Paper Menu >>

Journal Menu >>

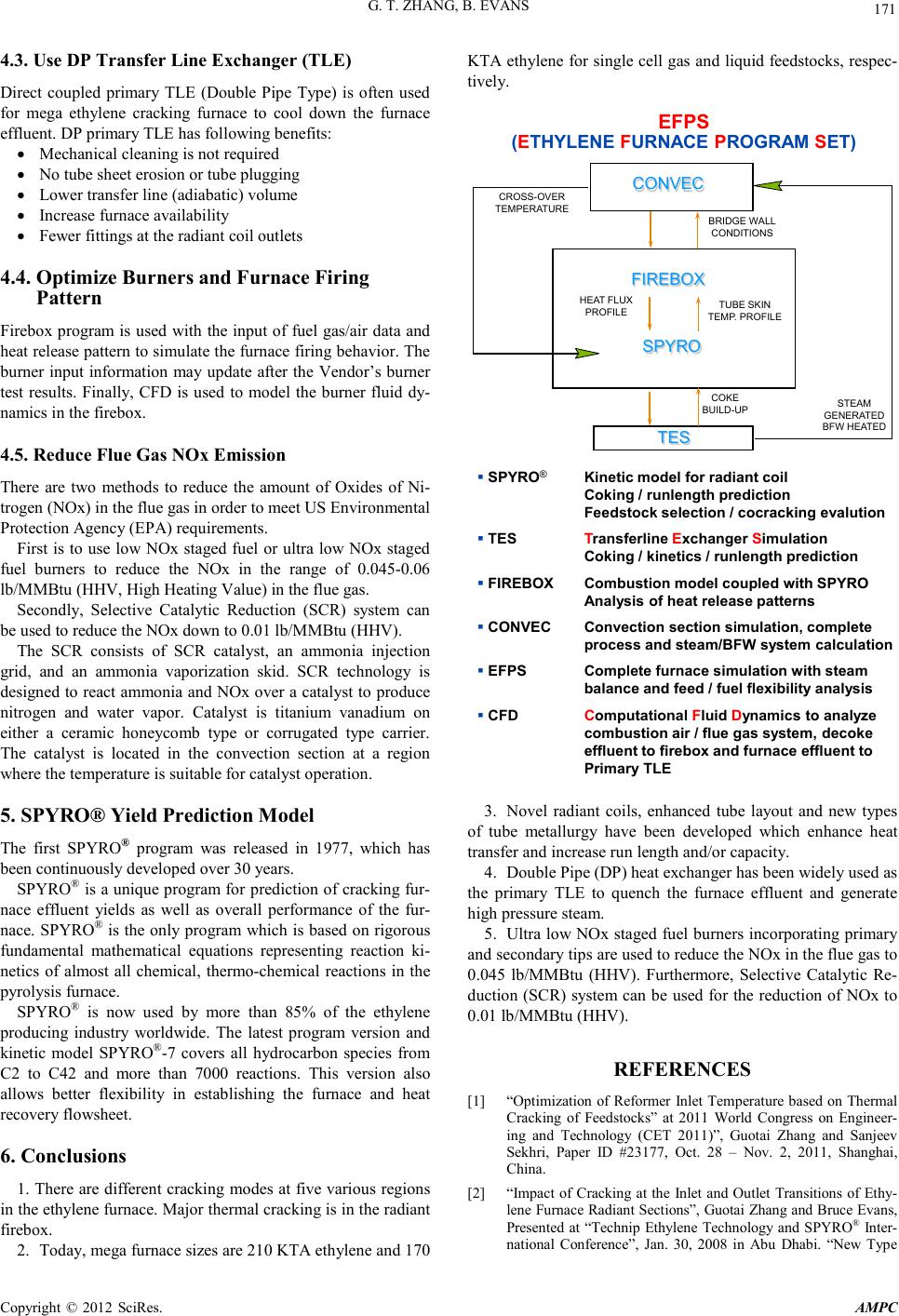

Advances in Ma terials Physics and Che mist ry, 2012, 2, 169-172 doi:10.4236/ampc.2012.24B044 Published Online December 2012 (htt p://www.SciRP.org/journal/ampc) Copyright © 2012 SciRes. AMPC Progress of Modern P yrolysis Furn ac e Technology Guotai Zhang, Bruce Evans Technip USA Inc., Claremont, California, USA Received 2012 ABSTRACT This paper presents the fundamentals of thermal pyrolysis and discusses the modern ethylene furnace technology and its design trends. Technip’s proprietary SPYRO® program is discussed for prediction of hydrocarbon cracking. Keywords: E thylene Furnace; C racking Kineti cs ; Adiabatic Cracki ng; Non-Adiabatic Cracking; Radiant Coil; Convection Section; Burn er and Select ive Catalytic Reduction 1. Introduction Ethylene, the simplest of olefins, is used as a base product for many syntheses in the petrochemical industry: plastics, solvents, cosmetics, pneumatics, paints, p ackin g, etc. Today, the d emand for ethylene is over 140 million tons per year with a growth rate of 3.5% per year. The production of ethylene has been dominated by the steam cracking process since the end of World War II. The feed stocks for steam cracking are hydrocarbons such as shale gas, ethane, liquefied petroleum (LPG), naphtha, heavy gas con- densat e, and gas oi l. The cracking furnace is the heart of ethylene plant which consists of the radiant section, the convection section and transferline exchangers (TLE’s) for waste heat recovery. (See Figure 1 ). The objectives of this paper are to present the fundamentals of thermal pyrolysis, to introduce different cracking types in the furnace and to discuss the Technip modern furnace technology and desig n t r e nds . The variou s feedst ock cracking kin etics have been simulated using Technip’s proprietary SPYRO® program which is widely used by the industry for prediction of hydrocarbon cracking. 2. Fundamentals of Thermal Pyrolysis Two scientific terminologies are used in the analysis below. [1] Bond Energy Bond energy is a measure of bond strength in a chemical bond. The larger the bond energy, the stronger the bond and hence t he higher t emperature required to break it. Bond Length Distance between centers of bounded atoms is called bond length. There is a general trend in that the shorter the bond length, the higher the bond energy. The general t hermal cracking trend is listed belo w: a) Th e H-H bond energy is higher than the C-H bond energy and C-H bond energy is higher than the C-C bond energy. Thus, the C-C bond is easier to break than H-H and H-C bonds, and the H-C bond is easier to break than the H-H bond. Table 1. Bond Length and Bond Energy. Bond Type H-H H-C C-C C=C C≡C Bond Length Picometers* 74 109 154 134 120 Bond Energy kcal/mol 104 99 83 147 200 * 1 Picometer = 10-12 m Feed Dilution Steam ECO FPH MFPH-1 Saturat ed Steam BFW Crossover Piping Transfer Lines Convection Section Primary TLE’s Coils C A Cracked Gas E B A ----- Non-Adiabatic Cracking-MFPH-2 A ----> B Crossover Piping Volume (Adiabatic Cracking) -CPV B ----> C Firebox (Thermal Cracking) -FB C ----> D Transferline Volume (Adiabatic Cracking) -TV D ----> E Transferline Exchanger (Non-Adiabatic Cracking) -TLE Steam Drum Radiant Section MFPH-2 D Figure 1. Eth yl en e cr acking furna ce.  