World Journal of Mechanics, 2012, 2, 297-310 doi:10.4236/wjm.2012.26036 Published Online December 2012 (http://www.SciRP.org/journal/wjm) Copyright © 2012 SciRes. WJM Free Vibration Analysis of Functionally Graded Beams with General Elastically End Constraints by DTM Nuttawit Wattanasakulpong1*, Variddhi Ungbhakorn2 1Department of Mechanical Engineering, Mahanakorn University of Technology, Bangkok, Thailand 2Department of Mechanical Engineering, Chulalongkorn University, Bangkok, Thailand Email: *nuttawit_mut@hotmail.com, v_ungbhakorn@yahoo.com Received August 24, 2012; revised September 25, 2012; accepted October 10, 2012 ABSTRACT The differential transformation method (DTM) is applied to investigate free vibration of functionally graded beams supported by arbitrary boundary conditions, including various types of elastically end constraints. The material proper- ties of functionally graded beams are assumed to obey the power law distribution. The main advantages of this method are known for its excellence in high accuracy with small computational expensiveness. The DTM also provides all natural frequencies and mode shapes without any frequency missing. Fundamental frequencies as well as their higher frequencies and mode shapes are presented. The significant aspects such as boundary conditions, values of translational and rotational spring constants and the material volume fraction index on the natural frequencies and mode shapes are discussed. For elastically end constraints, some available results of special cases for isotropic beams are used to validate the present results. The new frequency results and mode shapes of functionally graded beams resting on elastically end constraints are presented. Keywords: Functionally Graded Beams; Free Vibration; Natural Frequency; Mode Shape; Differential Transformation Method 1. Introduction A new class of composite materials, called functionally graded materials (FGMs), is considered in this paper. The potential uses of FGMs in engineering applications include aerospace structures, engine combustion cham- bers, fusion energy devices, engine parts and other engi- neering structures. In recent years, the static and dynamic analyses of functionally graded (FG) beams have in- creasingly attracted many researchers. Sankar [1] provided an elasticity solution based on Euler-Bernoulli beam theory for bending analysis of FG beams. An analytical solution of cantilever FG beams subjected to various types of loadings was presented by Zhong and Yu [2] using the Airy stress function. Deflec- tion and natural frequency results of the layered FG beams were obtained from the zigzag theoretical model- ing and experiment by Kapuria et al. [3]. Sina et al. [4] employed the first order shear deformation (FSDT) to solve the free vibration problem of FG beams. The La- grange multiplier method was used to solve the funda- mental frequency of FG beams based on different higher- order beam theories in the study of Simsek [5]. Free vi- bration analysis of simply supported FG beams was done by Aydogdu and Taskin [6]. Wattanasakulpong et al. [7] used an improved third order shear deformation theory to analyze free vibration of FG beams using the Ritz me- thod. The finite element method was used by Alshorbagy et al. [8] to investigate free vibration characteristics of FG beams. Yang and Chen [9] provided analytical solu- tion based on classical beam theory (CBT) for investi- gating natural frequencies and critical buckling load of FG beams with edge cracks. The edge cracked FG beams were also studied by Kitipornchai et al. [10] using Ti- moshenko beam theory. The problems of FG beams rest- ing on elastic foundations were solved by Sahraee et al. [11] and Pradhan and Murmu [12] using differential qua- drature method (DQM). Isotropic beams, supported by elastically end constraints, were the subject of many re- searchers [13-16], but none is dealing with FG beams. Differential transformation method (DTM) based on Taylor series expansion was initially introduced by Zhou [17] in his study of electrical circuits. It was first imple- mented to solve vibration analysis of beams by Malik and Dang [18]. Kaya and Ozgumus [19-21] successfully used the DTM to solve many cases of vibration problems. Pradhan et al. [22] also used the DTM to solve the buck- ling problem of a single walled carbon nanotube. According to the authors’ knowledge, there is no pre- *Corresponding author.  