Paper Menu >>

Journal Menu >>

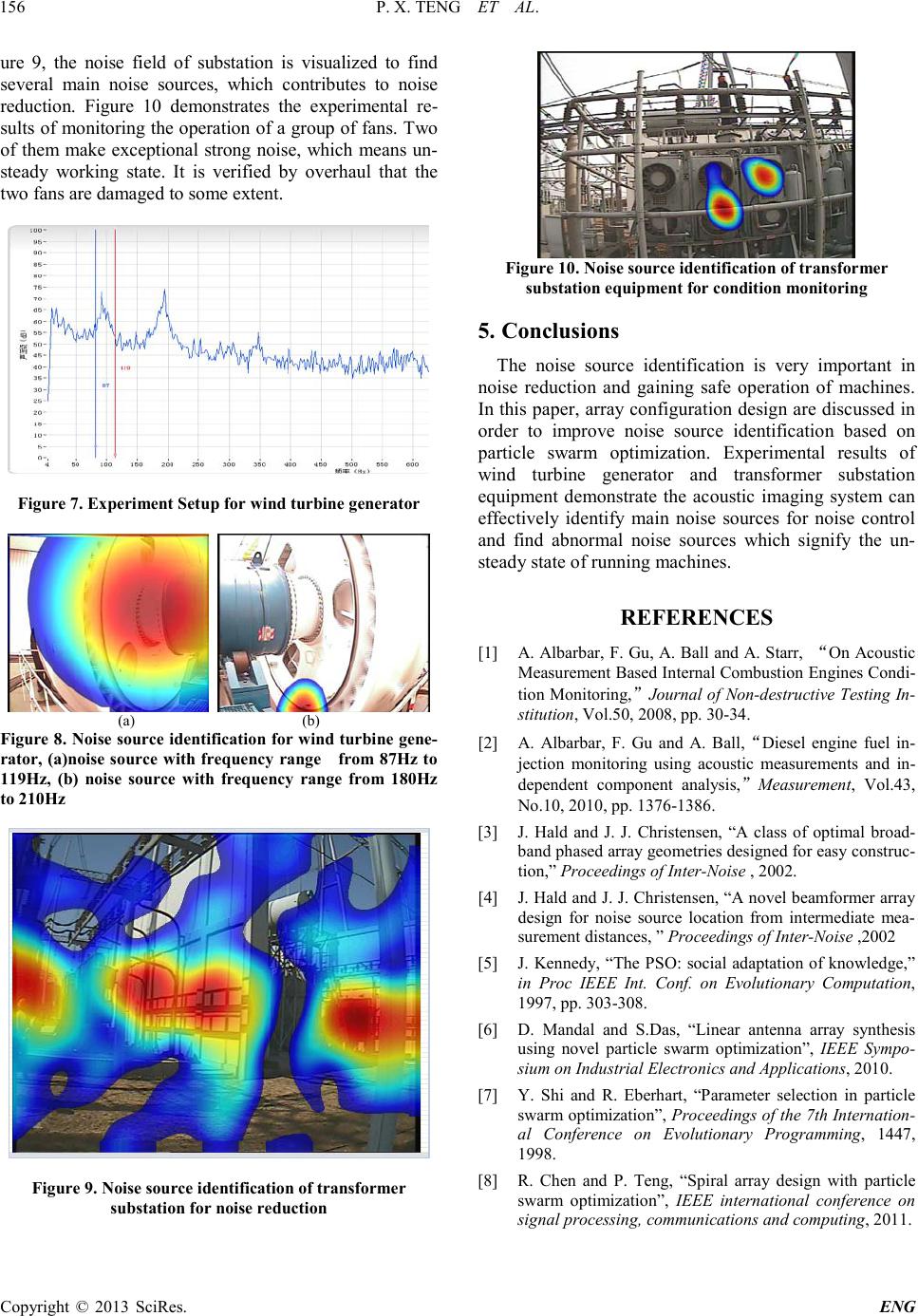

Engineering, 2013, 5, 152-156 doi:10.4236/eng.2013.51b028 Published Online January 2013 (http://www.SciRP.org/journal/eng) Copyright © 2013 SciRes. ENG Noise Source Identification Applied in Electric Power Industry Using Microphone Arrays Pengxiao Teng, Rilin Chen, Yichun Yang Key Laboratory of Noise and Vibration Research, Chinese Acad emy of Scie nces, Beijing, China Email: px.teng@mail.ioa.ac.cn Received 2013 Abstract The noise source identification is an i mportant issue in noise reductio n and co ndition monitoring(CM) for machines in- site using microphone arrays. In this paper, we propose a new approach to optimize array configuration based on par- ticles swarm optimization algor ith m in order to improve noise source identification and condition monitoring perfor- mance. T wo distinct opti mized array configuratio ns are designed under the certain conditions. Furthermore, an aco ustic imagi ng equi pment is d eveloped to carry out experiments on transformer subs tation equipment and wind turbine gene- rator, which d e monstrate t hat the ac ous tic i ma gi ng s yst e m a llo ws a high resolutio n in id ent ifyi ng main no ise sour ces fo r noise reduction and abnormal noise sources for condition mo nitorin g. Keywords: Noise Source Identification; Condition Monitoring; Noise Reduction; Microphone Arra y; Particle Swarm Op- timization 1. Introduction As noise reduction and condition monitoring has gained in importance to modern industries, noise source identi- fication has become the focus of a wide variety of re- search approaches in recent years. In the application of noise reduction on transformer substation or electric equipments, noise source identification is a prerequisite, which facilitates to find out main noise sources from mixed noise field. In addition, the desired noise source can be extracted among mixed sources and acoustic cha- racteristics can be analyzed to find solutions to noise control. In compar ison with the mainstr eam tec hnique o f vibration based monitoring, acoustic CMhas the po tentia l to become a generic approach because it has a number of unique features such as generality of acoustic signals in the majority of machines, the richness of information included in acoustic signals and simplicity in sensor placement and hence in CM practice. Although there has been considerable progress in sin- gle-channel acoustic CM in recent years[1,2], acoustic signals are, however, often adversely influenced by their measurement environment and by the range of different acoustic sources within a typical monitoring location. This can make it very difficult to extra ct useful informa- tion for condition monitoring purposes. Recent advances in microphone array technology offer great potential to overcome this problem. Utilizing microphone array technology, an acoustic camera has been invented to vi- sualize sound field which allows to identify main emit- ting sources. The performance of visualization or locali- zation is significantly affected by the microphone array configuration[3]. The microphone array configuration design is the most crucial p arameter to affect localiza tion performance characterized b y the array