Paper Menu >>

Journal Menu >>

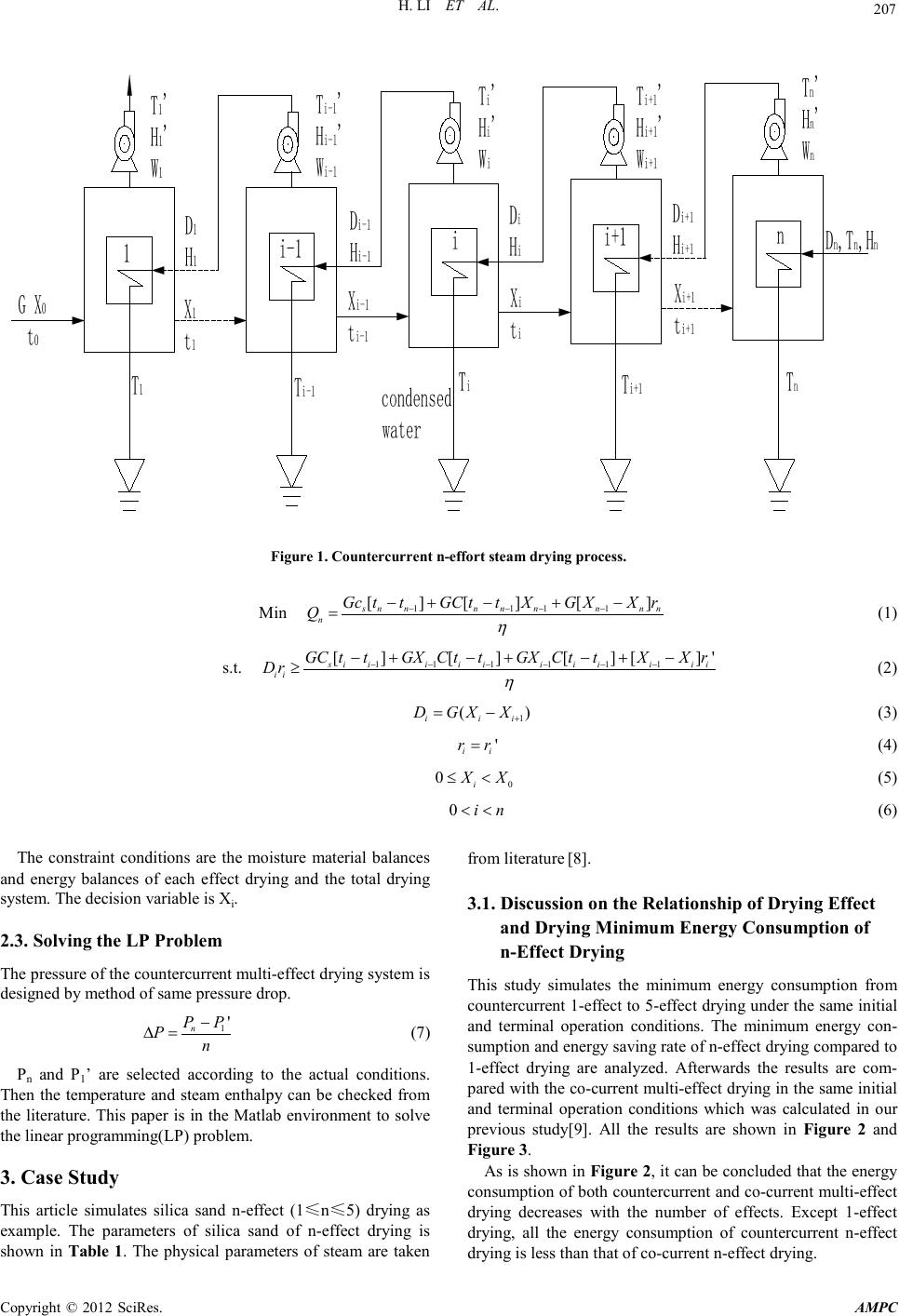

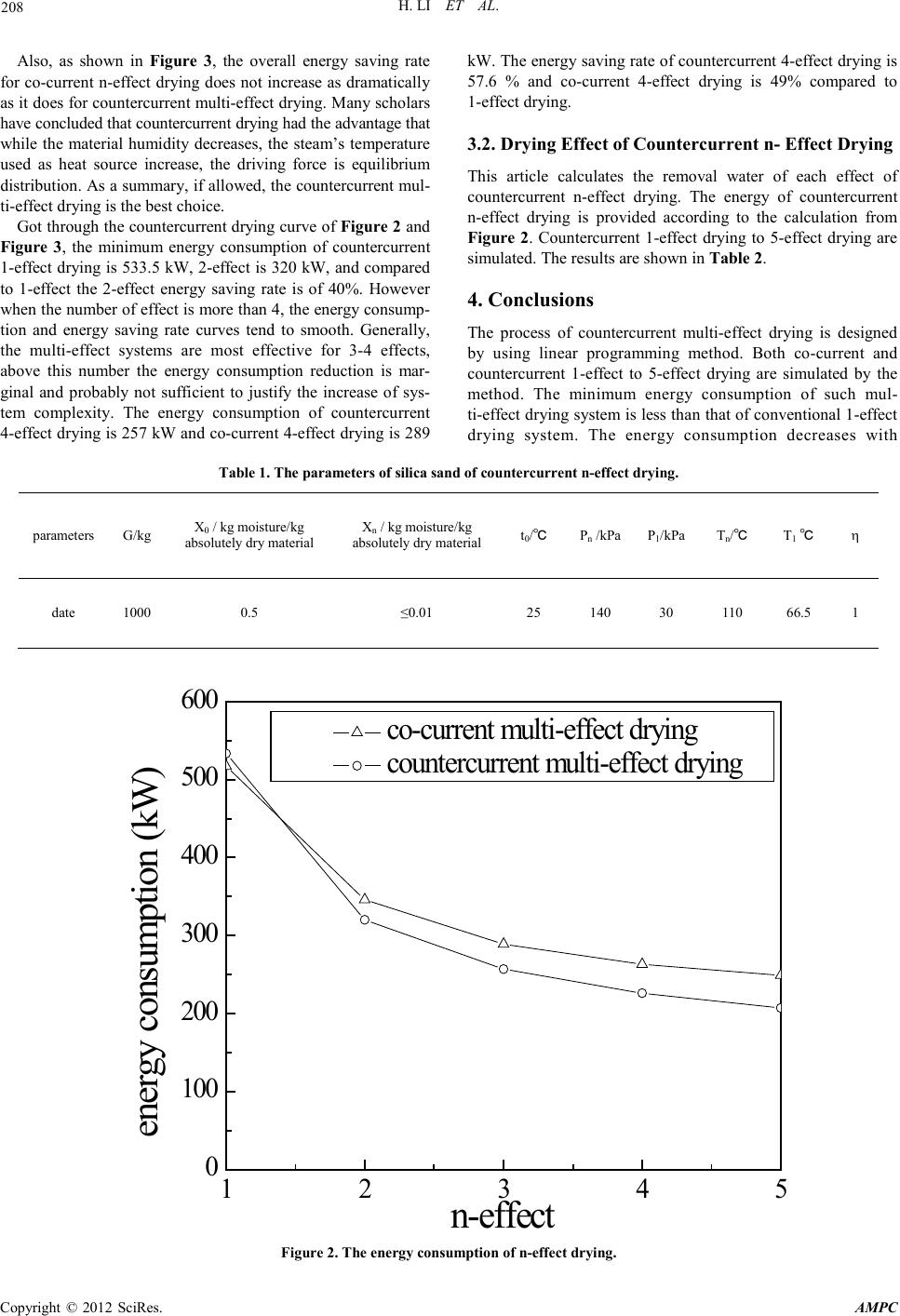

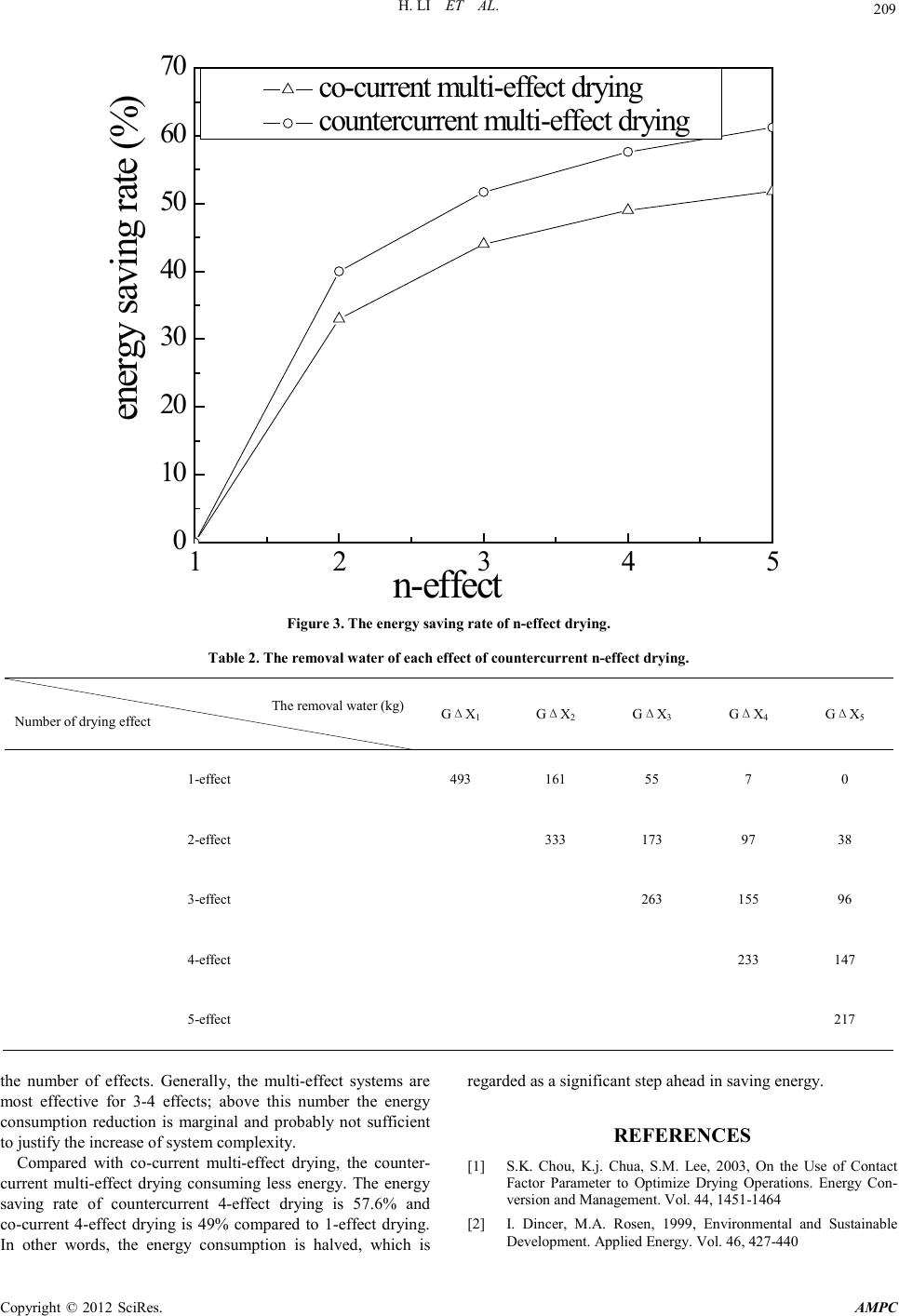

Advances in Ma terials Physics and Che mist ry, 2012, 2, 206-211 doi:10.4236/ampc.2012.24B053 Published Online December 2012 (htt p://www.SciRP.org/journal/ampc) Copyright © 2012 SciRes. AMPC Simulation of Count ercurrent Multi-Effect Dry i ng Sy st e m Hong Li , Lianying Wu, Xianli Wu, Yangdong Hu Department of Chemical Engineering, Ocean University of China, Qingdao 266000, China Email: ydhuhd@ouc.edu.cn Received 2012 ABSTRACT The paper bulids a countercurrent multi-effect drying process model which can be expressed as a linear programming(LP) problem with the minimum total energy consumption as target function. Based on the model it can be conventient to solve the heat load , de- gree of drying and other drying parameters of each effect. And it realizes the mathematical simulation an analysis of multi-effect drying process. Such process not only reuses the secondary steam but also utilizes the high energy grade. Drying silica sand using 1-effect dr ying t o 5 -effect drying is presented as an example. The energy consumption and energy saving rate are compared by using co-current multi-effect drying an d coun tercurrent multi-effect dr ying. As a su mmary, the cou ntercurr ent multi-effect drying is better than co-current drying. Considered the equipment investment and energy conservation, the study also concluded that the countercur- rent 4-effect drying is the optimum selection, and it can save 57.6% energy compared to countercurrent 1-effect drying. Keywords: Countercurrent Drying; Multi-Effect Drying; Second ar y Steam; LP 1. Introduction Among many process operations in industry, drying is probably one of the most important, as it is common to all sectors of solids processing. Many investigations have shown that drying is an energy intensive operation, which involves complex processes of h eat an d mass transfer between the product and the drying medium[1-4]. Nowadays, with the situation of energy shortage becoming more and more serious, how to improve the energy utilization efficiency has become a research hot spot. Although a large number