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 298 vious study on free vibration of FG beams supported by elastically end constraints in the open literature. In this study, the effective tool, DTM, is implemented to ana- lyze free vibration of FG beams with arbitrary boundary conditions, including various types of elastically end constraints. Fundamental frequencies as well as their higher frequencies and mode shapes are presented. The effects of spring constants and the material volume frac- tion index on the natural frequencies and mode shapes are discussed. Some available special cases in the open literature are used to validate the present results derived from DTM. 2. Functionally Graded Materials A functionally graded beam made of ceramic-metal is considered in this study. The beam geometry and the variation of material volume fraction across the beam thickness associated with the power law distribution are shown in Figure 1. Based on the rule of mixture, the effective material properties, P, can be written as mm cc PPV PV (1) where Pm, Pc, Vm and Vc are material properties and the volume fraction of the metal and ceramic respectively with the relation 1 mc VV. (2) According to the power law distribution, the volume fraction of ceramic can be written as 1 2 n c z Vh (3) where the positive number, 0n , is the power law or volume fraction index. The FG beam becomes a fully ceramic beam when n is set to zero. From the above rela- tionship, the material properties, in terms of Young’s modulus and mass density are expressed as 1 2 n cm m z EzE EE h , (4a) 1 2 n cm m z zh . (4b) Delale and Erdogan [23] indicated that the effect of Poisson’s ratio on the behavior of the FG plate is much less than that of the Young’s modulus, thus the Poisson’s ratio will assume to be constant in our study. 3. The FGM Beam Vibration Analysis Consider a classical beam theory (CBT) based on the Kirchhoff-Love hypothesis, the displacements of an arbi- trary point along x and z axes can be expressed as fol- lows: 00 ,,,,,, w uxztuzwxztw xt x . (5) where 0 u and 0 w are the displacements at a point in the mid-plane. From the displacements in Equation (5), one can obtain the non-zero strains of the beam as 22 00 00 22 ;, xxx x uu ww zz xx x . (6) The normal force resultant, N, moment resultant, , and transverse shear force, Q, take the form: 11 011 x NA B , (7a) 11 011 x MB D , (7b) 0 11 11 x x M QBD xx , (7c) where 22 11 11112 2 ,,1,, d 1 h h Ez BDzz z . (8) The extensional stiffness 11 , extensional-bending Figure 1. Geometry of a functionally graded beam and volume fraction profile.  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 299 coupling stiffness 11 B and bending stiffness 11 D can be written in the function of the volume faction index (n) as: 11 21 1 cm m EE h E n (9a) 2 11 221 2 1 cm EEh n Bnn (9b) 2 3 11 2 2 41 2312 1 cm m EE nnE h Dnn n (9c) The axial inertia term is neglected, therefore, the gov- erning equations of the FG beams derived from Hamil- ton’s principle can be expressed as follows: 23 0 01111 23 :0 0 x Nu w uAB xxx , (10) 22 242 11 0110 242 11 :0 0. x MB www wI DI xA txt (11) Substituting harmonic vibration mode, i et wW , into Equation (11) leads to a time independent governing equation as follows: 24 2 11 11 0 4 11 0 BW DIW Ax . (12) where is a natural frequency and 2 02d h h zz is the moment of inertia which can be expressed in term of the volume faction index as: 01 cm m Ih n . (13) 4. Application of DTM to FG Beam Vibration Analysis The principle of the DTM is to transform the governing differential and boundary condition equations into a set of algebraic equations using transformation rules. The basic operations required in differential transformation for the governing differential and boundary condition equations are shown in Tables 1 and 2 respectively. The general function, f (x) in Tables 1 and 2 is con- sidered as the transverse displacement W (x). Apply the basic operations of DTM in Table 1 with the fundamen- tals of the DTM presented in [18] to the governing dif- ferential equation, Equation (12), one can obtain the re- currence equation as: 2 0 41234 I Wr Wr rrr r (14) where 2 11 11 11 B D . It is seen that Equation (14) is independent from boun- dary conditions. Therefore to obtain frequency results, the displacement function of Equation (14) must be used to satisfy the corresponding boundary equations. 4.1. FG beams without Elastically End Constraints Three types of general edge conditions, without any springs, at x = 0 and L are: Simply supported (S), Table 1. Basic operations of DTM for the governing equa- tions. Original functions Transformed functions xgxhx rGrHr xgx rGr xgxhx 0 r l rGrlHl d d p p x fx x ! ! rp rGrp r p xx 0 1 rp Frr prp Table 2. Basic operations of DTM for the boundary c onditions. x = 0 x = L Original B.C. Transforme d B.C. Original B.C. Transforme d B.C. 00f 00F 0fL 00 r rLFr d0 0 d f x 10F d0 d fL x 1 00 r rrLF r 2 2 d00 d f x 20F 2 2 d0 d fL x 2 010 r rrrL Fr 3 3 d00 d f x 30F 3 3 d0 d fL x 3 012 0 r rrrrL Fr  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 300 W = 0, 2 2 d0 d W x; Clamped (C), W = 0, d0 d W x ; and Free (F), 2 2 d0 d W x, 3 3 