Paper Menu >>

Journal Menu >>

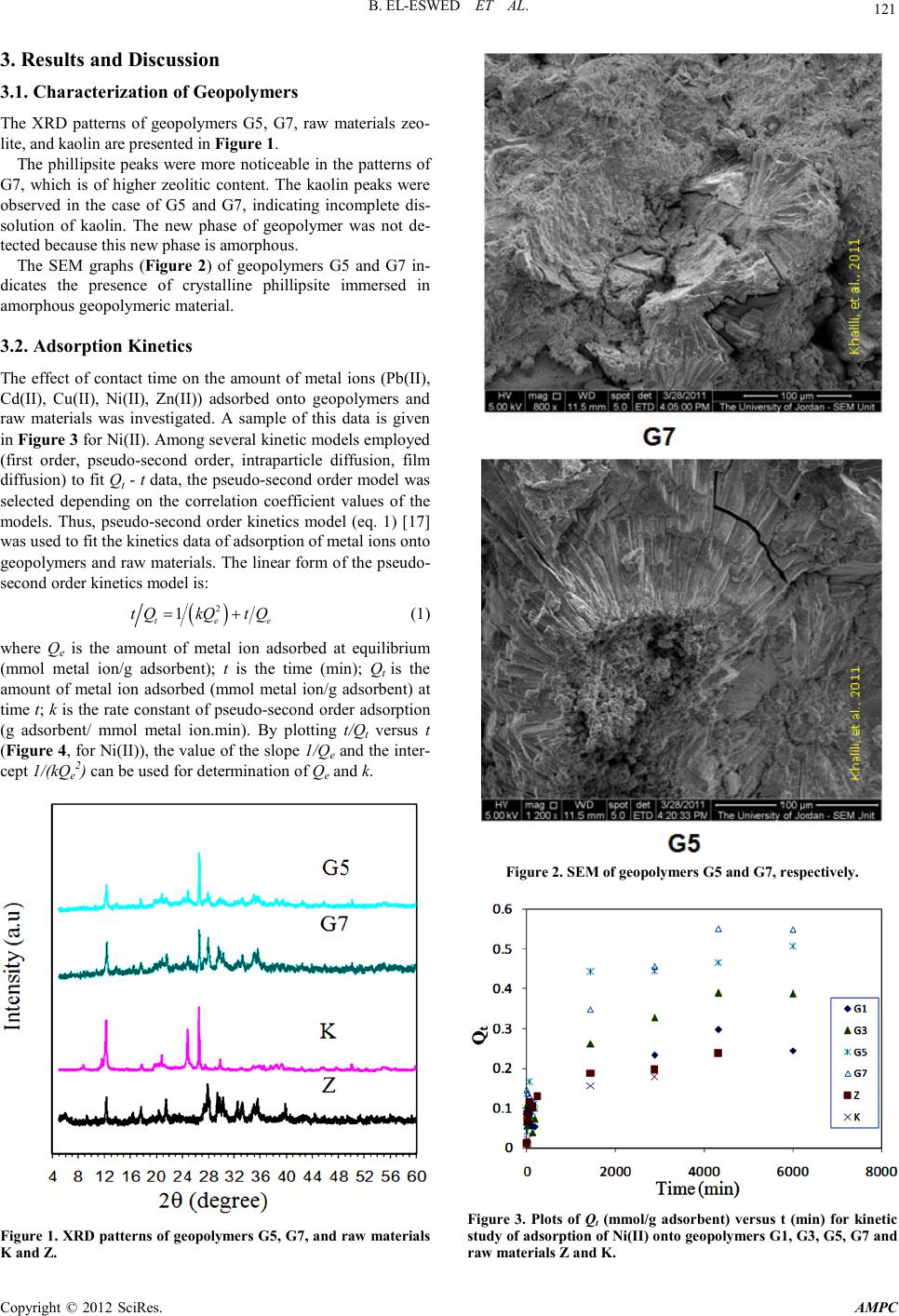

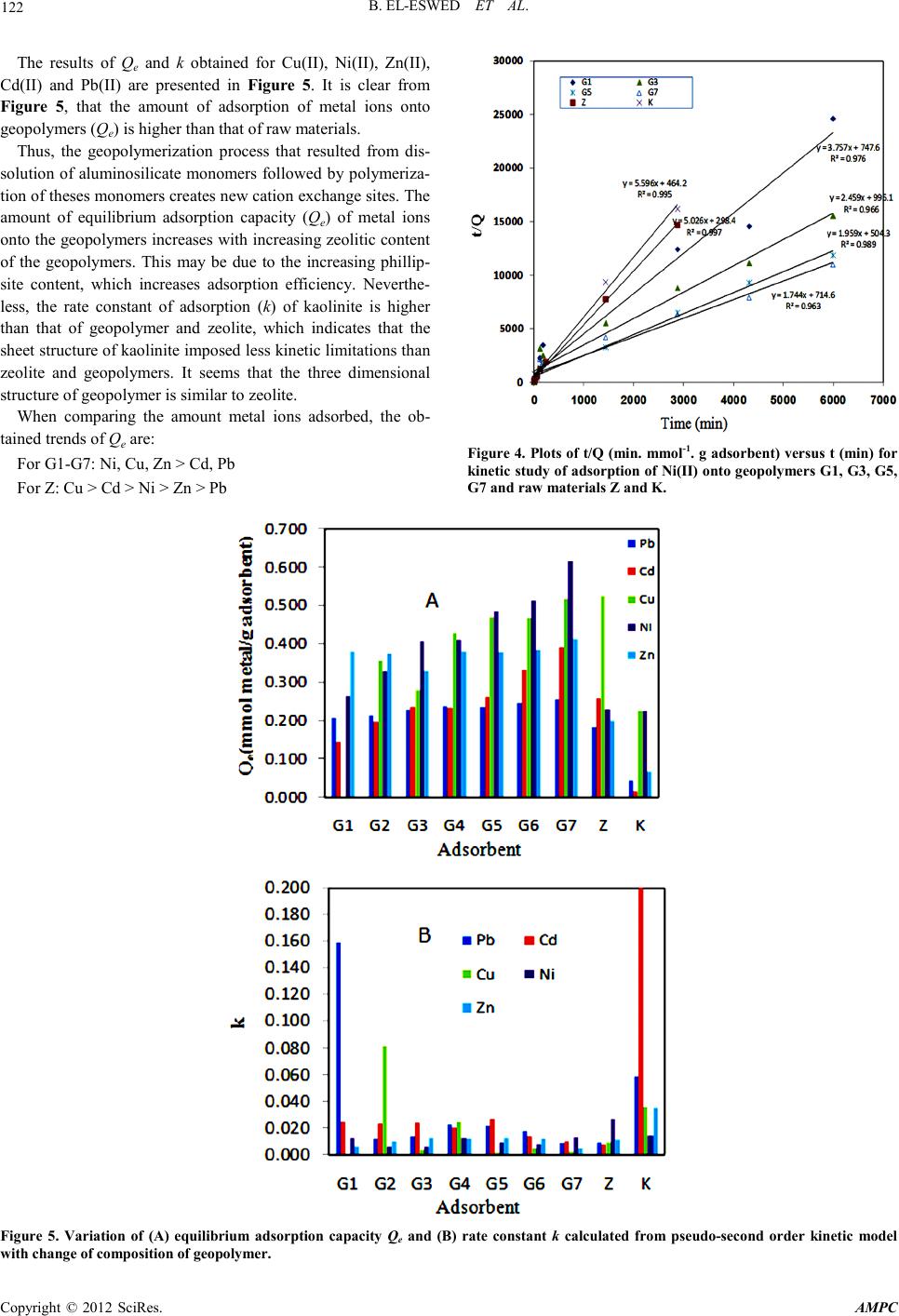

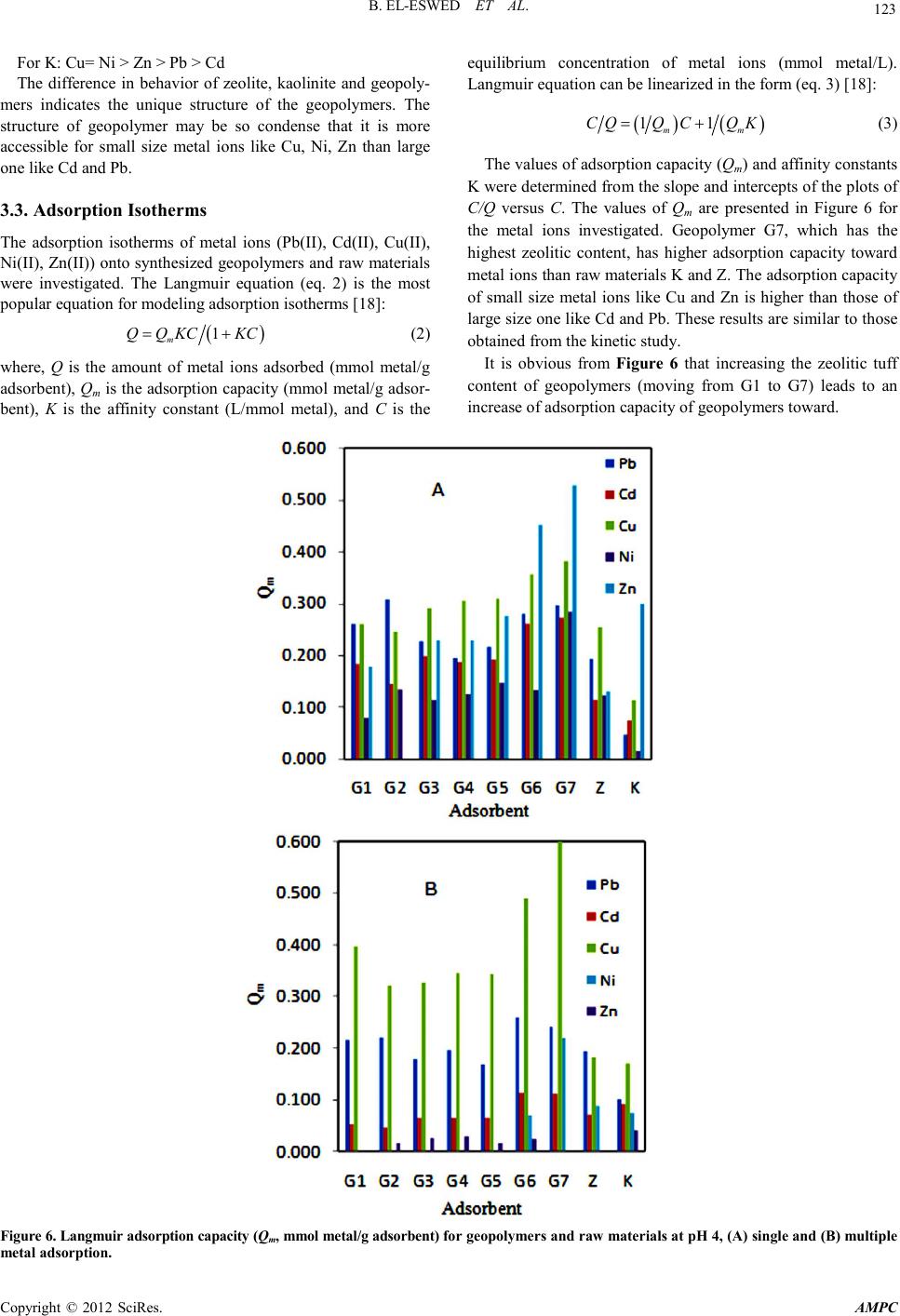

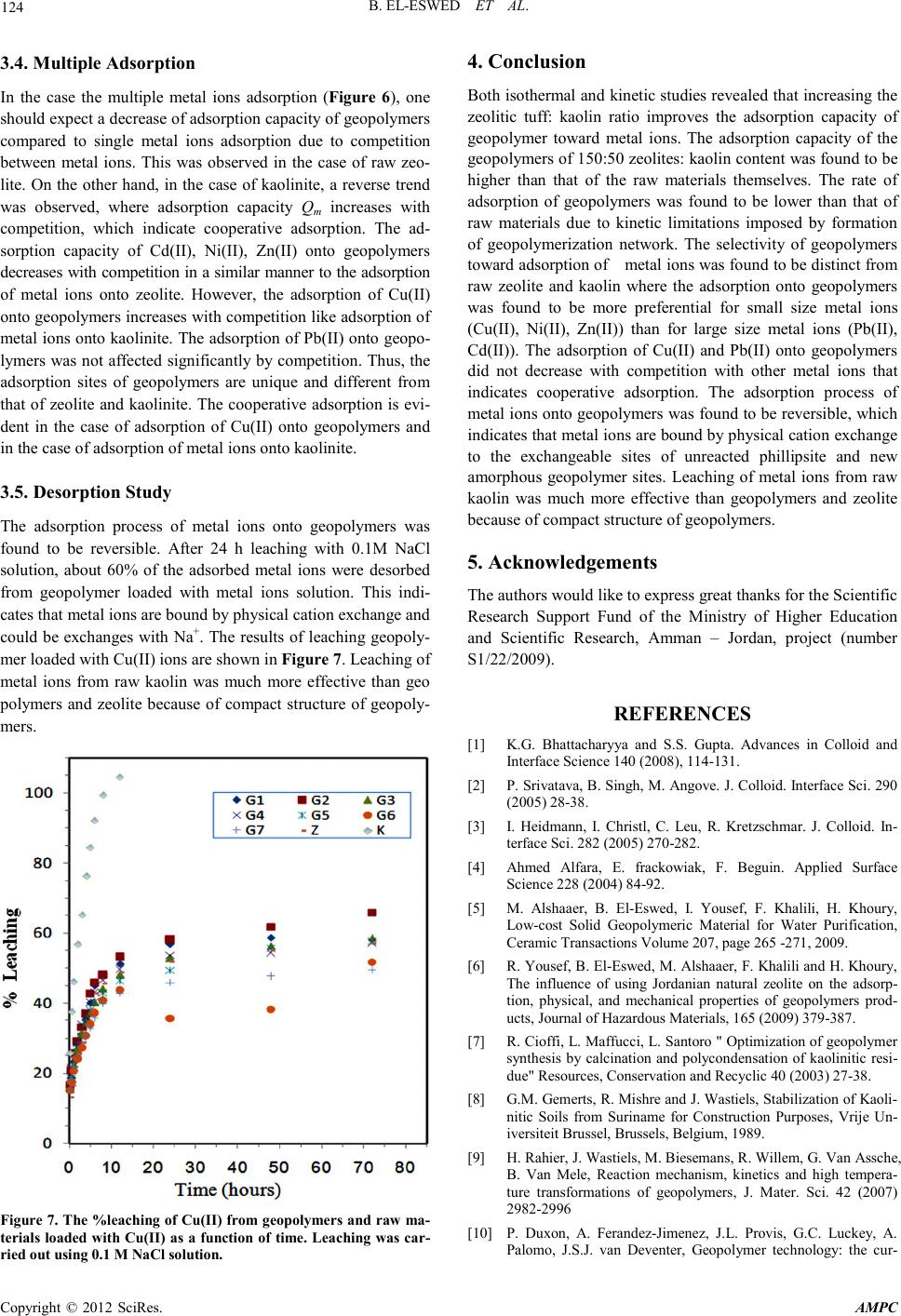

Advances in Ma terials Physics and Che mist ry, 2012, 2, 119-125 doi:10.4236/ampc.2012.24B032 Published Online December 2012 (http://www.SciRP.org/journal/ampc) Copyright © 2012 SciRes. AMPC Adsorption of Cu(II), Ni(II), Zn(II), Cd(II) and Pb(II) onto Kaolin/Zeolite Based- Geopolymers Bassam El-Esw ed1, Mazen Alshaaer2, Rush di Ibr ahim Yousef3, Imad Hamadneh4, Fawwaz Khalili4 1Zarka University College, Al-Balqa Applied University, Zarka, Jordan 2Deanship of Academic Research, Uni vers ity of Jordan, Amma n, Jordan 3Chemistry Department, Faculty of Science, Preparatory Year Program, King Faisal University, Al-Ahsaa, Saudi Arabia 4Department of Chemistry, Faculty of Sciences, University of Jordan, Amman, Jordan. Email: bassameleswed@yahoo.com, bassameswed@bau.edu.jo, mazen72@yahoo.com, rushdiy@hotmail.com, i.hamadneh@ju.edu.jo, fkhalili@ju.edu.jo Received 2012 ABSTRACT This work deals with geopolymers based on local Jordanian resources, namely, kaolin and zeoltitic (phillipsite) tuff. The geopoly- mers were prepared from these two materials by a reaction with an alkali solution at 80ºC. The research group of the present work has demonstrated in previous work that addition of zeolitic tuff to kaolin based-geopolymers increases the adsorption capaci ty toward Cu(II) metal io n compared to zeolite-free geop olymers, while ret aining high mechanical strength. The ai m of the p resent work is to extend our work and to study the effect of changing geopolymers components (zeolitic tuff and kaolin) on their adsorption properties toward Cu(II), Ni(II), Zn(II), Cd(II) and Pb(II) metal ions. Both isothermal and kinetic studies revealed that increasing the zeolitic tuff: kaolin ratio improves the adsorption capacity of geopolymer toward metal ions. The adsorption capacity of the geopolymers of 150: 50 zeolites: kaolin content was found to be higher than that of the raw materials themselves. The rate of adsorption of geopoly- mers was fou nd to be lower than that of raw materials due to kinetic limitations imposed by the formation of geopolymerization net- work. The selectivity of geopolymers toward adsorption of metal ions was found to be distinct from raw zeolite and kaolin where the adsorption onto geopolymers was found to be more preferential for small size metal ions (Cu(II), Ni(II), Zn(II)) than for large size metal ions (Pb(II), Cd(II)). The adsorption of Cu(II) and Pb(II) onto geopolymers did not decrease with competition with other metal io ns, which indi cates cooperative adsorption. The adsorption process of metal ions onto geopolymers was found to be reversi- ble that indicates that