Paper Menu >>

Journal Menu >>

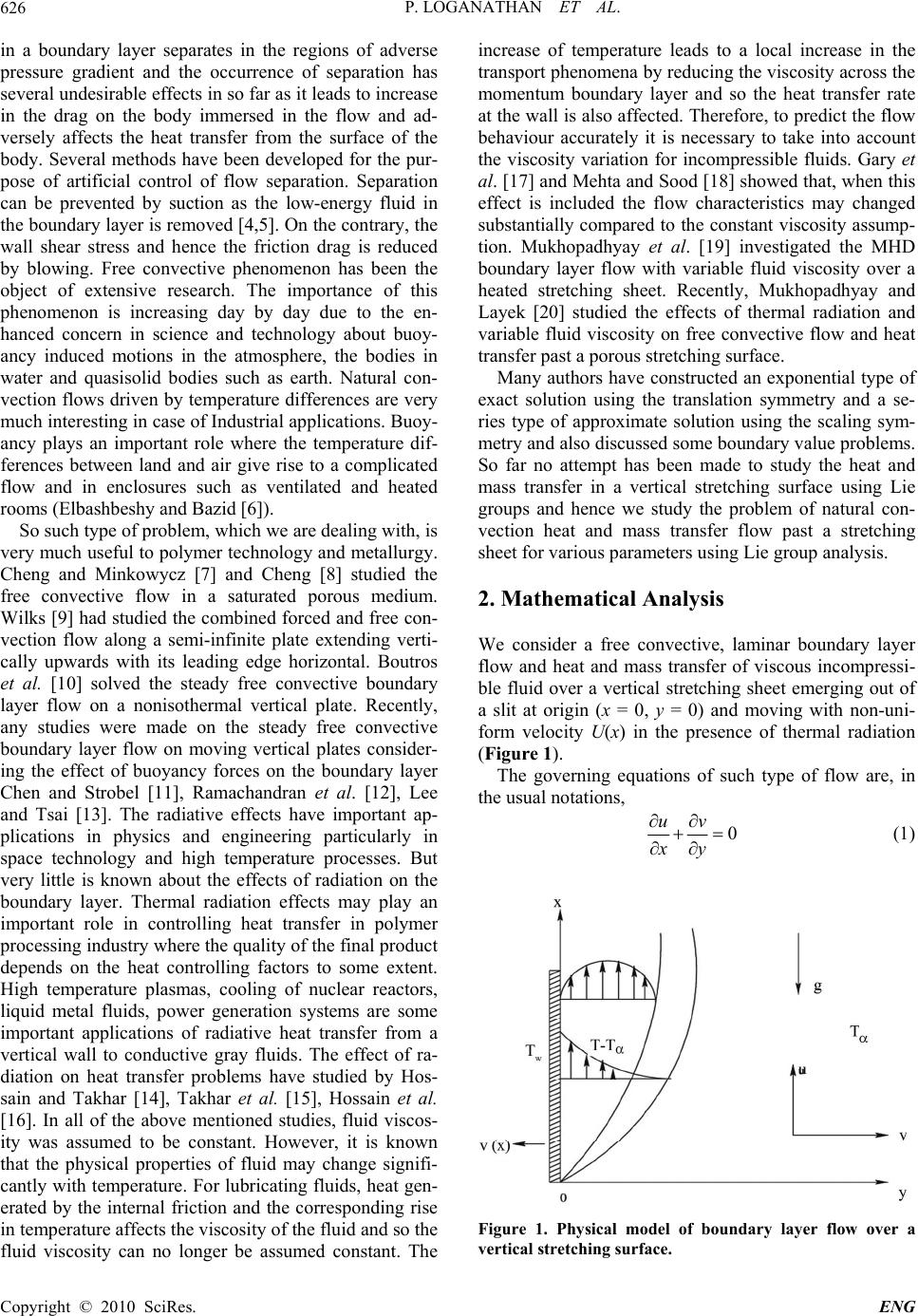

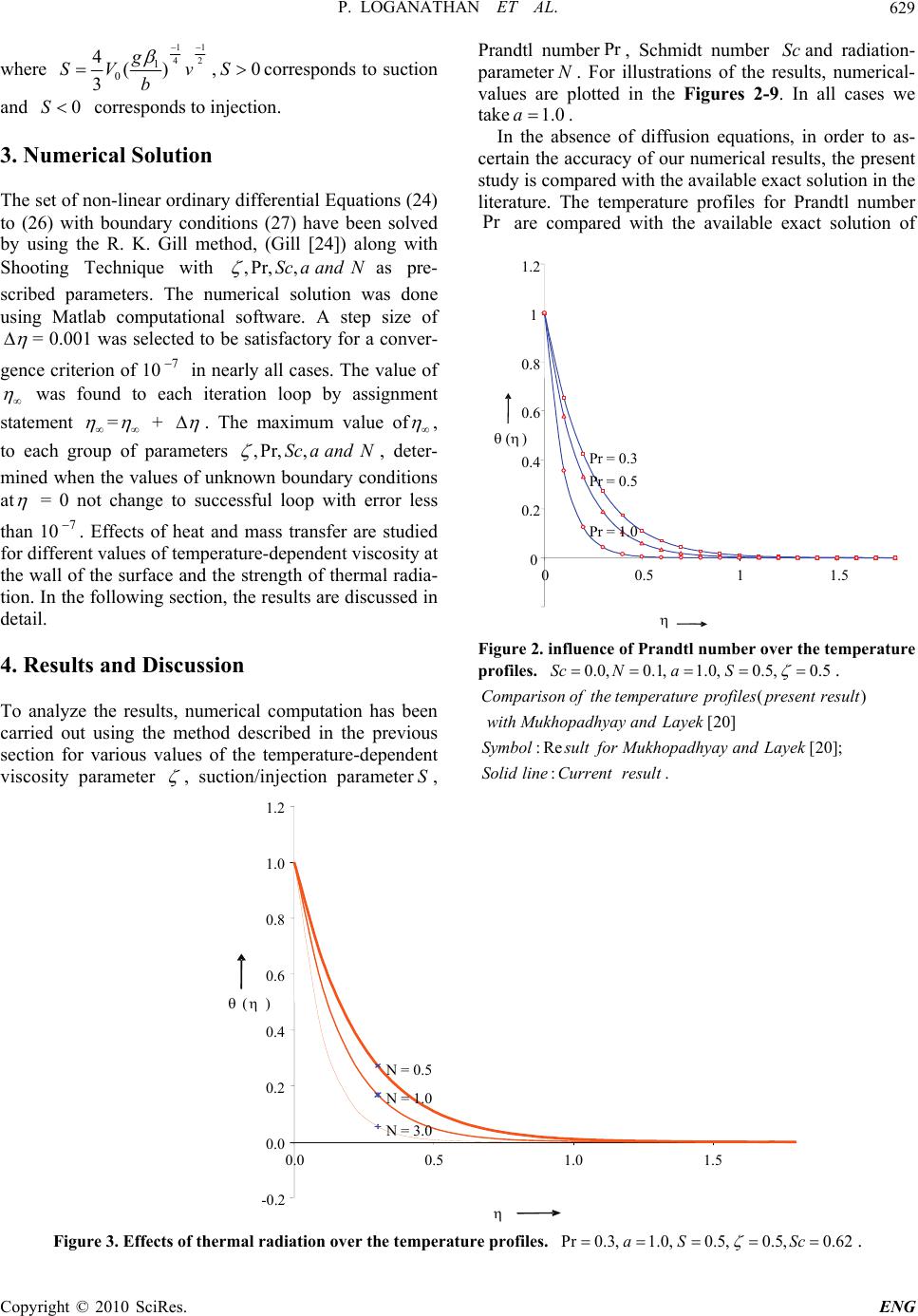

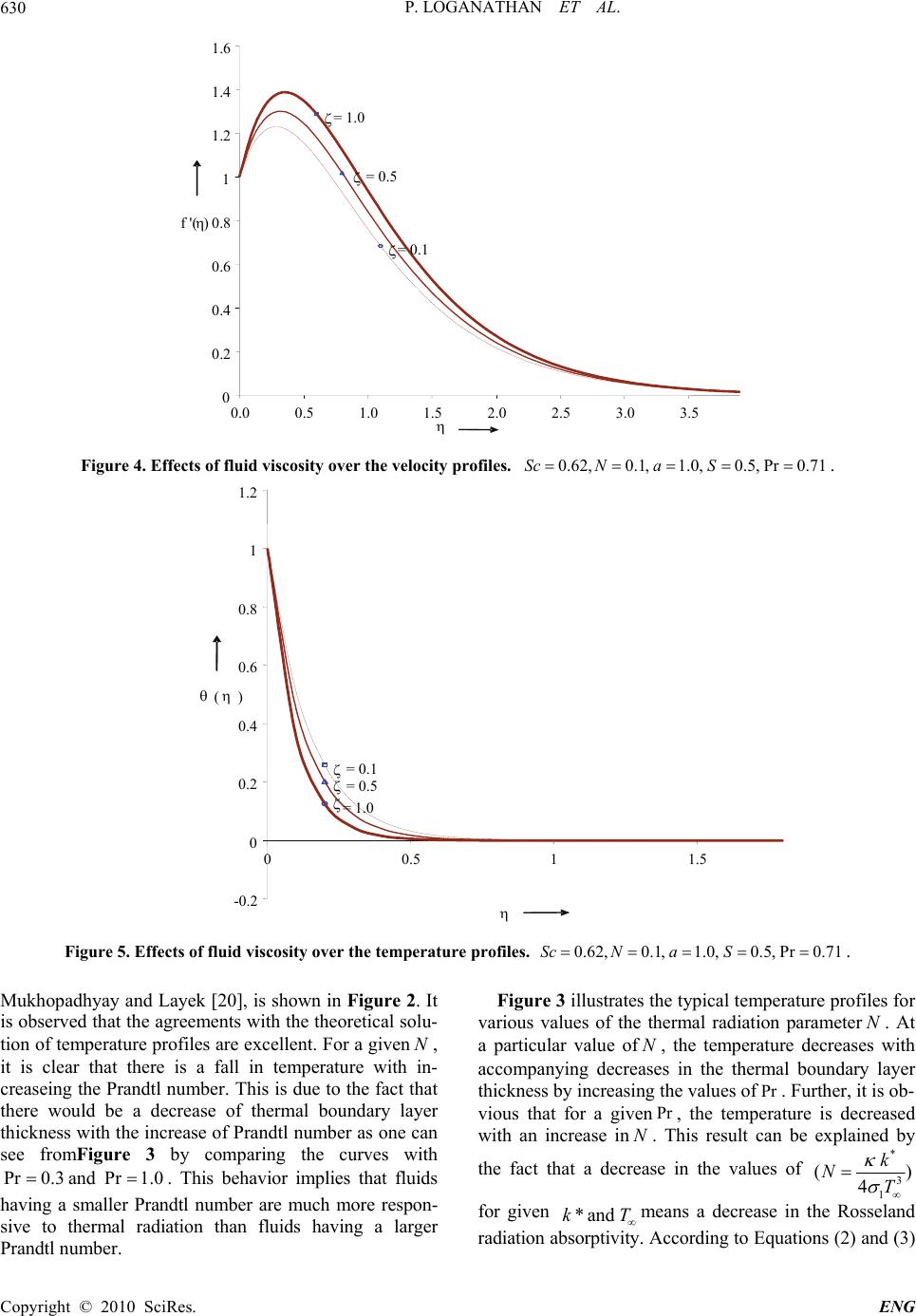

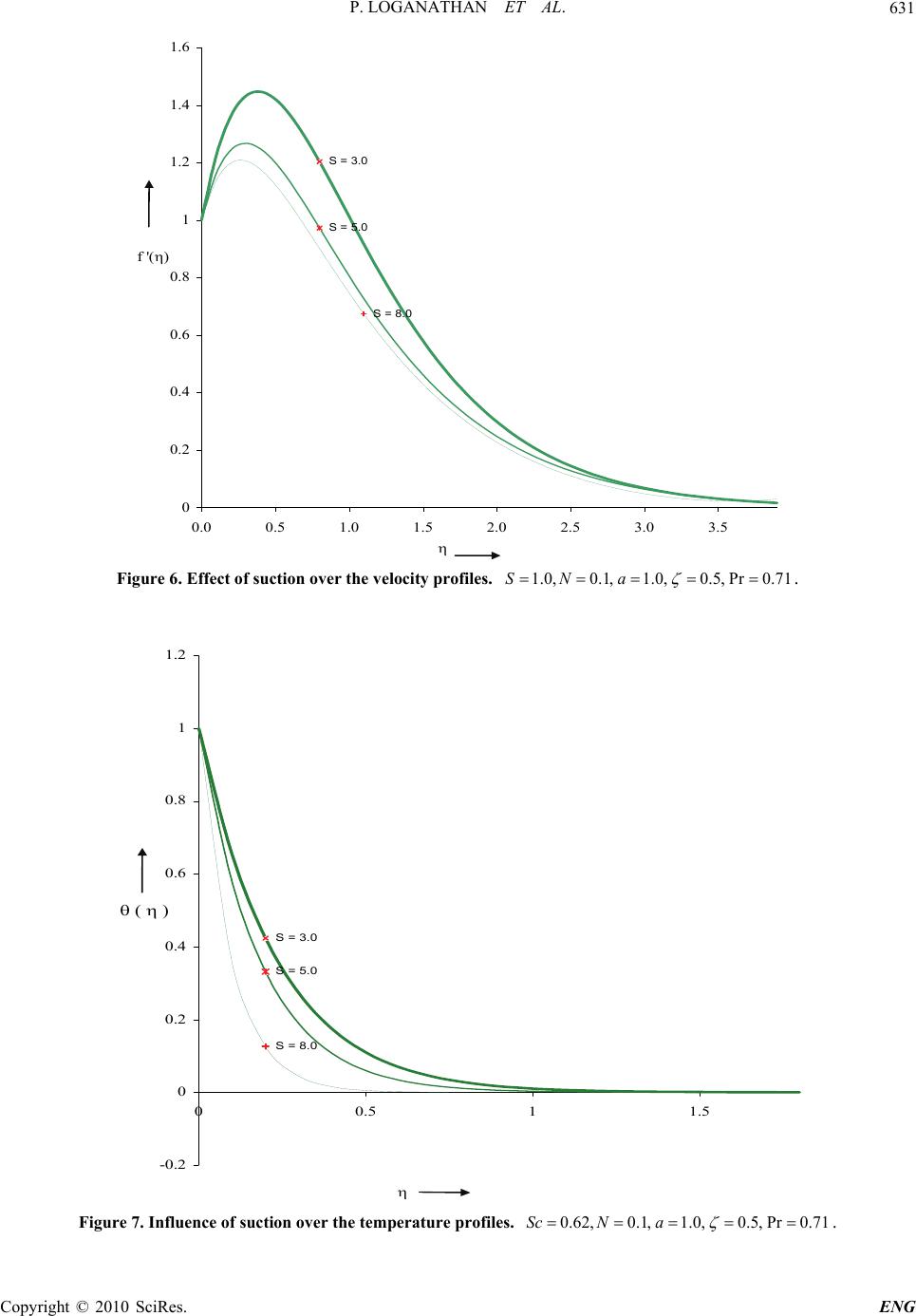

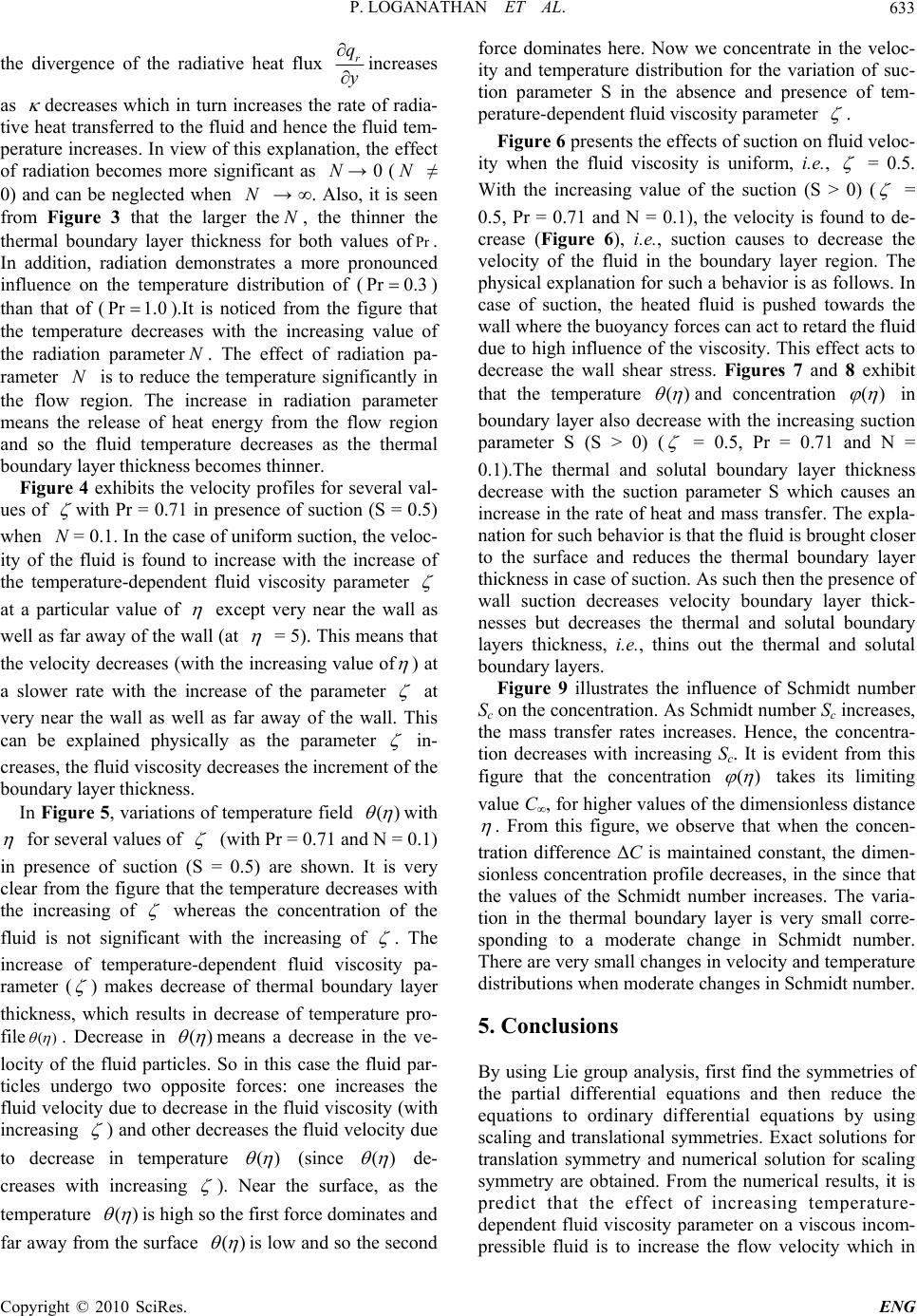

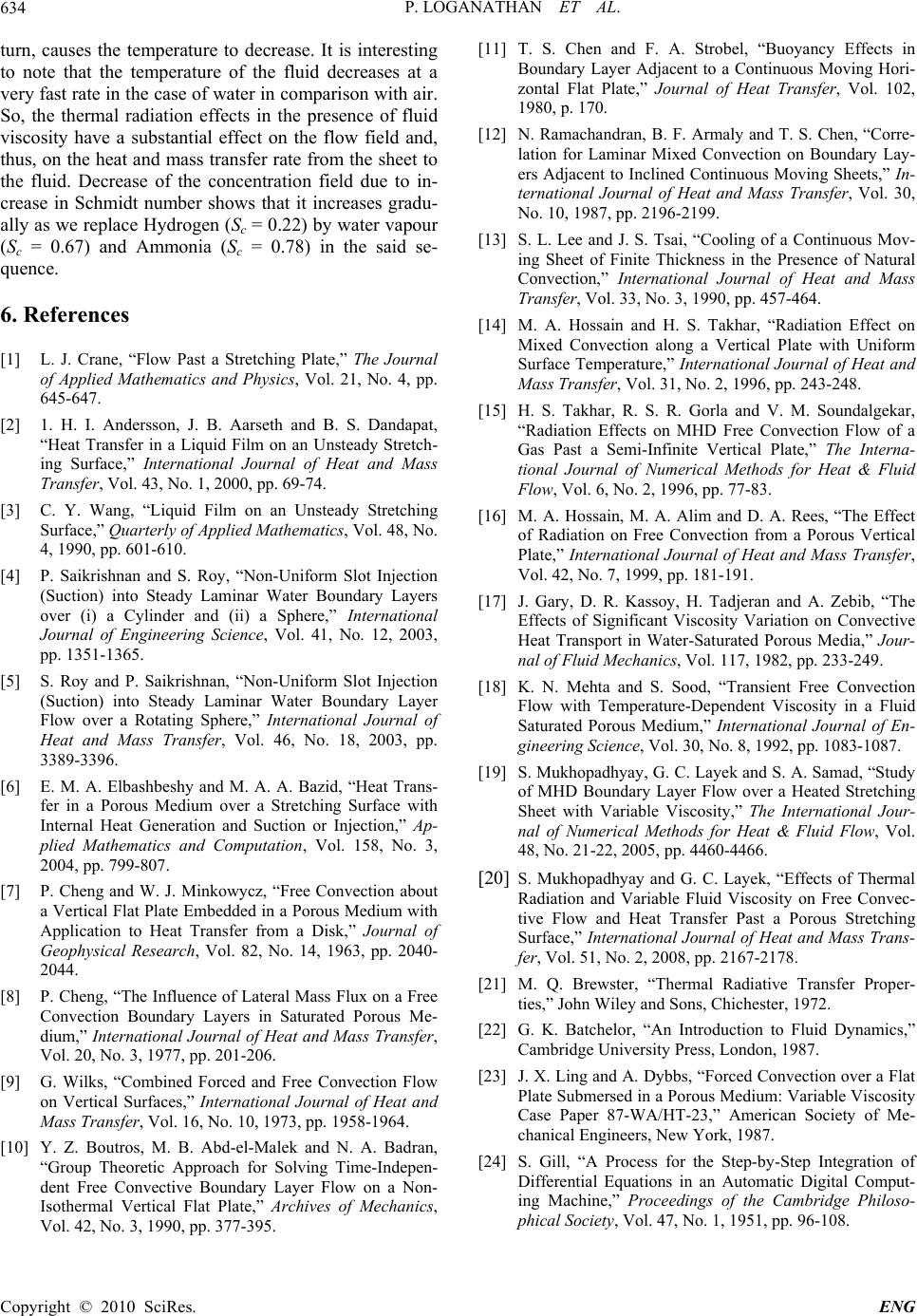

Engineering, 2010, 2, 625-634 doi:10.4236/eng.2010.28080 Published Online August 2010 (http://www.SciRP.org/journal/eng). Copyright © 2010 SciRes. ENG Lie Group Analysis for the Effects of Variable Fluid Viscosity and Thermal Radiation on Free Convective Heat and Mass Transfer with Variable Stream Condition P. Loganathan1, P. Puvi Arasu2 1Department of Mathematics, Anna University, Chennai, India 2Erode Sengunthar Engineering College, Thudupathi, India E-mail: puviarasup@gmail.com Received December 23, 2009; revised February 26, 2010; accepted March 6, 2010 Abstract Natural convective boundary layer flow and heat and mass transfer of a fluid with variable viscosity and thermal radiation over a vertical stretching surface in the presence of suction/injection is investigated by Lie group analysis. Fluid viscosity is assumed to vary as a linear function of temperature. The symmetry groups admitted by the corresponding boundary value problem are obtained by using a special form of Lie group transformations viz. scaling group of transformations. An exact solution is obtained for translation symmetry and numerical solutions for scaling symmetry. The effects of fluid viscosity and thermal radiation on the di- mensionless velocity, temperature and concentration profiles are shown graphically. Comparisons with pre- viously published works are performed and excellent agreement between the results is obtained. The conclu- sion is drawn that the flow field and temperature profiles are significantly influenced by these parameters. Keywords: Scaling Group of Transformations, Free Convective Flow, Temperature-Dependent Fluid Viscosity, Suction/Blowing, Thermal Radiation 1. Introduction The study of natural convection flow for an incompressi- ble viscous fluid past a heated surface has attracted the interest of many researchers in view of its important ap- plications to many engineering problems such as cooling of nuclear reactors, the boundary layer control in aero- dynamics, crystal growth, food processing and cooling towers. In this paper, symmetry methods are applied to a natural convection boundary layer problem. The main advantage of such methods is that they can successfully be applied to non-linear differential equations. The sym- metries of differential equations are those continuous groups of transformations under which the differential equations remain invariant, that is, a symmetry group maps any solution to another solution. The symmetry solutions are quite popular because they result in the re- duction of the number of independent variables of the problem. A class of flow problems with obvious relevance to polymer extrusion is the flow induced by the stretching motion of a flat elastic sheet. In a melt-spinning process, the extrudate from the die is generally drawn and simul- taneously stretched into a filament or sheet, which is thereafter solidified through rapid quenching or gradual cooling by direct contact with water or chilled metal rolls. In fact, stretching imports a unidirectional orientation to the extrudate, thereby improving its mechanical proper- ties and the quality of the final product greatly depends on the rate of cooling. Crane [1] was the first who stud- ied the motion set up in the ambient fluid due to a line- arly stretching surface. Several authors see e.g., the ref- erences cited in [2], have subsequently explored various aspects of the accompanying heat transfer occurring