Paper Menu >>

Journal Menu >>

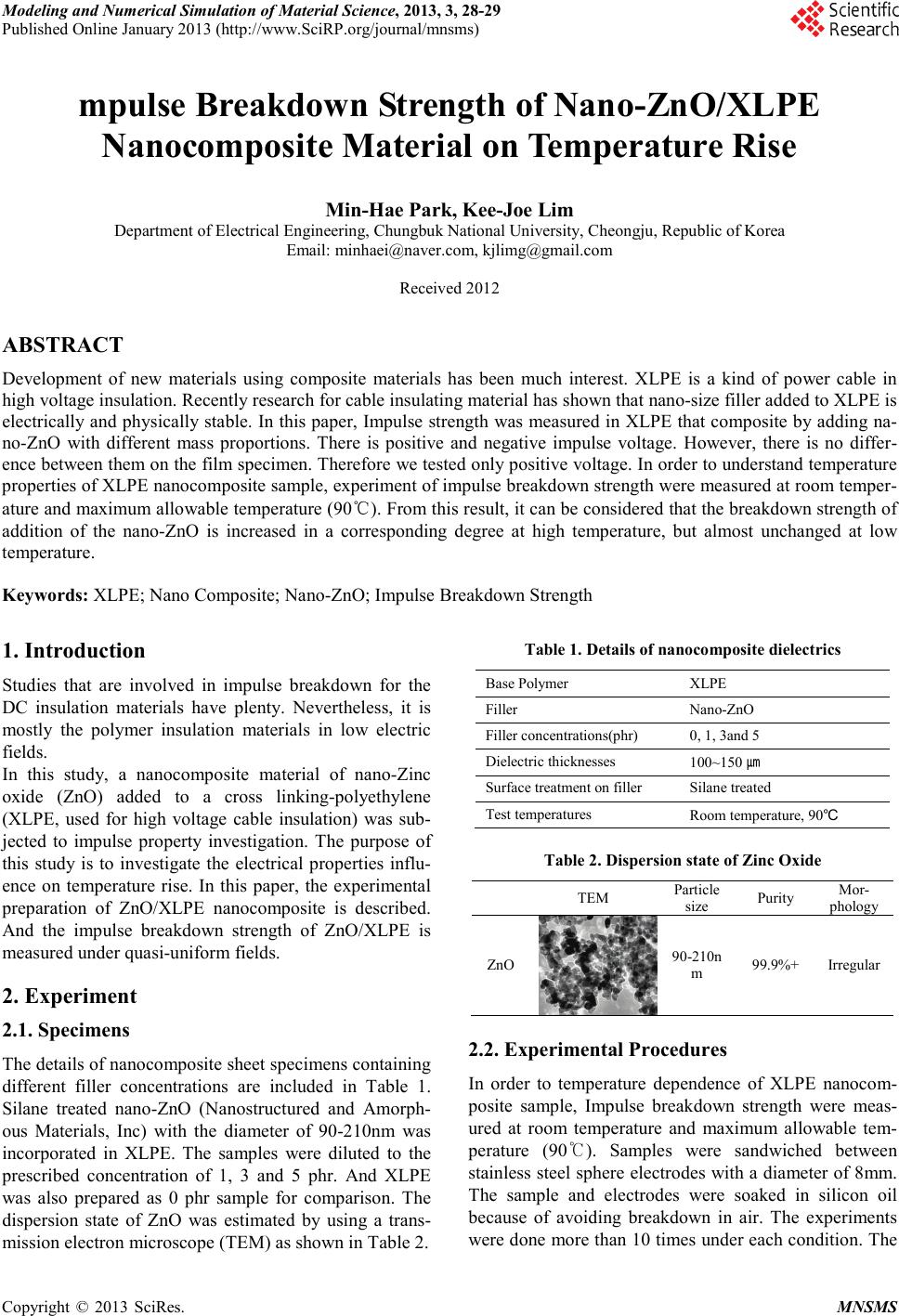

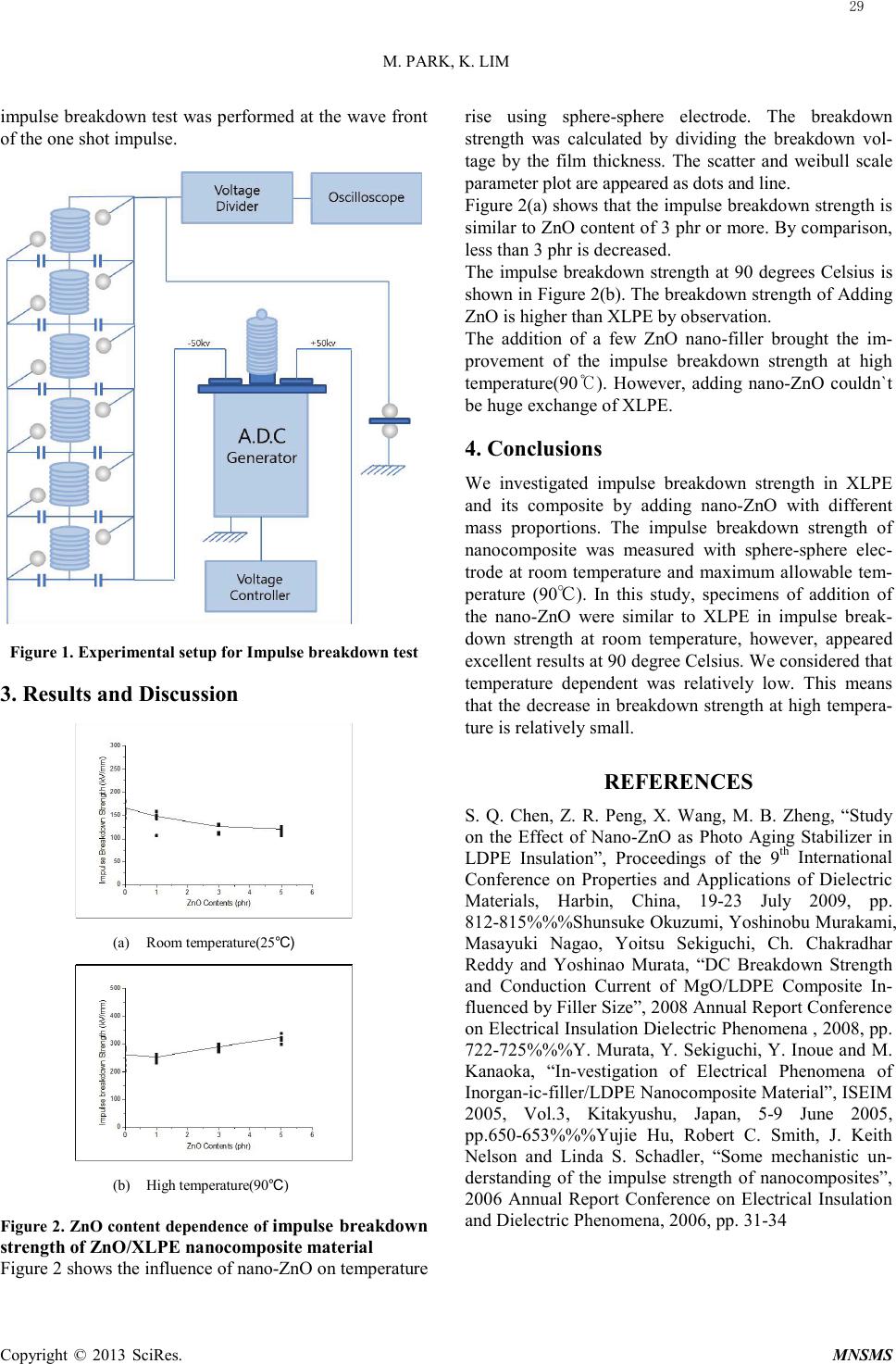

Modeling and Numerical Simulation of Material Science, 2013, 3, 28-29 Published Online January 2013 (http://www.SciRP.org/journal/mnsms) Copyright © 2013 SciRes. MNSMS mpulse Breakdown Strength of Nano-ZnO/XLPE Nanocomposite Material on Temperature Rise Min-Hae Park, Kee-Joe Lim Department of Electrical Engineering, Chungbuk National University, Cheongju, Republic of Korea Email: minhaei@naver.com, kjlimg@gmail.com Received 2012 ABSTRACT Development of new materials using composite materials has been much interest. XLPE is a kind of power cable in high voltage insulation. Recently research for cable insulating material has shown that nano-size filler added to XLPE is electrically and physically stable. In this paper, Impulse strength was measured in XLPE that composite by adding na- no-ZnO with different mass proportions. There is positive and negative impulse voltage. However, there is no differ- ence between them on the film specimen. Therefore we tested only positive volta ge. In order to understand temperature properties of XLPE nanocomposite sample, experiment of impulse breakdown strength were measured at room temper- ature and maximum allowable temperature (90℃). From this result, it can be considered that the breakdown strength of addition of the nano-ZnO is increased in a corresponding degree at high temperature, but almost unchanged at low temperature. Keywords: XLPE ; Nano Composite; Na no-ZnO ; Impulse Breakdown Strength 1. Introduction Studies that are involved in impulse breakdown for the DC insulation materials have plenty. Nevertheless, it is mostly the polymer insulation materials in low electric fields. In this study, a nanocomposite material of nano-Zinc oxide (ZnO) added to a cross linking-polyethylene (XLPE, used for high voltage cable insulation) was sub- jected to impulse property investigation. The purpose of this study is to investigate the electrical properties influ- ence on temperature rise. In this paper, the experimental preparation of ZnO/XLPE nanocomposite is described. And the impulse breakdown strength of ZnO/XLPE is measured under quasi-uniform fields. 