metal ions are bound by physical cation exchange to the exchangeable sites of unreacted phillipsite and new amorphous geopolymer sites. Leaching of metal ions from raw kaolin was much more effective than geopolymers and zeolite be- cause of compact structur e of geopo lymers. Keywords: Geopolymers; Kaoli n; Zeolitic Tuff; Adsorption; Heavy Metal Io ns 1. Introduction Several methods h ave evolved o ver the years on the removal of heavy metal ions present in industrial wastewaters and soils. These are chemical precipitations, conventional coagulation, reverse osmosis, ion exchange, and adsorption. Out of these methods, adsorption appears to be the most widely used for the removal of heavy metals [1]. Substances like kaolin and zeo- lites have assumed a wid e application i n this regard [2-4]. This work deals with geopolymers based on local Jordanian resources, namely, kaolin and zeoltitic (phillipsite) tuff. The geopolymers were prepared previously from 1:1 mass ratio of these two materials b y a reaction with an alkali solution at 80ºC. The research group of the present work has demonstrated in previous work that addition of zeolitic tuff to kaolin based- geopolymers increases the adsorption capacity toward Cu(II) metal ions compared to zeolite-free geopolymers, while retain- ing high mechanical strength [5,6]. These geoplymers can be used as construction materials for water treatment, storage and transportation. The process used in the present work is of much lower cost than the most popular metakaolin based geopoly- mers which, involves calcination of kaolin at 600ºC which re- quires large amounts of energy and complete dissolution of metakolin which r equir es large amount of base [7]. The exact mechanism of the geopolymerization is not known precisely. It was suggested that Na+ or K+ from alkaline solu- tion to exchange the hydrogen ions on the broken edges of the clay. Because of this ion exchange, repulsion between the Na+ ions will dissolute some clay particles [8]. The breakdown of the solid aluminosilicate into smaller ‘monomers’ where Al is already tetrahedrally coordinated is followed by polycondensa- tion of these monomers into the geopolymer [9,10]. Because o f these reactions, solid, hard, and stable materials with hydrox- ysodali te, feldspatiod, or zeolit e like structure are formed [11]. When aluminum is four coordinated to oxygen atoms, a neg- ative charge is created and therefore the presence of cations such as Na+ is essential to maintain electric neutrality in the geopolymeric matrix (hydroxysodalite). Hydroxysodalite, which ranges fro m amorphous to microcr ystalline materi al, consists o f SiO4 and AlO4 tetrahedral linked alternately by sharing all the oxygen atoms [11]. Positive ions (Na+, K+, Li+, Ca2+, Ba2+, NH4+, and H3O+) must be present in the framework cavities to balan ce the negative charge of Al in the fo ur-fold coordination.  