d0 d W x. Now consider a beam with free-free (F-F) boundary conditions. The bending moment and shear force at x = 0 and L are zero. Let the non-zero values of deflection and slope at x = 0 indicate by C0 and C1 respectively. Applying the basic operations of DTM for the boundary condition at x = 0, using Table 2, one obtains 01 0,1,20,30WCWCWW. (15) Substituting Equation (15) into the recurrence equation Equation (14) leads to Wr for all values of r as fol- lows: 2 0 0 40,1,2,3, 4! rr r I WrC r r (16a) 2 0 1 410,1,2,3, 41! rr r I WrC r r (16b) 420 0,1,2,3,Wr r (16c) 430 0,1,2,3,Wr r (16d) For the boundary condition at x = L, applying the basic operations of DTM using Table 2, one obtains 2 0 3 0 10, 12 0 r r r r rrL Wr rrrLWr (17) Substituting Wr from Equation (16) into Equation (17) leads to two polynomial equations which can be arranged into the following matrix form. 11 120 21 221 0 0 ee C ee C (18) where 42 41 22 00 11 12 11 43 42 22 00 21 22 11 ;; 42! 41! ;. 43! 42! rr rr rr rr rr rr rrrr rr rr IL IL ee rr IL IL ee rr The frequency results can be determined by setting the determinant of the coefficient matrix of Equation (18) to zero. Hence, the frequency equation can be expressed with the finite number of terms in each component of the matrix from r to R as: 42 42 22 00 11 43 41 22 00 11 42! 42! 0 43! 41! rr rr rr RR rr rr rr rr rr RR rr rr IL IL rr IL IL rr (19) Solving the frequency equation in Equation (19), one obtains the frequency results as: r , where r = 1, 2, 3,···, R. Therefore, r is the th r estimated frequency corresponding to R. Hence, an appropriate value of R is obtained by convergence analysis with the following criterion, 1RR rr (20) where δ is a given error tolerance. The mode shape function can be obtained using 0 Rr r Wx xWr , that is 2 4 0 0 42 2 0 2 141 0 41 20 0 1 4! 42! 41! 41! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r (21) Following the same procedure, one can obtain the fre- quency equation and mode shape function for other kinds of boundary conditions without any spring support as given in Appendix A. 4.2. FG Beams with Elastically End Constraints A FG beam supporting by elastic translational and rota- tional springs at both ends, called E-E boundary condi- tions, is shown in Figure 2. For this case, the boundary conditions at the left end can be expressed as, d 0, 0 d TL xRLx W kW QkM x . (22) The boundary conditions in Equation (22) can be take another form as 32 32 ddd 0, 0 d dd TL RL kk WWW Wx xx . (23) Figure 2. Geometry of FG beam with E-E boundary condi- tion.  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 301 Where kTL and kRL are the translational spring constant (MN/m) and the rotational spring constant (MN·m/rad) at the left end respectively. Let the non-zero values of de- flection and slope at x = 0 be C0 and C1 respectively. Use Table 2 to apply the basic operations of DTM for these non-zero quantities at x = 0, one obtains 01 d 0,1 d Wx WWxCW C x . (24) The expressions for non-zero values of bending mo- ment and shear force at x = 0 can be written as 0 1 2,3 26 TL RL kC kC WW . (25) To find []Wr for all values of r, the components in Equations (24) and (25) are substituted into the recur- rence Equation (14). 2 00 4,0,1, 2,3,. 4! rr r IC Wr r r (26a) 2 00 4,0,1, 2,3,. 4! rr r IC Wr r r (26b) 2 01 (1) 42 0,1,2,3,. 42! rr RL r IkC Wr r r , (26c) 2 00 (1) 43 0,1,2,3,. 43! rr TL r Ik C Wr r r , (26d) At x = L, the boundary conditions are d0, 0 d RRxTR x W kMkWQ x . (27) They can be written as: 23 23 ddd 0, 0 d dd RR TR kk WW W W x xx . (28) Similarly, applying the DTM to the boundary condi- tions (28) yields 21 00 10 rr RR rr k rrLWrrL Wr , (29a) 3 00 12 0 rr TR rr k rrrLWrLWr .(29b) Substituting Wr from Equation (26) into Equation (29) leads to two polynomial equations which can be arranged into the following matrix form: 11 120 21 221 0 0 ppC ppC (30) where: 42 41 22 00 11 1 11 41 42 22 00 12 00 42!41! 41! 42! rr rr rr RR rr rr rr rr rr TLRR TL rr rr LI LI pk rr LIL I kkk rr 41 4 22 00 12 1 10 441 22 00 12 00 41!4! 4!4 1! rr rr rr RR rr rr rr rr rr RLRR RL rr rr LI LI pk rr LIL I kkk rr 43 4 22 00 21 1 10 443 22 00 12 00 43! 4! 4!4 3! rr rr rr TR rr rr rr rr rr TLTR TL rr rr LI LI pk rr LIL I kkk rr 42 41 22 00 22 1 10 414 2 22 00 12 10 42! 41! . 41!42! rr rr rr TR rr rr rr rr rr RLTR RL rr rr LI LI pk rr LIL I kkk rr Similarly, set the determinant of the coefficient matrix of Equation (30) to zero with finite number of terms, one obtains the following frequency equation. 42 414142 222 2 000 0 112 10 42 4141 222 000 11 42! 41!41!4 2! 42! 41! 4 rrr r rr rrrrrr RR RRTLRR TL rrrr rr rr r rr rrrr RL TR rrr LI LILILI kkkk rrrr LI LILI kk rrr 42 2 0 2 10 43434 4 2222 0000 211 10 41 41 22 0 1!4 2! 43! 43! 4! 4! 41! rrr RR TR RLr rr rrrr rrrrrr rr RR TR TLTRTL rrrr rr rr rr RR RL r LI kk r LILILI LI kkkk rrrr LI L kk r 44 22 000 211 10 0 41! 