Paper Menu >>

Journal Menu >>

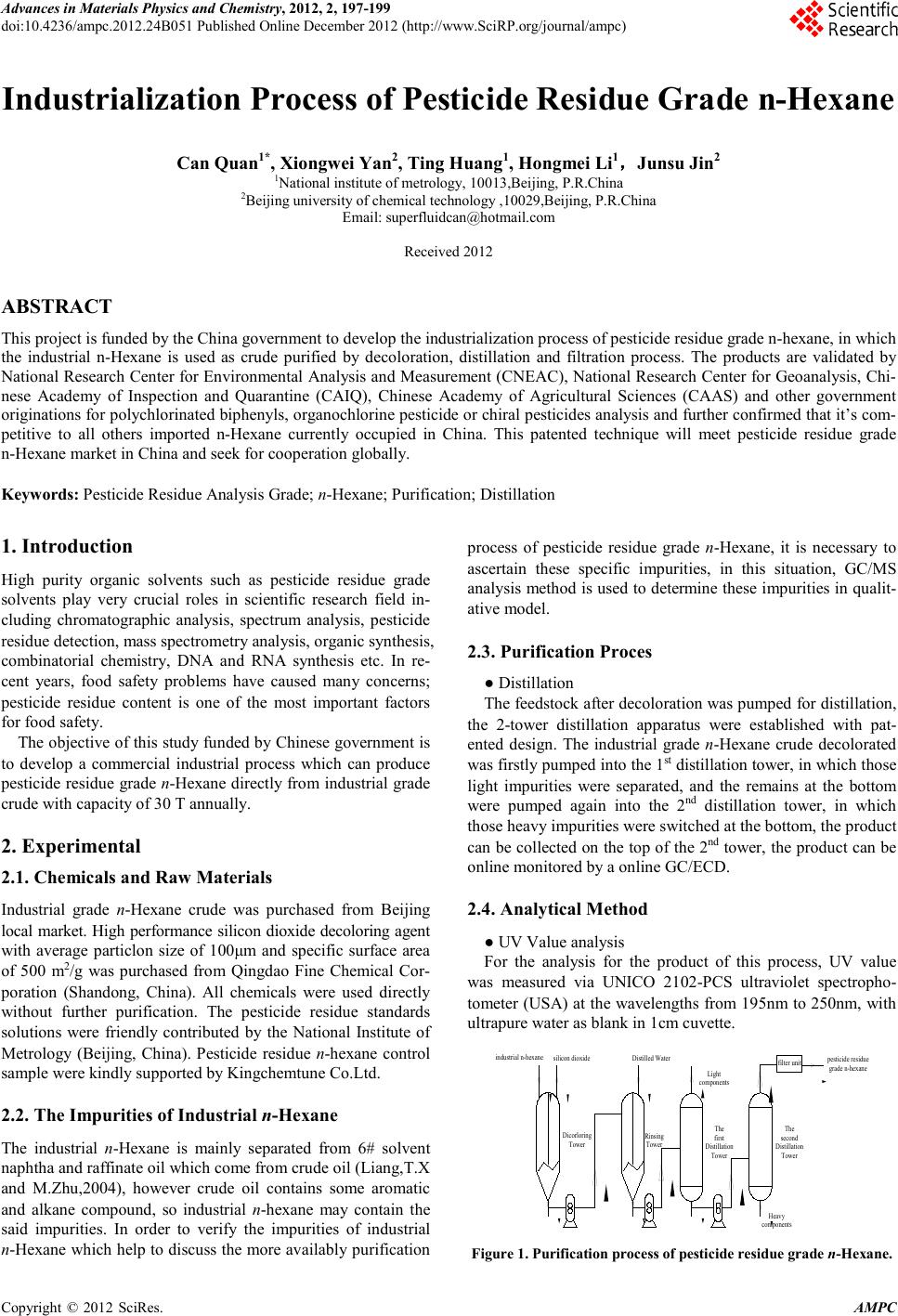

Advances in Ma terials Physics and Che mist ry, 2012, 2, 197-199 doi:10.4236/ampc.2012.24B051 Published Online December 2012 (htt p://www.SciRP.org/journal/ampc) Copyright © 2012 SciRes. AMPC Industrialization Process of Pesticide Residue Grade n-Hexane Can Quan1*, Xiongwei Yan2, Ting Huang1, Hongmei Li1,Junsu J in2 1National institute of metrology, 10013,Beijing, P.R.China 2Beiji ng university of chemical technology ,10029 ,Beijing, P.R.Chin a Email: superfluidcan@hotmail.com Received 2012 ABSTRACT This project is funded by the China government to develop the industrialization process of pesticide residue grade n-hexane, in which the industrial n-Hexane is used as crude purified by decoloration, distillation and filtration process. The products are validated by Nation al Research Cen ter for Envi ronmental Analysis and M easurement ( CNEAC), Nati onal Research Center for Geoanalysis, C hi- nese Academy of Inspection and Quarantine (CAIQ), Chinese Academy of Agricultural Sciences (CAAS) and other government originations for polychlorinated biphenyls, organochlorine pesticide or chiral pesticides analysis and further confirmed that it’s com- petitive to all others imported n-Hexane currently occupied in China. This patented technique will meet pesticide residue grade n-Hexane market in China and seek for cooperation globally. Keywords: Pestici de Residue Analysis Grade; n-Hexane; Purification; Distillation 1. Introduction High purity organic solvents such as pesticide residue grade solvents play very crucial roles in scientific research field in- cluding chromatographic anal ysis, spectrum analysis, pesticide residue detect ion, mass spectrometry analysis, organic synthesi s , combinatorial chemistry, DNA and RNA synthesis etc. In re- cent years, food safety problems have caused many concerns; pesticide residue content is one of the most important factors for food safety. The objective of this study funded by Chinese government is to develop a commercial industrial process which can produce pestici de residue grad e n-Hexane directly from industrial grade crude with capacity of 30 T annually. 2. Experimental 2.1. Chemicals and Raw Materials Industrial grade n-Hexane crude was purchased from Beijing local market. High perfo rmance silicon dioxide decoloring agent with average particlon size of 100μm and specific surface area of 500 m2/g was purchased from Qingdao Fine Chemical Cor- poration (Shandong, China). All chemicals were used directly without further purification. The pesticide residue standards solutions were friendly contributed by the National Institute of Metrology (Beijing, China). Pesticide residue n-hexane control sample were kindly supported by Kingchemtune Co.Ltd. 2.2. The Impurities of Industrial n-Hexa ne The industrial n-Hexane is mainly separ ated from 6# solvent naphtha and raffinate oil which come from crude o il (Liang,T.X and M.Zhu,2004), however crude oil contains some aromatic and alkane compound, so industrial n-hexane may contain the said impurities. In order to verify the impurities of industrial n-Hexane whi ch help to discuss the more availably purification process of pesticide residue grade n-Hexane, it is necessary to ascertain these specific impurities, in this situation, GC/MS analysis method is used to determine these impurities in qualit- ative model. 