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 120 Little work was found in the literature on the adsorption be- havior of geopolymers. Li et al. [12] studied the adsorption of methylene blue (MB) dye onto geopolymeric adsorbent based on fly ash. The synthesized geopolymer was found to have much higher adsorption capacity towards MB (0.12 mmol MB/g adsorbent) than fly ash itself (5.6 x 10-3 mmol MB/g adsorbent). Wan g et al. [13] reported an amorphous aluminosi- licate geopolymer resulting from solid-state conversion of fly ash. The synthesized geopolymer was found to have a higher adsorption capacity towards Cu2+ ion (1.4 mmol Cu/g adsorbent) than the fly ash it self (1.6x10-3 mmol Cu/g adsorbent). A Geopolymer of Jordanian kaolin and zeolitic tuff prepared by the research group of the present article was found in previous works to have adsorption capacity of 8.06 mmol MB/g adsor- bent and 0.83 mmol Cu/ g adsorbent [6] and 0.36 mmol Pb/ g adsorbent (at pH 6) [14]. Cheng et al. [15] demonstrates that at pH 4, the adsorption capacity of meta-kaolin based geopolymer toward Pb(II), Cu(II), Cr(III) and Cd(II) was 0.71, 0.77, 0.38, 0.60 mmol/g adsorbent. The aim of the present work is to ex- tend previous studies and to study different kaolin: zeolitic tuff geopolymeric samples in order determine the best ratio of the geopolymer that gives the highest adsorption capacity toward Cu(II), Ni(II), Zn(II), Cd(II) and Pb(II). The main concern is determining the optimum zeolitic content in the geopolymer that will provide a material with high efficiency for water puri- fication. 2. Materials and Methods 2.1. Materials Preparation and characterization of Jordanian kaolinite and zeo- litic (phillipsite) tuff were discussed in our previous works [6,14, 16]. 2.2. Fabrication of Geopolymeric Samples Seven geopolymeric samples with different zeolitic content were prepared from kaolinitic Jordanian soil (K), functional reactive filler (zeolitic tuff, Z), and alkali solution as shown in Table 1. The zeolitic tuff and kaolinitic soil were mixed in different ratios (Table 1), and then the sodium hydroxide solution was Table 1. Composition of synthesized geopolymers in grams. Geopolymer K Z NaOH Water G1 200 0 14 44 G2 175 25 14 40 G3 150 50 14 36 G4 125 75 14 32 G5 100 100 14 28 G6 75 125 14 24 G7 50 150 14 20 added. After mixing, a semi-dry mixture was formed. After molding, compacting, curing at 80ºC, the samples were ground and sieved into aggregate size between 250-500 μm. Then the product was washed with excess amount of distilled water (to remove unr e ac te d a lk a li) , dr ied a t 100ºC a nd k e pt i n a de s ic cator. 