in the infinite fluid medium surrounding the stretching sheet. The hydrodynamics of a finite fluid medium, i.e. a thin liquid film, on a stretching sheet was first considered by Wang [3] who by means of a similarity transforma- tion reduced the unsteady Navier–Stokes equations to a non-linear ordinary differential equation. The accompa- nying heat transfer problem was solved more recently by Andersson et al. [2]. In these studies the film surface was planar and free of any stresses. The production of sheeting material arises in a number of industrial manufacturing processes and includes both metal and polymer sheets. It is well known that the flow  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 626 in a boundary layer separates in the regions of adverse pressure gradient and the occurrence of separation has several undesirable effects in so far as it leads to increase in the drag on the body immersed in the flow and ad- versely affects the heat transfer from the surface of the body. Several methods have been developed for the pur- pose of artificial control of flow separation. Separation can be prevented by suction as the low-energy fluid in the boundary layer is removed [4,5]. On the contrary, the wall shear stress and hence the friction drag is reduced by blowing. Free convective phenomenon has been the object of extensive research. The importance of this phenomenon is increasing day by day due to the en- hanced concern in science and technology about buoy- ancy induced motions in the atmosphere, the bodies in water and quasisolid bodies such as earth. Natural con- vection flows driven by temperature differences are very much interesting in case of Industrial applications. Buoy- ancy plays an important role where the temperature dif- ferences between land and air give rise to a complicated flow and in enclosures such as ventilated and heated rooms (Elbashbeshy and Bazid [6]). So such type of problem, which we are dealing with, is very much useful to polymer technology and metallurgy. Cheng and Minkowycz [7] and Cheng [8] studied the free convective flow in a saturated porous medium. Wilks [9] had studied the combined forced and free con- vection flow along a semi-infinite plate extending verti- cally upwards with its leading edge horizontal. Boutros et al. [10] solved the steady free convective boundary layer flow on a nonisothermal vertical plate. Recently, any studies were made on the steady free convective boundary layer flow on moving vertical plates consider- ing the effect of buoyancy forces on the boundary layer Chen and Strobel [11], Ramachandran et al. [12], Lee and Tsai [13]. The radiative effects have important ap- plications in physics and engineering particularly in space technology and high temperature processes. But very little is known about the effects of radiation on the boundary layer. Thermal radiation effects may play an important role in controlling heat transfer in polymer processing industry where the quality of the final product depends on the heat controlling factors to some extent. High temperature plasmas, cooling of nuclear reactors, liquid metal fluids, power generation systems are some important applications of radiative heat transfer from a vertical wall to conductive gray fluids. The effect of ra- diation on heat transfer problems have studied by Hos- sain and Takhar [14], Takhar et al. [15], Hossain et al. [16]. In all of the above mentioned studies, fluid viscos- ity was assumed to be constant. However, it is known that the physical properties of fluid may change signifi- cantly with temperature. For lubricating fluids, heat gen- erated by the internal friction and the corresponding rise in temperature affects the viscosity