4!4! rr rrrr rr RR RR RL rrr rr ILILI kk rrr (31)  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 302 The mode shape function corresponding to the fre- quency in Equation (31) can be derived as: 22 441 00 1 00 22 42 43 00 111 00 4!4 1! 42! 43! rr rr RR rr rr rr rr rr RR rr RL TL rr rr Wx II xC x rr Ik Ik Cx x rr (32) where: (please see the Equation (33) below). Following similar procedure, one can obtain the fre- quency equation and mode shape function for a clamped- elastic supported (C-E) beam in Figure 3 as follows. The frequency equation: 441 22 00 1 0 443 22 00 1 0 414 2 22 00 1 10 41 2 0 4! 41! 4! 43! 41!42! 41! rr rrrr R RR rr r rr rr rr R TR rr r rr rrrr RR TR rr rr rrr r LIL I k rr LIL I k rr LIL I k rr LI r 42 2 0 1 0 0 42! rrr R RR r r LI kr (34) The mode shape function: 2 42 0 0 2 43 0 1 0 42! 43! rr Rr r r rr Rr r r I Wx x r I Cx r (35) where: 441 22 00 1 0 141 42 22 00 1 0 4! 41! . 41!42! rr rrrr R RR rr r rr rr rr R RR rr r LIL I k rr C LI LI k rr (36) For the case of simply supported-elastic (S-E) FG beams as shown in Figure 4, the expressions for the fre- quency equation and the mode shape function can be written as: The frequency equation: 41 4 22 00 1 10 443 22 00 1 0 42 41 22 00 1 10 41 2 0 41!4! 4! 43! 42! 41! 41! rr rr rr RR RR rr rr rr rr rr R TR rr r rr rrrr RR TR rr rr rrr RR r LI LI k rr LIL I k rr LI LI k rr LI k r 42 2 0 1 0 0 42! rrr R r r LI r (37) The mode shape function: 2 41 0 0 2 43 0 1 0 41! 43! rr Rr r r rr Rr r r I Wx x r I Cx r (38) where 41 4 22 00 1 10 141 42 22 00 1 0 41!4! 41!42! rr rr rr RR RR rr rr rr rr rr R RR rr r LI LI k rr C LI LI k rr (39) Figure 3. Geometry of FG beam with C-E boundary condi- tion. Figure 4. Geometry of FG beam with S-E boundary condi- tion. 42 414142 222 2 000 0 112 10 141414 4 2222 0000 21 42!41!41!4 2! 41! 41! 4! rrr r rrrrrrrr RR RRTLRR TL rrrr rr rrrr rrrrrr r RR RLRRRL rrr LI LILILI kkkk rrrr C LILILI LI kkk k rrr 1 10 . 4! r RR r rr r (33)  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 303 5. Numerical Results and Discussions 5.1. FG Beams without Elastically End Constraints FG beams made of Alumina (Al2O3) and Aluminum (Al); whose material properties are: E = 380 GPa, ρ = 3960 kg/m3, ν = 0.3 for Al2O3 and E = 70 GPa, ρ = 2702 kg/m3, ν = 0.3 for Al; are chosen for this study. Six types of boundary conditions are considered as shown in Table 3. The dimensionless frequency is defined as 2 Al Al LhE . From convergence study it is found out that R equals to 15 is sufficient for the required accuracy. Using R more than 15 will present the same results for the first to sixth modes. To receive the fre- quency results that are higher than sixth mode, the value of R more than 15 may be needed. Five modes of vibra- tion with various volume fraction indexes are presented in Table 3. Only the fundamental frequencies of the work by Simsek [5] for three types of boundary conditions, namely, (S-S), (C-F) and (C-C), are found in the open literature. Very good agreement with the present results for all volume fraction indexes is confirmed as shown in Table 3. It is seen that, for all boundary conditions, all frequen- cies decrease as volume fraction indexes increase. The C-C and F-F frequencies are practically equal and they are the highest of all boundary conditions. Results in the table show that the volume fraction index is one of the most important parameters that have significant impact on the frequency of vibration and therefore, it must be Table 3. Dimensionless frequencies of Al2O3/Al beams without spr i ngs (L/h = 20). B.C. Mode Al2O3 n = 0.2 n = 0.5 n = 1.0 n = 2.0 n = 5.0 Al 1 5.483 5.478* 5.102 5.098* 4.669 4.665* 4.221 4.216* 3.852 3.847* 3.668 3.663* 2.849 2.846* 2 21.933 20.408 18.676 16.884 15.407 14.670 11.396 S-S 3 49.350 45.917 42.021 37.989 34.667 33.007 25.642 4 87.734 81.631 74.703 67.536 61.629 58.680 45.586 5 137.082 127.551 116.726 105.528 96.299 91.687 71.227 1 1.953 1.952* 1.816 1.817* 1.663 1.663* 1.504 1.503* 1.372 1.371* 1.307 1.306* 1.015 1.015* 2 12.242 11.390 10.424 9.424 8.599 8.188 6.361 C-F 3 34.278 31.893 29.187 26.386 24.079 22.926 17.810 4 67.171 62.498 57.194 51.707 47.185 44.926 34.901 5 111.037 103.313 94.547 85.474 77.998 74.267 57.694 1 12.430 12.414* 11.566 11.554* 10.584 10.571* 9.569 9.555* 8.732 8.719* 8.314 8.301* 6.459 6.450* 2 34.264 31.881 29.175 26.376 24.069 22.917 17.803 C-C 3 67.172 62.499 57.195 51.707 47.185 44.927 34.902 4 111.037 103.313 94.546 85.477 78.001 74.266 57.694 5 165.915 154.337 141.262 127.640 116.503 110.935 86.210 1 8.566 7.970 7.294 6.594 6.017 5.729 4.451 2 27.760 25.828 23.637 21.369 19.500 18.567 14.424 S-C 3 57.918 53.889 49.316 44.584 40.685 38.738 30.094 4 99.043 92.153 84.333 76.242 69.574 66.244 51.462 5 151.137 140.632 128.692 116.343 106.174 101.085 78.536 1 8.566 7.970 7.294 6.594 6.017 5.729 4.451 2 27.760 25.828 23.637 21.369 19.500 18.567 14.424 S-F 3 57.918 53.889 49.316 44.584 40.685 38.738 30.094 4 99.043 92.153 84.333 76.241 69.573 66.244 51.462 5 151.124 140.628 128.681 116.350 106.171 101.079 78.526 1 12.430 11.566 10.584 9.569 8.732 8.314 6.459 2 34.264 31.881 29.175 26.376 24.069 22.917 17.803 F-F 3 67.172 62.499 57.195 51.707 47.185 44.927 34.902 4 111.039 103.314 94.547 85.475 77.998 74.267 57.695 5 165.921 154.375 141.272 127.755 116.557 110.945 86.200 *Simsek [5].  