2.3. Characterization of Geopolymers XRD pattern and SEM pictures were obtained for geopoply- mers G5 and G7 in order to determine the fate of kaolinite and phillipsite in the geopolymers sample. 2.4. Kinetics of A dsorption of Meta l Ions onto Geopolymers and Raw Materials A 0.5000 g sample of geopolymers (G1-G7) and raw materials (Z and K) were independently placed in a 500 mL-conical flas k, to which 250 mL of 100 ppm of a standard solution of a metal ion (Cu(II), Ni(II), Zn(II), Cd(II), Pb(II)) prepared in 0.1 M NaCl was added . The solution was adjusted to pH 4 and sha- ken in the shaker water bath at 25°C and 320 rpm. A 1.0 mL sample of the solution was withdrawn at different contact times (0 - 72 h) and diluted to 5 mL with distilled water, then filtered by microfilter and centrifuged. The concentrations of metal ions were measured using the atomic absorption spectrometer (Va- ria n, AA-250 plus). 2.5. Adsorption Isotherms of Metal Ions onto Geopolymers and Raw Materials Adsorption of single metal ions: Standard solutions (10–100 ppm) of metal (Cu (II), Ni(II), Zn(II), Cd(II, Pb(II)) in 0.1M NaCl at pH 4 were prepared (pH adjustment using NaOH/HCl). Conical flasks were filled with 50 ml of the prepared standard solutions of metal ions and 0.05 g of geopolymer (G1- G7) or raw materials (K, Z). A 10.0 mL portions from each conical flask were withdrawn after 24 h of shaking in water bath at 25ºC and 320 rpm and filtered by microfilters (0.45μm Nylon). The concentrations of metal ions were determined using the atomic absorption spect rometer. Adsorption of multiple metal ions: The same procedure above was followed, but using standards prepared from combi- nation of metal ions (Cu(II), Ni(II), Zn(II), Cd(II, Pb(II)). Analysis using atomic absorption was made for the four ele- ments in each sample. 2.6. Desorption of Metal Ions A 0.5 g of geoplymers or raw materials was shaken with 250 mL of 1000-ppm solution of metal ions at pH 4 and 0.1 M NaCl ionic strength for 24 h. The solution was then filtered and dried in an o ven at 100 C. The solid was then leached with 250 mL of 0.1 M NaCl solution at different contact times ranging from 0.25-72 h, where 1.00 mL was pipetted at each time, and diluted to 5.00 ml and analyzed for metal ions concentration using atomic absorption spectrometer.  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 121 3. Results and Discussion 3.1. Characterization of Geopolymers The XRD patterns of geopolymers G5, G7, raw materials zeo- lite, and kaolin are presented in Fig ure 1. The phi llipsite peaks were more noticeable in the patt erns of G7, which is of higher zeolitic content. The kaolin peaks were observed in the case of G5 and G7, indicating incomplete dis- solution of kaolin. The new phase of geopolymer was not de- tected because this new phase is amorphous. The SEM graphs (Figure 2) of geopolymers G5 and G7 in- dicates the presence of crystalline phillipsite immersed in amorphous geopolymeric material. 