G. T. ZHANG, B. EVANS Copyright © 2012 SciRes. AMPC 170 b) The dehydrogenation ability of a hydrocarbon depends upon its structure. Tertiary H is easily dehydrogenated and Primary H is more difficult to dehydrogenate. The dehydroge- nation ability is in the order of Tertiary H > Secondary H > Primary H c) Order of bond energy for Carbon-Carbon bonds is: C≡C > C=C > C-C d) Paraffin stability is lower with the molecular weight in- crease or the longer carbon chain length. There is a general trend in that the longer the carbon chain length the lower the bond energy and h en ce the easier cr ackin g (breaki ng th e C-C o r C-H bond) will occur. Therefore, the cracking temperature for hydrocarbon molecules with long carbon chain length will be lower. e) Heat stability will be different for hydrocarbons with var- ious structures. For hydrocarbons with the same numbers of carbon atoms, the heat stability order is Aromatics > Naphthene > Di-olefins > Olefin > Paraffin 3. Different Cracking Types in Pyrolysis Furna ce Undesired cracking reactions can take place in the convection coil MFPH-2, crossover piping, transfer line or Transfer Line Exchanger ( TLE) as shown in Figure 1. The cracking react ion s which take place in the convection section and TLE are non-adiabatic cr acking. The cracking react ions in the crosso ver piping and transfer line are adiabatic cracking reactions and those that occur in the radiant box are thermal cracking. [2] The extent of both the non-adiabatic cracking reactions and the adiabatic cracking reactions depends on the hydrocarbon feed type, st eam/ carb on mole rat io , mixed feed te mperat ure an d pressure as well as mixed feed Residence Time (RT) in the crossover piping or furnace effluent RT in the transfer line vo- lume. 4. Modern Furnace Technology and Design Trends In this sectio n we descri be the state-of-art stea m cracki ng tech- nology and its design trends. 4.1. Build Larger Ethylene Furnaces, Pl ants and Complexes Toda y, the largest single cell gas cracking furnace produces 210 KTA ethylene, and the largest single cell liquid cracking fur- nace produces 170 KTA ethylene. Limits of these technologies have no t yet been reached. The largest ethylene plant has 1500 KTA ethylene capacity. New mega plants with 2000 KTA ethylene capacity are under consideration. Currently, the world’s largest ethylene complex is Formosa Petrochemical Corporation which produces about 3000 KTA ethylene. 4.2. Develop Novel Radiant Coil New radian t coils have b een develop ed to enhance heat t ransfer and increase furnace run length, selectivity or operating capac- ity. a) SFT (It has been granted a patent) Technip has developed a new coil, Swirl Flow Tube (SFT) by bending tube process which can vary the amplitudes and pitches of the tube swirl to reduce tube skin temperature or increase run length and/or capacity. For the same feed and feed rate with on-stream time of 50 days, the maximum Tube Metal Temperature (TMT) of SFT is about 50 oC lower than that of bare tube. In other words, feed rate can b e increased 23 % to reach maximu m TMT of 10 70 oC at 50 days. Similar comparisons can be made