Paper Menu >>

Journal Menu >>

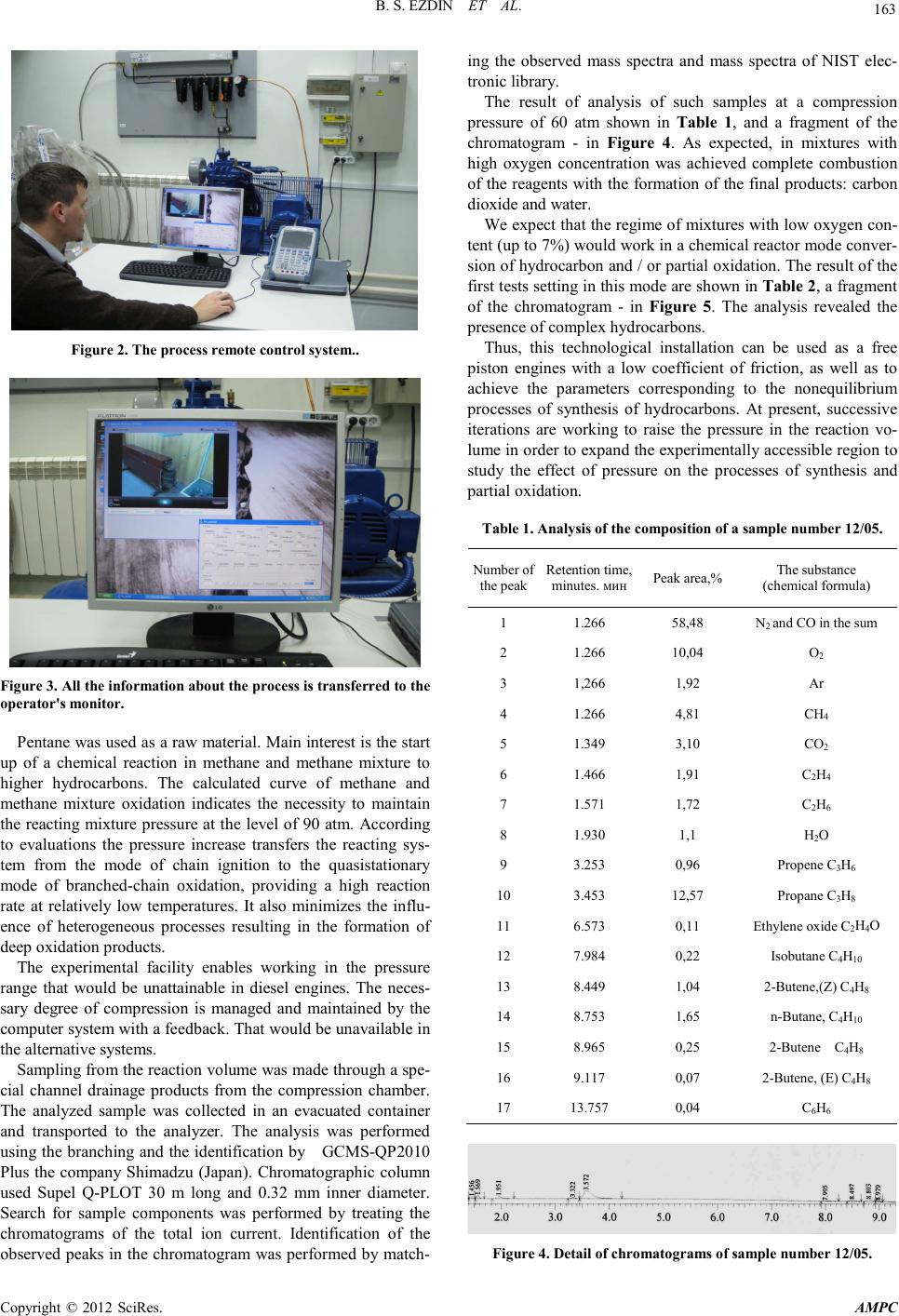

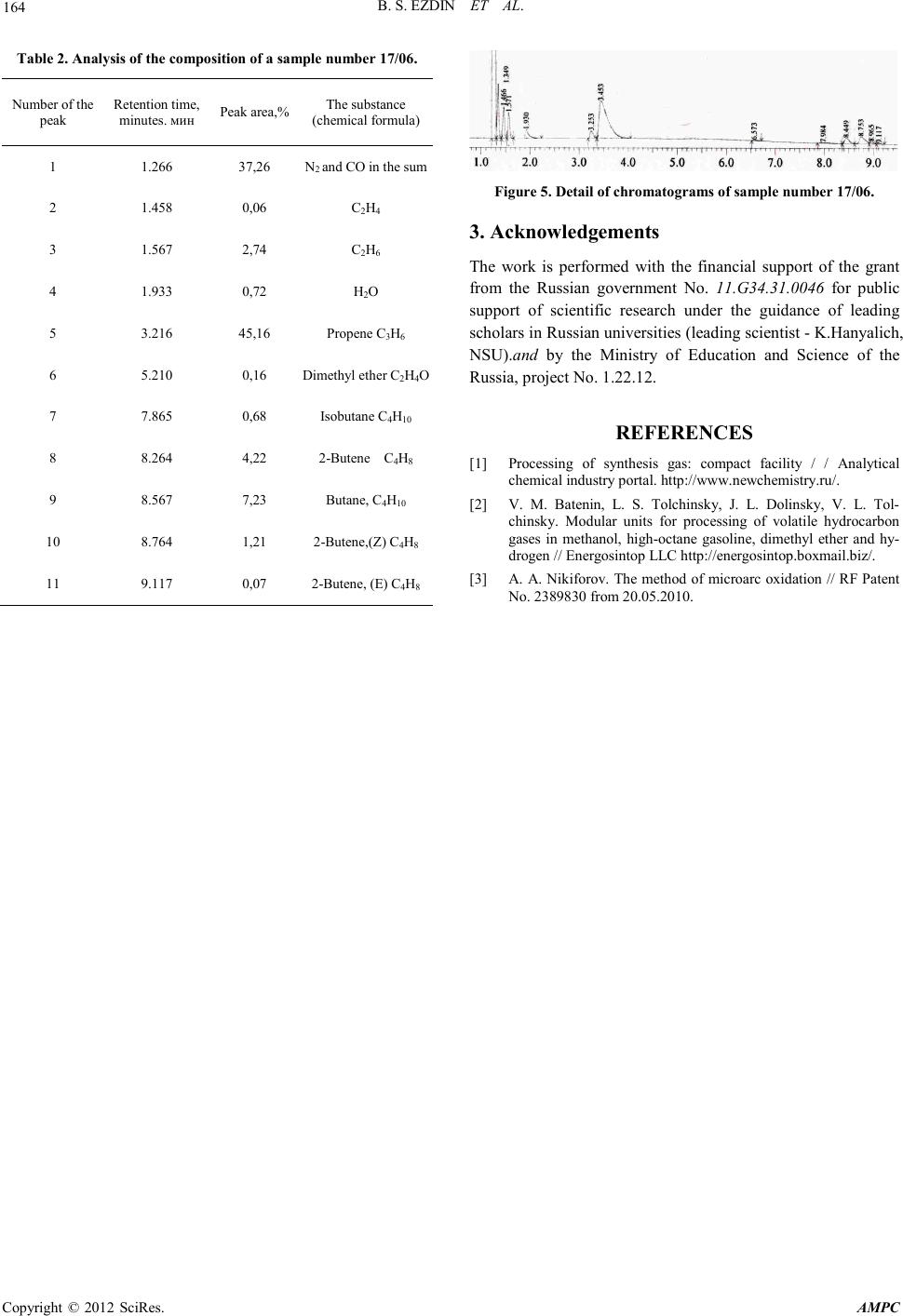

Advances in Ma terials Physics and Chemistry, 2012, 2, 162-164 doi:10.4236/ampc.2012.24B042 Published Online December 2012 (http://www.SciRP.org/journal/ampc) Copyright © 2012 SciRes. AMPC Use of Compressive Reac tor for Associated Petroleum Gas Processing B. S. Ezdin, A. A. Nikiforov, V. E. Fedorov, A. E. Zarvin, S. A. Konovalov, V. V. Kalyada, I. V. M ishchenko Department of Applied Physics, Novosibirsk State Universit y, Novosibirsk, Russia Email: sintez-t@ngs.ru Received 2012 ABSTRACT The possibility of using of a pair of compression piston - cylinder with the unique performance features for the conversion of hydro- carbon s are discusses. The experi mental facility en ables working in the p ressure range that would be unattainab le in diesel engines. The necessary degree of compression is managed and maintained by the computer system with a feedback. Keywords: Oxidation; Natural Gas; Assotiatied Gas; Chemical Compression Reactor 1. Introduction For the past two decades, researchers in many countries try to invent a direct method of natural and petroleum gas conversion into heavy hydrocarbons bypassing a gas synthesis stage. The idea is t o cr eate a co mpact hi gh-perfor mance mobi le p rocessing unit to use it directly in the oil processing industry. 2. Experiment Methods were developed to produce the synthesis gas and other produ cts of associated gas fro m the natural gas in the ch emical compression reactor - diesel engine for exampl e [1,2]. Research team headed by A. Nikiforov, has worked out a method of a surface TECH-oxidation [3]. The covering resis- tant to the thermal cycling, is highly resistant to abrasion and heat. Th e coeffici ent of frictio n between th e two co verin gs do es not exceed 5 * 10-2. Sur faces in the reacti on zone can withst and operating temperatures of more than 2000 K. One of the pers- pective applications of this innovation is to use a pair of com- pression "piston - cylinder" with the unique performance fea- tures for the conversion of hydrocarbons. We have developed an original compression reactor to pro- duce synthesis gas and for the controlled oxidation of asso- ciated gas to ethers and peroxy compounds. The reactor con- sists of piston and cylinder that are cooled. They are driven