2.3. Purification Pro ces ● Distillation The feedstock after decoloration was pumped for distillation, the 2-tower distillation apparatus were established with pat- ented design. The industrial grade n-Hexane crude decolorated was firstly pumped into the 1st distillation tower, in which those light impurities were separated, and the remains at the bottom were pumped again into the 2nd distillation tower, in which tho se heavy impurities w er e switched at the bottom, the product can be collected on the top of the 2nd tower, the product can be online monitored by a online GC/ECD. 2.4. Analytical Method ● UV Value analysis For the analysis for the product of this process, UV value was measured via UNICO 2102-PCS ultraviolet spectropho- tometer (USA) at the wavelengths from 195nm to 250nm, with ultrapure water as blank in 1cm cuvette. industrial n-hexanesilicon dioxide Dicorloring Tower Rinsing Tower The first Distillation Tower The second Distillation Tower Distilled Waterpesticide residue grade n-hexane Heavy components Light components filter unit Figure 1. Purification process of pesticide residue grade n-Hexane.  C. QUAN ET AL. Copyright © 2012 SciRes. AMPC 198 ● Gas chromatography-electron capture detector (GC/ECD) analysis For the analysis for the product by this process, GC/ECD analysis was carried out by Agilent 6890(USA) gas chroma- tography equipped with Ni63 electron-captu re detecto r. Samples were introduced into the GC-column via electronic pressure control, with cold-column injector mode. ● Gas chromatography-mass spectr ometry (GC/MS) analysis For the analysis for industrial grade n-hexane and the product by this process, GCMS analysis was carried out by SHIMAD- ZU GCMS-QP2010 Plus. Samples were introduced into the GCMS via el ectronic pressure cont rol, with cold-column injec- tor mode. 3. Results and Discussion 3.1. Impurities Determination of Industrial n-H exane ● Solvent peak In GC/MS analysis, solvent peak should be found and cut. Industrial n-hexane contain many impurities, however, whose purity is still up to 96%, after it is injected to GC/MS, the n-Hexane cannot be detected by MS, or the MS will be dam- aged by n-Hexane solvent, meanwhile it is hard to analysis those impurities peak because of ultra high main solvent peak. In order to determine the retention time of solvent peak, the less injection volume and higher split ratio is chosen that is 0.1μL and 100:1 respect ively, th e r es ult is showed in Figure 2. 3.2. Parameters of Purification Process ● Two towers distillation After the processes of the front two steps, the feedstock was transferred to two distillation units, the use of the first tower was to remove the low point constituents, then the remaining liquid was transferred to the second tower, the use of which was to remove the high point constituents, lastly the product was got from the second tower top. Distillation is a highly efficient separation method whose advantages are simple process, high effect and flexible opera- tion etc. The controlled indexes of this process included heating temperature, reflux ratio and heavy constituents discharge rate etc. After a lo t of experiment s the optimized process parameters are got: the heating temperature