of the fluid and so the fluid viscosity can no longer be assumed constant. The increase of temperature leads to a local increase in the transport phenomena by reducing the viscosity across the momentum boundary layer and so the heat transfer rate at the wall is also affected. Therefore, to predict the flow behaviour accurately it is necessary to take into account the viscosity variation for incompressible fluids. Gary et al. [17] and Mehta and Sood [18] showed that, when this effect is included the flow characteristics may changed substantially compared to the constant viscosity assump- tion. Mukhopadhyay et al. [19] investigated the MHD boundary layer flow with variable fluid viscosity over a heated stretching sheet. Recently, Mukhopadhyay and Layek [20] studied the effects of thermal radiation and variable fluid viscosity on free convective flow and heat transfer past a porous stretching surface. Many authors have constructed an exponential type of exact solution using the translation symmetry and a se- ries type of approximate solution using the scaling sym- metry and also discussed some boundary value problems. So far no attempt has been made to study the heat and mass transfer in a vertical stretching surface using Lie groups and hence we study the problem of natural con- vection heat and mass transfer flow past a stretching sheet for various parameters using Lie group analysis. 2. Mathematical Analysis We consider a free convective, laminar boundary layer flow and heat and mass transfer of viscous incompressi- ble fluid over a vertical stretching sheet emerging out of a slit at origin (x = 0, y = 0) and moving with non-uni- form velocity U(x) in the presence of thermal radiation (Figure 1). The governing equations of such type of flow are, in the usual notations, 0 uv xy (1) Figure 1. Physical model of boundary layer flow over a vertical stretching surface.  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 627 2 * 2 1[( )()] uu uv xy Tuu gTTg CC Tyyx (2) 2 2 1r pp q TT T uv x yc cy y (3) 2 2 CC C uv D xy y (4) (), (),,0 ww uUxvVxCCTTaty 0, ,uCCTTasy (5) when the viscous dissipation term in the energy equation is neglected (as the fluid velocity is very low). Here u and v are the components of velocity respectively in the x and y directions, is the coefficient of fluid viscosity, is the fluid density (assumed constant), T is the temperature, is the thermal conductivity of the fluid, Dis diffusional coefficient, is the volumetric coefficient of thermal expansion, * is the volumetric coefficient of concentration expansion, g is the gravity field, T is the temperature at infinity, where ()Ux is the stream wise velocity and ()Vx is the velocity of suction of the fluid, w Tis the wall temperature. Using Rosseland approximation for radiation (Brew- ster [21]) we can write 4 1 * 4 3 r T qy k where 1 is the Stefan–Boltzman constant, k* is the absorption coeffi- cient. Assuming that the temperature difference within the flow is such that 4 T may be expanded in a Taylor se- ries and expanding 4 T about T and neglecting higher orders we get 43 4 43TTTT Therefore, the Equation (3) becomes 3 22 1 2*2 16 3 pp T TT TT uv xyc ycky (6) We now introduce the following relations for ,,uv and as uy ,v x , w TT TT and w CC CC (7) where u is the stream function. The stream wise ve- locity and the suction/injection velocity are taken as 1 2 0 (), () m m UxcxVxV x (8) Here 0cis constant, w T is the wall temperature, the power-law exponent m is also constant. In this study we take 1c. The temperature-dependent fluid viscosity is given by (Batchelor [22]), *[( )] w abTT where * is the constant value of the coefficient of viscosity far away from the sheet and ba, are constants and (0)b. For a viscous fluid, Ling and Dybbs [23] suggest a viscosity dependence on temperature T of the form [1 ()]TT where c is a thermal property of the fluid and is the viscosity away from the hot sheet. This relation does not differ at all with our formu- lation. The range of temperature, i.e., () w TT studied here is0 (023 )C. Using the relations (5) in the boundary layer Equation (2) and in the energy and diffusion Equations (3) and (4) we get the following equations 22 2 23 ** * 23 [(1)]( ) yxy xy vva g yb yy (9) 32 1 *2 16 () 3 pp T yx xycck y (10) 2 2 D yx xyy (11) where * * (), w bTTv The boundary conditions Equation (5) become 1 2 0 ,, 10; 0,0,0 m m xVx yx atyas y y (12) We now introduce the simplified form of Lie-group transformations namely, the scaling group of transforma- tions (Mukhopadhyay et al. [19]), 3 12 567 4 ** * ** ** :, ,, ,, , xxeyyee uuevveee (13) Equation (13) may be considered as a point-transfor- mation which transforms co-ordinates (, ,,,,, )xy uv to the coordinates ** ***** (,,,,,, )xy uv . Substituting (13) in (9), (10) and (11) we get,  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 628 123 236 23 236 67 *2* *2* (2 2) **** *2 *2* (3 ) * **2 3* 3* (3 )(3) *** *3 *3 ** * [] () eyxyx y ve yy va eve yy ge e b (14) 1236 26 ** ** () ** ** 32* (2 ) 1 **2 16 3 pp eyx xy Te cck y (15) 1237 27 ** ** () ** ** 2* (2 ) *2 eyx xy De y (16) The system will remain invariant under the group of transformations , we would have the following relations among the parameters, namely 123 236 23 671236 261237 27 223 3 ; 22and These relations give6721 3 11 0, 43 . The boundary conditions yield411 1, 2 m 511 11 1 () 24 2 mas m In view of these, the boundary conditions become 11 () 24 ** ***** 0 * * ** * * ,,1 00,0,0 x Vx aty x y andas y y (17) The set of transformations reduces to 3 11 44 1 11 24 ** * ** ** ,, , ,,,, xxe yyee uuevve Expanding by Taylor’s method in powers of and keeping terms up to the order we get ** * 11 1 ** ** 11 3 ,, , 44 ,, 0 24 xxx yyy uuuvv v In terms of differentials these yield 1111 1300 4424 dxdyddudv d d xyuv Solving the above equations we get, 13 44 *** *** ,(),(),()yxx F (18) With the help of these relations, the (14), (15) and (16) become 2* ** * 23 4 4()44 () FFF vF avFvF g b (19) 3 1 * 16 430 3 pp TF cck (20) 430DF (21) The boundary conditions take the following form 0 4 1,, 1 3 00,0,0 V FF at and Fas (22) Again, we introduce the following transformations for ,, F and in Equations (19), (20) and (21): 11 11 11 11 ** ** 11 * ** ** 11 1 (), (), () ,()2 bb bb gg vF vF bb gg vvwhere bb (23) Taking *,andFf the Equations (19), (20) and (21) finally take the following form 2 4( )44 23 4() aF F F FFF (24) 44 130 Pr 3F N (25) 430F Sc (26) where ** Pr p p vcc is the Prandtl number, * 3 1 4 k NT is the Radiation parameter, * v Sc D is the Schmidt number. The boundary conditions take the fol- lowing forms. ** 1, ,1, 00,0,0 ffS atand fas (27)  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 629 where 11 42 1 0 4() 3 g SV v b ,0Scorresponds to suction and 0S corresponds to injection. 3. Numerical Solution The set of non-linear ordinary differential Equations (24) to (26) with boundary conditions (27) have been solved by using the R. K. Gill method, (Gill [24]) along with Shooting Technique with ,Pr, ,ScaandN as pre- scribed parameters. The numerical solution was done using Matlab computational software. A step size of = 0.001 was selected to be satisfactory for a conver- gence criterion of 107 in nearly all cases. The value of was found to each iteration loop by assignment statement = + . The maximum value of , to each group of parameters ,Pr, ,ScaandN , deter- mined when the values of unknown boundary conditions at = 0 not change to successful loop with error less than 107. Effects of heat and mass transfer are studied for different values of temperature-dependent viscosity at the wall of the surface and the strength of thermal radia- tion. In the following section, the results are discussed in detail. 