H. K. KHANDELWAL ET AL. 1099

Figure 7. Variation of yield strength at three zones of simi-

lar weld joint.

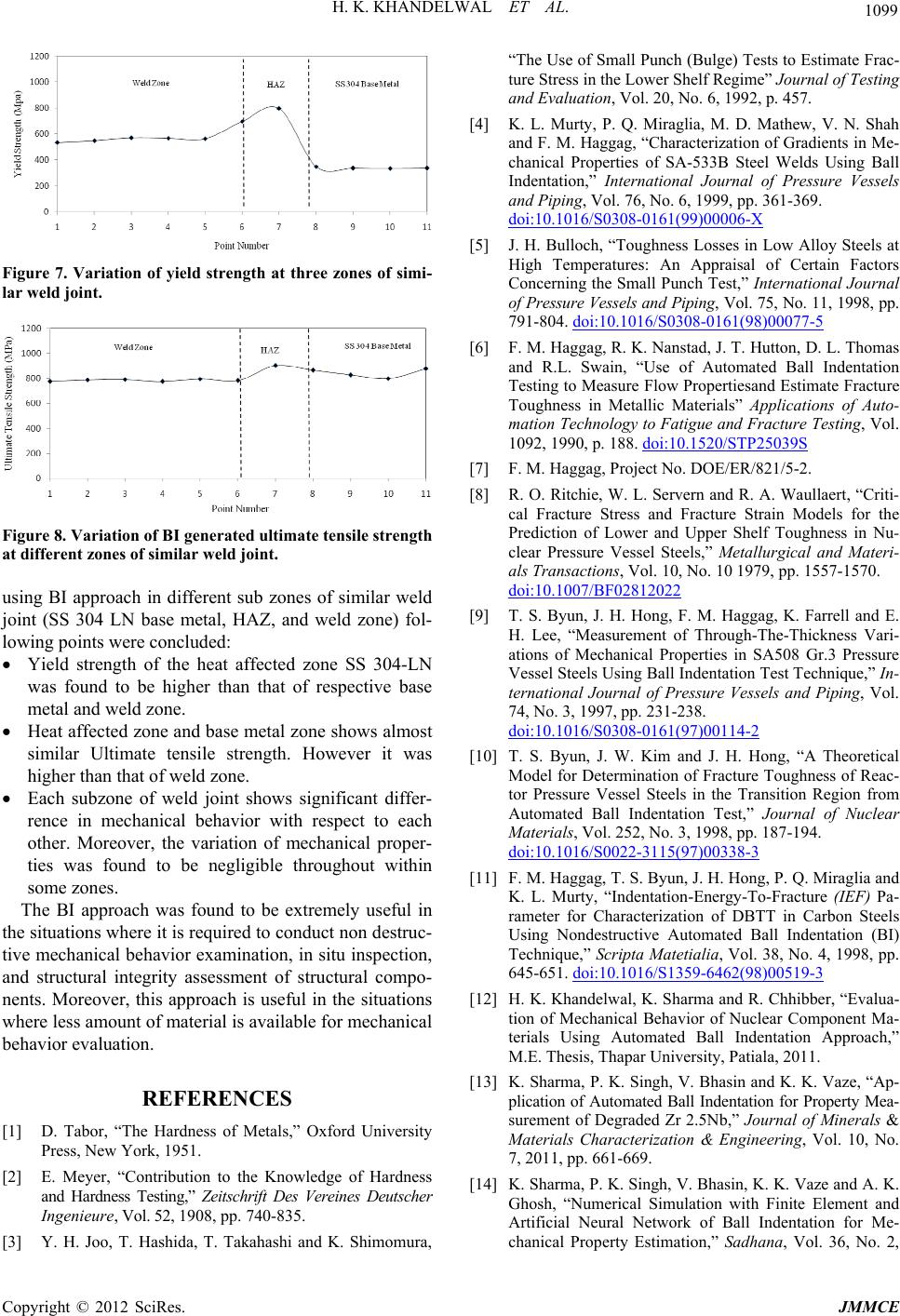

Figure 8. Variation of BI generated ultimate tensile strength

at different zones of similar weld joint.

using BI approach in different sub zones of similar weld

joint (SS 304 LN base metal, HAZ, and weld zone) fol-

lowing points were concluded:

Yield strength of the heat affected zone SS 304-LN

was found to be higher than that of respective base

metal and weld zone.

Heat affected zone and base metal zone shows almost

similar Ultimate tensile strength. However it was

higher than that of weld zone.

Each subzone of weld joint shows significant differ-

rence in mechanical behavior with respect to each

other. Moreover, the variation of mechanical proper-

ties was found to be negligible throughout within

some zones.