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 304 considered in designing a beam to meet the required fre- quency. Changing this parameter also means changing flexibility of beams. 5.2. FG Beams with Elastically End Constraints Three types of boundary condition; namely, C-E, S-E and E-E, of FG beams with elastically end constraints will be investigated in the following sections. Due to classical beam theory considered in this study, it is ap- propriate to choose the thickness ratio (L/h) more than 20. In the following investigation the ratio (L/h = 30) is se- lected for all of the next calculation. However, the fre- quency equation and mode shape function presented in this study can be used effectively for other values of the thickness ratio. 5.2.1. Vibration Analysis of FG Beams with C-E Boundar y C on d it i o n Consider a FG beam completely clamped at the left end and supported by translational and rotational springs at the right end. The beam is defined as the C-E beam. The frequency results for the first six modes with various volume fraction indexes are shown in Table 4. To verify the results, only the available work of Lai et al. [14] on the isotropic beam (n = 0 for full Al2O3) with the same type of support is shown in the second row. All modes of frequencies agree excellently. Again, all frequencies de- crease as volume fraction indexes increase. Effects of varying the values of spring constants, with n fixed at 0.5, on the response of FG beams for the first three modes are shown in Table 5. All frequencies in- crease as spring constants increase as expected. Observe Table 4. Dimensionless frequencies of Al2O3/Al beams (L/h = 30, kTR = 1.173 MN/m and kRR = 1.056 × 103 MN·m/rad). 1 2 3 4 5 6 n = 0 Lai et al. [14] 2.566 2.566 13.213 13.213 35.270 35.270 68.193 68.193 112.077 112.078 166.941 166.923 n = 0.2 2.547 12.970 34.493 66.611 109.420 162.902 n = 0.5 2.429 12.056 31.780 61.192 100.378 149.361 n = 1.0 2.305 11.112 28.987 55.605 91.051 135.293 n = 2.0 2.206 10.343 26.707 51.033 83.400 123.834 n = 5.0 2.171 9.987 25.611 48.803 79.643 118.170 n = 10.0 2.146 9.768 24.957 47.482 77.423 114.786 Table 5. Dimensionless frequencies of Al2O3/Al beams (n = 0.5; L/h = 30). kRR (MN·m/rad) (MN/m) 1 10 102 103 104 105 106 1 2.051 2.056 2.102 2.383 2.788 2.891 2.903 2 10.983 10.995 11.113 12.006 14.116 14.898 14.997 kTR = 1 3 30.617 30.628 30.745 31.726 35.036 36.755 36.994 1 3.669 3.670 3.678 3.733 3.826 3.853 3.856 2 11.493 11.505 11.613 12.430 14.362 15.085 15.177 kTR = 10 3 30.793 30.805 30.920 31.890 35.144 36.831 37.067 1 6.737 6.739 6.766 6.969 7.492 7.710 7.738 2 16.370 16.372 16.391 16.541 16.967 17.163 17.189 kTR = 102 3 32.806 32.816 32.911 33.704 36.300 37.649 37.839 1 7.553 7.559 7.616 8.091 9.669 10.544 10.673 2 23.677 23.680 23.718 24.051 25.559 26.793 27.008 kTR = 103 3 46.330 46.331 46.336 46.385 46.612 46.809 46.844 1 7.637 7.644 7.705 8.213 9.932 10.897 11.038 2 24.674 24.680 24.736 25.248 27.718 29.845 30.217 kTR = 104 3 51.235 51.240 51.293 51.786 54.615 57.896 58.574 1 7.646 7.652 7.713 8.225 9.958 10.932 11.074 2 24.768 24.774 24.832 25.362 27.924 30.124 30.507 kTR = 105 3 51.653 51.659 51.717 52.262 55.410 59.017 59.746 1 7.647 7.653 7.714 8.226 9.961 10.935 11.078 2 24.778 24.783 24.842 25.374 27.945 30.152 30.535 kTR = 106 3 51.693 51.699 51.758 52.309 55.486 59.122 59.855  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 305 that for very large value of kTR and kRR, the frequencies, 1, 2 and 3 approach those of C-C beam in Table 3. The first to forth mode shapes of FG beams with C-E boundary condition are shown in Figures 5(a)-(d), re- spectively. It is seen that different values of spring sup- port change the mode shapes of the vibrating beams sig- nificantly. Note that for kTR = k RR = 0, the beam corre- sponds to a C-F beam and as kTR = kRR, a C-C beam is obtained. 