H. S. EL-FARAMAWY ET AL. 1111

Table 3. The predicted solubility and solubility product of

Temp K 10000/T(K) Intercept mic

TiC with temperature according to Aronsson [13].

Solubility Solubility (S) Ato

product (S2) (mole fraction) %

1173 8.525149 2.8807 0.317188 0.563194

1248 8.012821 2.8807 0.471245 0.686473

1323 7.558579 2.8807 0.607835 0.779638

1073 9.319664 2.8807 0.078277 0.27978

1053 9.496676 2.8807 0.025049 0.15827

1044 9.578544 2.8807 0.000432 0.02078

1043 9.587728 2.8807 –0.00233 -

able 4. Actual solubility and solubility product of investi-

Type Ti mole Fraction Solubility product

T

gated steels.

Ti 0 0.0017 2.972E-06

Ti 1 0.0559 3.124E-03

Ti 2 0.1148 1.318E-02

Ti 3 0.2644 6.992E-02

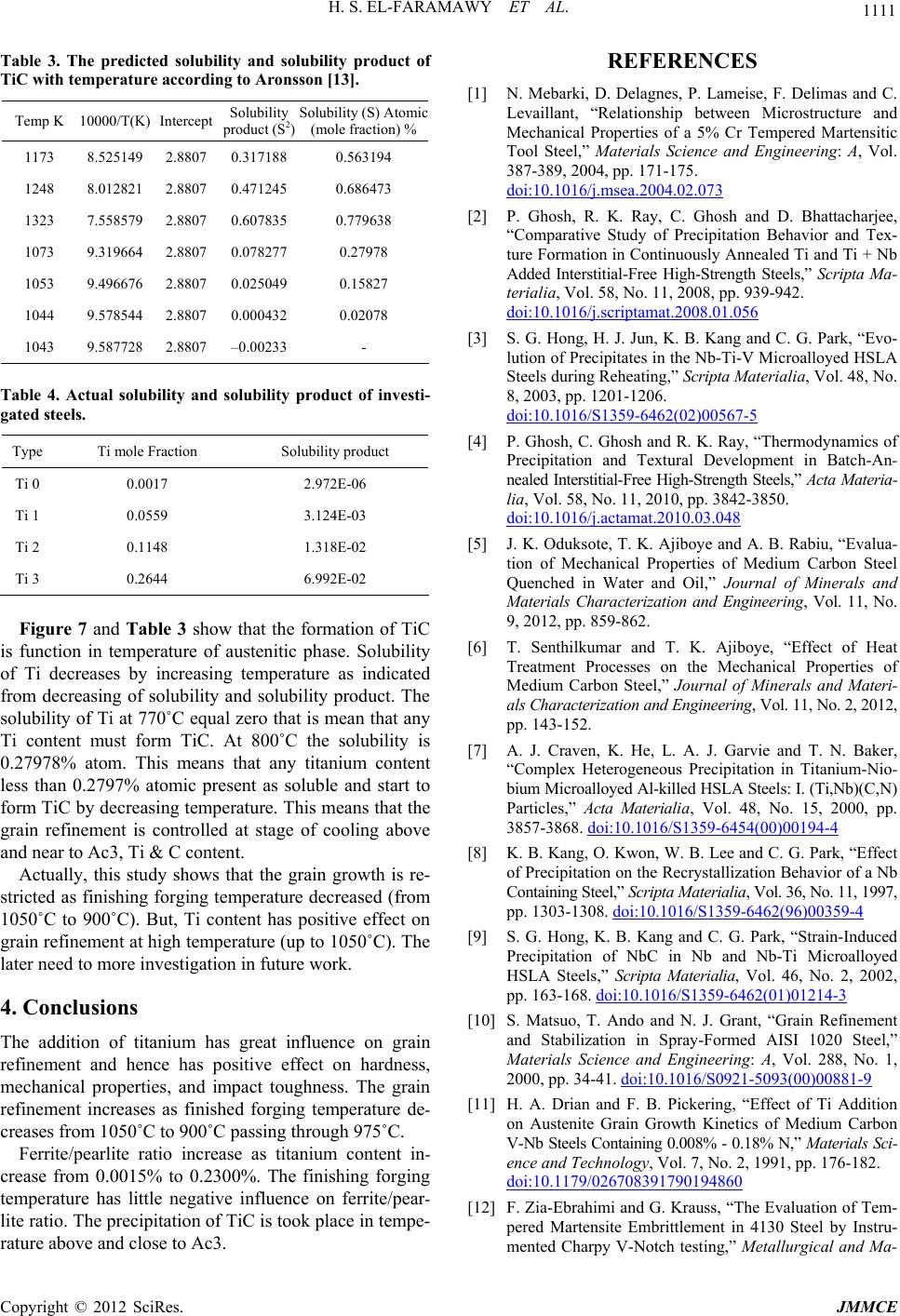

Figure 7 and Table 3 show that the formation of TiC

is

the grain growth is re-

st

4. Conclusions

nium has great influence on grain

cr

[1] N. Mebarki, D. Delagnes, P. Lameise, F. Delimas and C.