of two towers distillation is 88℃ with reflux ratio of 15:1 and 4:1 for both respectively, the discharge rate of heavy components is 20mL/min, the yield is approximately 70%. If heating temperature was too high and too low, they would cause flood and effect mass transfer, meanwhile if reflux ratio was too high, it would cost too much energy, else if the reflux ratio was too low, products were hard to meet the r equir ement, so it is necessary to find the best reflux ratio which is the essential elements of distillation operation. 3.3. Quality Assessment of the Product ● UV value measure ment Take n-Hexane crude and three bottl es of differen t b atch es of products as the test sample with ultrapure water as blank, from Table 1, it can be seen that cr ude n-hexan e cannot pass th e UV value indexes, while UV value of all the products mee t the UV value indexes at all the t es ted wavelengths. The results show that the numbers of crude impurities are too many and the height is too high, three products show thr ee time points which are most easy to appear exceeding peak resp ect- tively. The results showed that the purity of crude is less than 97% and the purity of these products reach 98% which meet the requirement of pesticide residue standard that is higher than 97%. 3.4. The Comparation of the Quality of our Product and Other Products Both at Domestic and Aboard From the test results, we can make the conclusion that the products got by this process meet the requirement of pesticide residue indexes. In order to analyze the market situation, we bought 5 kinds of brands of pesticide residue grade n-hexane both at domestic and abroad, all the products were tested in the said test method, the results were showed in Table 1. Figure 2. The main solvent peak. Table 1. Qualit y comparison of pesticides residue n-Hexa n e . title Foreign product 1 Foreign product 2 Foreign prod uct 3 Foreign prod uct 4 Domestic product 1 The product 195nm absorb ance 0.702 0.713 0.662 0.732 0.908 0.943 210nm absorb ance 0.176 0.201 0.182 0.234 0.246 0.231 220nm absorb ance 0.061 0.079 0.072 0.058 0.098 0.071 230nm absorbance 0.029 0.042 0.038 0.028 0.049 0.028 240nm absorb ance 0.015 0.026 0.023 0.015 0.025 0.012 250nm absorb ance 0.010 0.018 0.016 0.011 0.016 0.005 Maximum peak height (GC-ECD) (ng·ml-1) 2.83 0.26 0.18 6 .3 1 1.38 0.590 purity(%)(GC-FID) 97.31 99.61 98.53 98.59 97.33 98.48  C. QUAN ET AL. Copyright © 2012 SciRes. AMPC 199 The results show that the overall quality of the product got by this process ranks middle, which is better than domestic product and part of foreign products and have not big gap with other be t te r f ore i g n products. In addition, the products were tested by National Research Center for Environmental Analysis and Measurement (CNEAC), National Research Center for Geoanalysis, Chinese Academy of Inspection and Quarantine (CAIQ), Chinese Academy of Agricultural Sciences (CAAS) and other government origina- tions for polychlorinated biphenyls, organochlorine pesticide or chiral pesticides analysis and further confirmed that it’s com- petitive to all others imported brand occupied China. 