beampattern. It is reasonable to optimize array configuration to form the desirable beampattern with narrow mainlobe width (MLW) and low sidelobe level (SLL) [4] which is in agreement with high spatial resolution and strong capa- bility of interference rejection, respectively. In array configuration optimization, heuristic methods like genetic algorithm (GA) and particle swarm optimi- zation (PSO)[5,6] are employed due to nonlinear objec- tive functions and constraint conditions. Although GA method pe rfor ms well i n sea rch o f solut io ns in the glob al space, it is inferior to PSO in finding precise optimal solutions. Particle swarm optimization was initially pro- posed by Kenney and Eberhart in studying social beha- vior o f bird flo cking a nd fish school ing in t heir sea rch of food. Particle swarm optimization iteratively updates parameters to converge according to the best individual solution and the best swarm solution. Therefore, it is intuitive for array configuration optimization, and fur- thermore PSO method is much easier to implement. In this paper, we propose a modified PSO method to op- timize an array configuration, which alternatively inves- tigates MLW and SLL.  P. X. TENG ET AL. Copyright © 2013 SciRes. ENG 153 This paper is organize as follows. In Sect.2, we give the array configuration model. A modified PSO method is proposed to optimize two distinct array configuration in Sect.3. We develop an acoustic imaging system and carry out experiments in Sect.4 and the conclusion are drawn in Sect. 5. 2. Array Model As is known that the noise so urce identification is hig hly related to the array beampattern, the beampattern formu- la is given for the designed array, and then an modified PSO method is proposed to optimize array configuration both according to MLW and SLL in thi s s ectio n. 2.1. Planar Array Model Figure 1 . Planar array model Spiral arrays are widely used due to the merit of low sidelobe. We optimize an array configuration based on spiral structure. Assume that a source signal propagates from the direction (,) θϕ and the coordinate of micro- phone m p is [ cos,sin] mmm m rr φφ . The time delay of m th micr ophone is represented as: ( )() cossin cossinsin sin m mm r m c τφθϕ φθϕ = + (1) Usin g Eqatio n (1) , one may obtain the beampattern as: ( ) 1 cossin cos ,exp sinsin sin Mm m m mm r B wj c φ θϕ ω θϕ φ θϕ = =+ ∑ (2) 2.2. 3D Array Model Considering practical applications in imaging large machine acou stically in a reve rb era nt ind ustrial pla nt, we design a 3D microphone array with 8 arms at which 8 microphones are installed. An eight-arm 3D microphone array is illustrated in Figure 2. The angle between the lth arm and z axis is denoted as ( ) ,1, 2,, l lL ϑ = and the angle between the projection of the lth arm on the xoy plane and x axis is ( ) ,1, 2,, l lL φ =. The time delay of l m th microphone at lth arm is represented by Eqation (3), where ( ) ,1, 2,,;1, 2,, l lm ll rl LmM= = is de- fined as the distance from the ml th microphone to the coordinate origin. Ml is the number of microphone at lth arm and c is sound velocity. Using Eqa tio n (3) , one may obtain the beampattern by Euq ation (4), where ω is the signal frequency and l lm w is the weight. Without loss of ge nerality, all