4. Results and Discussion To analyze the results, numerical computation has been carried out using the method described in the previous section for various values of the temperature-dependent viscosity parameter , suction/injection parameterS, Prandtl numberPr , Schmidt number Sc and radiation- parameterN. For illustrations of the results, numerical- values are plotted in the Figures 2-9. In all cases we take 1.0a . In the absence of diffusion equations, in order to as- certain the accuracy of our numerical results, the present study is compared with the available exact solution in the literature. The temperature profiles for Prandtl number Pr are compared with the available exact solution of Figure 2. influence of Prandtl number over the temperature profiles. 0.0,0.1, 1.0,0.5,0.5Sc Na S . () [20] : Re[20]; :. Comparison ofthe temperatureprofilespresentresult with Mukhopadhyay andLayek SymbolsultforMukhopadhyay andLayek Solid lineCurrentresult Figure 3. Effects of thermal radiation over the temperature profiles. Pr 0.3,1.0,0.5,0.5,0.62aS Sc . Pr = 0.3 Pr = 0.5 Pr = 1.0 0 0.2 0.4 0.6 0.8 1 1.2 00.5 11.5 ( ) N = 0.5 N = 1.0 N = 3.0 -0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2 0.00.51.01.5 ( )  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 630 Figure 4. Effects of fluid viscosity over the velocity profiles. 0.62,0.1,1.0,0.5,Pr0.71ScNa S . Figure 5. Effects of fluid viscosity over the temperature profiles. 0.62,0.1,1.0,0.5,Pr0.71ScNa S . Mukhopadhyay and Layek [20], is shown in Figure 2. It is observed that the agreements with the theoretical solu- tion of temperature profiles are excellent. For a givenN, it is clear that there is a fall in temperature with in- creaseing the Prandtl number. This is due to the fact that there would be a decrease of thermal boundary layer thickness with the increase of Prandtl number as one can see fromFigure 3 by comparing the curves with Pr0.3andPr 1.0. This behavior implies that fluids having a smaller Prandtl number are much more respon- sive to thermal radiation than fluids having a larger Prandtl number. Figure 3 illustrates the typical temperature profiles for various values of the thermal radiation parameterN. At a particular value ofN, the temperature decreases with accompanying decreases in the thermal boundary layer thickness by increasing the values of Pr . Further, it is ob- vious that for a givenPr , the temperature is decreased with an increase inN. This result can be explained by the fact that a decrease in the values of * 3 1 () 4 k NT for given *andkT means a decrease in the Rosseland radiation absorptivity. According to Equations (2) and (3) = 1.0 = 0.5 = 0.1 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 f '( ) = 0.1 = 0.5 = 1.0 -0.2 0 0.2 0.4 0.6 0.8 1 1.2 0 0.51 1.5 ( )  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 631 S = 3.0 S = 5.0 S = 8.0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 f '() Figure 6. Effect of suction over the velocity profiles. 1.0,0.1,1.0,0.5,Pr0.71SNa . S = 3.0 S = 5.0 S = 8.0 -0. 2 0 0.2 0.4 0.6 0.8 1 1.2 0 0.5 1 1.5 ( ) Figure 7. Influence of suction over the temperature profiles. 0.62,0.1,1.0,0.5, Pr0.71ScNa .  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 632 S = 3.0 S = 5.0 S = 8.0 -0.2 0 0.2 0.4 0.6 0.8 1 1.2 00.511.5 ( ) Figure 8. Effects of Suction over the concentration profiles. 0.62,0.1,1.0,0.5, Pr0.71ScNa . Sc = 0.22 Sc = 0.62 Sc = 0.78 -0.2 0 0.2 0.4 0.6 0.8 1 1.2 00.511.5 ( ) Figure 9. Effects of Schmidt number over the concentration profiles. 