American Journal of Industrial and Business Management, 2012, 2, 176-183 http://dx.doi.org/10.4236/ajibm.2012.24023 Published Online October 2012 (http://www.SciRP.org/journal/ajibm) Technological Capability in Metal Fabricating Firms in Southwestern Nigeria Victor Oluwasina Sobanke1, Matthew Olugbega Ilori2, Stephen Akinade Adegbite3 1National Centre for Technology Management, Obafemi Awolowo University, Ile-Ife, Nigeria; 2African Institute for Science Policy and Innovation, Obafemi Awolowo University, Ile-Ife, Nigeria; 3Centre for Industrial Research and Development, Obafemi Awo- lowo University, Ile-Ife, Nigeria. Email: v_sobanke@hotmail.com Received March 28th, 2012; revised April 29th, 2012; accepted May 22nd, 2012 ABSTRACT The study assessed the technological capability in the metal fabricating firms in southwestern Nigeria. A technology capability index (TCI) was used in assessing 200 randomly sampled firms. Data for the study was analyzed by using descriptive analysis. The results showed a variation in the TCI scores of firms with micro, small and medium fabricat- ing firms scoring an average of 0.82, 1.10 and 1.54 respectively. Firms which reported that process innovation were incremental are 24.8%; new to the firm (100.0%) and creative (3.0%). Similarly, product innovation variables showed that 85.5% were incremental; i mitation (95.5%) and creativity (50.4%). The study sugg ests the need for policy interve- netion to enhance th e knowledge and skills of the operators. Keywords: Technological Capability; Industrializatio n; Knowledge and Skills; Metal Fabricating Firms; Small and Medium Enterprises 1. Introduction Technological capability has received considerable atten- tion of many researchers worldwide. This is with a view to understanding those factors responsible for the differ- ences among the countries classified as developed, newly developed and less developed. In fact, technological ca- pability is a major contributory factor to the paradigm shift that occurred in the ways n atio ns relate an d co mpete. Specifically, technological competitiveness, which re- searchers refer to as a game of nations, has been an indi- cator for measuring economic performance and standards of living of nations [1]. As a consequence, developed and developing nations are now categorized as having desir- able and undesirable economic status respectively [2]. Hence, an attempt to move from the undesirable status, by the less developed nations, to the desirable status re- quires a technological ladder, which is explained to be synonymous to technological capability [2]. The realities in Africa however shows that many Afri- can countries are still struggling to get back on the de- velopmental track after the aftermath of the Structural Adjustment Programme (SAP) introduced to the African economies by the World Bank [3]. Similarly, Nigeria is categorized as a developing nation with decreasing in- dustrial productivity. Various research studies, together with expert opinions have attributed the failure to social, economic, and political factors. However, in addressing these challenges various policies h ave been adopted. One of such policy is International Technology Transfer (ITT) which is regarded as a factor to the success of the newly industrialized countries (NICs) of the East and South- East Asia [2]. This could be one of the reasons why most African governments depend on the industrialized and the newly industrialized nation s for techn ological sup port to develop their economies. But recently, there have been some shocking revela- tions from results of various researches in comparing various developmental activities among the newly Indus- trialized countries in Asia and some countries in Africa. The result shows that the pattern and the level of techno- logical capability development among the two economic blocks are significantly different [4,5]. Alternatively, researchers have therefore suggested rapid industrialization for developing economies to en- hance economic development, and this in general term means raising the level of technological capability in- volved in the manufacturing activities [2,6] at all levels. Further studies have shown that every society has its own level of indigenous technical knowledge, and there are substantive literatures that established this knowledge to be very low in Africa [7] despite the endowment of many natural resources. It is based on this assertion that this Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria 177 study appreciates the significant role the metalworking sub-sector of the Nigerian manufacturing sectors has played in the industrialization effort of Nigeria, and at the same time, tries to understand the level of techno- logical capability of operators in the sub-sector. Amdi [8] notes that during the third and fourth na- tional development plans of Nigeria, the metalworking sub-sector of the Nigerian manufacturing sector was identified as crucial for achieving rapid industrial devel- opment and technical change. This is because the sector is considered a centre-piece of any nation’s real industri- alization efforts. In fact, one of the factors that accelerate the industrial revolution in the industrialized nations of the world is attributed to the vibran t metalworking Indus- try [9]. This sector manufacture parts and components for automobile industry, construction industry, agricultural tools and equipment with wide applications and a num- ber of basic household and industrial equipment [10]. Therefore, a technology-based metalworking industry is the bedrock of an industrialized nation. Furthermore, available literature revealed that there are various em- pirical works on technological and innovation capabili- ties in many areas of the Nigerian industrial sector, most especially in the manufacturing sector [11-13]. However, little of such studies have been directed towards the ac- tivities of the metal fabricators in Nigeria. Hence, the objective of this paper is to assess the activities of the metal fabricating firms as well as the capability of op- erators in the sector. 