2. Experi ment 2.1. Specimens The details of nanocomposite sheet specimens containing different filler concentrations are included in Table 1. Silane treated nano-ZnO (Nano struc tur ed and Amorp h- ous Materials, Inc ) with the diameter of 90-210nm was incorporated in XLPE. The samples were diluted to the prescribed concentration of 1, 3 and 5 phr. And XLPE was also prepared as 0 phr sample for comparison. The dispersion state of ZnO was estimated by using a trans- mission electron mi croscope (TEM) as shown in Table 2. Table 1. Details of nanocomposite dielectrics Base Polymer XLPE Filler Nano-ZnO Filler concentrations(phr) 0, 1, 3and 5 Dielectric thicknesses 100~150 ㎛ Surface treatment on filler Silane treated Test temperatures Room temperature, 90℃ Table 2. Dispersion state of Zinc Oxide TEM Particle size Purity Mor- phology ZnO 90-210n m 99.9% + Irregular 2.2. Experimental Procedures In order to temperature dependence of XLPE nanocom- posite sample, Impulse breakdown strength were meas- ured at room temperature and maximum allowable tem- perature (90℃). Samples were sandwiched between stainless steel sphere electrodes with a diameter of 8mm. The sample and electrodes were soaked in silicon oil because of avoiding breakdown in air. The experiments were done more than 10 times under each condition. The  M. P ARK, K. LI M Copyright © 2013 SciRes. MNSMS impulse breakdown test was performed at the wave front of the one shot impulse. Figure 1. Experimental setup for Impulse breakdown test 3. Results and Discussion Figure 2. ZnO content dependence of impulse breakdown strength of ZnO/XLPE nanocomposite material Figure 2 shows the influence of nano-ZnO on temperature rise using sphere-sphere electrode. The breakdown strength was calculated by dividing the breakdown vol- tage by the film thickness. The scatter and weibull scale parameter plot are appeared as dots and line. Figure 2( a) shows that the impulse breakdown strength is similar to ZnO content of 