1.0,0.1,1.0,0.5, Pr0.71SNa .  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 633 the divergence of the radiative heat flux r q y increases as decreases which in turn increases the rate of radia- tive heat transferred to the fluid and hence the fluid tem- perature increases. In view of this explanation, the effect of radiation becomes more significant as N→ 0 (N ≠ 0) and can be neglected when N → ∞. Also, it is seen from Figure 3 that the larger theN, the thinner the thermal boundary layer thickness for both values ofPr . In addition, radiation demonstrates a more pronounced influence on the temperature distribution of (Pr 0.3 ) than that of (Pr 1.0).It is noticed from the figure that the temperature decreases with the increasing value of the radiation parameterN. The effect of radiation pa- rameter N is to reduce the temperature significantly in the flow region. The increase in radiation parameter means the release of heat energy from the flow region and so the fluid temperature decreases as the thermal boundary layer thickness becomes thinner. Figure 4 exhibits the velocity profiles for several val- ues of with Pr = 0.71 in presence of suction (S = 0.5) when N= 0.1. In the case of uniform suction, the veloc- ity of the fluid is found to increase with the increase of the temperature-dependent fluid viscosity parameter at a particular value of except very near the wall as well as far away of the wall (at = 5). This means that the velocity decreases (with the increasing value of ) at a slower rate with the increase of the parameter at very near the wall as well as far away of the wall. This can be explained physically as the parameter in- creases, the fluid viscosity decreases the increment of the boundary layer thickness. In Figure 5, variations of temperature field () with for several values of (with Pr = 0.71 and N = 0.1) in presence of suction (S = 0.5) are shown. It is very clear from the figure that the temperature decreases with the increasing of whereas the concentration of the fluid is not significant with the increasing of . The increase of temperature-dependent fluid viscosity pa- rameter ( ) makes decrease of thermal boundary layer thickness, which results in decrease of temperature pro- file )( . Decrease in () means a decrease in the ve- locity of the fluid particles. So in this case the fluid par- ticles undergo two opposite forces: one increases the fluid velocity due to decrease in the fluid viscosity (with increasing ) and other decreases the fluid velocity due to decrease in temperature () (since () de- creases with increasing ). Near the surface, as the temperature () is high so the first force dominates and far away from the surface () is low and so the second force dominates here. Now we concentrate in the veloc- ity and temperature distribution for the variation of suc- tion parameter S in the absence and presence of tem- perature-dependent fluid viscosity parameter . Figure 6 presents the effects of suction on fluid veloc- ity when the fluid viscosity is uniform, i.e., = 0.5. With the increasing value of the suction (S > 0) ( = 0.5, Pr = 0.71 and N = 0.1), the velocity is found to de- crease (Figure 6), i.e., suction causes to decrease the velocity of the fluid in the boundary layer region. The physical explanation for such a behavior is as follows. In case of suction, the heated fluid is pushed towards the wall where the buoyancy forces can act to retard the fluid due to high influence of the viscosity. This effect acts to decrease the wall shear stress. Figures 7 and 8 exhibit that the temperature () and concentration () in boundary layer also decrease with