2. Literature Review 2.1. Concept of Technological Capability Technological capability has been explained in various ways depending on the interest of the researchers. Gar- cia-Muina [14] conceptualized technological capability as a tool for implementing competitive strategy and cre- ating value in any given environment. They further de- fined it as the ability to jointly mobilize different scien- tific and technical resources which enables a firm to suc- cessfully develop its innovative products or productive pr- cesses. Similarly, Marjolein [15] described technological capability as the ability to make the right investment choices; increase production capacity; and engage in con- tinuous upgrading of product quality. They further ar- gued that technological capability are efforts geared to- wards investment in time and resources aimed at assimi- lating, adapting and improving existing technologies and creating new technologies through reverse engineering . Similarly, Jin [4] observed that technological capabil- ity in developing countries could be used interchangeably with “absorptive capacity” which means absorbing ex- isting knowledge from the developed economy, assimi- lating it, and in turn generating new knowledge. The re- searchers further defined technological capability as the effective use of technical knowledge and skills required to improve and develop products and processes; improve existing technology; and also to generate new knowledge and skills in response to the competitive business envi- ronment. The focus of technological capability in developing countries is on the relationship between the Firm-level Technological Capability (FTC) and the National-level Technological Capability (NTC). This focus at the firm level is on equipment, skills, knowledge, attitudes and aptitudes needed to choose, install, operate, maintain, understand, adapt, improve and develop technologies [5]. The process involves specific efforts and strategies by firms for developing technologies. At the national level, the focus is on collection of individual firm-level techno- logical capabilities together with various linkages avail- able in the National Innovation System (NIS) [4,16,17]. In addition, technolog ical capability can also be classi- fied in terms of basic and key skills required by firms operating in a given country. These are the skills and knowledge required by firms to start a new business or upgrade an existing one. This type of technological ca- pability is needed b y firm to choose, install and operate a set of modern machinery and equipment that are widely used in a given industry. Basic technological cap ability is readily available to all co mpetitors and it is the minimum requirement for standard production [9]. Key techno- logical capability is required for the management of the effect of a technological change in a particular industry or system. It can be defined as the skills and knowledge required to operate, maintain, adapt and to improve on existing technologies. It gives the firm a competitive edge over other competitors and also allows the firm to compete favorably at the international market [9]. Fur- thermore, key technological capability can also create a technological change in an industry, where it discontin- ues an existing system and creates a new one. Technological capability is composed of two broad elements, namely embodied and disembodied. The em- bodied elements of technological capability are tho se that involve the human aspect. It includes the skills, knowl- edge, attitude and aptitude. It is generally believed that these types of elements are tacit in nature and very diffi- cult to measure or transfer [16]. The second is the non- embodied/disembodied elements. These are the part of technological capab ilities that are codified and can easily be transferred among users. These include equipment and software [16]. 2.2. Indicators for Measuring Technological Capability At the firm-level, there are many indicators for measure- Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria 178 ing technological capabilities. These are based on the level of complexity and functionality of the four main categories of technological capabilities which include investment, production, innovation and linkage capabili- ties [5,7]. 2.2.1. Investment Capability Investment capability is described as the skills and in- formation needed to id entify feasible investment projects; prepare, locate and purchase technologies; staff, design and manage construction; commissioning and start-up. Under investment capability, the pre-feasibility and de- tailed feasibility study are prepared for the identified projects to determine the capital cost, sponsors, the ap- propriateness of the scale, product mix, technology and equipment to be used. The ability to undertake this pro- cess in-house has been considered to be important for firms [9]. Also, the economic viability and technical feasibility of the new project must be critically analyzed to deter- mine the best combination of options for the project. This capability has been found to be very low among the Af- rican enterprises when compared with their counterpart from the industrialized and newly industrialized nations [7]. Alternatively, this function can be contracted out to be conducted by more experienced domestic or foreign firms that can help to perform the function effectively and efficiently. However, the method of external contract as observed, sometimes comes with its own associated challenges such as increase in the project’s capital costs and the “not invented here” syndrome which make it difficult for the recipient to master, adapt and subse- quently upgr ade the technology [9]. 