Paper Menu >>

Journal Menu >>

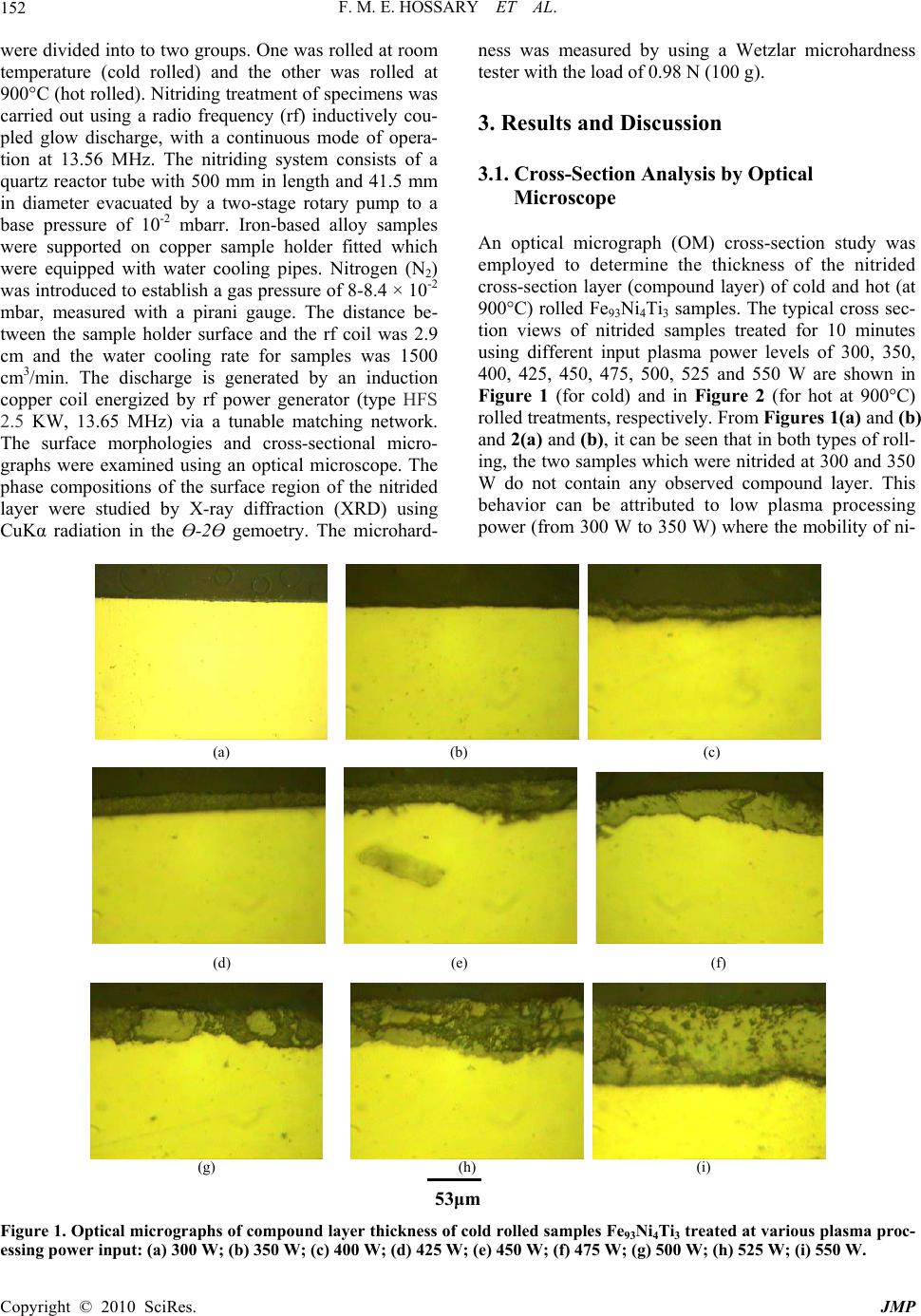

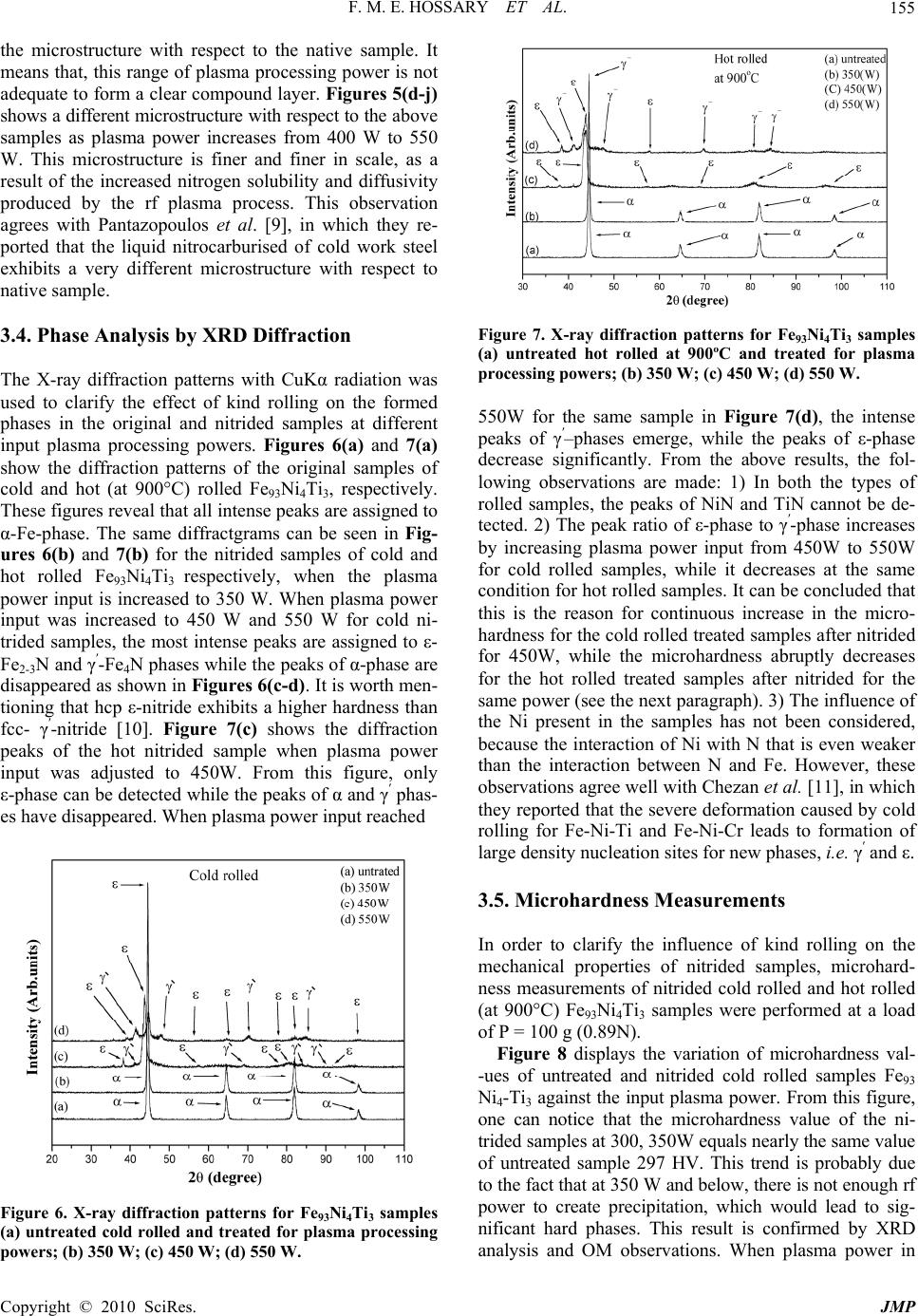

J. Mod. Phys., 2010, 1, 151-157 doi:10.4236/jmp.2010.13022 Published Online August 2010 (http://www.scirp.org/journal/jmp) Copyright © 2010 SciRes. JMP Effect of Kind Rolling on the Properties of Plasma-Formed Nitride Layers on Fe93Ni4Ti3 Fayez Mahomoud El-Hossary1, Sayed Mohammed Khalil1,2, Magdy Abdel Wahab Kassem3, Khaled Lotfy1 1Physics Department, Faculty of Science, Sohag University, Sohag, Egypt 2Physics Department, University of Colorado at Boulder, Boulder, USA 3Department of Materials and Metallurgical Engineering, Faculty of Petroleum and Mining Engineering, Suez Canal University, Suez, Egypt E-mail: khalil_20002000@yahoo.com Received April 15, 2010; revised May 21, 2010; accepted June 10, 2010 Abstract The nitriding behavior of cold rolled Fe93Ni4Ti3 specimens was compared with that of hot rolled specimens of the same materials. Radio frequency (rf) nitriding was performed for 10 minutes in a 10-2 mbar nitrogen atmosphere. The continuous plasma power was varied from 300-550 W in steps 50 W or less. Results of op- tical microscopy (OM), x-ray diffraction (XRD) and microhardness measurements (Hv) are presented and discussed with regard to the influence of kind rolling on the nitriding behavior, particularly nitride formation and nitride layer growth on mechanical properties. The results show a remarkable increase of nitrogen diffu- sivity and microhardness of cold rolled nitride samples. These best results may be attributed to enhancement of the defect and/or a compressive stress. Keywords: Cold Rolled, Hot Rolled-Radio Frequency (Rf), Microhardness, Optical Microscopy (OM), X-Ray Diffraction (XRD) 1. Introduction Surface plasma nitriding of steels is a well-established technique to produce a modified (hard) surface layer on steels or other iron based alloys with good anti-corrosive and wear resistance properties. Both the nitrogen case depth and the resulting nitride type commonly depend on the nitriding conditions as well as on the properties of material, such as composition, crystallographic structure and the density of various lattice defects. In particular, the thickness and the composition of the nitrided layer are strongly affected by the type of chemical reactions oc- curring at the specimen’s surface as well as by the diffu- sivity of nitrogen in the treated material. Nitrogen diffusivity in materials depends on many fa- ctors including lattice structure, grain size, chemical com- position and defect density. In ultrafine-grained materials, which can be fabricated by consolidation of nanopow- ders [1,2], sever plastic deformation [3], hot rolling [4] and cold rolling [5], the increased grain boundary area and the dislocation density will promote the diffusion of alloying elements and nitrogen. Therefore, it can be ex- pected that during a thermochemical treatment, e.g. pla- sma nitriding, such materials will develop a large thick- ness of