weights are set to one. The MLW is defined as Θ which is the angular inter- val of the first pair nulls of ( ) |, |B θϕ for a given ϕ and the sid elob e level is represented as: ( ) ( ) 10 max SSL , 20log , B B θϕ θϕ ∉Θ = (5) where ∉Θ means sidelobe which is the angular interval outside the mainlobe. Based on the narrow MLW and low SLL criterion, an array configuration can be opti- mized by ( ) ( ) 1 minmax 0 max0 1 0 min {MLW,max{SLL}} .. , 1 1,1, 0. ll ll l lM lml l l ll m st rrrr r rrrMmr l LmMr + = = +≤≤−−− ≤≤≤≤> , , (6) where 1 min l l rr= and max l lM rr= , with [ min r ,max r ] being the distance interva l within which microp hones are deployed. We also constrain the distance between two adjacent microphones is larger than 0 r . I n this p a p er, we employ PSO method to implement the optimization. ( )() ,sincossin cossinsinsin sincoscos l lm llllll r lm c τϑφθϕ ϑφθϕϑθ = ++ (3) ( )() 11 ,expsincossin cossinsinsin sincoscos l l l l Llm lm lllll l M m r B wj c ω θϕϑφθϕ ϑφθϕϑθ = = = ++ ∑∑ (4)  P. X. TENG ET AL. Copyright © 2013 SciRes. ENG 154 Figure 2. 3D array model 3. Modified Particle Swarm Optimization The aim of employing PSO method to implement equa- tion (6) is to exploit possible microphone positions in order to find a set of optimal position which obtains both narrow MLW and low SLL. Consider a swarm with N particles, each of which represents an array configu- ration. [ ] T 12 ,, nN =Xxxx x (7) where each particle can be denoted as 12 [, ,,] nn nndnD xx x x=x (8) where D is the dimension of optimization. We represent the best individual solut ion for each particle in the itera- tion process as: [ ] T 12 ,, nN =Pppp p (9) where 12 [, ,,] nn nndnD pp p p=p is the best indi- vidual solution for the nth particle, and the best swarm solution is represented as: 12 [, ,,] dD gg gg=g (10) With Equation(7)through (10), the particles are up- dated ac c ording to the following equations: () () 112 2 11 1 1 nd ndndnd ndnd nd tt tt d ttt nd w vcrpxcrgxv xxv −− − − =⋅+− +− = + (11) where 1 c and 2 c are two positive constants (typically 12 2 cc= = ), 1 r and 2 r are two random variables, and w is inertia weight. The t and 1t− represent newly updated variable and previous one, respectively. From Equation(11), we can see that the new velocity is deter- mined by three terms. The first term represents how much the previous velocity is kept. The second term re- lated to the distance between the best indi vidual so lutio n and its current one allows each particle to approach closely to best individual solution. Last term related to the distance between the best global swarm solution and its current one allows each particle to approach closely to best swarm solution. A large inertia weight w tends to explore global area while a small one tends to search local area. Shi[7]suggested a way to d etermine the inertia weight written in Equation(12) to make a balance in ex- ploring global and local area . max min maxt ww ww t T − = − (12) where max w and min ware maximum and minimum weight respectively, and T is the total iteration number, t is current iterat ion inde x. We p rop ose a modified PSO method to optimize array configuration based on MLW and SLL in an alternate way. B y establishin g a uppe r limit (,) ζθϕ for SLL