The BI approach was found to be extremely useful in

the situations where it is required to conduct non destruc-

tive mechanical behavior examination, in situ inspection,

and structural integrity assessment of structural compo-

nents. Moreover, this approach is useful in the situations

where less amount of material is available for mechanical

behavior evaluation.

REFERENCES

[1] D. Tabor, “The Hardness of Metals,” Oxford University

Press, New York, 1951.

[2] E. Meyer, “Contribution to the Knowledge of Hardness

and Hardness Testing,” Zeitschrift Des Vereines Deutscher

Ingenieure, Vol. 52, 1908, pp. 740-835.

[3] Y. H. Joo, T. Hashida, T. Takahashi and K. Shimomura,

“The Use of Small Punch (Bulge) Tests to Estimate Frac-

ture Stress in the Lower Shelf Regime” Journal of Testing

and Evaluation, Vol. 20, No. 6, 1992, p. 457.

[4] K. L. Murty, P. Q. Miraglia, M. D. Mathew, V. N. Shah

and F. M. Haggag, “Characterization of Gradients in Me-

chanical Properties of SA-533B Steel Welds Using Ball

Indentation,” International Journal of Pressure Vessels

and Piping, Vol. 76, No. 6, 1999, pp. 361-369.

doi:10.1016/S0308-0161(99)00006-X

[5] J. H. Bulloch, “Toughness Losses in Low Alloy Steels at

High Temperatures: An Appraisal of Certain Factors

Concerning the Small Punch Test,” International Journal

of Pressure Vessels and Piping, Vol. 75, No. 11, 1998, pp.

791-804. doi:10.1016/S0308-0161(98)00077-5

[6] F. M. Haggag, R. K. Nanstad, J. T. Hutton, D. L. Thomas

and R.L. Swain, “Use of Automated Ball Indentation

Testing to Measure Flow Propertiesand Estimate Fracture

Toughness in Metallic Materials” Applications of Auto-

mation Technology to Fatigue and Fracture Testing, Vol.

1092, 1990, p. 188. doi:10.1520/STP25039S

[7] F. M. Haggag, Project No. DOE/ER/821/5-2.

[8] R. O. Ritchie, W. L. Servern and R. A. Waullaert, “Criti-

cal Fracture Stress and Fracture Strain Models for the

Prediction of Lower and Upper Shelf Toughness in Nu-

clear Pressure Vessel Steels,” Metallurgical and Materi-

als Transactions, Vol. 10, No. 10 1979, pp. 1557-1570.

doi:10.1007/BF02812022

[9] T. S. Byun, J. H. Hong, F. M. Haggag, K. Farrell and E.

H. Lee, “Measurement of Through-The-Thickness Vari-

ations of Mechanical Properties in SA508 Gr.3 Pressure

Vessel Steels Using Ball Indentation Test Technique,” In-

ternational Journal of Pressure Vessels and Piping, Vol.

74, No. 3, 1997, pp. 231-238.

doi:10.1016/S0308-0161(97)00114-2

[10] T. S. Byun, J. W. Kim and J. H. Hong, “A Theoretical

Model for Determination of Fracture Toughness of Reac-

tor Pressure Vessel Steels in the Transition Region from

Automated Ball Indentation Test,” Journal of Nuclear

Materials, Vol. 252, No. 3, 1998, pp. 187-194.

doi:10.1016/S0022-3115(97)00338-3

[11] F. M. Haggag, T. S. Byun, J. H. Hong, P. Q. Miraglia and

K. L. Murty, “Indentation-Energy-To-Fracture (IEF) Pa-

rameter for Characterization of DBTT in Carbon Steels

Using Nondestructive Automated Ball Indentation (BI)

Technique,” Scripta Matetialia, Vol. 38, No. 4, 1998, pp.

645-651. doi:10.1016/S1359-6462(98)00519-3

[12] H. K. Khandelwal, K. Sharma and R. Chhibber, “Evalua-

tion of Mechanical Behavior of Nuclear Component Ma-

terials Using Automated Ball Indentation Approach,”

M.E. Thesis, Thapar University, Patiala, 2011.

[13] K. Sharma, P. K. Singh, V. Bhasin and K. K. Vaze, “Ap-

plication of Automated Ball Indentation for Property Mea-

surement of Degraded Zr 2.5Nb,” Journal of Minerals &

Materials Characterization & Engineering, Vol. 10, No.

7, 2011, pp. 661-669.

[14] K. Sharma, P. K. Singh, V. Bhasin, K. K. Vaze and A. K.

Ghosh, “Numerical Simulation with Finite Element and

Artificial Neural Network of Ball Indentation for Me-

chanical Property Estimation,” Sadhana, Vol. 36, No. 2,

Copyright © 2012 SciRes. JMMCE