nitriding layer. Ferkel et al. [6] reported that sever deformation of X5CrNi1810 steel rf nitrided at 350°C can enhance the nitrogen diffusion. This enhance- ment may be attributed to an increased grain boundary area and dislocation density. In the present investigation, an attempt has been made to evaluate the effect of kind rolling prior to rf plasma nitriding mainly on the proper- ties of Fe93Ni4Ti3 samples. After rf plasma nitriding, the surface microhardness, nitrogen diffusion layer thickness, surface morphology and formed phases have been ana- lyzed using a Vickers microhardness tester, optical mi- croscopy (OM) and x-ray diffraction (XRD). 2. Experimental Procedure The material studied was Fe93Ni4Ti3 iron-based alloy. Cupon-shaped specimens 1 cm × 2 cm in diameter and 2 mm thick. The cupons were prepared by arc-melting pure metals with nominal purities of 99.99 wt.% in an induc- tion furnace under an argon atmosphere (99.9999% pu- rity). The produced castings were heated at 900ºC for two hours. The heated specimens were hot rolled with about 10% reduction each time at 800°C up to 2mm thickness. After the initial hot rolling, these specimens  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 152 were divided into to two groups. One was rolled at room temperature (cold rolled) and the other was rolled at 900°C (hot rolled). Nitriding treatment of specimens was carried out using a radio frequency (rf) inductively cou- pled glow discharge, with a continuous mode of opera- tion at 13.56 MHz. The nitriding system consists of a quartz reactor tube with 500 mm in length and 41.5 mm in diameter evacuated by a two-stage rotary pump to a base pressure of 10-2 mbarr. Iron-based alloy samples were supported on copper sample holder fitted which were equipped with water cooling pipes. Nitrogen (N2) was introduced to establish a gas pressure of 8-8.4 × 10-2 mbar, measured with a pirani gauge. The distance be- tween the sample holder surface and the rf coil was 2.9 cm and the water cooling rate for samples was 1500 cm3/min. The discharge is generated by an induction copper coil energized by rf power generator (type HFS 2.5 KW, 13.65 MHz) via a tunable matching network. The surface morphologies and cross-sectional micro- graphs were examined using an optical microscope. The phase compositions of the surface region of the nitrided layer were studied by X-ray diffraction (XRD) using CuKα radiation in the Ө-2Ө gemoetry. The microhard- ness was measured by using a Wetzlar microhardness tester with the load of 0.98 N (100 g). 3. Results and Discussion 3.1. Cross-Section Analysis by Optical Microscope An optical micrograph (OM) cross-section study was employed to determine the thickness of the nitrided cross-section layer (compound layer) of cold and hot (at 900°C) rolled Fe93Ni4Ti3 samples. The typical cross sec- tion views of nitrided samples treated for 10 minutes using different input plasma power levels of 300, 350, 400, 425, 450, 475, 500, 525 and 550 W are shown in Figure 1 (for