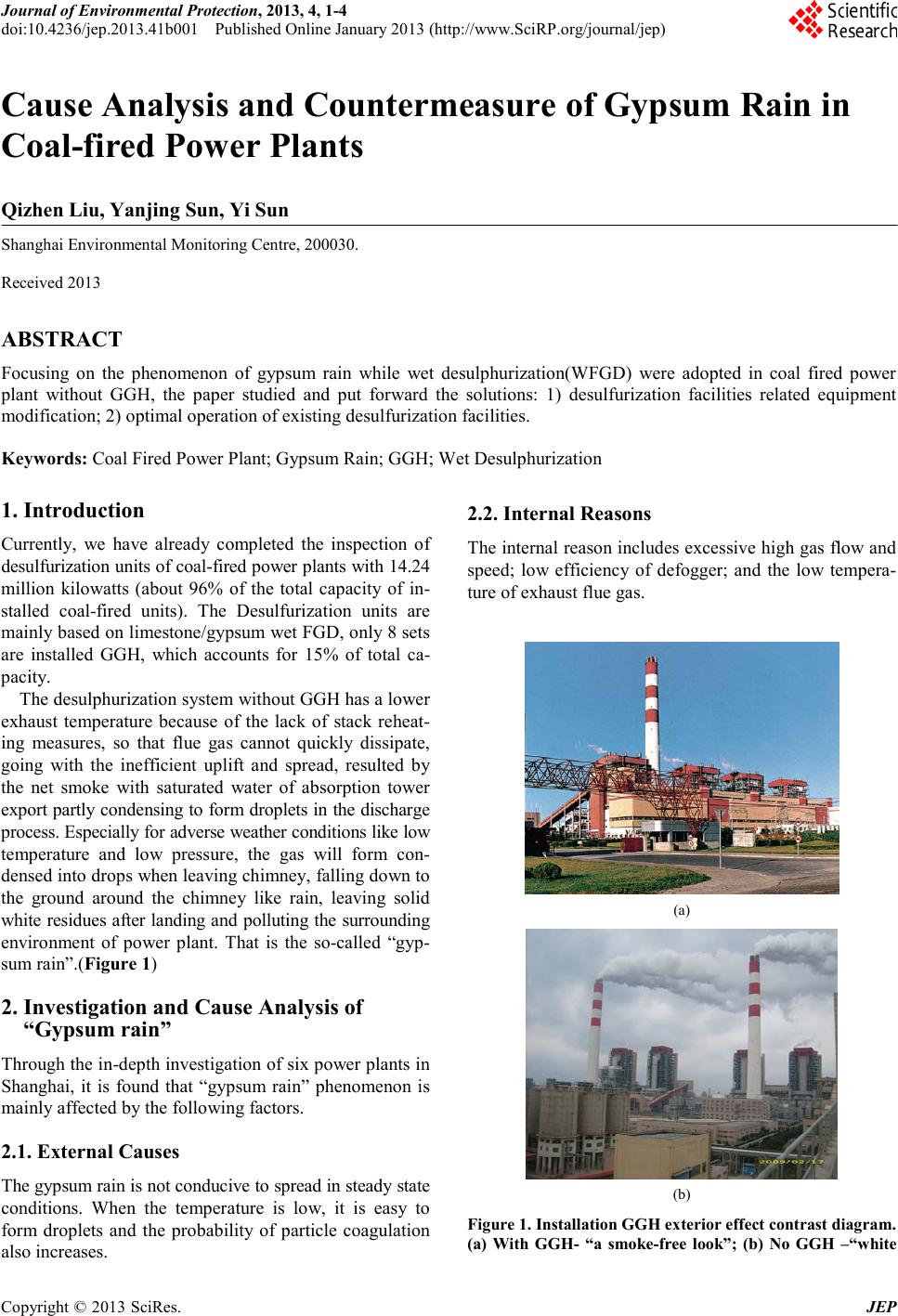

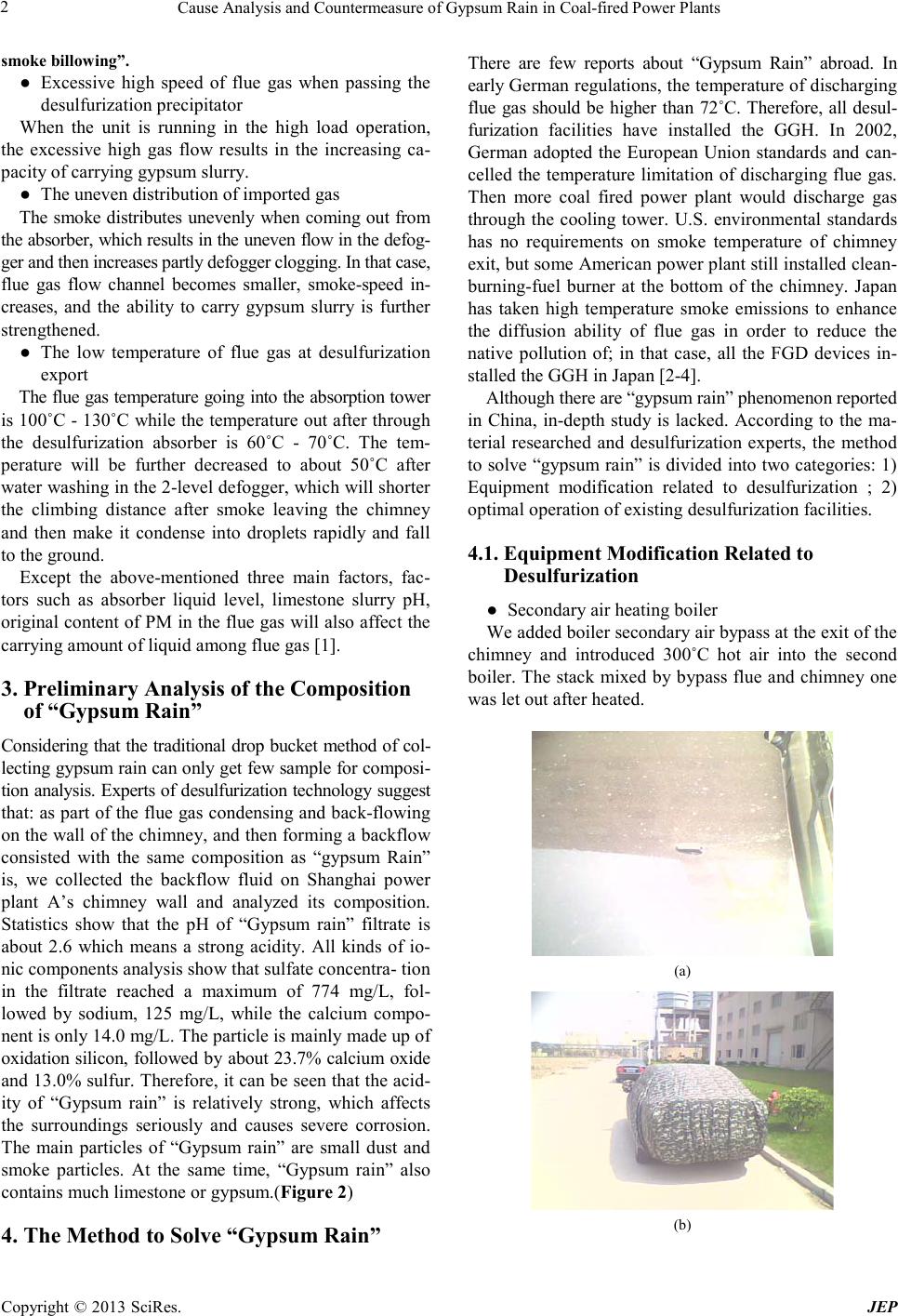

Journal Menu >>

Journal of Environmental Protec tion, 2013, 4, 1-4 doi:10.4236/jep.2013.41b001 Published Online January 2013 (http://www.SciRP.org/journal/jep) Copyright © 2013 SciRes. JEP 1 Cause Analysis and Countermeasure of Gypsum Rain in Coal-fired Power Plants Qizhen Liu, Yanjing Sun, Yi Sun Shanghai Environmental Monitoring Centre, 200030. Received 2013 ABSTRACT Focusing on the phenomenon of gypsum rain while wet desulphurization(WFGD) were adopted in coal fired power plant without GGH, the paper studied and put forward the solutions: 1) desulfurization facilities related equipment modification; 2) optimal opera tion of existin g de sulfurization facilities. Keywords: Coal Fired Power Plant; Gypsum Rain; GGH; Wet Desulphuriza tion 1. Introduction Currently, we have already completed the inspection of desulfurization units of coal-fired power plants with 14.24 million kilowatts (about 96% of the total capacity of in- stalled coal-fired units). The Desulfurization units are mainly based on limestone/gypsum wet FGD, onl y 8 set s are installed GGH, which accounts for 15% of total ca- pacity. The des ulp huri za tion s ys te m wit hout G GH ha s a lo wer exhaust temperature because of the lack of stack reheat- ing measures, so that flue gas cannot quickly dissipate, going with the inefficient uplift and spread, resulted by the net smoke with saturated water of absorption tower expo rt par tly co ndensing to form droplets in the discharge process. Especially for adverse weather conditions like low temperature and low pressure, the gas will form con- densed into drops when leaving chimney, falli ng d own to the ground around the chimney like rain, leaving solid white residues after landing and polluting the surrounding environment of power plant. That is the so-called “gyp- sum r ain”.(F igure 1) 2. Investigation and Cause Analysis of “Gypsum r ain” Thr ough the i n-depth investigation of six power plants in Shanghai, it is found that “gypsum rain” phenomenon is mainly affected by the following factors. 2.1. External Causes The g yp su m ra i n is no t conduc ive to sprea d in stead y state conditions. When the temperature is low, it is easy to form droplets and the probability of particle coagulation also increases. 2.2. Internal Reasons The internal reason includes excessive high ga s flo w and speed; low efficiency of defogger; and the low te mpera- ture of ex haust flue gas. (a) (b) Figure 1. I nstal lation GGH exterior effect c ontrast diagra m. (a) With GGH- “a smoke-free look”; (b) No GGH –“white  Cause Analysis and Countermeasure of Gypsum Rain in Coal-fired Power Plants Copyright © 2013 SciRes. JEP 2 smoke billowing”. ● Excessive high speed of flue gas when passing the desulfurizat ion precipita tor When the unit is