F. C. DOS SANTOS LIMA ET AL.

522

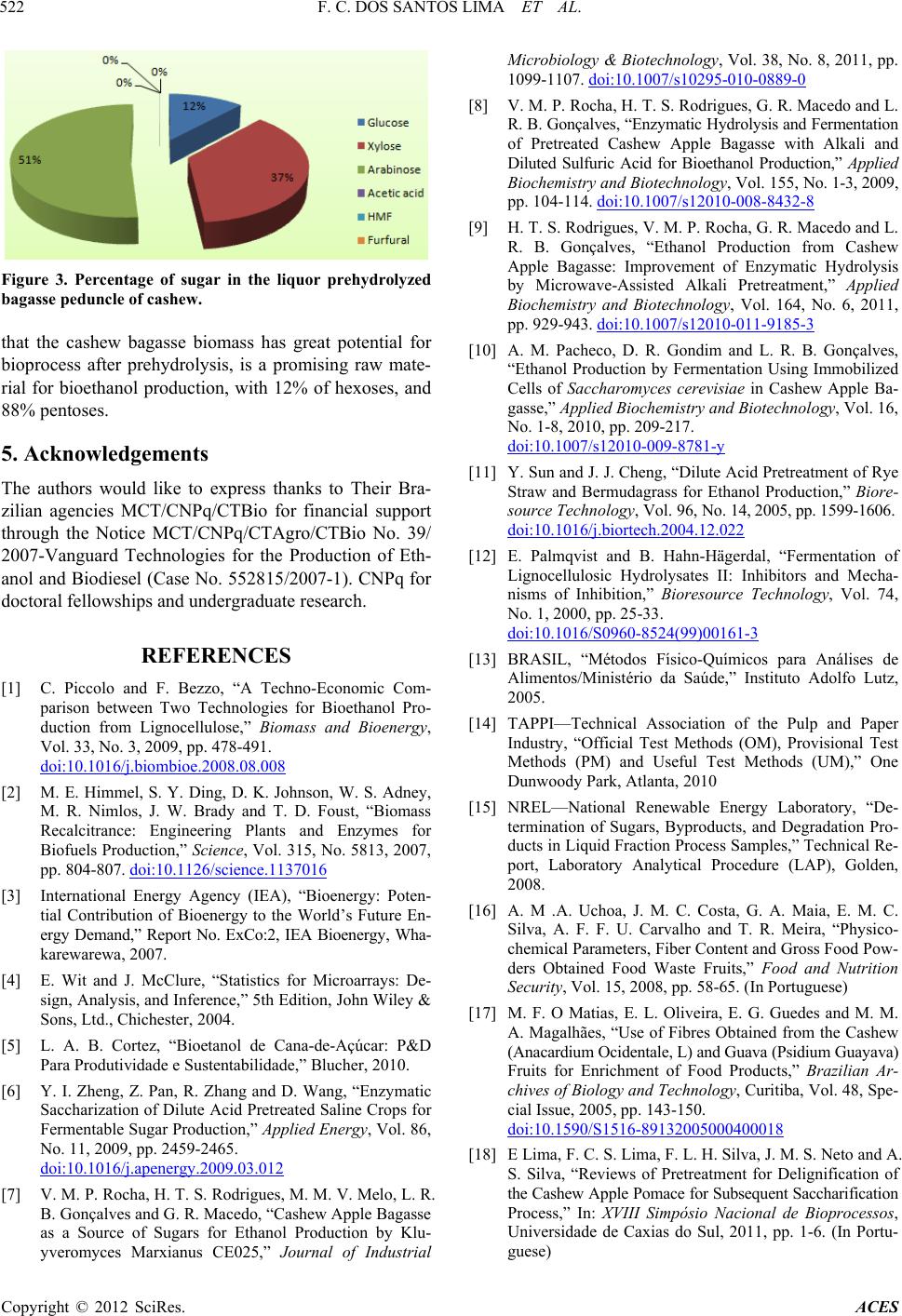

Figure 3. Percentage of sugar in the liquor prehydrolyzed

bagasse peduncle of c a shew.

that the cashew bagasse biomass has great potential for

bioprocess after prehydrolysis, is a promising raw mate-

rial for bioethanol production, with 12% of hexoses, and

88% pentoses.

5. Acknowledgements

The authors would like to express thanks to Their Bra-

zilian agencies MCT/CNPq/CTBio for financial support

through the Notice MCT/CNPq/CTAgro/CTBio No. 39/

2007-Vanguard Technologies for the Production of Eth-

anol and Biod iesel (Case No. 5528 15/2007-1). CNPq for

doctoral fell o w ships and underg rad uat e r esearch.

REFERENCES

[1] C. Piccolo and F. Bezzo, “A Techno-Economic Com-

parison between Two Technologies for Bioethanol Pro-

duction from Lignocellulose,” Biomass and Bioenergy,

Vol. 33, No. 3, 2009, pp. 478-491.

doi:10.1016/j.biombioe.2008.08.008

[2] M. E. Himmel, S. Y. Ding, D. K. Johnson, W. S. Adney,

M. R. Nimlos, J. W. Brady and T. D. Foust, “Biomass

Recalcitrance: Engineering Plants and Enzymes for

Biofuels Production,” Science, Vol. 315, No. 5813, 2007,

pp. 804-807. doi:10.1126/science.1137016

[3] International Energy Agency (IEA), “Bioenergy: Poten-

tial Contribution of Bioenergy to the World’s Future En-

ergy Demand,” Report No. ExCo:2, IEA Bioenergy, Wha-

karewarewa, 2007.