2.2.2. Production Capability Production capability is referred to as the skills and knowledge required for the operation of the production facilities. That is, once the two stages under the invest- ment capability (Pre-investment and Project execution) have been co mpleted, the production facilities need to be operated for optimum production . In achieving th is, three different stages of activities with different levels of com- plexity were proposed in the literature. These are process engineering, product engineering and industrial engi- neering [5,7]. These three different activities combined together foster efficient and effective operation, mainte- nance, adaptation, improvement, quality and inventory control, work flow and sch eduling, monitoring and so on for the newly commissioned production facilities [5 ,7,18]. In addition, Biggs [7] note that industrial engineering skills requires a good knowledge of mathematical, statis- tical and organizational techniques; time and motion studies; and layout and materials-handling analysis which will help to achieve productivity improvement through the change of time and sequence of manufactur- ing and aux iliary operations [7]. 2.2.3. Technology Innovation Innovation is the creation of value. It is an economic phenomenon involving the commercial use of new idea. Khalil [1] argued that inn ovation represents the important connection between an idea and its exploitation or com- mercialization. In the actual sense, innovation occurs after the first commercial transaction resulting from the introduction of the new product, process, or system. However, the length of time that usually separates the discovery of an invention, its application and exploitation which before now could take several years, have also reduced drastically. Also, innovation is a complex phe- nomenon [19] and like entrepreneurship, it appears in many fields of study [18]. Notwithstanding the largely shared views on the importance of innovation, several definitions for innovation types have been developed, resulting in an ambiguity in the term innovation [20]. To this end, this study define innovation as the scientific, technical, commercial and financial steps necessary for the successful development and marketing of new or improved processes, products or equipment; or the in- troduction of new approach to manufacturing activity [11]. 2.2.4. Innovatio n Capability Innovation capability is knowledge and skills needed to find new ways of carrying out the firm’s activities such as investment, production, marketing and organizational as well as their implementation. Egbetokun [18] de- scribed innovation capability as ‘search’ capabilities and the capacity to actualize the outcome of the searching process. He further observed that the search for new rou- tines is likely to create new patterns of human resource development, R & D, technological information, techno- logical adaptations and market research. Romijn [17] citing Lall [5] also defined innovation capability as the skills and knowledge needed to effectively absorb, mas- ter and improve existing technologies and to create new ones. Innovation capability has always been used for various organizational activities which cover ability to invent, innovate and improve existing technology beyond the original design parameters [21]. Therefore, for the purpose of this study, innovation capability will be re- ferred to as the ability to make minor improvement and modifications to existing technologies and to create new technologies. 2.2.5. Linkage Capability Linkage capability is a system used for transmitting and receiving supportive information at three different levels. These are within an enterprise; with other enterprises Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria Copyright © 2012 SciRes. AJIBM 179 (intra-industry and inter-indu stry); and with R & D insti- tutions (local and overseas), including Universities [22]. Lall [23] conceived this capability as tho se skills that are required for transmitting information, skills and technol- ogy to, and receive them from component/raw material suppliers, customers, subcontractors, consultants, service firms and technology institutions. Linkage capability forms the basis for interaction among the above men- tioned agents. It also boost access to information about markets, technologies, technical assistance, research and technical knowledge [24] as well as learning facilities, on which the process of building technological capability lies. Other observed forms of linkages as highlighted by Egbetokun [18] include licensing, management and mar- keting agreements; joint ventures; interaction with local and foreign competitors; government policy and regula- tions, interactions with domestic and international fi- nance institutions and so on. 3. Research Methodology To determine the technological capability of individual fabricating firm in the study area, random sampling tech- niques was employed in taking sample of 200 metal fab- ricating firms from the registers of the Manufacturers Association of Nigeria (metal fabrication sub-section) and the State Ministry of Commerce and Industry. The survey covers Lagos and Ogun States in Southwestern Nigeria. Lagos State was selected because of the high industrial activities which have contributed to the large population and clustering of many manufacturing firms in the area, while Ogun State was selected due to the influx of manufacturing firms to the area in search of a large factory space for their manufacturing operations. A set of questionnaire was used for collection of the pri- mary data from the respondents. Draft of the question- naire adapted from similar studies elsewhere was sent to six purposively selected individual stakeholders in the academics, government research institutes and the Indus- try as a pre-test. The data collected were subjected to reliability test (Cronbach’s α: 0.839 t o 0.855) . Technological capability ind ex (TCI) which composed of four (4) variables was developed. These variables are investment, production, innovation and linkage capabili- ties. Each of these variables represents the taxonomies of technological capability developed by Lall [5] and has been widely adopted and used as a standard for opera- tionalizing technological capability at micro-level [25]. The variables measured were grouped into