on run length impact at constant capacity or on selectivity improvement with shorter coil l ength and short resid ence time. Swi r l Flow Tube (SFT) New coils geometry to improve selectivit y and/or longer run length and/or higher capacity Recent Innovations: –Swirl Flow Tube s (SFT) with varying amplitudes and pitches b) GK-7 Coil (It has b een granted a patent) A new coil called GK-7 has been developed by Technip, which has an improved layout of the Technip GK-6. It has fol- lowing features [3]: • Inlet tubes have an extra wide t ube spacing • Outlet t ubes have an IN-LINE layout • Small differ ence in TMT’s betwe en inlet/outlet passes • Symmetrical tube layout • Easier access for coil mai ntenance A fur n a c e wi t h GK-7 coils is currently being constructed. c) Crackin g t ube surface treat ments Cracking furnace tub es can use a su rface treatment to redu ce coking. For example, Kubota’s ANK 400 achieves unprece- dented furnace run length by dramatically lowering coke for- mation. The key to coke reduction is an inert, nanocrystalline spinel surface which has been proven to reduce both catalytic and pyrolytic coking. d) Improved cracking tube alloys Improved alloys can contain higher levels of chrome and nickel, but can also contain other additives. For example, the Schmidt + Clemens HT-E alloy, with a certain level of alumi- nium (Al) addition, is claimed to significantly reduce the effect of catalytic coking, while also offering protection against oxi- dation and carburization. The positive impact on run length has been verified for HT-E compared to conventional 25/35 or 35/45 (Cr/Ni) alloys.  G. T. ZHANG, B. EVANS Copyright © 2012 SciRes. AMPC 171 4.3. Use DP Transfer Line Exchanger (TLE) Direct coupled primary TLE (Double Pipe Type) is often used for mega ethylene cracking furnace to cool down the furnace effluent . DP pr imary TLE has following benefits: • Mechani cal cleaning is not r equired • No tube sheet erosion or tube plugging • Lower transf er line ( adiabatic) volume • Increase furnace availability • Fewer fittings at the radiant coil outlets 4.4. Optimiz e Burn ers an d Furnace Fir ing Pattern Firebox program is used with the input of fuel gas/air data and heat releas e pattern to si mulate t he furn ace firin g behavio r. The burner input information may update after the Vendor’s burner test results. Finally, CFD is used to model the burner fluid dy- namics in th e firebox. 4.5. Reduce Flue Gas NOx Emission There are two methods to reduce the amount of Oxides of Ni- trogen (NOx) in the flue gas in order to meet US Environmental Prot ection Agency (EPA) requirement s . First is to use low NOx staged fuel or ultra low NOx staged fuel burners to reduce the NOx in the range of 0.045-0.06 lb/MMBtu (HHV, High Heating Value) in the flue gas. Secondly, Selective Catalytic Reduction (SCR) system can be used to reduce the NOx down to 0.01 lb/MMBtu (HHV). The SCR consists of SCR catalyst, an ammonia injection grid, and an ammonia vaporization skid. SCR technology is designed to react ammonia and NOx over a catal yst to produce nitrogen and water vapor. Catalyst is titanium vanadium on either a ceramic honeycomb type or corrugated type carrier. The catalyst is located in the convection section at a region where the temperatu r e is suitable for catalyst operation. 