5.2.2. Vibration Analysis of FG Beams with S-E Boundar y C on d it i o n Dimensionless frequency results of FG beams, with S-E boundary conditions as shown in Figure 4, for the first six modes are tabulated in Table 6. To verify the results, again, only the work of Lai et al. [14] on the isotropic beam (n = 0) is available as shown in the second row of Table 6. All frequencies, 1 to 6, agree excellently. It is seen that, all frequencies decrease as volume fraction indexes increase. The first three frequencies for S-E boundary condition with variable spring constants, kTR and kRR are presented in Table 7. To illustrate the effects of spring constants and material volume fraction on the fundamental fre- quency, 3-D figures for S-E and C-E beams are plotted in Figure 6. And Figure 7 shows the 1st to 4th mode shapes of FG beams with S-E boundary condition. 5.2.3. Vibration Analysis of FG Beams with E-E Boundar y C on d it i o n FG beams supported by translational and rotational springs at both ends as shown in Figure 2 are considered in this section. Dimensionless frequencies of various modes and volume fraction indexes are presented in Ta- ble 8. Again, the accuracy is confirmed by the case of isotropic beams by Lai et al. [14]. It is observed that the first and second frequency results depend mostly on the effects of translational and rotational spring stiffnesses at both ends, Hence, they show different trends of change in comparison with other modes when the value of the (a) (b) (c) (d) Figure 5. The 1st to 4th mode shapes of Al2O3/Al beams with C-E boundary conditions (n = 0.5; L/h = 30; kTR = kRR).  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 306 Table 6. Dimensionless frequency results of Al2O3/Al beams (L/h = 30; kTR = 29.32 MN/m; kRR = 0 MN·m/rad). 1 2 3 4 5 6 n = 0 Lai et al. [14] 3.826 3.826 10.471 10.471 28.340 28.340 58.189 58.189 99.200 99.200 151.238 151.238 n = 0.2 3.843 10.412 27.707 56.785 96.773 147.525 n = 0.5 3.736 10.001 25.517 52.039 88.603 135.026 n = 1.0 3.576 9.616 23.284 47.142 80.156 122.113 n = 2.0 3.411 9.355 21.493 43.128 73.207 111.470 n = 5.0 3.331 9.322 20.663 41.150 69.752 106.164 n = 10.0 3.273 9.282 20.176 39.986 67.718 103.042 Table 7. Dimensionless frequencies of Al2O3/Al beams (n = 0.5; L/h = 30). kRR (MN·m/rad) (MN/m) 1 10 102 103 104 105 106 1 0.929 0.933 0.968 1.160 1.386 1.437 1.442 2 7.725 7.736 7.849 8.662 10.379 10.959 11.031 kTR = 1 3 24.803 24.815 24.931 25.893 28.919 30.378 30.577 1 2.652 2.652 2.652 2.653 2.654 2.655 2.655 2 8.455 8.464 8.558 9.239 10.707 11.216 11.279 kTR = 10 3 25.022 25.034 25.148 26.093 29.048 30.471 30.665 1 4.503 4.507 4.544 4.830 5.549 5.845 5.884 2 13.800 13.800 13.803 13.830 13.906 13.940 13.945 kTR = 102 3 27.559 27.567 27.650 28.331 30.434 31.470 31.613 1 4.855 4.860 4.916 5.362 6.689 7.345 7.437 2 18.907 18.911 18.955 19.339 21.004 22.274 22.488 kTR = 103 3 40.260 40.261 40.274 40.392 40.944 41.430 41.519 1 4.891 4.897 4.954 5.418 6.818 7.517 7.615 2 19.513 19.519 19.576 20.088 22.404 24.226 24.532 kTR = 104 3 43.716 43.722 43.776 44.278 47.059 50.075 50.673 1 4.895 4.901 4.958 5.424 6.831 7.534 7.633 2 19.572 19.578 19.636 20.161 22.540 24.408 24.720 kTR = 105 3 44.018 44.023 44.082 44.625 47.648 50.896 51.530 1 4.895 4.901 4.959 5.425 6.832 7.535 7.634 2 19.578 19.584 19.642 20.168 22.553 24.426 24.739 kTR = 106 3 44.047 44.053 44.112 44.659 47.706 50.975 51.611 (a) S-E (b) C-E Figure 6. Fundamental frequenc y of Al 2O3/Al beams with S-E and C-E bound ar y c onditions ( L/h = 30).  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 307 Figure 7. The 1st to 4th mode shapes of Al2O3/Al beams with S-E boundary conditions (n = 0.5; L/h = 30; kTR = 10 M N/m , kRR = 10 MN·m/rad). volume fraction index increases. It is clear that as the values of kTL = k TR = k RL = k RR, this E-E FG beam behaves like the C-C FG beam (see Table 3). Table 9 shows the frequency results of the first three modes with variable spring constants. It is similar to the previous cases that frequencies increase as the spring constants increase. To understand the vibration behavior of FG beams supported by elastically end constraints, the effect of spring constants at both ends on the fundamental fre- quencies is shown as 3-D plot in Figure 8. Figure 9 shows the 1st to 4th mode shapes of E-E beams. It is ob- served that the first mode shape depends mostly on the translational springs which move up and down, including a small bending along the length of the beam. But for the second mode shape, it seems to be dependent on the rota- tional springs in which the movement is clockwise and Table 8. Dimensionless frequencies of Al2O3/Al beams (L/h = 30; kTL = kTR = 1.173 MN/m; kRL = kRR = 1.056 × 103 MN·m/rad). 