4. Conclusion For the solvents of pesticide residue analysis, they not only require high purity, but more importantly, which do not pro- duce interference peak in pesticide chromatographic detection when solution are concentrated dozens to hundreds times, so the traditional purification methods are not suitable for the preparation of this kind of solvents. This study build a new proces s,which can remove the trace impurities that influence the pesticide residue analysis and overcome some technology bottleneck problems such as complex process, too much impu- rities peak and heavy environment pollution, thus achieve the process of transforming industrial n-Hexane to p es ticide r es idue grade n-hexane directly. Put industrial n-hexane as crud e, after thi s pr ocess contai nin g decolour-two towers distillation-filter, pesticide residue grade n-Hexane which can be ap p ly to pesti cid e resid u e anal ysis were prepared. This prod uct can meet the clients in the n eed of pesticide re- sidue analysis, which would reduce the independent of do- mestic laboratory to imported pesticide residue grade solvents and could support the product of good quality and cheap price. 5. Acknowledgements Can QUAN ackno wledges the Ministry of science and tech- nology of People’s Republic of China for Key Projects in the Nation al Science & Techno logy Pillar Pr ogram du ring the Ele- venth Five-Year Plan Period (2009BAK61B02); the Minis- try of science and technology of People’s Republic of China (2011FY130100); the General Administration of Quality Su- pervision, Inspection and Quarantine of the People’s Republic of China (ASPAQ1101-1); the National Institute of Metrology (21-JB1127) for financing. REFERENCES [1] Yang P, Ye X N, Lau C W. Design of efficient zeolite sensor materials for n-hexane [J]. Anal. Chem., 2007, 79(4): 1425-1432 [2] Sivasankar N, Vasudevan S. Adsorption of n-hexane in zeo- lite-5A: a temperature-programmed desorption and IR-spectroscopic study [J]. J. Phys. Chem. B, 2005,109(32): 15417-15421 [3] B árcia P S, Si lva J A C, R odr igues A E. Adsorption equilibrium and kinetics of branched hexane isomers in pellets of BETA zeo- lite[J].Microporous and Mesoporous Materials, 2005, 79(1-3): 145–163 [4] Krishna R, Van baten J M. Screening of zeolite adsorbents for separation of hexane isomers: a molecular simulation study [J]. Separation and Purification Technology, 2007, 55(2): 246-255 [5] Yonli A H, Boui llault N, Mignard S. Separation of mono- branched and dibranched isomers of n-hexane on zeolitic mole- cular sieves: a thermodynamic study [J]. J. Phys. Chem. B, 2010, 114(13): 4465–4470 [6] Bárcia P S, Zapata F, Silva J A C. Kinetic separation of hexane isomers by fixed-bed adsorption with a microporous met- al-organic framework [J]. J. Phys. Chem. B, 2007, 111(22): 6101-6103 [7] Shanbhag P V, Guha A K, Sikar K K. Membrane-based ozona- tion orga nic compounds [J]. Ind. Eng. Chem. Res, 1998, 37(11): 4388-4398 [8] Bessarabov D G, Theron J P, Sanderson R D. Separation of 1-hexene/n-hexane mixtures using a hybrid membrane/extraction system[J]. Separation and Purification Technology, 1999, 16(2): 167–174 [9] Funke H H, Argo A M, Baertsch C D. Separation of close-boiling hydrocarbons with silicalite zeolite membranes[J]. J. Chem. SOC., Faraday Trans., 1996, 92(13): 2499-2502 [10] Gump C J, Noble R D, Falconer J L. Separation of hexane iso- mers through nonzeolite pores in ZSM-5 zeolite membranes [J]. Ind. Eng. Chem . R e s .1999 , 38(7): 2775-2781. |