5. SPYRO® Y ield Pred ict ion Mod el The first SPYRO® program was released in 1977, which has been continuously developed over 30 years. SPYRO® is a unique program for prediction of cracking fur- nace effluent yields as well as overall performance of the fur- nace. SP YRO® is the only program which is based on rigorous fundamental mathematical equations representing reaction ki- netics of almost all chemical, thermo-chemical reactions in the pyrolysis furnace. SPYRO® is now used by more than 85% of the ethylene producing industry worldwide. The latest program version and kinetic model SPYRO®-7 covers all hydrocarbon species from C2 to C42 and more than 7000 reactions. This version also allows better flexibility in establishing the furnace and heat recover y flowsheet. 6. Conclusions 1. There are different crackin g modes at five vario us regions in th e ethylene fur nace. Majo r t her mal crac king i s in th e radian t firebox. 2. Today, mega furnace sizes ar e 210 KTA ethylene and 170 KTA ethylene for sin gle cell gas an d liquid feedsto cks, respec- tively. EFPS (ETHYLENE FURNACE PROGRAM SET) CONVEC SPYRO TES FIREBOX CROSS-OVER TEMPERATURE BRIDGE WALL CONDITIONS HEAT FLUX PROFILE TUBE SKIN TEMP. PROFILE STEAM GENERATED BFW HEA TED COKE BUILD-UP SPYRO®Kinetic model for radiant coil Coking / runlengthprediction Feedstock selection / cocracking evalution TES TransferlineExchanger Simulation Coking / kinetics / runlength prediction FIREBOX Combustion model coupled with SPYRO Analysis of heat release patterns CONVEC Convection section simulation, complete process and steam/BFW system calculation EFPS Complete furnace simu lation with steam balance and feed / fuel flexibilit y analysis CFD Computational Fluid Dynamics to analyze combustion ai r / flue gas system, decoke effluent to firebox and furnace effluent to Primary TLE 3. Novel radiant coils, enhanced tube layout and new types of tube metallurgy have been developed which enhance heat transfer an d incr eas e r un length and/or capacity. 4. Double Pipe (DP) heat exchanger has been widely used as the primary TLE to quench the furnace effluent and generate high pressur e s team. 5. Ultra low NOx staged fuel burners incorporating primary and seco ndar y tips are u sed to reduce th e NOx in th e flue gas to 0.045 lb/MMBtu (HHV). Furthermore, Selective Catalytic Re- duction (SCR) system can be used for the reduction of NOx to 0.01 lb/MMBtu (HHV). REFERENCES [1] “Optimization of Reformer Inlet Temperatu re based on Thermal Cracking of Feedstocks” at 2011 World Congress on Engineer- ing and Technology (CET 2011)”, Guotai Zhang and Sanjeev Sekhri, Paper ID #23177, Oct. 28 – Nov. 2, 2011, Shanghai, China. [2] “Impact of Cracking at the Inlet and Outlet Transitions of Ethy- lene Furnace Radiant Sections”, Guotai Zhang and Bruce Evans, Presented at “Technip Ethylene Technology and SPYRO® Inter- national Conference”, Jan. 30, 2008 in Abu Dhabi. “New Type  G. T. ZHANG, B. EVANS Copyright © 2012 SciRes. AMPC 172 of Cracking Furnace Radiant Coil”, Johan [3] van der Eijk, Paper ID #173546 at the AIChE 2010 Spring Na- tional Meeting, March, 21-25, 2010 in San Antonio, Texas, USA. |