cold) and in Figure 2 (for hot at 900°C) rolled treatments, respectively. From Figures 1(a) and (b) and 2(a) and (b), it can be seen that in both types of roll- ing, the two samples which were nitrided at 300 and 350 W do not contain any observed compound layer. This behavior can be attributed to low plasma processing power (from 300 W to 350 W) where the mobility of ni- (a) (b) (c) (d) (e) (f) (g) (h) (i) 53μm Figure 1. Optical micrographs of compound layer thickness of cold rolled samples Fe93Ni4Ti3 treated at various plasma proc- essing power input: (a) 300 W; (b) 350 W; (c) 400 W; (d) 425 W; (e) 450 W; (f) 475 W; (g) 500 W; (h) 525 W; (i) 550 W.  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 153 (a) (b) (c) (d) (e) (f) (g) (h) (i) 49μm Figure 2. Optical micrographs of compound layer thickness of hot rolled samples Fe93Ni4Ti3 at 900ºC treated at various plasma processing power input. (a) 300 W; (b) 350 W; (c) 400 W; (d) 425 W; (e) 450 W; (f) 475 W; (g) 500 W; (h) 525 W and (i) 550 W. trogen atoms is low and penetration is done more easily- through grain boundaries [7]. When the plasma power input is increases with increasing the input plasma power from 400 W to 550 W for cold and hot rolled samples, respectively. The variation range of the layer thickness is 15 μm to 79 μm for cold rolled while from 11 μm to 56 μm for hot rolled at 900°C. This enhancement of thick- ness for the cold rolled samples is probably due to the promotion of nitrogen ionization, leading to high con- centrations of high-energy ions supplied onto the speci- men. However, this result agrees with Mahboubi et al. [7]. Also, Ferkel et al. [8] reported that, the cold high pressure torsion (HPT) processed material shows a thicker and more homogeneous compound layer than the material not subjected to HPT; the nitrogen uptake is largest in the HPT-processed material. 3.2. Compound Layer Thickness The variation of the compound layer thickness of cold rolled Fe93Ni4Ti3 and hot rolled Fe93Ni4Ti3 at 900°C ni- trided samples for different input plasma power are shown in the Figures 3 and 4 respectively. However, these values of thickness are measured from the cross section morphology. From these figures, for both the kinds of rolling, one can see that the thickness increases continuously as the plasma power increases. The en- hancement of thickness is probably due to the domina- tion of lattice and the penetration of nitrogen atoms through the grains, which all enhance the formation of a more uniform compound layer [8]. 3.3. Surface Morphology Figure 5 shows typical OM micrograph of the surface features of untreated and treated cold rolled Fe93Ni4Ti3 samples for different plasma processing power. The mi- crograph of the untreated sample is shown in Figure 5(a). This figure appears to be a relatively coarse-grained structure composed of iron α–phase. The micrographs of treated samples at 300 W and 350 W are shown in Fig- ures 5(b) and (c), which reveal no observed change in  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 