of works have been devoted to ex- ploring different features and applications of the thermal drying system, most of those changed the high grade energy to lower grade energ y when u tilized th e waste gas, so a large nu mber of high quality stream latent heat is wasted. A promising alternative to improve the problem is the use of multi-effect dying system based on the process integration as formulated by Linnhoff[5] and is directed on the effici ent us e of energy for drying [6-7]. Such a system consists of a number of dryers. By directly utilizing the secondary steam resulting from energy degradation in the drying system, the drying process imports the secondary steam produced by the former effect as the heat source o f the fol lowing effect thereby redu cing energ y consumption. 2. Description the Process of the Countercurrent Multi-Effect Drying The countercurrent multi-effect drying process is designed by follow postulated: (1) Multi-effect drying is a typical batch process. (2) The dryer is vacuum tray drier. The material is h eated by conduction heating(3) The secondary steam is water vapor. In actual operation, it can be recycled by draught fan. Thedraught fan has the function of also dust r e mo v al. (4) Apply secondary steam to heat the wet material indirect- ly. (5) The drying materials are not flowing, but by controlling the flowing of secondary steam, the drying materials can be regarded as flowing. It can be operated by simulated moving bed in actual operation. (6) Dried material is distributed very thinly in the dryers, which increases the heating surface area, giving the drying system bett er heat transfer effect and efficiency. (7) Best fit for the drying process that water evaporation proces s occurs in small particle materials surface. 2.1. Technological Process The countercurrent multi-effect stea m dr ying flowch art is sho wn in Figure 1. Set t he n u mber of to tal effect a s n. Hot fresh vapor enters the last drying room to heat the solid materials in it, while secondary steam discharged from the last drying room n enters the front drying room n-1 to heat t he solid materials th er e. Taking the i-1, i, i+1 effect drying for example, the secondary steam produced by the i+1 