Z. XIONG, W. WU

Copyright © 2013 SciRes. MNSMS

every separate layer is accurately controlled by RHEED

intensity oscillation which is extremely sensitive to the

presence of surface atoms in the top crystalline layer [3].

The individual BTO layer and STO layer have the uni-

form thickness of 14nm and 21nm, respectively. Ac-

cording to the results of RHEED monitored, the growth

rate of STO and BTO are estimated to be 0.037 ML/s and

0.043 ML/s, where 1 monolayer (ML) corresponds to a

layer thickness of 0.781 nm (STO) and 0.806 nm (BTO),

the double value of the c-axis lattice constant of bulk

STO (0.3905 nm) and BTO (0.4029 nm) [5], respectively.

So it is concluded that one period of RHEED intensity

oscillation corresponds to the growth of two STO unit

cells and two BTO unit cells, respectively. We achieve

atomic-level control for the growth of the nanocomposite

fil m.

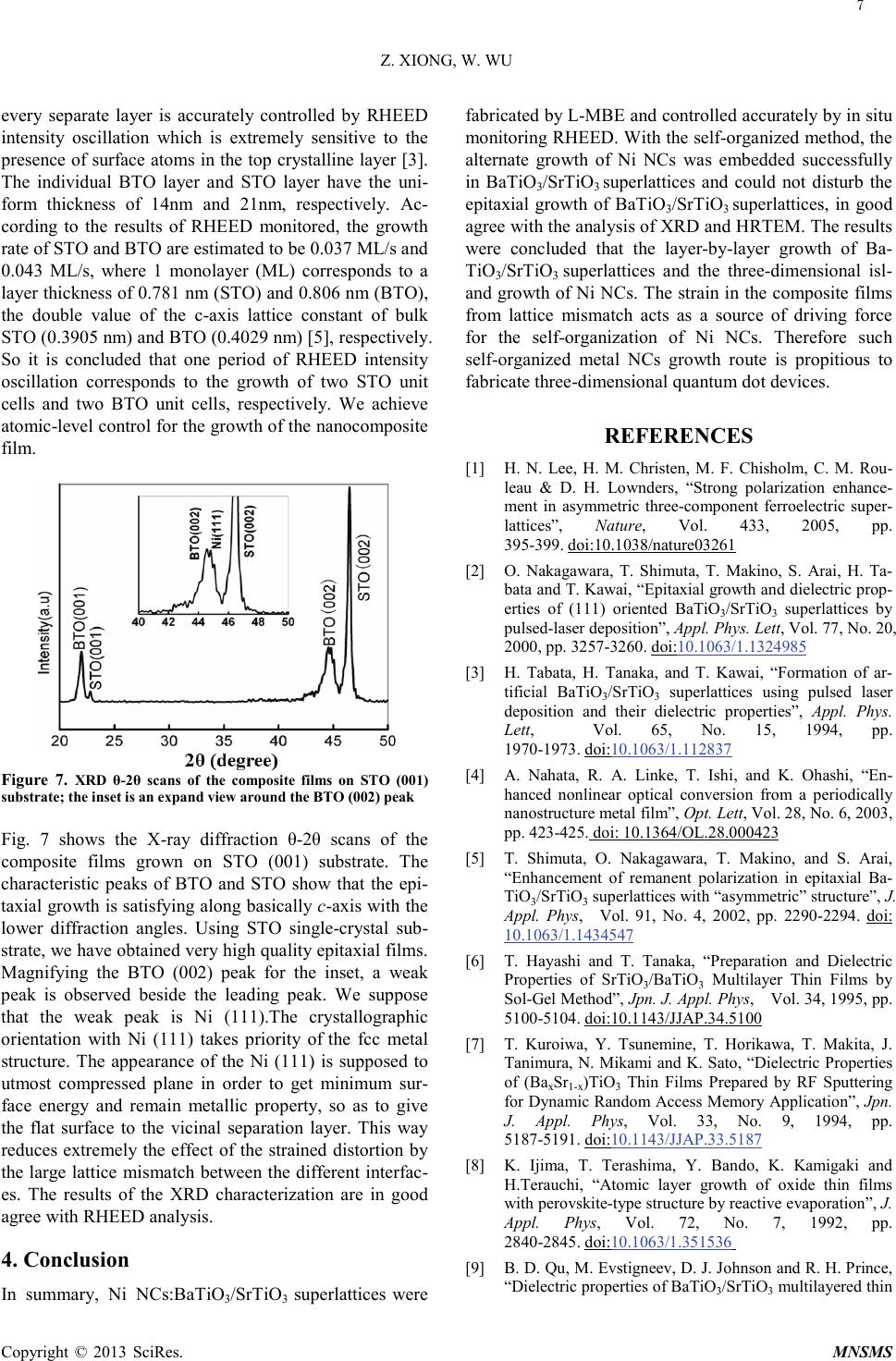

Figure 7. XRD θ-2θ scans of the composite films on STO (001)

substrate; the inset is an expand view around the BTO (002) peak

Fig. 7 shows the X-ray diffraction θ-2θ scans of the

composite films grown on STO (001) substrate. The

characteristic peaks of BTO and STO show that the epi-

taxial growth is satisfying along basically c-axis with the

lower diffraction angles. Using STO single-crystal sub-

strate, we have obtained very high quality epitaxial films.