3.2. Adsorption K i ne tics The effect of contact time on the amount of metal ions (Pb(II), Cd(II), Cu(II), Ni(II), Zn(II)) adsorbed onto geopolymers and raw materials was investigated. A sample of this data is given in Fi gure 3 for Ni(II). Among several kinetic models employed (first order, pseudo-second order, intraparticle diffusion, film diffusion) to fit Qt - t data, the pseudo-second order mod el was selected depending on the correlation coefficient values of the models. Thus, pseudo-second order kinetics model (eq. 1) [17] was used to fit the kinetics data of adsorption of metal ions onto geopo lymers and raw mat erials. Th e linear for m of the pseu do- second order kinetics model is: ( ) 2 1 t ee tQkQt Q= + (1) where Qe is the amount of metal ion adsorbed at equilibrium (mmol metal ion/g adsorbent); t is the time (min); Qt is the amount of metal ion adsorbed (mmol metal ion/g adsorbent) at time t; k is the rate constant of pseudo-second order adsorption (g adsorbent/ mmol metal ion.min). By plotting t/Qt versus t (Figure 4, for Ni(II)), the value of the slope 1/Qe and the i nter- cept 1/(kQe2) can be used for determination of Qe and k. Figure 1. XRD patterns of geopolymers G5, G7, and raw materials K and Z. Figure 2. SEM of geopolymers G5 and G7, respectively. Figure 3. Plots of Qt (mmol/g adsorbent) versus t (min) for kinetic study of adsorption of Ni(II) onto geopolymers G1, G3, G5, G7 and raw materials Z and K.  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 122 The results of Qe and k obtained for Cu(II), Ni(II), Zn(II), Cd(II) and Pb(II) are presented in Figure 5. It is clear from Figure 5, that the amount of adsorption of metal ions onto geopolymers (Qe) is higher than that of raw mater ials. Thus, the geopolymerization process that resulted from dis- solution of aluminosilicate monomers followed by polymeriza- tion o f theses mon o mers creates new cat io n exch ange si tes. The amount of equilibrium adsorption capacity (Qe) of metal ions onto t he geopolymers i ncreases with increasin g zeolitic content of the geopolymers. This may be due to the increasing phillip- site content, which increases adsorption efficiency. Neverthe- less, the rate constant of adsorption (k) of kaolinite is higher than that of geopolymer and zeolite, which indicates that the sheet structure of kaolinite imposed less kinetic limitations than zeolite and geopolymers. It seems that the three dimensional struct ure of geopolymer is similar to zeolite. When comparing the amount metal ions adsorbed, the ob- tained trends of Qe are: For G1-G7: Ni, Cu, Zn > Cd, Pb For Z : Cu > Cd > Ni > Zn > Pb Figure 4. Plots of t/Q (mi n. m mol -1. g adsorbent) vers us t (min) for kinetic study of adsorption of Ni(II) onto geopolymers G1, G3, G5, G7 and raw materials Z and K. Figure 5. Variation of (A) equilibrium adsorption capacity Qe and (B) rate constant k calculated from pseudo-second order kinetic model with ch a nge of c ompos ition of geopolym er.  