effect drying enters the i effect dry- ing room, while the secondary steam produced by the i effect drying enters the i-1 effect drying room, as so on until the 1 effect drying, the secondary steam produced by the 1 effect drying ent ers the con denser. Th e drying material s are not flow- ing, after the drying material of the i effect drying dried by the secondary steam of the i+1 effect drying room produced, this drying room and drying material is regarded as i+1 effect dry- ing in the next batch process production cycle. 2.2. Mathematic Model The obj ective is recycling the s econ d stream energy as a means to minimize the energy consumption of n-effect drying needing.  H. LI ET AL. Copyright © 2012 SciRes. AMPC 207 G X 0 t 0 T 1 ' H 1 ' W 1 T i ' H i ' W i T i+1 ' H i+1 ' W i+1 T n ' H n ' W n T i-1 ' H i-1 ' W i-1 D n ,T n ,H n D 1 H 1 X 1 t 1 D i-1 H i-1 X i-1 t i-1 D i H i X i t i D i+1 H i+1 X i+1 t i+1 T 1 T i-1 T i T i+1 T n 1i-1 ii+1 n condensed water Figure 1. Countercurrent n-effort steam drying process. Min 111 1 [][] [] snnnn nnnn n Gct tGCt t XGXXr Q η −−− − −+ −+− = (1) s.t. 111111 [] [] [][]' siii iii iiiii ii GCt tGXCt tGXCt tXXr Dr η −−−−−− −+ −+ −+− ≥ (2) 1 () i ii D GXX + = − (3) ' ii rr= (4) 0 0 i XX≤< (5) 0in<< (6) The constraint conditions are the moisture material balances and energy balances of each effect drying and the total drying s ys tem. The decision variabl e is Xi. 2.3. Solving the LP Problem The pressure of the countercurrent multi-effect d rying s yste m is designed by method of same pressure drop. 1' n PP Pn − ∆= (7) Pn and P1’ are selected according to the actual conditions. Then the temperature and steam enthalpy can be checked from the literature. This paper is in the Matlab environment to solve the linear programming(LP) problem. 3. Case Study This article simulates silica sand n-effect (1≤n≤5) dryi ng as example. The parameters of silica sand of n-effect drying is shown in Table 1. The physical parameters of steam are taken from literature [8]. 