and minimizing mainlobe width, Equation(4) can be rewrit- ten as ( ) ( ) 1 minmax 0 max0 1 0 min {MLW} . .max{SLL}(,) , 1 1,1, 0. ll ll l lM lml l l ll m st rrr r r rrrMmr l LmMr ζθϕ + ≤ = = +≤≤−−− ≤≤≤≤> , , (13) In order to implement optimization, a fitness value is designed to evaluate the updated particles. ( )( ) ( ) ( ) 0 , ,, lim F Bdd θπ θπ θϕξθϕδ θϕθϕ ∉Θ − = − ∫∫ (14) where the integral lower limit 0 θ is the first null of ( ) ,B θϕ outside the mainlobe and the integral upper limit lim θ is the angle boundary limit. [ ] 0,lim θθ is angle volume where we pay more attention to sidelobe. In Eq- uation(14), ( ) , δ θϕ is defined as: ( )( )( ) ( )() 1, ,, ,0, ,, B B θϕ ξθϕ δ θϕθϕ ξθϕ ∉Θ ∉Θ > =≤ (15) As a result, the modified PSO procedure can be summa- rized as follows:  P. X. TENG ET AL. Copyright © 2013 SciRes. ENG 155 STEP1. Initialize PSO parameters including the number of particle N , the optimization dimension D , particles X , best individual sol utio n P , and best global solution g , inertia weight min w , max w . Set a preliminary SLL and MLW 0 θ . STEP2. All particles are updated using Equation(9) through (10). STEP3. Calculate the fitness value using Equation (12) to evaluate new particles, and j udge if P and g are replaced by newly updated particles. STEP4. Judge if the fitness value is zero. If so, decrease the 0 θ in a small amount and go to step2, and then re- peat step2 through step 4. Otherwise, go to step5. STEP5. Judge if the iteration number reaches the maxi- mum T . If not, repeat step2 through step4. Otherwise, go to step6. STEP6. T erminate and obtain the final result g . In order to demonstrate the performance of optimized array, we calculate the beampattern of the optimized ar- ray configuration. Figure 3 shows the beampattern of the optimized planar array configuration. It can be seen that the optimized array configuratio n has low sidelobe which means better performance of noise source identification. In Figure 4, we compare the beampattern of optimized eight-ar m 3D array and uniform arra y which means that the microphon es are dist ributed even ly at each arm. Figure 3. Beampatt ern co mparison o f optimized planar spir al array configuration Figure 3. Beampat ter n o f opti m ized planar s pir al array configuration Figure 4. Beampat ter n comparison of optimized 3D eig ht-arm array configuration As shown in Figur e 4 inset, the beampattern of optimized array possesses narrower mainlobe and lower sidelobe, which means higher spatial resolution and better noise source identification within focused area. 4. Experimental results An acoustic imaging system is developed based on the two optimized array configuration illustrated in Figure 5. In this section, we employ the acoustic imaging system to identify noise sources and monitor electric power equipments. Figure 5. Acoustic imaging system Figure 6 shows the experiment setup for wind turbine generator and the spectrum of noise sources is displayed in Figure 7. Figure 6. Experiment Setup for wi nd turbine generator From Figure 7, it can be observed that there are distinct peaks within the frequency range fro m 87Hz to 119Hz and within the frequency range from 180Hz to 210Hz, respectively. The experimental results are illustrated in Figure 