3 phr or more. By comparison, less than 3 phr is decreased. The impulse breakdown strength at 90 degrees Celsius is shown in Figure 2(b). The breakdown strength of Adding ZnO is higher than XLPE by observation. The addition of a few ZnO nano-filler brought the im- provement of the impulse breakdown strength at high temperature(90℃). However, adding nano-ZnO couldn`t be huge exchange of XLPE. 4. Conclusions We investigated impulse breakdown strength in XLPE and its composite by adding nano-ZnO with different mass proportions. The impulse breakdown strength of nanocomposite was measured with sphere-sphere elec- trode at room temperature and maximum allowable tem- peratur e (90℃). In this study, specimens of addition of the nano-ZnO were similar to XLPE in impulse break- down strength at room temperature, however, appeared excellent results at 90 degree Celsius. We considered that temperature dependent was relatively low. This means that the decrease in breakdown strength at high tempera- ture is relatively small. REFERENCES S. Q. Chen, Z. R. Peng, X. Wang, M. B. Zheng, “Study on the Effect of Nano-ZnO as Photo Aging Stabilizer in LDPE Insulation”, Proceedings of the 9th International Conference on Properties and Applications of Dielectric Materials, Harbin, China, 19-23 July 2009, pp. 812-815%%%Shunsuke Okuzumi, Yoshinobu Murakami, Masayuki Nagao, Yoitsu Sekiguchi, Ch. Chakradhar Reddy and Yoshinao Murata, “DC Breakdown Strength and Conduction Current of MgO/LDPE Composite In- fluenced by Filler Size”, 2008 Annual Report Conference on Electrical Insulation Dielectric Phenomena , 2008, pp. 722-725%%%Y. Murata, Y. Sekiguchi, Y. Inoue and M. Kanaoka, “In-vestigation of Electrical Phenomena of Inorga n-ic-filler/LDPE Nanocomposite Material”, ISEIM 2005, Vol.3, Kitakyushu, Japan, 5-9 June 2005, pp.650-653%%%Yujie Hu, Robert C. Smith, J. Keith Nelson and Linda S. Schadler, “Some mechanistic un- derstanding of the impulse strength of nanocomposites”, 2006 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, 2006, pp. 31-34 (a) Room temperatur e (2 5℃) (b) High temperature(90℃) 29 |