M. BOUROUSHIAN, T. KOSANOVIC

38

thickness is estimated as 180 nm. This value deviates

from the above calculated, certainly as expected from the

simplistic argument we used, and can be trusted only as

an order-of-magnitude calculation. In any case, accurate

assignment of the α-angle marking the disappearance of

the substrate is essential for the calculation. Note also

that factors related to material density and surface rough-

ness account for limited accuracy as to the thickness

evaluation of the present anodic films. Actually, the up-

per values of the above estimation should be preferred

since the effective density of the anodic oxide layer is

less than the bulk value, due to a porous structure [6].

Clearly, independent measurements should be used in

order to verify the reliability of the presented procedure,

and possibly standardize a correction or scaling factor for

a range of thickness values. Along this line, our GAXRD

results for cadmium selenide (CdSe) films of sub micro-

metric thickness (electrodeposited on Ti or Ni electrodes

by various electrolysis charges) were found to be in fair

agreement with stylus profilometry measurements, namely,

within an accuracy of 50 nm (unpublished results). Else-

where also [1], application of the above model has been

shown to give results in consistence with other mea-

suring techniques.

3.4. Analysis of Multilayer Heterostructures

The present GAXRD protocol was employed for per-

forming analysis of a multilayer heterostructure, namely

the two-layer ZnSe/CdSe/Ni system, prepared by se-

quential cathodic electrodeposition of polycrystalline ZnSe

and CdSe on Ni substrate. The (111) reflection of the

upper ZnSe layer (2θ = 27.3˚) along with the CdSe(111)

(2θ = 25.3˚) were used for the estimation (Figure 5). The

GAXRD patterns of the system as given in Figure 5 re-

veal the layer sequence and the depth profile of the

stratified film. Note that upon decreasing the angle of

incidence the signals from the lowest lying phase (Ni

substrate; not shown in the figure) disappear first, follow-

ed by the complete vanishing of signals from the interme-

diate CdSe layer. Eventually, only the response from the

ZnSe layer remains, and no other phases are detected. It

can be concluded thus that appreciable intermixing of the

various phases can be excluded, that is, the electroche-

mical deposition sequence yields the intended stratified

structure with abrupt transition at the interfaces. In other

words, the very existence of a barrier-type upper layer

(ZnSe) is observed by the disappearance of the CdSe(111)

reflection at a certain low incidence angle (Figure 5: line

at 0.6˚).