[4] E. Wit and J. McClure, “Statistics for Microarrays: De-

sign, Analysis, and Inference,” 5th Edition, John Wiley &

Sons, Ltd., Chichester, 2004.

[5] L. A. B. Cortez, “Bioetanol de Cana-de-Açúcar: P&D

Para Produtividade e Sustentabilidade,” Blucher, 2010.

[6] Y. I. Zheng, Z. Pan, R. Zhang and D. Wang, “Enzymatic

Saccharization of Dilute Acid Pretreated Saline Crops for

Fermentable Sugar Production,” Applied Energy, Vol. 86,

No. 11, 2009, pp. 2459-2465.

doi:10.1016/j.apenergy.2009.03.012

[7] V. M. P. Rocha, H. T. S. Rodrigues, M. M. V. Melo, L. R.

B. Gonçalves and G. R. Macedo, “Cashew Apple Bagasse

as a Source of Sugars for Ethanol Production by Klu-

yveromyces Marxianus CE025,” Journal of Industrial

Microbiology & Biotechnology, Vol. 38, No. 8, 2011, pp.

1099-1107. doi:10.1007/s10295-010-0889-0

[8] V. M. P. Rocha, H. T. S. Rodrigues, G. R. Macedo and L.

R. B. Gonçalves, “Enzymatic Hydroly sis and Fermentation

of Pretreated Cashew Apple Bagasse with Alkali and

Diluted Sulfuric Acid for Bioethanol Production,” Applied

Biochemistry and Biotechnology, Vo l. 15 5, No. 1-3, 2009,

pp. 104-114. doi:10.1007/s12010-008-8432-8

[9] H. T. S. Rodrigues, V. M. P. Rocha, G. R. Macedo and L.

R. B. Gonçalves, “Ethanol Production from Cashew

Apple Bagasse: Improvement of Enzymatic Hydrolysis

by Microwave-Assisted Alkali Pretreatment,” Applied

Biochemistry and Biotechnology, Vol. 164, No. 6, 2011,

pp. 929-943. doi:10.1007/s12010-011-9185-3

[10] A. M. Pacheco, D. R. Gondim and L. R. B. Gonçalves,

“Ethanol Production by Fermentation Using Immobilized

Cells of Saccharomyces cerevisiae in Cashew Apple Ba-

gasse,” Applied Biochemistry and Biotechnology, Vol. 16,

No. 1-8, 2010, pp. 209-217.

doi:10.1007/s12010-009-8781-y

[11] Y. Sun and J. J. Cheng, “Dilute Acid Pretreatment of Rye

Straw and Bermudagrass for Ethanol Production,” Biore-

source Technology, Vol. 96, No. 14, 2005, pp. 1599-1606.

doi:10.1016/j.biortech.2004.12.022

[12] E. Palmqvist and B. Hahn-Hägerdal, “Fermentation of

Lignocellulosic Hydrolysates II: Inhibitors and Mecha-

nisms of Inhibition,” Bioresource Technology, Vol. 74,

No. 1, 2000, pp. 25-33.

doi:10.1016/S0960-8524(99)00161-3

[13] BRASIL, “Métodos Físico-Químicos para Análises de

Alimentos/Ministério da Saúde,” Instituto Adolfo Lutz,

2005.

[14] TAPPI—Technical Association of the Pulp and Paper

Industry, “Official Test Methods (OM), Provisional Test

Methods (PM) and Useful Test Methods (UM),” One

Dunwoody Park, Atlanta, 2010

[15] NREL—National Renewable Energy Laboratory, “De-

termination of Sugars, Byproducts, and Degradation Pro-

ducts in Liquid Fraction Process Samples,” Technical Re-

port, Laboratory Analytical Procedure (LAP), Golden,

2008.

[16] A. M .A. Uchoa, J. M. C. Costa, G. A. Maia, E. M. C.

Silva, A. F. F. U. Carvalho and T. R. Meira, “Physico-

chemical Parameters, Fiber Content and Gross Food Pow-

ders Obtained Food Waste Fruits,” Food and Nutrition

Security, Vol. 15, 2008, pp. 58-65. (In Portuguese)

[17] M. F. O Matias, E. L. Oliveira, E. G. Guedes and M. M.

A. Magalhães, “Use of Fibres Obtained from the Cashew

(Anacardium Ocidentale, L) and Guava (Psidium Guayava)

Fruits for Enrichment of Food Products,” Brazilian Ar-

chives of Biology and Technology, Curitiba, Vol. 48, Spe-

cial Issue, 2005, pp. 143-150.

doi:10.1590/S1516-89132005000400018

[18] E Lima, F. C. S. Lima, F. L. H. Silva, J. M. S. Neto and A.

S. Silva, “Reviews of Pretreatment for Delignification of

the Cashew Apple Pomace for Subsequent Saccharification

Process,” In: XVIII Simpósio Nacional de Bioprocessos,

Universidade de Caxias do Sul, 2011, pp. 1-6. (In Portu-

guese)

Copyright © 2012 SciRes. ACES