running in the high load operation, the excessive high gas flow results in the increasing ca- pacity of carrying gypsum slurry. ● The uneve n distribution of imported gas The smoke distributes unevenly when coming out from the absorb er, which re sul ts i n the u neve n flo w in the defog- ger and then increases partly defogger clogging. In th at c as e, flue gas flow channel becomes smaller, smoke-speed in- creases, and the ability to carry gypsum slurry is further strengthened. ● The low temperature of flue gas at desulfurization export The flue ga s tempe ratur e goi ng int o the ab sorp tion to wer is 100˚C - 130˚C while the temperature out after through the desulfurization absorber is 60˚C - 70˚C. The tem- perature will be further decreased to about 50˚C after water was hin g in t he 2-le vel d efog ger , whic h will shorter the climbing distance after smoke leaving the chimney and then make it condense into droplets rapidly and fall to the ground. Except the above-mentioned three main factors, fac- tors such as absorber liquid level, limestone slurry pH, original content o f PM in the flue gas will also affect the car rying amount of liquid amo ng flue ga s [1]. 3. Preliminary Analysis of the Composition of “Gypsum Rain” Consid ering that the traditional drop bucket method of col- lecting gypsum rain can onl y get few sample for composi- tion analysis. Experts of desulfurization technology suggest that: as par t of the flue gas condensing and back-flowing on the wall of the chimney, and then fo rming a backflow consisted with the same co m p o sitio n as “gypsum Rain” is, we collected the backflow fluid on Shanghai power plant A’s chimney wall and analyzed its co mposition. Statistics show that the pH of “Gypsum rain” filtrate is about 2.6 which means a strong acid ity. All kinds of io- nic compone nts analysis show that sulfate concentra - tion in the filtrate reached a maximum of 774 mg/L, fol- lowed by sodium, 125 mg/L, while the calcium compo- nent is only 14.0 mg/L. The particle is mainly made up of oxidation silicon, followed by about 23.7% calcium oxide and 13.0% sulfur. Therefore, it can be seen that the acid- ity of “Gypsum rain” is relatively strong, which affects the surroundings seriously and causes severe corrosion. The main pa r ticle s of “Gypsum rain” are small dust and smoke particles. At the same time, “Gypsum rain” also contains much limestone or gypsum.(Figure 2) 4. The Method to Solve “Gypsum Rain” There are few reports about “Gypsum Rain” abroad. In early German regulations, the temperature of discharging flue gas should be higher than 72˚C. Therefore, all desul- furization facilities have installed the GGH. In 2002, German adopted the European Union standards and can- celled the temperature limitation of discharging flue gas. Then more coal fired power plant would discharge gas