the increasing suction parameter S (S > 0) ( = 0.5, Pr = 0.71 and N = 0.1).The thermal and solutal boundary layer thickness decrease with the suction parameter S which causes an increase in the rate of heat and mass transfer. The expla- nation for such behavior is that the fluid is brought closer to the surface and reduces the thermal boundary layer thickness in case of suction. As such then the presence of wall suction decreases velocity boundary layer thick- nesses but decreases the thermal and solutal boundary layers thickness, i.e., thins out the thermal and solutal boundary layers. Figure 9 illustrates the influence of Schmidt number Sc on the concentration. As Schmidt number Sc increases, the mass transfer rates increases. Hence, the concentra- tion decreases with increasing Sc. It is evident from this figure that the concentration () takes its limiting value C∞, for higher values of the dimensionless distance . From this figure, we observe that when the concen- tration difference ΔC is maintained constant, the dimen- sionless concentration profile decreases, in the since that the values of the Schmidt number increases. The varia- tion in the thermal boundary layer is very small corre- sponding to a moderate change in Schmidt number. There are very small changes in velocity and temperature distributions when moderate changes in Schmidt number. 5. Conclusions By using Lie group analysis, first find the symmetries of the partial differential equations and then reduce the equations to ordinary differential equations by using scaling and translational symmetries. Exact solutions for translation symmetry and numerical solution for scaling symmetry are obtained. From the numerical results, it is predict that the effect of increasing temperature- dependent fluid viscosity parameter on a viscous incom- pressible fluid is to increase the flow velocity which in  P. LOGANATHAN ET AL. Copyright © 2010 SciRes. ENG 634 turn, causes the temperature to decrease. It is interesting to note that the temperature of the fluid decreases at a very fast rate in the case of water in comparison with air. So, the thermal radiation effects in the presence of fluid viscosity have a substantial effect on the flow field and, thus, on the heat and mass transfer rate from the sheet to the fluid. Decrease of the concentration field due to in- crease in Schmidt number shows that it increases gradu- ally as we replace Hydrogen (Sc = 0.22) by water vapour (Sc = 0.67) and Ammonia (Sc = 0.78) in the said se- quence. 6. References [1] L. J. Crane, “Flow Past a Stretching Plate,” The Journal of Applied Mathematics and Physics, Vol. 21, No. 4, pp. 645-647. [2] 1. H. I. Andersson, J. B. Aarseth and B. S. Dandapat, “Heat Transfer in a Liquid Film on an Unsteady Stretch- ing Surface,” International Journal of Heat and Mass Transfer, Vol. 43, No. 1, 2000, pp. 69-74. [3] C. Y. Wang, “Liquid Film on an Unsteady Stretching Surface,” Quarterly of Applied Mathematics, Vol. 48, No. 4, 1990, pp. 601-610. [4] P. Saikrishnan and S. Roy, “Non-Uniform Slot Injection (Suction) into Steady Laminar Water Boundary Layers over (i) a Cylinder and (ii) a Sphere,” International Journal of Engineering Science, Vol. 41, No. 12, 2003, pp. 1351-1365. [5] S. Roy and P. Saikrishnan, “Non-Uniform Slot Injection (Suction) into Steady Laminar Water Boundary Layer Flow over a Rotating Sphere,” International Journal of Heat and Mass Transfer, Vol. 46, No. 18, 2003, pp. 3389-3396. [6] E. M. A. Elbashbeshy and M. A. A. Bazid, “Heat Trans- fer in a Porous Medium over a Stretching Surface with Internal Heat Generation and Suction or Injection,” Ap- plied Mathematics and Computation, Vol. 158, No. 3, 2004, pp. 799-807. [7] P. Cheng and