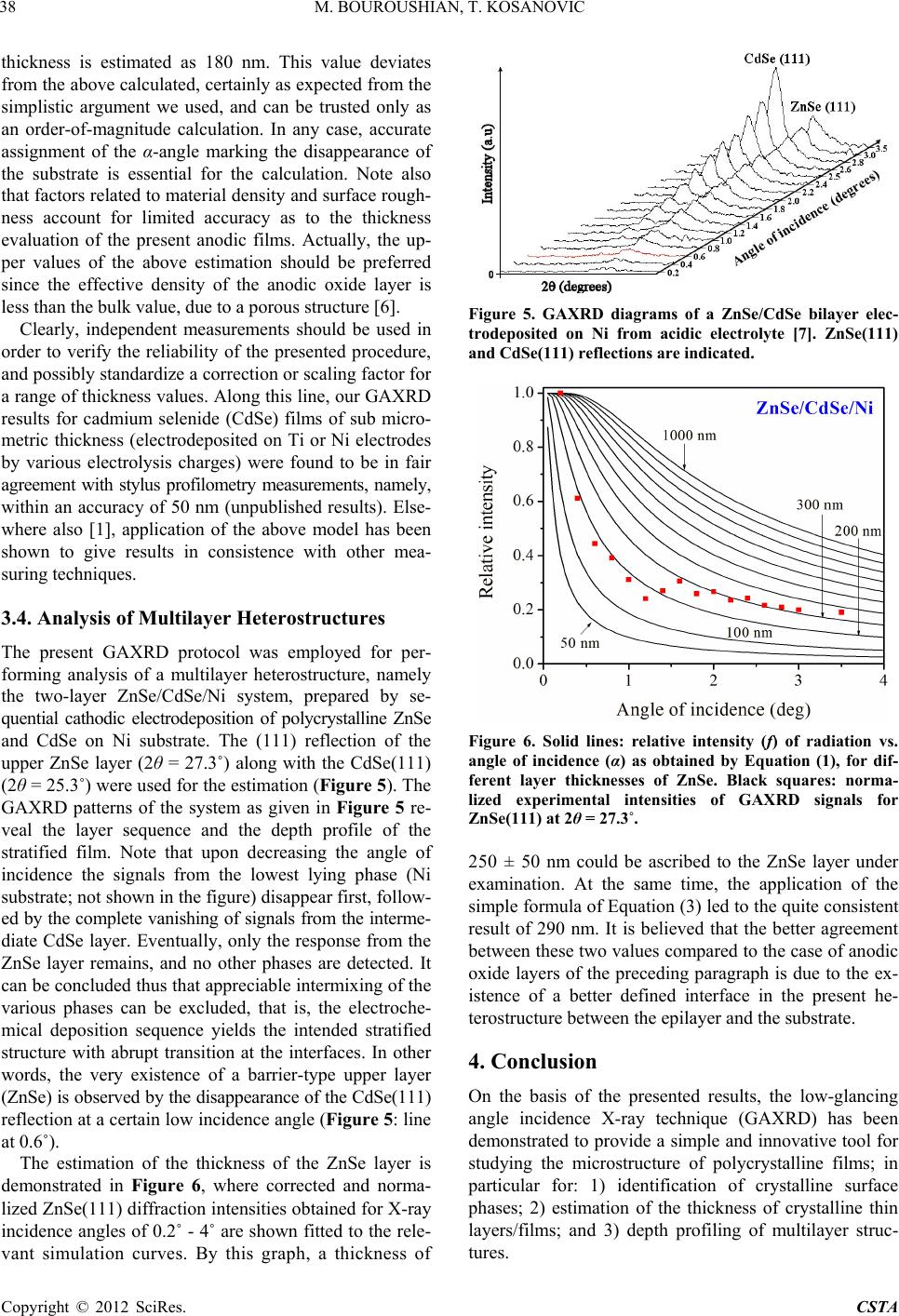

The estimation of the thickness of the ZnSe layer is

demonstrated in Figure 6, where corrected and norma-

lized ZnSe(111) diffraction intensities obtained for X-ray

incidence angles of 0.2˚ - 4˚ are shown fitted to the rele-

vant simulation curves. By this graph, a thickness of

Figure 5. GAXRD diagrams of a ZnSe/CdSe bilayer elec-

trodeposited on Ni from acidic electrolyte [7]. ZnSe(111)

and CdSe(111) reflections are indicated.

Figure 6. Solid lines: relative intensity (f) of radiation vs.

angle of incidence (α) as obtained by Equation (1), for dif-

ferent layer thicknesses of ZnSe. Black squares: norma-

lized experimental intensities of GAXRD signals for

ZnSe(111) at 2θ = 27.3˚.

250 ± 50 nm could be ascribed to the ZnSe layer under

examination. At the same time, the application of the

simple formula of Equation (3) led to the quite consistent

result of 290 nm. It is believed that the better agreement

between these two values compared to the case of anodic

oxide layers of the preceding paragraph is due to the ex-

istence of a better defined interface in the present he-

terostructure between the epilayer and the substrate.

4. Conclusion

On the basis of the presented results, the low-glancing

angle incidence X-ray technique (GAXRD) has been

demonstrated to provide a simple and innovative tool for

studying the microstructure of polycrystalline films; in

particular for: 1) identification of crystalline surface

phases; 2) estimation of the thickness of crystalline thin

layers/films; and 3) depth profiling of multilayer struc-

tures.

Copyright © 2012 SciRes. CSTA