by a crank mechanism with tension rod. This mechanism provides a translational-rotational motion of the cylinder without lateral forces on the piston. The reactor has a system of measuring pressure in the reaction volume in real time. The construction provides the controlled regulation mechanisms of the cylinder upper dead point. These mechanisms have a response time of 0.1 seconds and an accuracy of 10 microns. Other mechanisms feed the reacting mixture in the reaction volume with a mini- mum response time of 0.5 ms. There is a system cooling the piston and the cylinder of the reactor in order to maintain an optimum gap between them. The working volume of the reactor is 0.1 to 0.6 liters. The optimal frequency of reactor operation is up to 10 Hz. The reactor is equipped with systems collecting reaction products, systems separating raw materials that didn’t react to bring them back to the reactor entrance. Hardware- software system supporting the reactor provides on-line data and enables to manage the reactor mechanisms in order to op- timize and to increase the reaction outcome percentage. The set in cludes the elect romechani cal reacto r startup syste m and the s yst em collectin g the excess en ergy released d uring th e chemical reactions. Without lubrication as the surface to sur- face friction coefficient is low, there is no influence of lubri- cating materi als durin g the process of chemical rea ctions in side of the reactor. The reactor construction enables to have a pres- sure above 100 atm in the chamber. This pressure in its turn enables a wide range of chemical reactions. The pressure con- trol mechanism inside of the reaction volume provides informa- tion about the processes taking place during the reaction. The appearance of the reactor, as well as remote control systems is shown in the photographs (Figures 1-3). We have carried out a series of primary research of the process of the controlled chemical reaction in the chamber up to the stage of the gas mixture oxidation and generation of ether and peroxide compounds. Figure 1. The appearance of the reactor. In the foreground is the engine with a crank mechanism and tension ro ds .  