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 123 For K: Cu= Ni > Zn > Pb > Cd The difference in behavior of zeolite, kaolinite and geopoly- mers indicates the unique structure of the geopolymers. The structure of geopolymer may be so condense that it is more accessible for small size metal ions like Cu, Ni, Zn than large one like Cd and Pb. 3.3. Adsorption Isotherms The adsorption isotherms of metal ions (Pb(II), Cd(II), Cu(II), Ni(II), Zn(II)) onto synthesized geopolymers and raw materials were investigated. The Langmuir equation (eq. 2) is the most popular equation for modeling adsorption isotherms [18]: ( ) 1 m QQ KCKC= + (2) where, Q is the amount of metal ions adsorbed (mmol metal/g adsorbent), Qm is the adsorption capacity (mmol metal/g adso r- bent), K is the affinity constant (L/mmol metal), and C is the equilibrium concentration of metal ions (mmol metal/L). Langmuir equation can be linearized in the form (eq. 3) [18]: ( )() 11 mm CQQCQK= + (3) The values o f adsorp tion capacit y (Qm) and affinity constants K were determined from the slope and intercepts of the plots of C/Q versus C. The values of Qm are presented in Figure 6 for the metal ions investigated. Geopolymer G7, which has the highest zeolitic content, has higher adsorption capacity toward metal io ns than r aw materials K and Z. The adso rption capaci ty of small size metal ions like Cu and Zn is higher than those of large siz e one li ke Cd and Pb. These r esults ar e simil ar to those obtained from the kinetic study. It is obvious from Figure 6 that increasing the zeolitic tuff content of geopolymers (moving from G1 to G7) leads to an increase of adsorption capacity of geo polymers to w ar d. Figure 6. Langmuir adsorption capacity (Qm, mmol metal/g adsorbent) for geopolymers and raw materials at pH 4, (A) single and (B) multiple metal adsorption.  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 124 3.4. Mult iple Adsorption In the case the multiple metal ions adsorption (Figure 6), one shou ld exp ect a d ecrease o f adso rpt ion capaci ty of geopolymers compared to single metal ions adsorption due to competition between metal ions. This was observed in the case of raw zeo- lite. On the other hand, in the case of kaolinite, a reverse trend was observed, where adsorption capacity Qm increases with competition, which indicate cooperative adsorption. The ad- sorption capacity of Cd(II), Ni(II), Zn(II) onto geopolymers decreases with competition in a similar manner to the adsorption of metal ions onto zeolite. However, the adsorption of Cu(II) onto geopolymers increases with competition like adsorption of metal ions onto kaolinite. The adsorption of Pb(II) onto geopo- lymers was no t affected significantly by competition. Thus, the adsorption sites of geopolymers are unique and different from that o f zeo lite and kaolinite. The cooperative adsorption is evi- dent in the case of adsorption of Cu(II) onto geopolymers and in the case of adsorption of metal ions onto kaolinite. 