3.1. Discussion on the Relationship of D r ying Eff e ct and Drying Minimum Energy Consumption of n-Effect Drying This study simulates the minimum energy consumption from countercurrent 1-effe ct to 5 -effect drying under the same initial and terminal operation conditions. The minimum energy con- sumption and energy saving rate of n-effect drying compared to 1-effect drying are analyzed. Afterwards the results are com- pared with the co-current multi-effect drying in the same initial and terminal operation conditions which was calculated in our previous study[9]. All the results are shown in Figure 2 and Figure 3. As is shown in Figure 2, it can be concluded that the energy consumption of both countercurrent and co-current multi-effect drying decreases with the number of effects. Except 1-effect drying, all the energy consumption of countercurrent n-effect drying is less than that of co-current n-effect d rying.  H. LI ET AL. Copyright © 2012 SciRes. AMPC 208 Also, as shown in Figure 3, the overall energy saving rate for co-curren t n-effect drying d oes not increase as dramatical ly as it does for countercurrent multi-effect dr ying. Many sch olars have concluded that countercurrent drying had the advantage that while the material humidity decreases, the steam’s temperature used as heat source increase, the driving force is equilibrium distr ibution. As a summar y, if allowed, t he countercu rrent mul- ti-effect dr yin g i s the bes t choice. Got through the countercurrent drying curve of Figure 2 and Figure 3, the minimum energy consumption of countercurrent 1-effect drying is 533.5 kW, 2-effe ct is 320 kW, and compared to 1-effect the 2-effect energy saving rate is of 40%. However when the number of effect is more than 4, the energy consump- tion and energy saving rate curves tend to smooth. Generally, the multi-effect systems are most effective for 3-4 effects, above this number the energy consumption reduction is mar- ginal and probably not sufficient to justify the increase of sys- tem complexity. The energy consumption of countercurrent 4-effect dr ying is 25 7 kW and co-curren t 4-effect drying is 289 kW. The energ y savin g rate o f cou ntercu rrent 4-effect d rying i s 57.6 % and co-current 4-effect drying is 49% compared to 1-effect drying. 