154 Figure 3. Thickness of compound layer as a function of plasma power for cold rolled samples of Fe93Ni4Ti3. Figure 4. Thickness of compound layer as a function of plasma power for hot rolled samples of Fe93Ni4Ti3 at 900ºC. (a) (b) (c) (d) (e) (f) (g) (h) (i) 53μm (j) Figure 5. Optical micrographs of the surface morphology of cold rolled samples Fe93Ni4Ti3 for plasma processing power input (a) 0.0 W; (b) 300 W; (c) 350 W; (d) 400 W; (e) 425 W; (f) 450 W; (g) 475 W; (h) 500 W; (i) 525 W; (j) 550 W. m) m)  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 155 the microstructure with respect to the native sample. It means that, this range of plasma processing power is not adequate to form a clear compound layer. Figures 5(d-j) shows a different microstructure with respect to the above samples as plasma power increases from 400 W to 550 W. This microstructure is finer and finer in scale, as a result of the increased nitrogen solubility and diffusivity produced by the rf plasma process. This observation agrees with Pantazopoulos et al. [9], in which they re- ported that the liquid nitrocarburised of cold work steel exhibits a very different microstructure with respect to native sample. 3.4. Phase Analysis by XRD Diffraction The X-ray diffraction patterns with CuKα radiation was used to clarify the effect of kind rolling on the formed phases in the original and nitrided samples at different input plasma processing powers. Figures 6(a) and 7(a) show the diffraction patterns of the original samples of cold and hot (at 900°C) rolled Fe93Ni4Ti3, respectively. These figures reveal that all intense peaks are assigned to α-Fe-phase. The same diffractgrams can be seen in Fig- ures 6(b) and 7(b) for the nitrided samples of cold and hot rolled Fe93Ni4Ti3 respectively, when the plasma power input is increased to 350 W. When plasma power input was increased to 450 W and 550 W for cold ni- trided samples, the most intense peaks are assigned to ε- Fe2-3N and γ′-Fe4N phases while the peaks of α-phase are disappeared as shown in Figures 6(c-d). It is worth men- tioning that hcp ε-nitride exhibits a higher hardness than fcc- γ′-nitride [10]. Figure 7(c) shows the diffraction peaks of the hot nitrided sample when plasma power input was adjusted to 450W. From this figure, only ε-phase can be detected while the peaks of α and γ′ phas- es have disappeared. When plasma power input reached Figure 6. X-ray diffraction patterns for Fe93Ni4Ti3 samples (a) untreated cold rolled and treated for plasma processing powers; (b) 350 W; (c) 450 W; (d) 550 W. Figure 7. X-ray diffraction patterns for Fe93Ni4Ti3 samples (a) untreated hot rolled at 900ºC and treated for plasma processing powers; (b) 350 W; (c) 450 W; (d) 550 W. 550W for the same sample in Figure 7(d), the intense peaks of γ′–phases emerge, while the peaks of ε-phase decrease significantly. From the above results, the fol- lowing observations are made: 1) In both the types of rolled samples, the peaks of NiN and TiN cannot be de- tected. 