8 using the acoustic imaging system. Figure 8(a) shows the noise source emitted from the generator rotor which is kno wn. Ho wever , an unexpected noise is finally identified in Figure 8(b), which pinpoint the location where noise comes. Another example is shown for electric transformer substation equipments from Figure 9 to Figure10. In Fig- 050100 150 200 250 300 350 400 0 5 10 15 20 A ngle dB Uniform array Opt i m i zed array 177 179181 183 185 15 20  P. X. TENG ET AL. Copyright © 2013 SciRes. ENG 156 ure 9, the noise field of substation is visualized to find several main noise sources, which contributes to noise reduction. Figure 10 demonstrates the experimental re- sults of monitoring the operation of a group of fans. Two of them make exceptional strong noise, which means un- steady working state. It is verified by overhaul that the two fans ar e d amaged to some extent. Figure 7. Expe ri ment Setup for wi nd turbine generator (a) (b) Figure 8. Noise sourc e ident ificat ion for w ind turbi ne gene- rator, (a)noise source with frequency range from 87Hz to 119Hz, (b) noise source with frequency range from 180Hz to 210Hz Figure 9. Noise source identifi cat ion of transformer substation for noise reduction Figure 10. Noise source identif icat ion of transformer substation equi pme nt for co ndition monitoring 5. Conclusions The noise source identification is very important in noise reduction and gaining safe operation of machines. In this paper, array configuration design are discussed in order to improve noise source identification based on particle swarm optimization. Experimental results of wind turbine generator and transformer substation equipment demonstrate the acoustic imaging system can effectively identify main noise sources for noise control and find abnormal noise sources which signify the un- steady state of running machines. REFERENCES [1] A. Alb arbar, F. Gu, A. Ball and A. Starr, “On Acoustic Measurement Based Internal Combustion Engines Condi- tion Monitoring,”Journal o f Non-d estructive Testing In- stitution, Vol.50, 2008, pp. 30-34. [2] A. Albarbar, F. Gu and A. Ball,“Diesel engine fuel in- jection monitoring using acoustic measurements and in- dependent component analysis,”Measurement, Vol . 43, No.10, 20 10, pp. 1376-1386. [3] J. Hald and J. J. Christensen, “A class of optimal broad- band phased array geometr ies d es igned for eas y co ns tru c- tion,” Proceedings of Inter-Noise , 2002. [4] J. Hald and J. J . Christen sen, “A novel b eamformer arra y design for noise source location from intermediate mea- surement distan ces , ” Proceedings of Inter-Noise ,2002 [5] J. Kennedy, “The PSO: social adaptation of knowledge,” in Proc IEEE Int. Conf. on Evolutionary Computation, 1997, pp . 303-308. [6] D. Mandal and S.Das, “Linear antenna array synthesis using novel particle swarm optimization”, IEEE Sympo- sium on Industrial Electronics and Applications, 2010. [7] Y. Shi and R. Eberhart, “Parameter selection in particle swarm optimization”, Proceedings of the 7th Internation- al Conference on Evolutionary Programming, 1447, 1998. [8] R. Chen and P. Teng, “Spiral array design with particle swarm optimization”, IEEE international conference on signal processing, communications and computing, 2011. |