3.2. Drying Effect of Countercurrent n- Effect Drying This article calculates the removal water of each effect of countercurrent n-effect drying. The energy of countercurrent n-effect drying is provided according to the calculation from Figure 2. Countercurrent 1-effect drying to 5-effect drying are simulated. The results are shown in Table 2. 4. Conclusions The process of countercurrent multi-effect drying is designed by using linear programming method. Both co -current and countercurrent 1-effect to 5-effect drying are simulated by the method. The minimum energy consumption of such mul- ti-effect drying system is less than that of conventional 1-effect drying system. The energy consumption decreases with Table 1. The parameters of silica sand of countercurrent n-effect drying. param ete rs G/kg X0 / kg moisture/kg absolutely dry material Xn / kg moisture/kg absolutely dry material t0/℃ Pn /kPa P1/kPa Tn/℃ T1 ℃ η date 1000 0 .5 ≤ 0.0 1 25 140 30 110 66.5 1 12345 0 100 200 300 400 500 600 n-effect energy consum ption (kW ) co -cu rren t multi-effect dry ing countercurrent m ulti-effect drying Figure 2. The energy consumption of n-effect drying.  H. LI ET AL. Copyright © 2012 SciRes. AM PC 209 12345 0 10 20 30 40 50 60 70 n-effect energy saving rate (% ) co -cu rrent multi-effe ct dry in g countercurrent m ulti-effect drying Figure 3. The energy saving rate of n-effect drying. Tabl e 2. The removal water of each effect of coun t er cu rr en t n-effect drying. The removal water (kg) Number of drying effect GΔX1 GΔX2 GΔX3 GΔX4 GΔX5 1-effect 493 161 55 7 0 2-effect 333 173 97 38 3-effect 263 155 96 4-effect 233 147 5-effect 217 the number of effects. Generally, the multi-effect systems are most effective for 3-4 effects; above this number the energy consumption reduction is marginal and probably not sufficient to justify the increase of system complexity. Compared with co-current multi-effect drying, the counter- current multi-effect drying consuming less energy. The energy saving rate of countercurrent 4-effect drying is 57.6% and co-current 4-effect drying is 49% compared to 1-effect drying. In other words, the energy consumption is halved, which is regarded as a s ignificant step ahead in saving ener gy. REFERENCES [1] S.K. Chou, K.j. Chua, S.M. Lee, 2003, On the Use of Contact Factor Parameter to Optimize Drying Operations. Energy Con- version and Management . Vol. 