W. J. Minkowycz, “Free Convection about a Vertical Flat Plate Embedded in a Porous Medium with Application to Heat Transfer from a Disk,” Journal of Geophysical Research, Vol. 82, No. 14, 1963, pp. 2040- 2044. [8] P. Cheng, “The Influence of Lateral Mass Flux on a Free Convection Boundary Layers in Saturated Porous Me- dium,” International Journal of Heat and Mass Transfer, Vol. 20, No. 3, 1977, pp. 201-206. [9] G. Wilks, “Combined Forced and Free Convection Flow on Vertical Surfaces,” International Journal of Heat and Mass Transfer, Vol. 16, No. 10, 1973, pp. 1958-1964. [10] Y. Z. Boutros, M. B. Abd-el-Malek and N. A. Badran, “Group Theoretic Approach for Solving Time-Indepen- dent Free Convective Boundary Layer Flow on a Non- Isothermal Vertical Flat Plate,” Archives of Mechanics, Vol. 42, No. 3, 1990, pp. 377-395. [11] T. S. Chen and F. A. Strobel, “Buoyancy Effects in Boundary Layer Adjacent to a Continuous Moving Hori- zontal Flat Plate,” Journal of Heat Transfer, Vol. 102, 1980, p. 170. [12] N. Ramachandran, B. F. Armaly and T. S. Chen, “Corre- lation for Laminar Mixed Convection on Boundary Lay- ers Adjacent to Inclined Continuous Moving Sheets,” In- ternational Journal of Heat and Mass Transfer, Vol. 30, No. 10, 1987, pp. 2196-2199. [13] S. L. Lee and J. S. Tsai, “Cooling of a Continuous Mov- ing Sheet of Finite Thickness in the Presence of Natural Convection,” International Journal of Heat and Mass Transfer, Vol. 33, No. 3, 1990, pp. 457-464. [14] M. A. Hossain and H. S. Takhar, “Radiation Effect on Mixed Convection along a Vertical Plate with Uniform Surface Temperature,” International Journal of Heat and Mass Transfer, Vol. 31, No. 2, 1996, pp. 243-248. [15] H. S. Takhar, R. S. R. Gorla and V. M. Soundalgekar, “Radiation Effects on MHD Free Convection Flow of a Gas Past a Semi-Infinite Vertical Plate,” The Interna- tional Journal of Numerical Methods for Heat & Fluid Flow, Vol. 6, No. 2, 1996, pp. 77-83. [16] M. A. Hossain, M. A. Alim and D. A. Rees, “The Effect of Radiation on Free Convection from a Porous Vertical Plate,” International Journal of Heat and Mass Transfer, Vol. 42, No. 7, 1999, pp. 181-191. [17] J. Gary, D. R. Kassoy, H. Tadjeran and A. Zebib, “The Effects of Significant Viscosity Variation on Convective Heat Transport in Water-Saturated Porous Media,” Jour- nal of Fluid Mechanics, Vol. 117, 1982, pp. 233-249. [18] K. N. Mehta and S. Sood, “Transient Free Convection Flow with Temperature-Dependent Viscosity in a Fluid Saturated Porous Medium,” International Journal of En- gineering Science, Vol. 30, No. 8, 1992, pp. 1083-1087. [19] S. Mukhopadhyay, G. C. Layek and S. A. Samad, “Study of MHD Boundary Layer Flow over a Heated Stretching Sheet with Variable Viscosity,” The International Jour- nal of Numerical Methods for Heat & Fluid Flow, Vol. 48, No. 21-22, 2005, pp. 4460-4466. [20] S. Mukhopadhyay and G. C. Layek, “Effects of Thermal Radiation and Variable Fluid Viscosity on Free Convec- tive Flow and Heat Transfer Past a Porous Stretching Surface,” International Journal of Heat and Mass Trans- fer, Vol. 51, No. 2, 2008, pp. 2167-2178. [21] M. Q. Brewster, “Thermal Radiative Transfer Proper- ties,” John Wiley and Sons, Chichester, 1972. [22] G. K. Batchelor, “An Introduction to Fluid Dynamics,” Cambridge University Press, London, 1987. [23] J. X. Ling and A. Dybbs, “Forced Convection over a Flat Plate Submersed in a Porous Medium: Variable Viscosity Case Paper 87-WA/HT-23,” American Society of Me- chanical Engineers, New York, 1987. [24] S. Gill, “A Process for the Step-by-Step Integration of Differential Equations in an Automatic Digital Comput- ing Machine,” Proceedings of the Cambridge Philoso- phical Society, Vol. 47, No. 1, 1951, pp. 96-108. |