2) The peak ratio of ε-phase to γ′-phase increases by increasing plasma power input from 450W to 550W for cold rolled samples, while it decreases at the same condition for hot rolled samples. It can be concluded that this is the reason for continuous increase in the micro- hardness for the cold rolled treated samples after nitrided for 450W, while the microhardness abruptly decreases for the hot rolled treated samples after nitrided for the same power (see the next paragraph). 3) The influence of the Ni present in the samples has not been considered, because the interaction of Ni with N that is even weaker than the interaction between N and Fe. However, these observations agree well with Chezan et al. [11], in which they reported that the severe deformation caused by cold rolling for Fe-Ni-Ti and Fe-Ni-Cr leads to formation of large density nucleation sites for new phases, i.e. γ′ and ε. 3.5. Microhardness Measurements In order to clarify the influence of kind rolling on the mechanical properties of nitrided samples, microhard- ness measurements of nitrided cold rolled and hot rolled (at 900°C) Fe93Ni4Ti3 samples were performed at a load of P = 100 g (0.89N). Figure 8 displays the variation of microhardness val- -ues of untreated and nitrided cold rolled samples Fe93 Ni4-Ti3 against the input plasma power. From this figure, one can notice that the microhardness value of the ni- trided samples at 300, 350W equals nearly the same value of untreated sample 297 HV. This trend is probably due to the fact that at 350 W and below, there is not enough rf power to create precipitation, which would lead to sig- nificant hard phases. This result is confirmed by XRD analysis and OM observations. When plasma power in  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 156 Figure 8. Microhardness values of untreated and treated cold rolled Fe93Ni4Ti3 samples for different plasma power input. put increases from 400 to 550W, the microhardness value increases exponentially to reach the value of 2098 HV. This represents a 7-fold increase in the surface- hardness comparing with the untreated sample (282 HV). The anomalously high microhardness values are due to the fact that high defect density in nitrided samples offers enough nucleation sites for nitrides and enough diffusion paths for nitrogen. In this case, a dense compound layer with high hardness can easily form [6]. Also, the dra- matic increase of hardness is a result of compressive stresses, which is induced in the target surface by the cold rolling and a compound layer produced on the target surface by nitriding. Figure 9 depicts the variation of microhardness values of untreated and nitrided hot rolled (at 900ºC) samples Fe93Ni4Ti3 against the input plasma power. From this figure, one can notice that the microhardness values of the nitrided samples at 300 W and 350 W equal nearly the same value of untreated sample 274 HV. As plasma power input increases from 400 W to 450 W, the micro- hardness value increases continuously