B. S . EZ DIN ET AL. Copyright © 2012 SciRes. AM PC 163 Figure 2. The pr oc es s remote control system .. Figure 3. All the information about the proc es s is transferre d to the operator's monitor. Pentan e was used as a raw material. Main interest is the start up of a chemical reaction in methane and methane mixture to higher hydrocarbons. The calculated curve of methane and methane mixture oxidation indicates the necessity to maintain the reacti ng mixture pressu re at the level of 90 atm. According to evaluations the pressure increase transfers the reacting sys- tem from the mode of chain ignition to the quasistationary mode of branched-chain oxidation, providing a high reaction rate at relatively low temperatures. It also minimizes the influ- ence of heterogeneous processes resulting in the formation of deep oxidation products. The experimental facility enables working in the pressure range that would be unattainable in diesel engines. The neces- sary degree of compression is managed and maintained by the computer system with a feedback. That would be unavailable in the alternative systems. Samplin g from the reacti on vo lume was mad e thro ugh a spe- cial channel drainage products from the compression chamber. The analyzed sample was collected in an evacuated container and transported to the analyzer. The analysis was performed using the branching and the identification by GCMS-QP2010 Plus the company Shimadzu (Japan). Chromatographic column used Supel Q-PLOT 30 m long and 0.32 mm inner diameter. Search for sample components was performed by treating the chromatograms of the total ion current. Identification of the observed peaks in the chromatogram was performed by match- ing the observed mass spectra and mass spectra of NIST elec- tronic library. The result of analysis of such samples at a compression pressure of 60 atm shown in Table 1, and a fragment of the chromatogram - in Figure 4. As expected, in mixtures with high oxygen concentration was achieved complete combustion of the reagents with the formation of the final products: carbon dioxide and water. We expect that the regime of mixtures with low oxygen con- tent (up to 7%) would work in a chemical reactor mode conver- sion of hydrocarbon and / or partial oxidation. The result of the first tests setting in this mode are shown in Table 2, a fragment of the chromatogram - in Figure 5. The analysis revealed the presence of complex hydrocarbons. Thus, this technological installation can be used as a free piston engines with a low coefficient of friction, as well as to