1 2 3 4 5 6 n = 0 Lai et al. [14] 0.781 0.781 2.771 2.771 14.243 14.242 36.242 - 69.209 - 113.112 - n = 0.2 0.802 2.822 14.046 35.532 67.700 110.531 n = 0.5 0.825 2.838 13.206 32.943 62.419 101.637 n = 1.0 0.849 2.838 12.343 30.290 56.994 92.486 n = 2.0 0.876 2.833 11.653 28.148 52.588 85.025 n = 5.0 0.906 2.858 11.364 27.163 50.494 81.420 n = 10.0 0.920 2.861 11.178 26.566 49.245 79.284 Table 9. Dimensionless frequencies of Al2O3/Al beams (n = 0.5; L/h = 30). kRL = kRR (MN·m/rad) (MN/m) kTL = kTR 1 10 102 103 104 105 106 1 0.760 0.760 0.760 0.762 0.765 0.766 0.766 2 1.330 1.355 1.582 2.746 4.439 4.945 5.006 1 3 11.204 11.226 11.444 13.112 17.442 19.325 19.579 1 2.208 2.209 2.218 2.275 2.361 2.384 2.386 2 4.144 4.150 4.212 4.658 5.596 5.924 5.966 10 3 12.144 12.163 12.355 13.842 17.836 19.611 19.852 1 4.213 4.221 4.293 4.823 6.031 6.487 6.545 2 11.536 11.536 11.536 11.538 11.543 11.546 11.546 102 3 19.378 19.384 19.445 19.952 21.611 22.494 22.621 1 4.816 4.828 4.937 5.811 8.529 10.070 10.305 2 18.314 18.323 18.406 19.133 22.115 24.313 24.683 103 3 37.532 37.535 37.565 37.832 39.012 39.962 40.127 1 4.888 4.899 5.014 5.936 8.922 10.705 10.983 2 19.450 19.461 19.575 20.585 25.188 29.146 29.864 104 3 43.392 43.403 43.509 44.497 49.920 56.023 57.300 1 4.895 4.907 5.022 5.949 8.963 10.772 11.054 2 19.566 19.578 19.695 20.736 25.521 29.675 30.430 105 3 43.986 43.997 44.114 45.196 51.223 58.101 59.537 1 4.896 4.907 5.023 5.951 8.967 10.779 11.061 2 19.578 19.589 19.707 20.751 25.555 29.728 30.486 106 3 44.044 44.056 44.174 45.265 51.352 58.304 59.754  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 308 Figure 8. The fundamental frequency of Al2O3/Al beams with E-E boundary condition (n = 0.5; L/h = 30). Figure 9. The 1st to 4th mode shape of Al2O3/Al beams with E-E boundary conditions (n = 0.5; L/ h = 30; kTR = 10 MN/m; kRR = 10 MN·m/rad). anti-clockwise. If the spring constant becomes large, the mode shapes of E-E beams behave like C-C beams. 6. Concluding Remarks This research applies the differential transformation method to solve the governing differential equation of free vibra- tion of functionally graded beams supported by various types of general boundary conditions, including elastic- cally end constraints. FG beams made of Al2O3/Al are chosen to study the free vibration behavior. In general, the results revealed that trend of frequency results for various modes of vibration decreases as the volume frac- tion indexes increase, except for the case of the E-E boundary conditions in which the trend of the first two modes is reversed owning to the effects of translational and rotational springs at both ends. It is also seen that there are considerable changes of frequencies as well as mode shapes when the stiffness of spring becomes larger. The frequency equation and mode function presented in this study can be specialized to approximate any other boundary conditions, with or without springs, by setting the values of spring constants as appropriate. REFERENCES [1] B. V. Sankar, “An Elasticity Solution for Functionally Graded Beams,” Composites Science and Technology, Vol. 61, No. 5, 2001, pp. 689-696. doi:10.1016/S0266-3538(01)00007-0 [2] Z. Zhong and T. Yu, “Analytical Solution of a Cantilever Functionally Graded Beam,” Composites Science and Technology, Vol. 67, No. 3-4, 2007, pp. 481-488. doi:10.1016/j.compscitech.2006.08.023 [3] S. Kapuria, M. Bhattacharyya and A. N. Kumar, “Bend- ing and Free Vibration Response of Layered Functionally Graded Beams: A Theoretical Model and Its Experimen- tal Validation,” Composite Structures, Vol. 82, No. 3, 2008, pp. 390-402. doi:10.1016/j.compstruct.2007.01.019 [4] S. A. Sina, H. M. Navazi and H. Haddadpour, “An Ana- lytical Method for Free Vibration Analysis of Function- ally Graded Beams,” Materials & Design, Vol. 30, No. 3, 2009, pp. 741-747. doi:10.1016/j.matdes.2008.05.015 [5] M. Simsek, “Fundamental Frequency Analysis of Func- tionally Graded Beams by Using Different Higher-Order Beam Theories,” Nuclear Engineering and Design, Vol. 240, No. 4, 2010, pp. 697-705. doi:10.1016/j.nucengdes.2009.12.013 [6] M. Aydogdu and V. Taskin, “Free Vibration Analysis of Functionally Graded Beams with Simply Supported Ed- ges,” Materials & Design, Vol. 28, No. 5, 2007, pp. 1651- 1656. doi:10.1016/j.matdes.2006.02.007 [7] N. Wattanasakulpong, B. G. Prusty, D. W. Kelly and M. Hoffman, “A Theoretical Investigation on the Free Vibra- tion of Functionally Graded Beams,” Proceedings of the 10th International Conference on Computational Struc- tures Technology, Valencia, 14-17 September 2010, p. 285. [8] E. Alshorbagy Amal, M. A. Eltaher and F. F. Mahmoud, “Free Vibration Characteristics of a Functionally Graded Beam by Finite Element Method,” Applied Mathematical Modelling, Vol. 35, No. 1, 2011, pp. 412-425. doi:10.1016/j.apm.2010.07.006 [9] J. Yang and Y. Chen, “Free Vibration and Buckling Analysis of Functionally Graded Beams with Edge Cra- cks,” Composite Structures, Vol. 83, No. 1, 2008, pp. 48- 60. doi:10.1016/j.compstruct.2007.03.006 [10] S. Kitipornchai, L. L. Ke, J. Yang and Y. Xiang, “Nonlin- ear Vibration of Edge Cracked Functionally Graded Ti- moshenko Beams,” Journal of Sound and Vibration, Vol. 324, No. 3-5, 2009, pp. 962-982. doi:10.1016/j.jsv.2009.02.023 [11] S. Sahraee and