to reach the value of 572 HV; this represents a 2-fold increase in the sur- face hardness comparing with untreated sample. This trend may be credited to the formation of a compound layer thickness of 11 µm to 56 µm, which contains a high concentration of nitrogen [12]. Similar behavior has been observed by Devi and Mohanty [13], in which a microhardness value of 1478 HV in hot rolled D2 steel was achieved after plasma nitriding at 510ºC for 18 h. With the high input plasma power of 475 W or more, the microhardness value decreases. This reduction can be attributed to the decrease the ratio of ε-phase to γ'-phase [10]. However, this result agrees well with XRD analy- sis. In light of the microhardness measurements, it can be concluded that a general hardness increase for cold rolled treated samples can be associated with enhancement of Figure 9. Microhardness values of untreated and treated hot rolled Fe93Ni4Ti3 at 900°C samples for different plasma power input. defect density and/or a compressive stress. i.e., the hard- ness of the plasma nitrided sample shows a kind of roll- ing dependent behavior. 4. Conclusions The thickness, hardness and phase composition of the modified layer formed on cold and hot rolled nitrided Fe93Ni4Ti3 are investigated in this work. All of the sam- ples were hardened by forming nitrided layers. The ad- vantage of the pre-cold rolling is that a thicker nitrided layer with higher hardness is formed. The cold rolling process is a well-known technique applied to improve the mechanical properties of steel surfaces. Through this process, a large number of grain boundaries, dislocations and positive holes form through the surface of specimens, which all enhance the nitrogen diffusion. The surface hardness of nitrided cold-rolled Fe93Ni4Ti3 samples re- presents a 3.7-fold increase with respect to the nitrided hot-rolled samples. This trend may be credited to the high defect density of nitrided cold rolled samples, which offers enough nucleation sites for nitrides and enough diffusion paths for nitrogen [12]. The modified surface of nitrided cold rolled samples is characterized with a finer microstructure. The phase analysis dictates that the peak ratio of ε to γ′ phase increases by increasing plasma power input from 450 to 550 W for nitrided cold rolled samples, while it decreases at the same conditions for nitrided hot-rolled samples. This is the reason behind the continuous increase in the microhardness for the cold rolled treated samples after application of 450 W plasma power, with a decrease for the hot rolled treated samples after being nitrided for the same power. The most strik- ing results of this work are the increased thickness of the nitrided cold rolled samples. Indeed, diffusion of nitro-  F. M. E. HOSSARY ET AL. Copyright © 2010 SciRes. JMP 157 gen by the microcracks mechanism could be expected to be significantly affected by an increase in grain boundary area as a result of cold rolling. However, the experimen- tal evidence demonstrates that the microstructure of cold rolled material does have a significant influence on ni- trogen diffusion. 