Magnifying the BTO (002) peak for the inset, a weak

peak is observed beside the leading peak. We suppose

that the weak peak is Ni (111).The crystallographic

orientation with Ni (111) takes priority of the fcc metal

structure. The appearance of the Ni (111) is supposed to

utmost compressed plane in order to get minimum sur-

face energy and remain metallic property, so as to give

the flat surface to the vicinal separation layer. This way

reduces extremely the effect of the strained distortion by

the large lattice mismatch between the different interfac-

es. The results of the XRD characterization are in good

agree with RHEED analysis.

4. Conclusion

In summary, Ni NCs:BaTiO3/SrTiO3 superlattices were

fabricated by L-MBE and controlled accurately by in situ

monitoring RHEED. With the self-or ga nized method, the

alternate growth of Ni NCs was embedded successfully

in BaTiO3/SrTiO3 superlattices and could not disturb the

epitaxial growth of BaTiO3/SrTiO3 superlattices, in good

agree with the anal ysi s of XRD and HRTEM. The results

wer e concluded that the layer-by-layer growth of Ba-

TiO3/SrTiO3 superlattices and the t hree -dimensional isl-

and growth of Ni NCs. The strain in the composite films

from lattice mismatch acts as a source of driving force

for the self-organization of Ni NCs. Therefore such

self-or ga nized metal NCs growth route is propitious to

fabricate three -di mensio nal quantum dot devices.

REFERENCES

[1] H. N. Lee, H. M. Christen, M. F. Chisholm, C. M. Rou-

leau & D. H. Lownders, “Strong polarization enhance-

ment in asymmetric three-component ferroelectric super-

lattices”, Nature, Vol. 433, 2005, pp.

395-399.

[2] O. Nakagawara, T. Shimuta, T. Makino, S. Arai, H. Ta-

bata and T. Kawai, “Epitaxial growth and dielectric prop-

erties of (111) oriented BaTiO3/SrTiO3 superlattices by

pulsed-laser deposition”, Appl. Phys. Lett, Vol. 77, No. 20,

2000, pp. 3257-3260. doi:

doi:10.1038/nature03261

10.1063/1.1324985

[3] H. Tabata, H. Tanaka, and T. Kawai, “Formation of ar-

tificial BaTiO3/SrTiO3 superlattices using pulsed laser

deposition and their dielectric properties”, Appl. Phys.

Lett, Vol. 65, No. 15, 1994, pp.

1970-1973.

[4] A. Nahata, R. A. Linke, T. Ishi, and K. Ohashi, “En-

hanced nonlinear optical conversion from a periodically

nanostructure metal film”, Opt. Lett, Vol. 28, No. 6, 2003,

pp. 423-425.

doi:10.1063/1.112837

[5] T. Shimuta, O. Nakagawara, T. Makino, and S. Arai,

“Enhancement of remanent polarization in epitaxial Ba-

TiO3/SrTiO3 superlattices with “asymmetric” structure”, J.

Appl. Phys, Vol. 91, No. 4, 2002, pp. 2290-2294.

doi: 10.1364/OL.28.000423

[6] T. Hayashi and T. Tanaka, “Preparation and Dielectric

Properties of SrTiO3/BaTiO3 Multilayer Thin Films by

Sol-Gel Method”, Jpn. J. Appl. Phys, Vol. 34, 1995, pp.

5100-5104.

doi:

10.1063/1.1434547

[7] T. Kuroiwa, Y. Tsunemine, T. Horikawa, T. Makita, J.

Tanimura, N. Mikami and K. Sato, “Dielectric Properties

of (BaxSr1-x)TiO3 Thin Films Prepared by RF Sputtering

for Dynamic Random Access Memory Application”, Jpn.

J. Appl. Phys, Vol. 33, No. 9, 1994, pp.

5187-5191.

doi:10.1143/JJAP.34.5100

[8] K. Ijima, T. Terashima, Y. Bando, K. Kamigaki and

H.Terauch i, “Atomic layer growth of oxide thin films

with perovskite-type structure by reactive evaporation”, J.

Appl. Phys, Vol. 72, No. 7, 1992, pp.

2840-2845.

doi:10.1143/JJAP.33.5187

[9] B. D. Qu, M. Evstigneev, D. J. Johnson and R. H. Prince,

“Dielectric properties of BaTi O 3/SrTiO3 multilayered thin

doi:10.1063/1.351536