44, 1451-1464 [2] I. Dincer, M.A. Rosen, 1999, Environmental and Sustainable Development. Applied Energy. Vol. 46, 427-440  H. LI ET AL. Copyright © 2012 SciRes. AM PC 210 [3] I. Dincer, A.Z. Sahin, 200 4, Incorporation of the Dincer Number into the Moisture Diffusion Equation. Interna tional Communica- tions in Heat and Mass Transfer. Vol. 31, 109-119 [4] C .St rumillo,1998, Developments in Drying. Report in Jinan Conference on Drying Technology [5] Linnhoff, B, 1994, User Guide on Process Integration for the Efficient Use of Energy. The Institution of Chemical Engineering. Rugby, UK [6] Djaeni, M. Bartels, P. Sanders, J. Straten, G. van. Van Boxtel, A.J.B, 2007, Process Integration for Food Drying with Air De- humidified by Zeolites. Drying Technology. 25, 1, 225-239 [7] Krokida, M.K. Bisharat, G. I, 2004, Heat Recovery from Dryer Exhaust Air. Drying Technology, 22, 7, 1661-1674 [8] Yu ying Yao, 1999, Principles of Chemical Engineering. Volume one. Tianjing University Press. In Chinese [9] Li Hon g, Hu Yangdon g, Zhang Pei , Wu Lian ying, Li Yonggang, 2011, Simulation of Co-current Multi-effect Drying Syst e m . Advanced Materials Research. 236-238, 808-83  H. LI ET AL. Copyright © 2012 SciRes. AM PC 211 Nomenclature C —— s pecific heat capacity of water , kJ/(kg·℃) Cs —— specific heat capacity of solid, kJ/(kg·℃) Di —— the amount of secondary steam which is put into the i-effect drying, kg G —— th e absolut ely dry material feed, kg Pn —— the pressure of the fresh vapor, kPa Pi’ —— the pressure of the countercurrent i-effect drying, kPa ti —— the solid temperature of the countercurrent i-effect drying, ℃ Tn —— th e temperature of fresh vapor, ℃ Ti —— the steam temperature of the countercurrent i-effect drying import, ℃ Ti’ —— the secondary steam temperature of the coun- tercurr ent i-effect drying produces, ℃ Qn —— the external energy, kW r —— evaporation heat of heating steam, kJ/kg r’ —— evaporation heat of secondary steam, kJ/kg Wi —— the amount of secondary steam that the i-effect drying produces, kg Xi —— dry basis water content of i-effect drying, kg moisture /kg absolute dry materials η —— th e heat transfer efficiency of each effect drier i —— the i effect n —— total number of drying effect |