through the cooling tower. U.S. environmental standards has no requirements on smoke temperature of chimney exit, but some American power plant still installed clean- burning-fuel burner at the bottom of the chimney. Japan has taken high temperature smoke emissions to enhance the diffusion ability of flue gas in order to reduce the native po llution of; in that case, all the FGD devices in- stalled the GGH in J a pan [2-4]. Although there are “gypsum rain” phenomenon reported in China, in-depth study is lacked. According to the ma- terial researched and desulfurization experts, the method to solve “gypsum rain” is divided into two categories: 1) Equipment modification related to desulfurizatio n ; 2) optimal ope ration of existing desulfurization facilities. 4.1. Equipment Modification Related to Desulfurization ● Secondary air heating boiler We added boiler secondary air bypass at the e xit of the chimney and introduced 300˚C hot air into the second boiler. The stack mixed by bypass flue and chimney one was let out after heate d. (a) (b)  Cause Analysis and Countermeasure of Gypsum Rain in Coal-fired Power Plants Copyright © 2013 SciRes. JEP 3 Figture 2. the impact of “Gy psum R ai n ” on v ehicles ar ound power plants. (a) “Wh ite” glass ; (b) Vehicles with proteciton. ● Defogger transformation 1) Addition layer of demisting facilities At present, most desulfurization facilities use one-layer or two-layer demisting facilities. It is suggested that one layer of de misting facilities s hould be a dded in the space location allowed. 2) Addition uniform guide plate on the demister inlet horizontal flue section According to the high speed of flue gas nea r t he chimney wall, a guide plate should be set up in the corner outside the flue to reduce its velocity and eli minate flue gas dis- turb ance of sprayer entrance. It makes smoke even into demisting pr e c ipitator and reduces local con gestion. 3) Mist eliminator washing sy stem transformation At p resent, co ld -water-rinse method is adop ted in mist eliminator wishing. The method could greatly reduce the temperature of flue gas and increase “gypsum rai n” phe- nomenon. It is suggested t hat vapor source should be a dded into the original mist eliminator washing system and a water desuperheating device be set up on pipeline, ad- justin g t he s tea m te mpera tur e, in order to prevent defogger base metal from excessive steam temperature. The unit adopts the method of water washing in conjunction with st e am fl u sh in normal operation. With the steam auxiliary steam source and contro lling pressure through a valve, a variable pressure flushing can be achieved. ● Addition flue gas heater In American, considering that a unit without GGH would make the temperature too low and produce a negative im- pact on t he surro unding e nviro nment, so me power plants