3.5. Desorption Study The adsorption process of metal ions onto geopolymers was found to be reversible. After 24 h leaching with 0.1M NaCl solution, about 60% of the adsorbed metal ions were desorbed from geopolymer loaded with metal ions solution. This indi- cates that metal ions ar e bound by physical cation exchange and could be exchanges with Na+. The results of leaching geopoly- mer loaded with Cu(II) ions are shown in Figure 7. Leaching of metal ions from raw kaolin was much more effective than geo polymers and zeolite because of compact structure of geopoly- mers. Fig ure 7. The %lea ching of Cu(II) from geopolymers and raw ma- terials loaded with Cu(II) as a function of time. Leaching was car- ried out using 0.1 M NaCl solution. 4. Conclusion Both isothermal and kinetic stu dies revealed th at increasin g the zeolitic tuff: kaolin ratio improves the adsorption capacity of geopolymer toward metal ions. The adsorption capacity of the geopolymers of 150:50 zeolites: kaolin content was found to be higher than that of the raw materials themselves. The rate of adsorption of geopolymers was found to be lower than that of raw materials due to kinetic limitations imposed by formation of geopolymerization network. The selectivity of geopolymers toward adsorption of metal ions was found to be distinct from raw zeolite and kaolin where the adsorption onto geopolymers was found to be more preferential for small size metal ions (Cu(II), Ni(II), Zn(II)) than for large size metal ions (Pb(II), Cd(II)). The adsorption of Cu(II) and Pb(II) onto geopolymers did not decrease with competition with other metal ions that indicates cooperative adsorption. The adsorption process of metal ions onto geopolymers was found to be reversible, whi ch ind icates that metal io ns are bound by physical cat ion exchange to the exchangeable sites of unreacted phillipsite and new amorphous geopolymer sites. Leaching of metal ions from raw kaolin was much more effective than geopolymers and zeolite because of compact structure of geopolymers. 