Levaillant, “Ricrostructure and

Mechanical Prpered Martensitic

function in temperature of austenitic phase. Solubility

of Ti decreases by increasing temperature as indicated

from decreasing of solubility and solubility product. The

solubility of Ti at 770˚C equal zero that is mean that any

Ti content must form TiC. At 800˚C the solubility is

0.27978% atom. This means that any titanium content

less than 0.2797% atomic present as soluble and start to

form TiC by decreasing temperature. This means that the

grain refinement is controlled at stage of cooling above

and near to Ac3, Ti & C content.

Actually, this study shows that

ricted as finishing forging temperature decreased (from

1050˚C to 900˚C). But, Ti content has positive effect on

grain refinement at high temperature (up to 1050˚C). The

later need to more investigation in future work.

The addition of tita

refinement and hence has positive effect on hardness,

mechanical properties, and impact toughness. The grain

refinement increases as finished forging temperature de-

creases fro m 1050˚C to 900˚C passing through 975˚C.

Ferrite/pearlite ratio increase as titanium content in-

ease from 0.0015% to 0.2300%. The finishing forging

temperature has little negative influence on ferrite/pear-

lite ratio. The precipitation of TiC is took place in tempe-

rature above an d close to Ac3.

REFERENCES

elationship between M

operties of a 5% Cr Tem

Tool Steel,” Materials Science and Engineering: A, Vol.

387-389, 2004, pp. 171-175.

doi:10.1016/j.msea.2004.02.073

[2] P. Ghosh, R. K. Ray, C. Ghosh and D. Bhattacharjee,

“Comparative Study of Precipita

ture Formation in Continuously Annealed

tion Behavior and Tex-

Ti and Ti + Nb

Added Interstitial-Free High-Strength Steels,” Scripta Ma-

terialia, Vol. 58, No. 11, 2008, pp. 939-942.

doi:10.1016/j.scriptamat.2008.01.056

[3] S. G. Hong, H. J. Jun, K. B. Kang and C. G. Park, “Evo-

lution of Precipitates in the Nb-Ti-V Microallo

Steels during Reheating,” Sc ripta Mateyed HSLA

rialia, Vol. 48, No.

8, 2003, pp. 1201-1206.

doi:10.1016/S1359-6462(02)00567-5

[4] P. Ghosh, C. Ghosh and R. K. Ray, “Thermodynamics of

Precipitation and Textural Developm

nealed Interstitial-Free High-Strength Stent in Batch-An-

eels,” Acta Materi a-

lia, Vol. 58, No. 11, 2010, pp. 3842-3850.

doi:10.1016/j.actamat.2010.03.048

[5] J. K. Oduksote, T. K. Ajiboye and A. B. Rabiu, “Evalua-

tion of Mechanical Properties of Medium

Quenched in Water and Oil,” Jou Carbon Steel

rnal of Minerals and

” Journal of Minerals and Materi-

oyed Al-killed HSLA Steels: I. (Ti,Nb)(C , N)

Materials Characterization and Engineering, Vol. 11, No.

9, 2012, pp. 859-862.

[6] T. Senthilkumar and T. K. Ajiboye, “Effect of Heat

Treatment Processes on the Mechanical Properties of

Medium Carbon Steel,

als Characterization and Engi neering, Vol. 11, No. 2, 2012,

pp. 143-152.

[7] A. J. Craven, K. He, L. A. J. Garvie and T. N. Baker,

“Complex Heterogeneous Precipitation in Titanium-Nio-

bium Microall

Particles,” Acta Materialia, Vol. 48, No. 15, 2000, pp.

3857-3868. doi:10.1016/S1359-6454(00)00194-4

[8] K. B. Kang, O. Kwon, W. B. Lee and C. G. Park, “Effect

of Precipitation on the Recrystallization Behavior of a Nb

Containi ng Steel,” Scripta Materialia, Vol. 36, No. 11, 1997,

pp. 1303-1308. doi:10.1016/S1359-6462(96)00359-4

[9] S. G. Hong, K. B. Kang and C. G. Park, “Strain-Induced

Precipitation of NbC in Nb and Nb-Ti Microalloyed

HSLA Steels,” Scripta Materialia, Vol. 46, No. 2, 2002,

pp. 163-168. doi:10.1016/S1359-6462(01)01214-3

[10] S. Matsuo, T. Ando and N. J. Grant, “Grain Refinement

and Stabilization in Spray-Formed AISI 1020 Steel,”

Materials Science and Engineering: A, Vol. 288, No. 1,

2000, pp. 34-41. doi:10.1016/S0921-5093(00)00881-9

[11] H. A. Drian and F. B. Pickering, “Effect of Ti Addition

on Austenite Grain Growth Kinetics of Medium Carbon

V-Nb Steels Containing 0.008% - 0.18% N,” Materi als Sci-

ence and Technology, Vol. 7, No. 2, 1991, pp. 176-182.

doi:10.1179/026708391790194860

[12] F. Zia-Ebrahimi and G. Krauss, “The Evaluation of Tem-

pered Martensite Embrittlement in 4130 Steel by Instru-

mented Charpy V-Notch testing,” M

etallurgical and Ma-

Copyright © 2012 SciRes. JMMCE