install clean burning fuel burner at the bottom of the chimney to temporarily heat the gas after desulfurizatio n in adverse weather conditions. This method can protect the environment with low investment and running costs. As a kind of practic al solutions, it is worth usi ng for r ef- erence. ● Installing the GG H Installing the GGH will be able to better solve the “gyp- sum rain” phenomenon; it is also conducive to long-dis- tance gas transportation. T hough it can so lve local po llu- tion problems, the investment costs are very high on one hand and , o n t he o the r hand , p a rt s o f the power plants are limited by space. Besides, GGH blockage reduces the rate of desulfurizatio n facilities into operation dra wbacks. Therefore, we recommended that it could be considered that coal-fired units could compromise GGH while in- stalling desulfurization devices [2-4]. ● Transformati on of the inner chimney wall As t he lower temperature of the inner chimney wall, it is easy for slurry to condense int o dr ops han ging o n t he wal l and be carried out of the c himne y by flue gas in the form of droplets. It is recommended that a circular blocking device should be set in the chimne y to reduce the slurry carried on the chimney wall. 4.2. Optimal Operation of Existing Desulfuriz at ion Fa ci lities ● Paying attention to the pressure gap of defoggers and reducing defogger jam Highe r s l urry de n si t y, pH a nd liquid-gas ratio will ca use defogger jam, increase the pressure of defogger and reduce the efficienc y. Ther efor e, p aying a tte ntio n to the pre ssure gap of defogge rs an d controll ing the slurry density, pH and liquid-gas ratio within reasonable ranges will decrease defogger jam and the probability to form “gypsum Rain”. ● Optimizing defogger washing and reducing the amount of slurry carried Taking the washi ng o rd er as “upper parts of secondary defogger, lower parts of secondary defogger, primary de- fogger upper, primary defogger lower, seco ndar y defogger upper and secondary lower parts again”. It means firstly washing the upper part of the secondary defogger, then washing the lower part to make the secondary defogger’s channel unobstructed and ease the congestion with a sudden increase in concentration of gypsum droplets into the secondary defogger. After the pressure of the second- dary defogger reduced, washing the upper and lower part of the primary defogger and then washing the secondary defogger again to remove the gypsum droplets from the primary defogger, avoiding being carried away. At the same time, pay attention to the rule of power flow. Be- fore unit load increases, washing defogger ahead will greatly reduce carrying capacity of gypsum slurry during high load [6]. ● Appropriately reducing the air flow and the flow rate of flue gas “Gypsum rain” phenomenon is often seen during high