5. Acknowledgements The authors would like to express great thanks for the Scientific Research Support Fund of the Ministry of Higher Education and Scientific Research, Amman – Jordan, project (number S1/22/2009). REFERENCES [1] K.G. Bhattacharyya and S.S. Gupta. Advances in Colloid and Interface Science 140 (2008), 114 -131. [2] P. Srivatava, B. Sin gh, M. Angove. J. Colloi d. Interf ace Sc i. 290 (2005) 28-38. [3] I. Heidmann, I. Christl, C. Leu, R. Kretzschmar. J. Colloid. In- terfac e Sci. 282 ( 2005) 270-282. [4] Ahmed Alfara, E. frackowiak, F. Beguin. Applied Surface Science 228 (200 4 ) 84-92. [5] M. Alshaaer, B. El-Eswed, I. Yousef, F. Khalili, H. Khoury, Low-cost Solid Geopolymeric Material for Water Purification, Ceramic Transactions V olume 207, page 2 65 -271, 2009. [6] R . Yousef, B. El-Eswed, M. Alshaaer, F. Khalili and H. Khoury, The influence of using Jordanian natural zeolite on the adsorp- tion, physical, and mechanical properties of geopolymers prod- ucts, J ourna l of Haza rdous Materials, 165 (2009) 379-387. [7] R. Cioffi, L. Maffuc ci, L. Santoro " Op timizati on of geopolymer synthesis by calcination and polycondensation of kaolinitic resi- due" Resourc es , Conserva tion and Rec yclic 40 (2003) 27-38. [8] G.M . Gem erts , R. Mish re and J. Wast iels, St abi liza tion of Kaoli- nitic Soils from Suriname for Construction Purposes, Vrije Un- iversiteit Brussel, Brussels, Belgium, 1989. [9] H. Rahier, J. Wastiels, M. Bi es ema n s, R . Wi llem, G. V an Assche, B. Van Mele, Reaction mechanism, kinetics and high tempera- ture transformations of geopolymers, J. Mater. Sci. 42 (2007) 2982-2996 [10] P. Duxon, A. Ferandez-Jimenez, J.L. Provis, G.C. Luckey, A. Palomo, J.S.J. van Deventer, Geopolymer technology: the cur-  B. EL-ESWED ET AL. Copyright © 2012 SciRes. AMPC 125 rent state of the art, Mater. Sci. 42 (2007) 2917 -2933. [11] M. Alshaaer, Stabilization of kaolinitic soil from Jordan for construction purposes, M. Sc. thesis, Vrije Universiteit Brussel, Brus sels, Belgi um, 2000. [12] L. Li, S. Wang, Z. Zhu, Geopolymeric adsorbents from fly ash for dye removal from aquous solution, J. Colloid Interface Sci. 300 (2 0 0 6) 52-59. [13] S. Wang, L. Li, Z.H. Zhu, Solid-state conversion of fly ash to effective adsorbents for Cu removal from wastewater, J. Hazrd. Mater. B 139 (2007) 254-259. [14] Bassam El- Eswed, Rushdi I. Yousef, Mazen Alshaaer, Fawwaz Khali li, Hani Khoury "Alkali solid-state conversion of kaolin and zeolite to effective adsorbents for removal of lead from aqueous solution" Desalination and Water Tre atment , 8 (2009) 124–130. [15] T. W. Cheng, M. L. Lee, M.S. Ko, T.H. Ueng, S. F. Yeng. Ap- plied Clay Science 56 (2012) 90-96. [16] Rushdi I. Yousef, Bassam El-Eswed,, Mazen Alshaaer, Fawwaz Khalili, Hubert Rahier. Degree of reactivity of two kaolinitic minerals in alkali solution using zeolitic tuff or silica sand filler Ceramics Internation al, In Press, Corrected Proof, 2012. [17] Y. Ho "Ps eudo-isotherms using a second order kinetic expression constant" Adsorption 10, 151-158, 2004. [18] Shaw, D. J. "Introduction to Colloid and Surface Chemistry". (chapter 5). Butterworth –Heinemann , Oxford (1992) |