achieve the parameters corresponding to the nonequilibrium processes of synthesis of hydrocarbons. At present, successive iterations are working to raise the pressure in the reaction vo- lume in order to expand the exp erimentall y accessib le regio n to study the effect of pressure on the processes of synthesis and partial oxidation. Table 1. Analysis of the composition of a sample number 12/05. Number o f the peak Re tention time , minutes. мин Peak area,% The substance (chemical formula) 1 1.266 58,48 N2 and СО in the sum 2 1.266 10,04 О2 3 1,266 1,92 Ar 4 1.266 4,81 СН4 5 1.349 3,10 СО2 6 1.466 1,91 С2Н4 7 1.571 1,72 С2Н6 8 1.930 1,1 H2O 9 3.253 0,96 Propene C3H6 10 3.453 12,57 Propane С3Н8 11 6.573 0,11 Ethylene oxide C2H4O 12 7.984 0,22 Isobutane C 4H10 13 8.449 1,04 2-But ene,(Z ) C4H8 14 8.753 1,65 n-Butane, C4H10 15 8.965 0,25 2-Butene C4H8 16 9.117 0,07 2-Butene, (E) C4H8 17 13.757 0,0 4 С6Н6 Figure 4. Detail of chromatograms of sample number 12/05.  B. S . EZ DIN ET AL. Copyright © 2012 SciRes. AM PC 164 Table 2. Analysis of the composition of a sample number 17/06. Number of the peak Re tentio n time, minutes. мин Peak area,% The substance (chemical formu la) 1 1.266 37,26 N2 and СО in the sum 2 1.458 0,06 С2Н4 3 1.567 2,74 С2Н6 4 1.933 0,72 H2O 5 3.216 45,16 Propene C3H6 6 5.210 0,16 Dimethyl ether C2H4O 7 7.865 0,68 Isobutane C4H10 8 8.264 4,22 2-Butene C4H8 9 8.567 7,23 Butane, C4H10 10 8.764 1,21 2-But ene,(Z) C4H8 11 9.117 0,07 2-Butene, (E) C4H8 Figure 5. Detail of chromatograms of sample number 17/06. 3. Acknowledgements The work is performed with the financial support of the grant from the Russian government No. 11.G34.31.0046 for public support of scientific research under the guidance of leading scholars in Russian universities (leading scientist - K.Hanyalich, NSU).and by the Ministry of Education and Science of the Russia, project No. 1.22.12. REFERENCES [1] Processing of synthesis gas: compact facility / / Analytical chemical industry portal. http://www.newchemistry.ru/. [2] V. M. Batenin, L. S. Tolchinsky, J. L. Dolinsky, V. L. Tol- chinsky. Modular units for processing of volatile hydrocarbon gases in methanol, high-octane gasoline, dimethyl ether and hy- drogen // Energosintop LLC http://energosintop.boxmail.biz/. [3] A. A. Nikiforov. The method of microarc oxidation // RF Patent No. 2389830 from 20. 05.2010. |