load operations of boilers, which is rela ted to the flue gas flow. When with a large load, under the premise of en- sure the oxygen of daily boiler combustion, reducing the air flow appropriately and controlling hearth negative pressure and boostering fan pressure to reduce the gas flow and veloc ity. 5. Conclusions and Recommendations For that mo st local coal -fired power plants adopt limestone / gypsum wet FGD without installing the GGH, “gypsum rain” is easily induced b y the low-temperature stac k under the adverse condition of weather, polluting the environ- men t and the surroundings of power plants. In combination with the actual circumstances of coal-fired power plant, we put forward the following recommendatio ns. ● All the local co al-fired power plants facilities which adopted wet desulphurization without GGH should strengthen the optimized operation and management  Cause Analysis and Countermeasure of Gypsum Rain in Coal-fired Power Plants Copyright © 2013 SciRes. JEP 4 so as to reduce the influence of the gypsum rain. ● For the exit coal-fired u nits without GGH i n nearb y areas, a check should be done to the Desulphuriza- tion facilities defogger. In the mean time, carrying out a technological transformation on the desulfur i- zation fa ciliti es whose effect of defogger is not idea l. Taking measures like adding a gas heater or hot air into the boiler equipment for reconstruction project in or der to lift the tempera ture of flue gas and cut from the source “gypsum Rain” production. ● While modifying the desulphurization facilities of the coal-fired units, an effective control should be taken t o “gyp sum Rain” as o ne of the ke ys of pollu- tion controllin g. It is required that a GGH and other gas heating facilities should be installed simu ltane- ously. All the abo ve-mentioned measures are aimed to avoid "gypsum rain" phenomenon. REFERENCES [1] CHENG Yong-xin. Analysis and Countermeasure to “gyp- sum rain” problem of wet flue gas desulfurization system [J]. central China electric power, vol.23 , page:27-30, 2010. [2] Ye chao, Zhang ran. Set Analysis of advantages and dis- advantages of the flue gas heat exchanger [J]. Shanghai electric power, vol .5, pa g e : 466- 468, 2006. [3] Zh ao P en ggao, Ma Guojun, Wan g Baode, etc. Discussion on flue gas heater of limestone-gypsum wet FGD [J]. Elec- tric power environmental protection, vol.21, no.4, page: 19-21, 2005. [4] Wang Yifang, Liu Wanju, Zhang bing. Technical analysis on GGH setting in desulfurization system [J]. Technology communion, vol.34, no. 3, pa g e : 47-4 8, 20 06. [5] Eliminate design and optimization of gypsum rain [J]. Low carbon, page: 70-80, 2010. [6] FU Yu , He Jinqi, Discussion about solution of gypsum rain when wet desulphurization used for power plant[J], Heilongjiang Electric Power, vol.31, no.5, page:374-376, 2009. |