A. R. Saidi, “Free Vibration and Buckling Analysis of Functionally Graded Deep Beam-Columns on Two-Parameter Elastic Foundations Using the Differen- tial Quadrature Method,” Journal of Mechanical Engi- neering Science, Vol. 223, No. 6, 2009, pp. 1273-1284. doi:10.1243/09544062JMES1349 [12] S. C. Pradhan and T. Murmu, “Thermo-Mechanical Vi-  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 309 bration of FGM Sandwich Beam under Variable Elastic Foundations Using Differential Quadrature Method,” Jour- nal of Sound and Vibration, Vol. 321, No. 1-2, 2009, pp. 342-362. doi:10.1016/j.jsv.2008.09.018 [13] J. C. Hsu, H. Y. Lai and C. K. Chen, “Free Vibration of Non-Uniform Euler-Bernoulli Beams with General Elas- tically End Constraints Using Adomain Modified Decom- position Method,” Journal of Sound and Vibration, Vol. 318, No. 4-5, 2008, pp. 965-981. [14] H. Y. Lai, J. C. Hsu and C. K. Chen, “An Innovative Ei- genvalue Problem Solver for Free Vibration of Euler- Bernoulli Beam by Using the Adomain Decomposition Method,” Computers & Mathematics with Applications, Vol. 56, No. 12, 2008, pp. 3204-3220. doi:10.1016/j.camwa.2008.07.029 [15] Y. Liu and C. S. Gurram, “The Use of He’s Variational Iteration Method for Obtaining the Free Vibration of an Euler-Bernoulli Beam,” Mathematical and Computer Mo- delling, Vol. 50, No. 11-12, 2009, pp. 1545-1552. doi:10.1016/j.mcm.2009.09.005 [16] Q. Mao and S. Pietrzko, “Free Vibration Analysis of Stepped Beams by Using Adomian Decomposition Me- thod,” Applied Mathematics and Computation, Vol. 217, No. 7, 2010, pp. 3429-3441. doi:10.1016/j.amc.2010.09.010 [17] J. K. Zhou, “Differential Transformation and Its Applica- tion for Electrical Circuits,” Huazhong University Press, Wuhan, 1986. [18] M. Malik and H. H. Dang, “Vibration Analysis of Con- tinuous Systems by Differential Transformation,” Applied Mathematics and Computation, Vol. 96, No. 1, 1998, pp. 17-26. doi:10.1016/S0096-3003(97)10076-5 [19] M. O. Kaya and O. O. Ozgumus, “Flexural-Torsional-Cou- pled Vibration Analysis of Axially Loaded Closed-Sec- tion Composite Timoshenko Beam by Using DTM,” Jour- nal of Sound and Vibration, Vol. 306, No. 3-5, 2007, pp. 495-506. [20] O. O. Ozgumus and M. O. Kaya, “Flapwise Bending Vi- bration Analysis of Double Tapered Rotating Euler-Bur- noulli Beam by Using the Differential Transform Me- thod,” Meccanica, Vol. 41, No. 6, 2006, pp. 661-670. doi:10.1007/s11012-006-9012-z [21] O. O. Ozgumus and M. O. Kaya, “Vibration Analysis of a Rotating Tapered Timoshenko Beam Using DTM,” Mec- canica, Vol. 45, No. 1, 2010, pp. 33-42. doi:10.1007/s11012-009-9221-3 [22] S. C. Pradhan and G. K. Reddy, “Buckling Analysis of Single Walled Carbon Nanotube on Winkler Foundation Using Nonlocal Elasticity Theory and DTM,” Computa- tional Materials Science, Vol. 50, No. 3, 2011, pp. 1052- 1056. doi:10.1016/j.commatsci.2010.11.001 [23] F. Delale and F. Erdogan, “The Crack Problem for a Non- Homogeneous Plane,” Journal of Applied Mechanics, Vol. 50, No. 3, 1983, pp. 609-614. doi:10.1115/1.3167098  N. WATTANASAKULPONG, V. UNGBHAKORN Copyright © 2012 SciRes. WJM 310 Appendix A S-S The frequency equation: 4141 22 00 00 41 43 22 00 10 41! 41! 0 41! 43! rr rr rr RR rr rr rr rrrr RR rr rr IL IL rr IL IL rr The mode shape function: 2 41 0 0 41 2 0 2 043 0 43 20 0 0 41! 41! 43! 43! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r S-C The frequency equation: 41 42 22 00 00 443 22 00 00 41!42! 0 4!4 3! rr rr rr RR rr rr rr rr rr RR rr rr IL IL rr IL IL rr The mode shape function: 2 41 0 0 41 2 0 2 043 0 43 20 0 0 41! 41! 43! 43! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r S-F The frequency equation: 41 4 22 00 10 42 41 22 00 10 41! 4! 0 42! 41! rr rrrr RR rr rr rr rrrr RR rr rr ILIL rr ILIL rr The mode shape function: 2 41 0 0 41 2 0 2 143 0 41 20 0 0 41! 41! 43! 41! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r C-F The frequency equation: 44 22 00 00 41 41 22 00 10 4! 4! 0 41! 41! rr rrrr RR rr rr rr rrrr RR rr rr IL IL rr IL IL rr The mode shape function: 2 42 0 0 4 2 0 2 043 0 41 20 0 0 42! 4! 43! 41! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r C-C The frequency equation: 42 42 22 00 00 41 43 22 00 00 42! 42! 0 41!43! rr rrrr RR rr rr rr rr rr RR rr rr IL IL rr IL IL rr The mode shape function: 2 42 0 0 42 2 0 2 043 0 43 20 0 0 42! 42! 43! 43! rr Rr r r r rr R rrr R rr r r rr Rr r r I Wx x r IL rIx r IL r

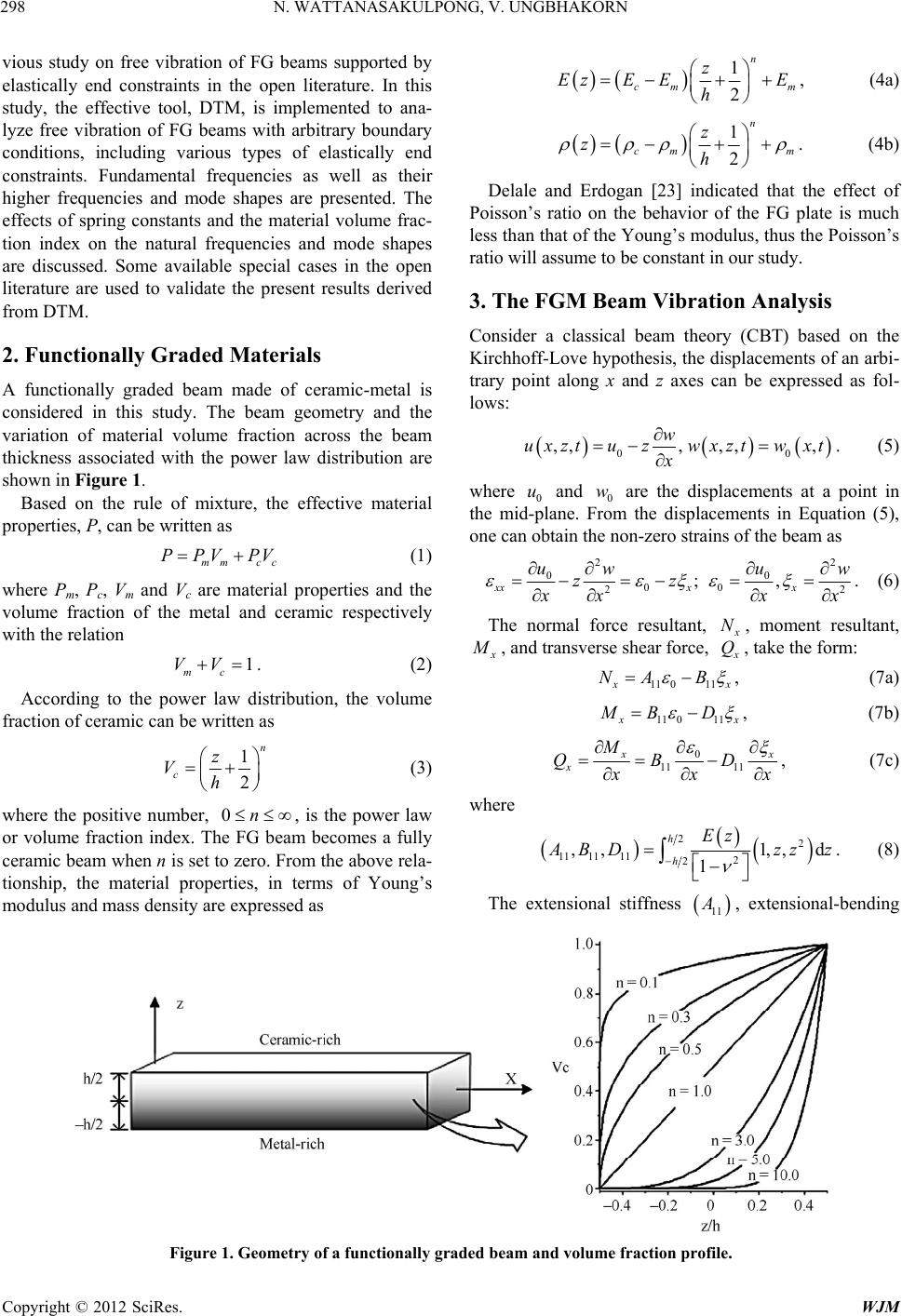

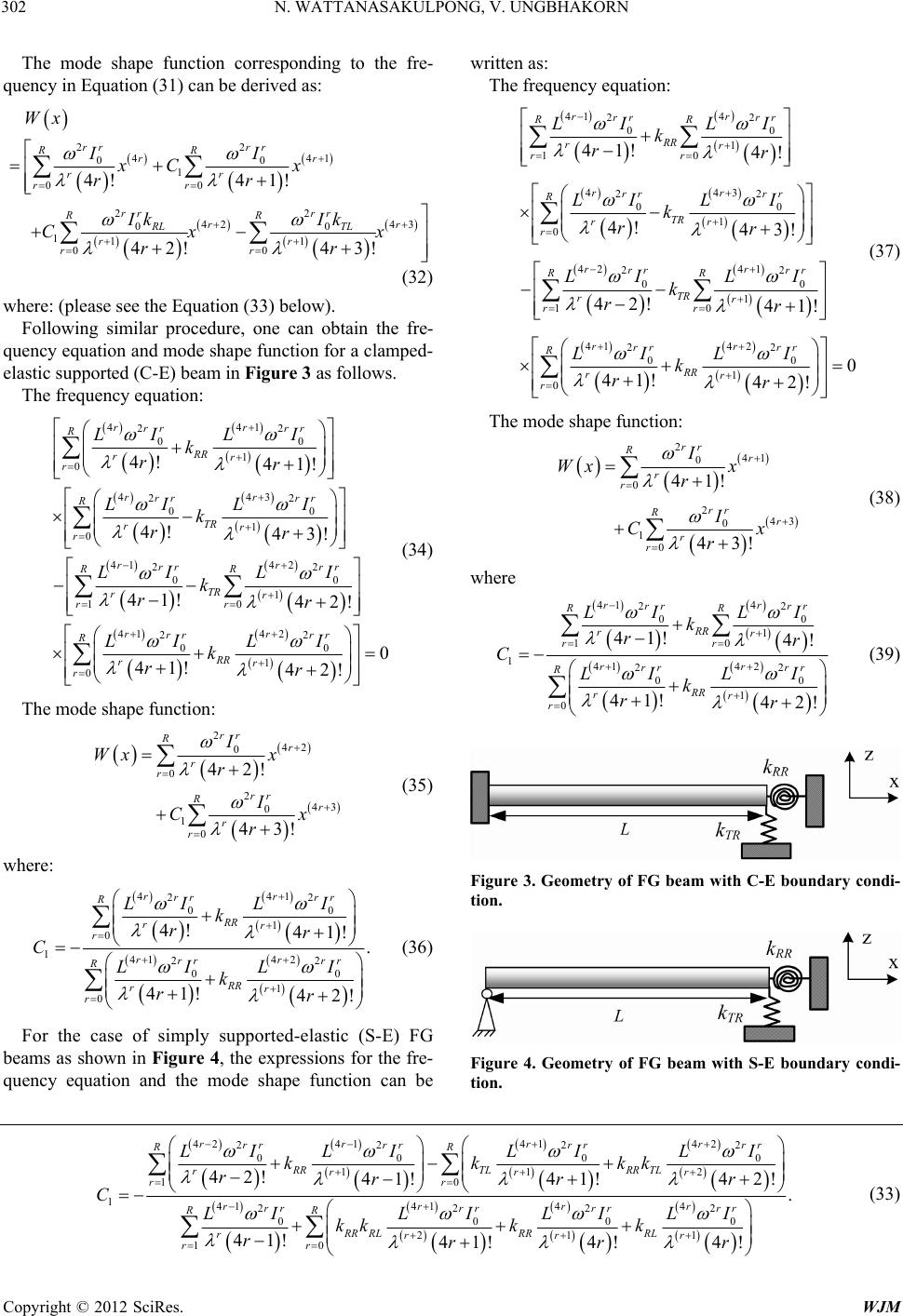

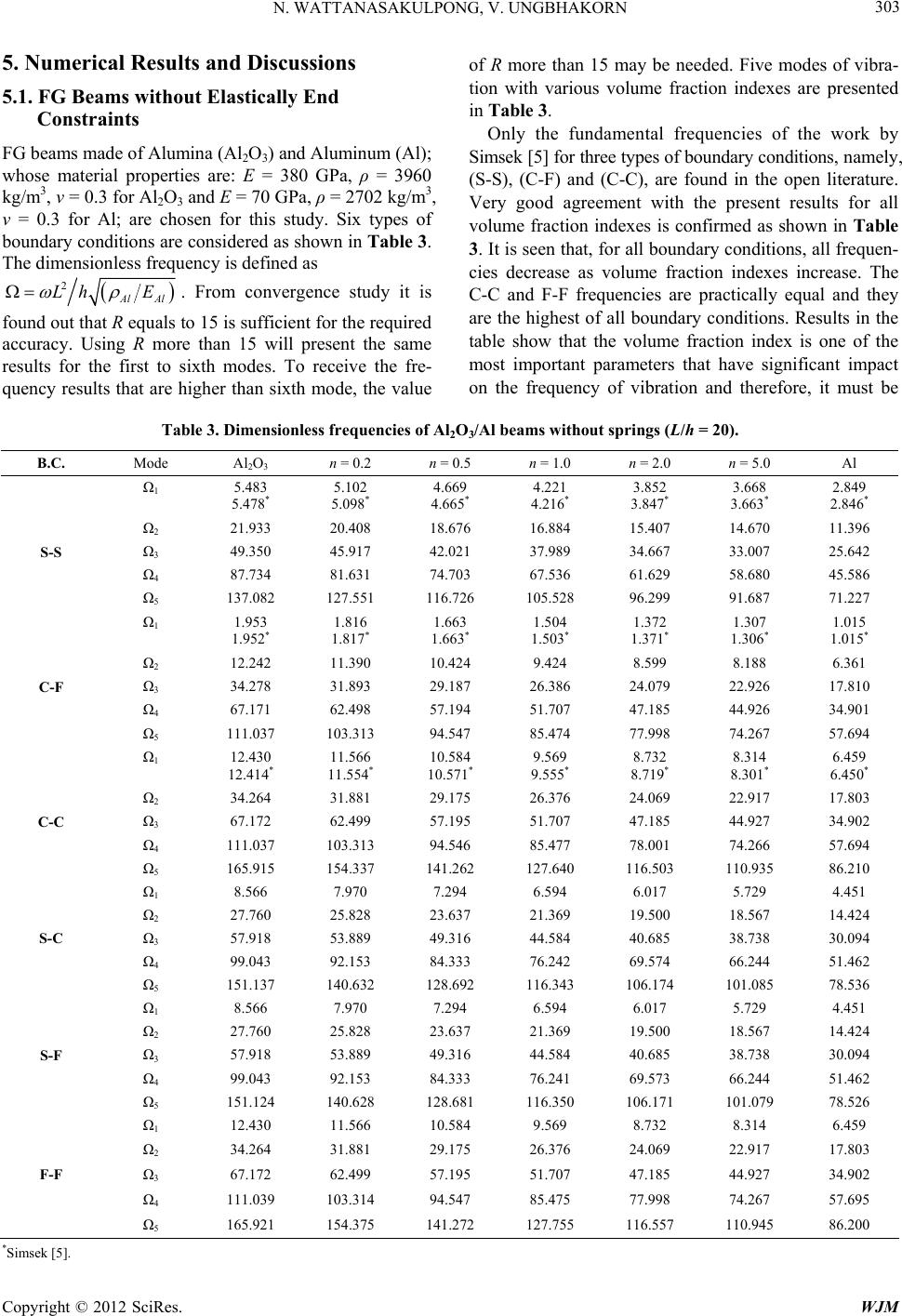

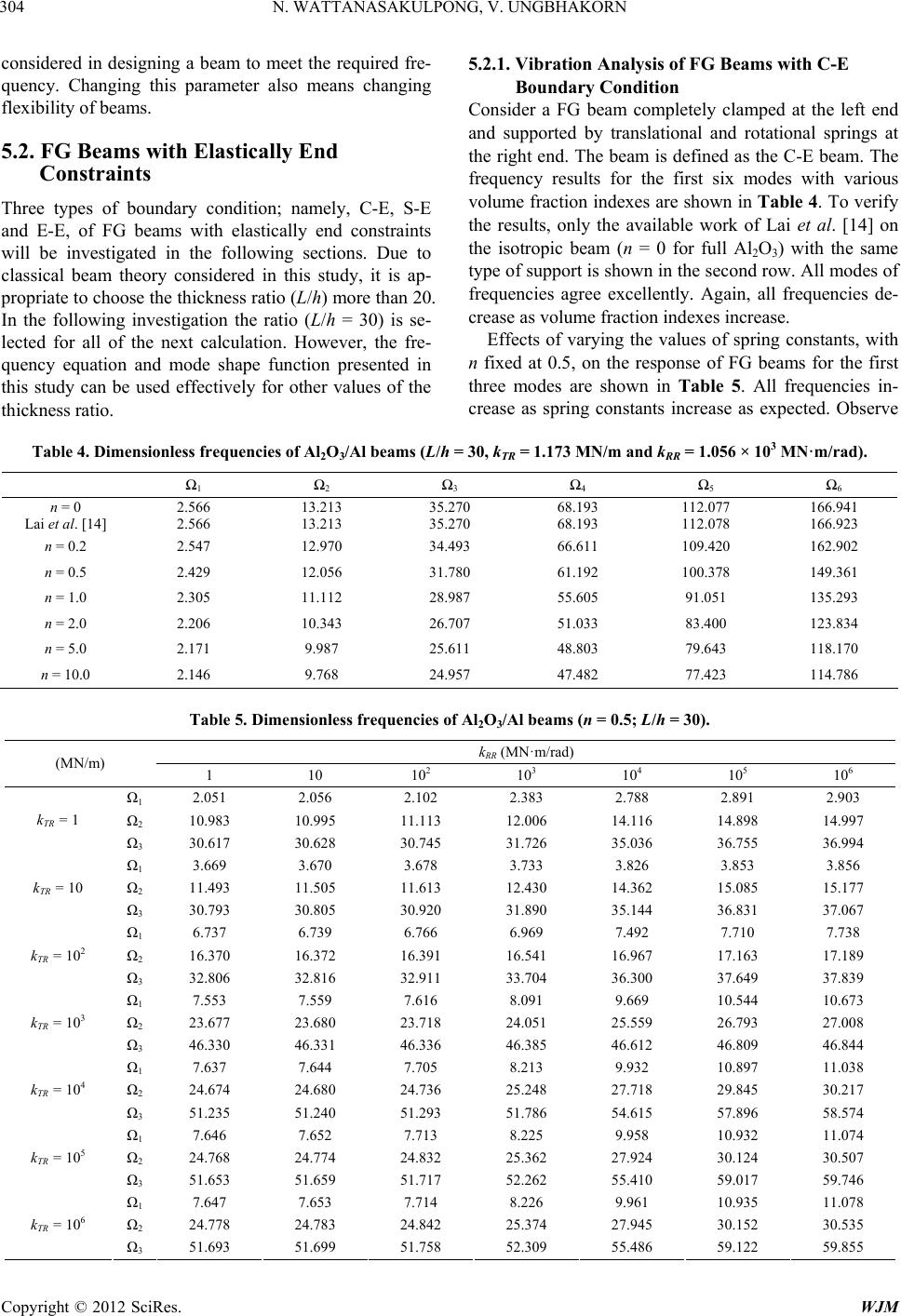

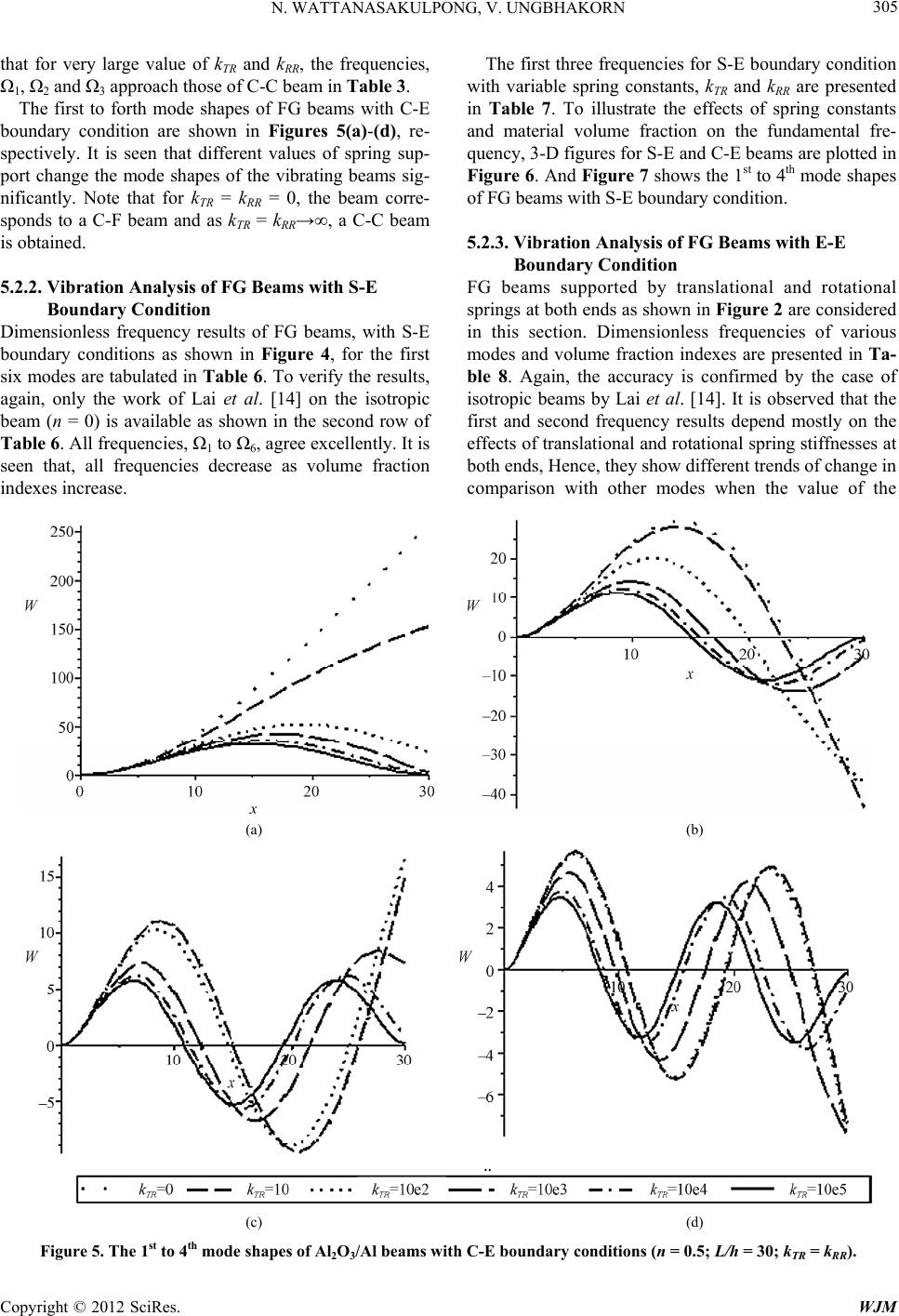

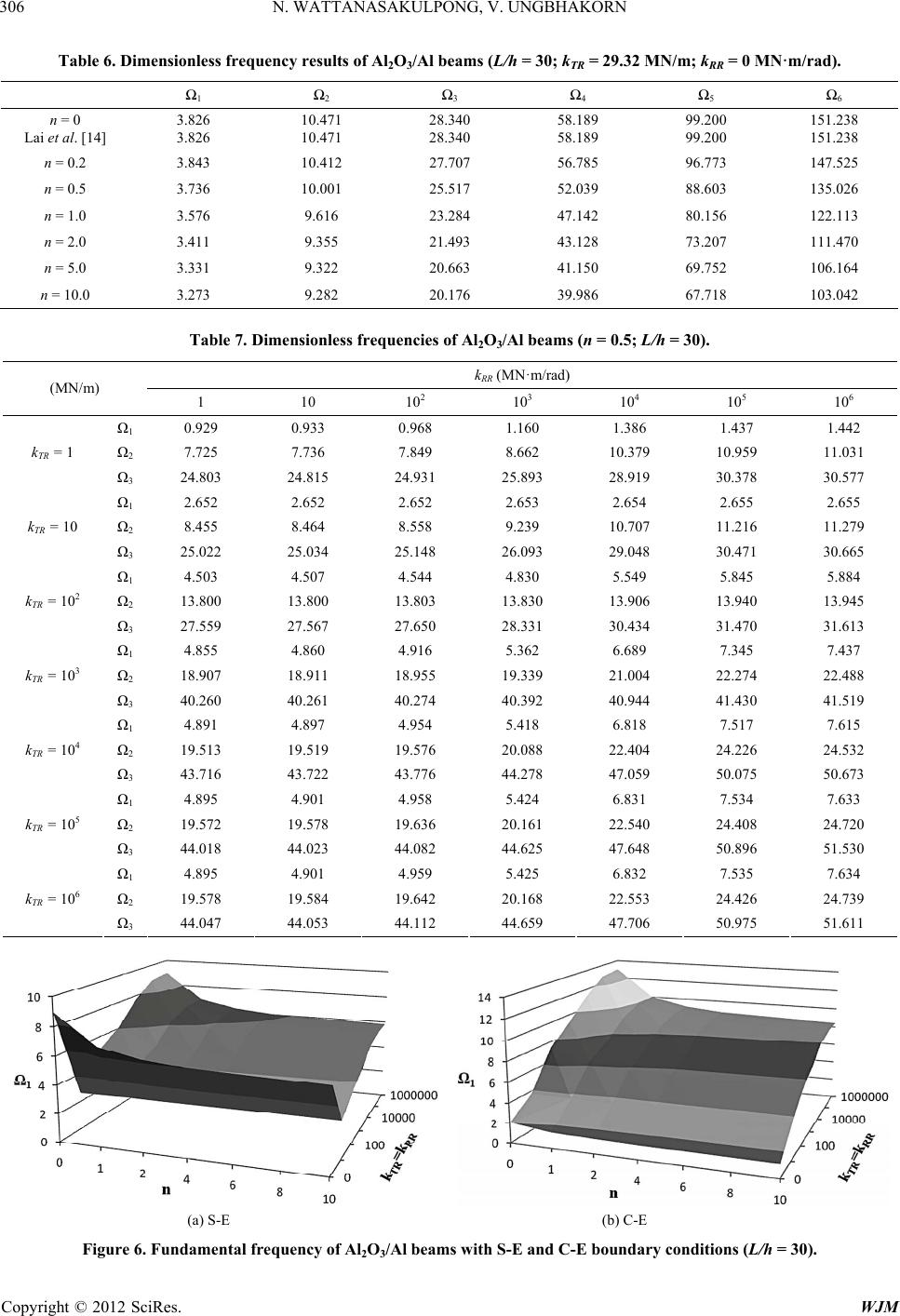

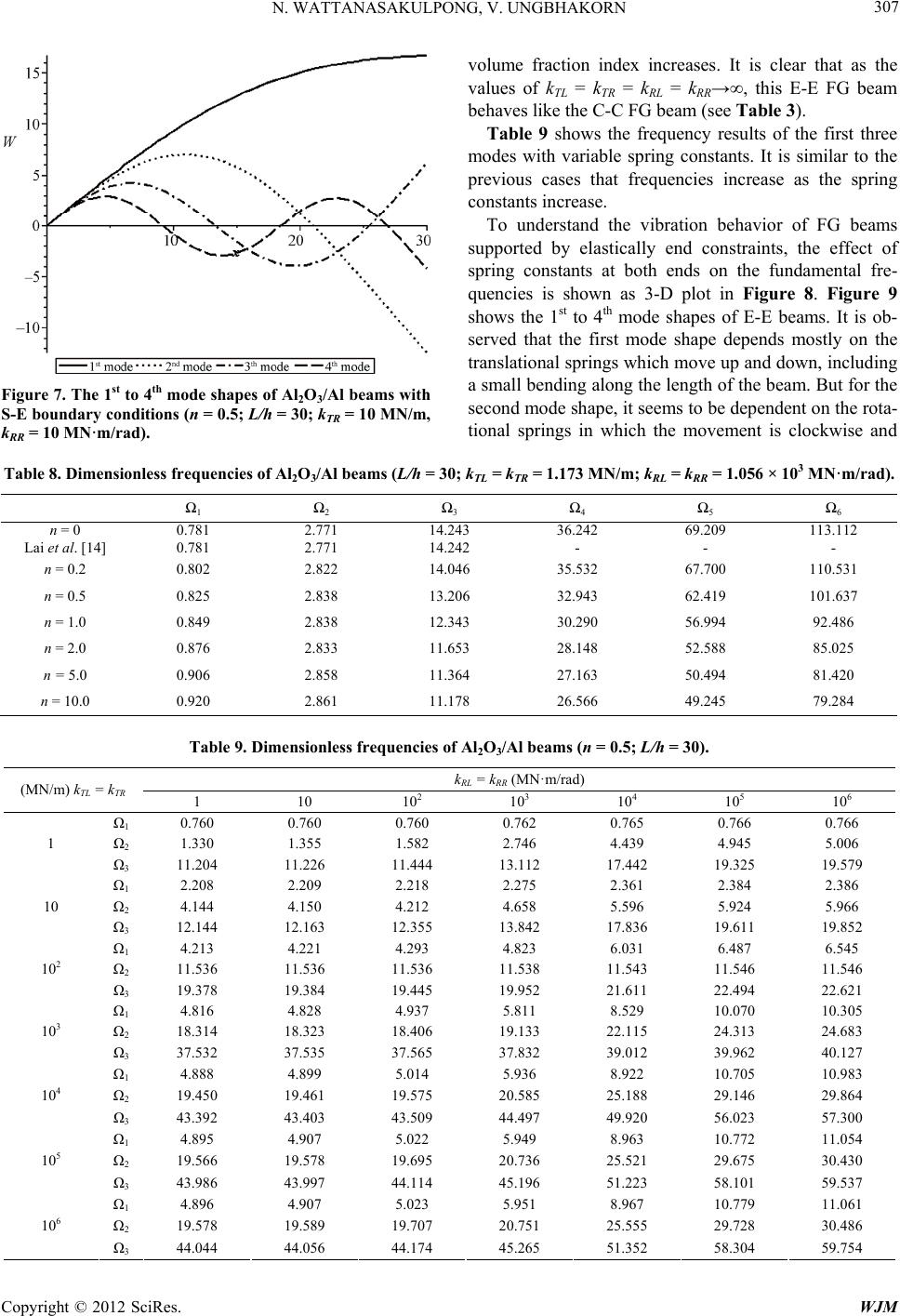

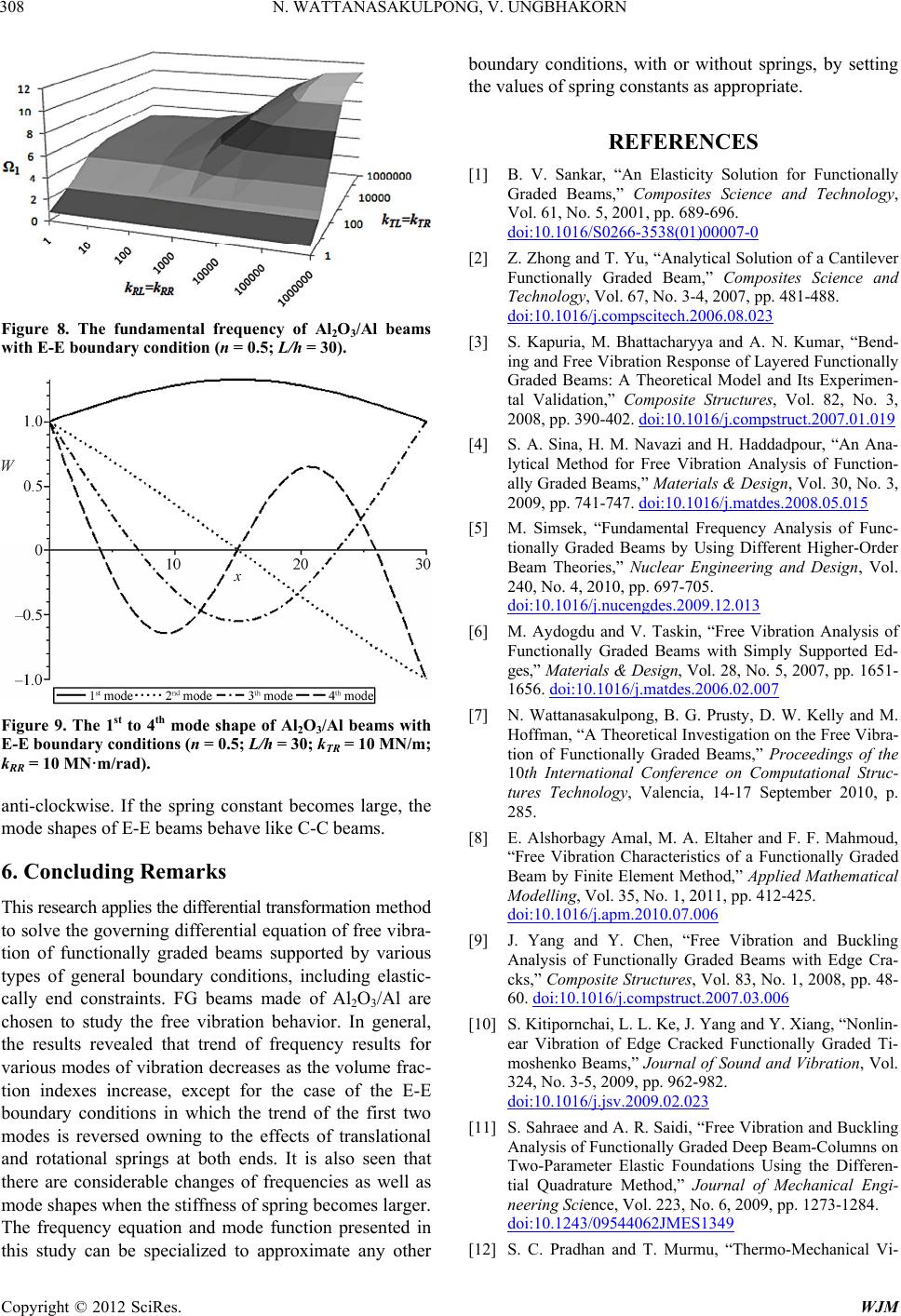

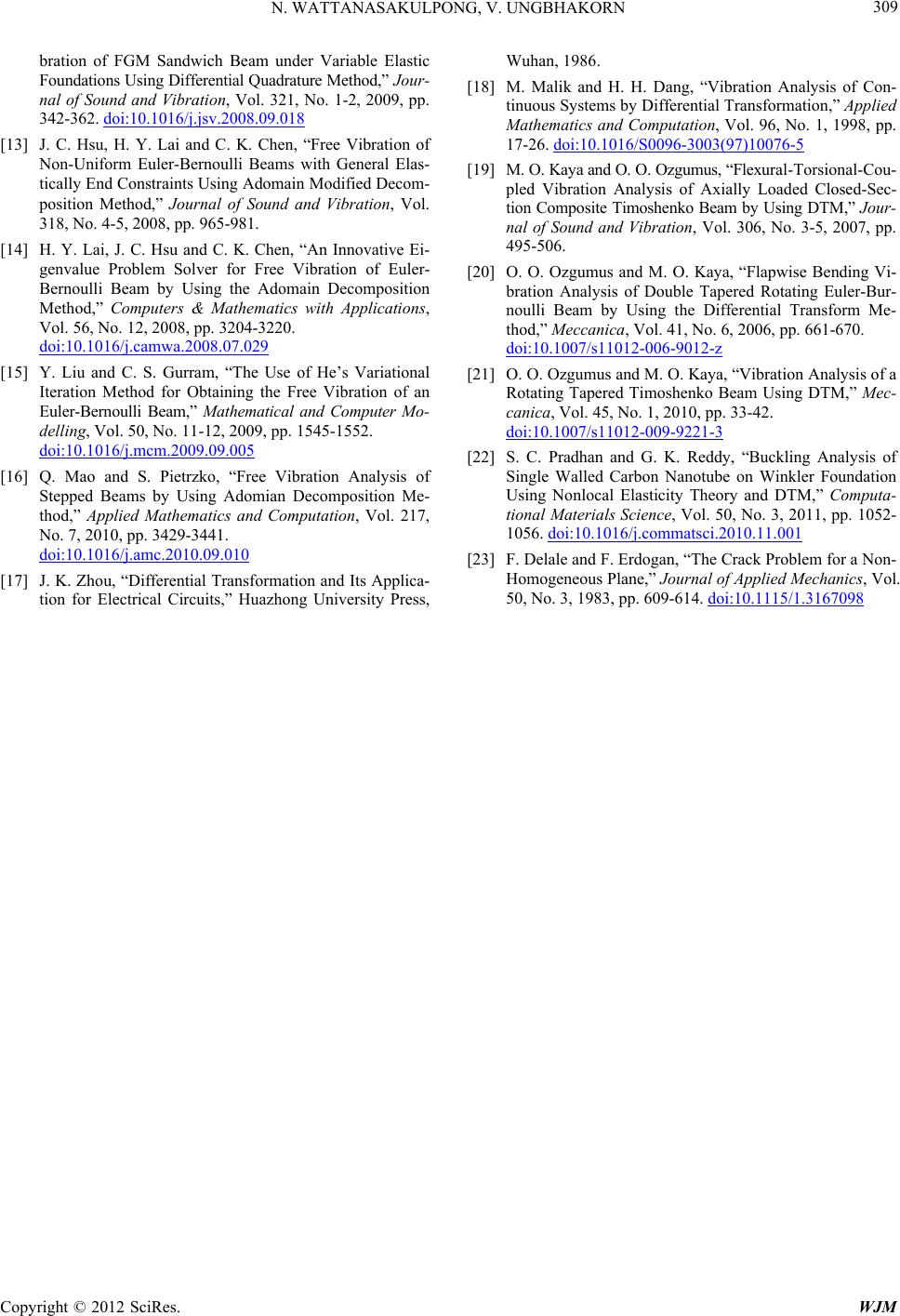

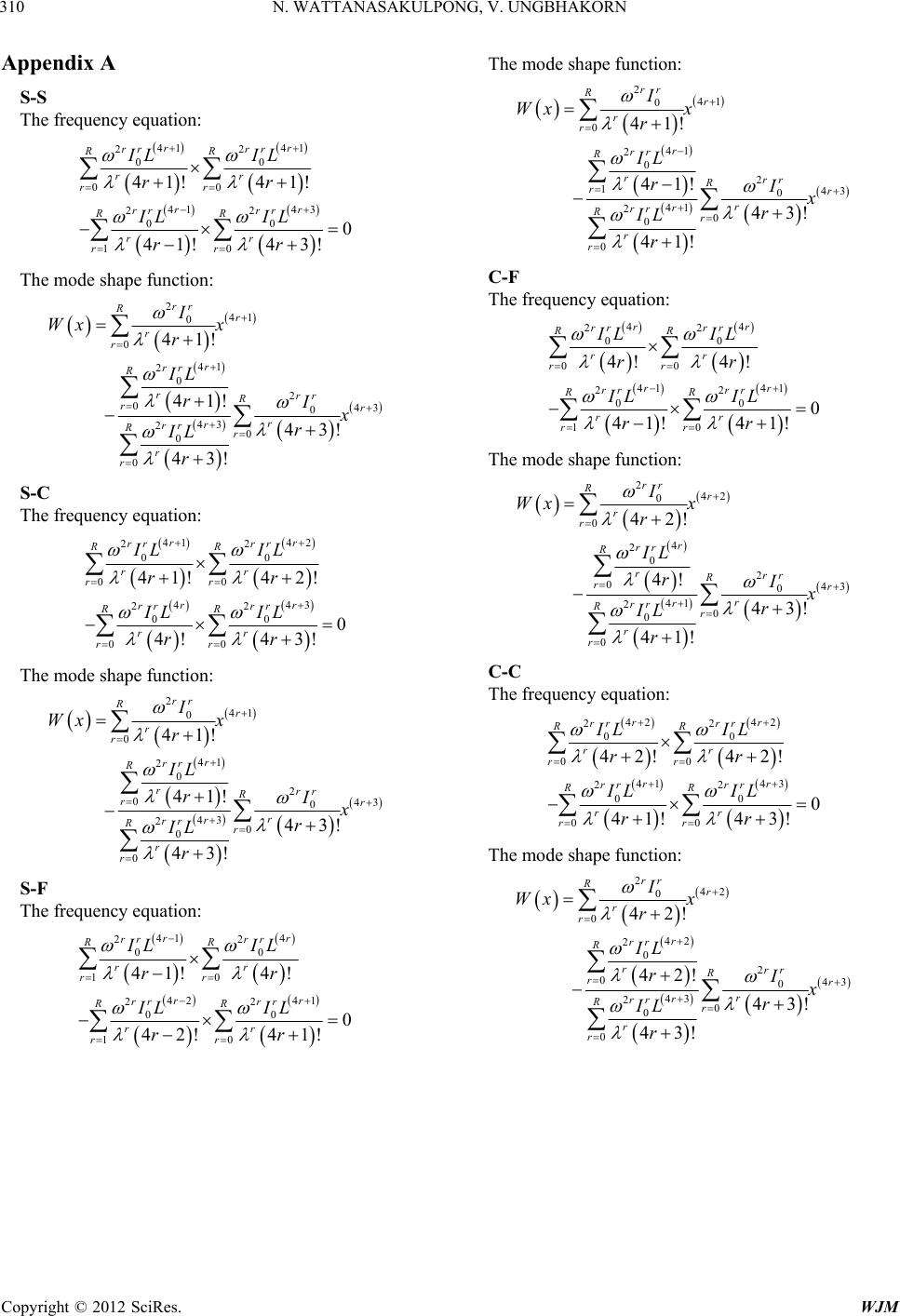

|