5. Acknowledgments The authors would like to thank Prof. T. Munsat at the University of Colorado for his help in preparing this manuscript. 6. References [1] F. M. El-Hossary, “The Influence of Surface Microcracks and Temperature Gradients on the Rf Plasma Nitriding Rate,” Surface and Coatings Technology, Vol. 150, No. 2, 2002, pp. 277-281. [2] F. M. EL-Hossary, N. Z. Negm, S. M. Khalil, A. M. Abd Elrahman and D. N. Mcllroy, “RF Plasma Carbonitriding of AISI Austenitic Stainless Steel,” Surface and Coatings Technology, Vol. 141, No. 2-3, 2001, pp. 194-201. [3] C. B. Craus, A. R. Chezan, N. G. Chechenin, D. O. Boerma and L. Niesen, “Soft Magnetism in Nitrided Fe93Ni4Cr3 and Fe94Ni4Ti2 Cold–Rolled Alloys,” Journal of Magnetism and Magnetic Materials, Vol. 263, No. 1-2, 2003, pp. 47-56. [4] G. Edrem and Y. Taptik, “Effect of Hot Rolling Condi- tions to Produce Deep Drawing Quality Steels for Con- tinuous Annealing Process,” Journal of Material Proc- essing Technology, Vol. 170, No. 1-2, 2005, pp. 17- 23. [5] H. Katoh, H. Takachi, N. Takahashi and M. Abe, “Cold Rolled Steel Sheets Produced by Continuous Annealing, Technology Continuously Annealed Cold-Rolled Steel,” 1984, pp. 37-38. [6] H. Ferkel, M. Glatzer, Y. Estrin and R. Z. Valiev, “RF Plasma Nitriding of Severely Deformed High Alloyed Steel,” Scripta Material Science, Vol. 46, No. 9, 2002, pp. 623-628. [7] F. Mahboubi and K. Abdolvahabi, “The Effect of Tem- perature on Plasma Nitriding Behavior of DIN 1.6959 Low Alloy Steel,” Vacuum, Vol. 81, No. 3, 2006, pp. 239-243. [8] H. Ferkel, M. Glatzer, Y. Estrin, R. Z. Valiev, C. Blawert and B. L. Mordike, “RF Plasma Nitriding of Severely Deformed Iron-Based Alloys,” Materials Science and Engineering A, Vol. 348, No. 1-2, 2003, pp. 100-110. [9] G. Pantazopoulos, P. Psyllaki, D. Kanakis, S. Antoniou, K. Papadimitriou and J. Sideris, “Tribological Properties of a Liquid Nitrocarburised Special Purpose Cold Work Tool Steel,” Surface and Coatings Technology, Vol. 200, No. 20-21, 2006, pp. 5889-5895. [10] H. Ferkel, Y. Estrin, C. Blawert and R. Z. Valiev, “RF Nitriding of Severely Deformed Armco Iron and St2 K50,” Surface and Coatings Technology, Vol. 173-174, 2003, pp. 1164-1170. [11] A. R. Chezan, C. B. Craus, N. G. Chechenin, T. Vystavel, L. Niesen, J. T. M. De Hosson and D. O. Boerma, “On the Formation of Ultra-Fine Grained Fe-Base Alloys Via Phase Transformations,” Materials Science and Engi- neering A, Vol. 367, No. 1-2, 2004, pp. 176-184. [12] F. M. El-Hossary, S. M. Khalil, K. Lotfy and M. A. Kassem, “The Influence of Hot-Rolled Temperature on Plasma Nitriding Behavior of Iron-Based Alloys,” Jour- nal of Low Temperature Physics, Vol. 156, No. 1-2, 2009, pp. 38-47. [13] M. U. Devi and O. N. Mohanty, “Plasma-Nitriding of Tool Steels for Combined Percussive Impact and Rolling Fatigue Wear Applications,” Surface and Coatings Tech- nology, Vol. 107, No. 1, 1998, pp. 55-64. |