investment; process, product and industrial engineering; process and product innovation; and linkage functional areas. The variables were further graded using a rating scale of 2 (systematic), 1 (ad-hoc), and 0 (None) which represents different level of competence. A firm is however award- ed a score based on its leve l of competen ce in perfo rming these technical functions as described under each of the variables. In all, a given metal fabricating firm was as- sessed out of a total capability score of fifty two (52), and the result was normalized between 0 and 2 to give the TCI. 4. Results and Discussions 4.1. Investment Capability of Responding Firms Table 1 shows the investment capability of responding firms. Investment capabilities, as noted earlier, are the skills and information needed to identify feasible invest- ment projects, locate and purchase suitable technologies, design and engineer the plant, and manage the construc- tion, commission and start-up. The response confirms that majority of the firms in the surv ey were above aver- age in the area of investment capability. The percentage of firms that indicated no compliance with investment functions were 2.3%, 31.6% and 39.1% for search and selection of technology; detailed engineering; and re- cruitment and training of technical personnel activities respectively. However, about half of those that indicated their compliance with pre-investment and project execu- tion activities did so in an unplann ed mann er (Ad-hoc). 4.2. Production Capability Production capability was considered under process, product and industrial engineering functions. These func- tions include debugging and calibration of new equip- ment, replacing original equipment parts, quality control, Table 1. Investment capability of the responding firms. Investment functions No Ad-hoc Systematic Feasibility studies for new factories, workshop or projects - 87(62.6) 46(34.6) Search for & select technology for new projects 3(2.3) 69(51.9) 61(45.9) Detailed engineering for new projects 42(31.6) 45(33.8) 46(34.6) Construction of workshop facilities - 121(91.0) 12(9.0) Recruitmen t & training of tec hnical personnel 52(39.1) 43(32.3) 38(28.6) N ote: Figures in parentheses are row percentages.  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria 180 reproduction of fixed specifications and designs, ac- creditation and certification of product quality, design and introduction of new products in-house, operation of inventory control system, scheduling production, and monitoring of productivity. Tabl e 2 shows that firms dis- played capability in production th at was similar to that of investment capability except for accreditation/certifi- cation of pro duct qu ality (56.4 %) that was above av erage for no compliance. Also, other activities were mostly con- ducted in a manner that is either systematic or ad-hoc. 4.3. Innovation Capability Innovation capability co ns ists of the poten tial o f a firm to search for ways of carrying out its key activities and the capacity to internalize the outcome of such searches. Ta- ble 3 shows that 97.0% and 75.2% firms did not under- stand the function of process innovation as a strategy for developing new production method and modification to existing production process respectively. Other activities followed the observed pattern of well above average compliance in capability. 4.4. Linkage Capability Interactions with various actors in the National Innova- tion System constitute one of the most important learning and innovation efforts for African firms [18,23,26]. How- ever, Table 4 shows a weak linkage capability between the firms and actors in the National Innovation System except for collaboration with the trade association where 91.0% of the firms demonstrated high level of formal cooperation. This suggests that firms in the fabriccating industry, whether in the formal or informal sector, belong to one form of trade association. Similarly, networking with other fabricating firms are 60.2% ad-hoc and 9.0% systematic; while collaboration with customers/suppliers are 66.2% ad-hoc and 12.0% systematic. Firms in the study area have poor linkage activity with educational and research institutes (91.7%) and financial institution (72.9%). 4.5. Innovations in the Metal Fabricating Firms Table 5 shows the sampled firms degree of novelty. The Table 2. Production capability of the responding firms. Production functions No Ad-hoc Systematic Debugging & calibra tion of new equipment 59(44.4) 27(20.3) 47(35.3) Do routine maintenance operation 65(48.9) 40(30.1) 28(21.1) Replacing original equipment parts 28(21.1) 77(57.9) 28(21.1) Quality control (Automated/Vision) - 100(75.2) 33(24.8) Reproduce fixed specifications and designs - 48(36.1) 85(63.9) Accreditation/certification of product quality 75(56.4) 42(31.6) 16(12.0) Design & introducing new products in-house 42(31.6) 53(39.8) 38(28.6) Operating inventory control system 18(13.5) 78(58.6) 37(27.8) Scheduling production - 72(54.1) 61(45.9) Monitoring of productivity - 100( 75 .2) 33(24.8) Note: Figures in parentheses are row percentages. Table 3. Innovation capability of the responding firms. Innovation func tio ns No Ad-hoc Systematic Develop new production method 129(97.0) 4(3.0) - Introduce new produ c t ion method - 50(37.6) 83(62.4) Modification to exist i n g p roduction method 100(75.2) 33(24.8) - Develop new product(s) 30(22.6) 67(50.4) 36(27.1) Copy/imitation o f imported produ ct (s) 6(4.5) 40(30.1) 87(65.4) Modification to exist i n g p roduct(s) 19(14.3) 34(25.6) 80(60.2) Note: Figures in parentheses are row percentages. Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria 181 Table 4. Linkage capability of the r esponding firms. Linkage functions No Ad-hoc Systematic Networking with other firms 41(30.8) 80(60.2) 12(9.0) Association with trade union 12(9.0) - 121(91.0) Collaboration with educational and research institutes 122(91.7) - 12(8.3) Relationship with customers/suppliers 29(21.8) 88(66.2) 16(12.0) Relationship with financial institution 97(72.9) - 36(27.1) Note: Figures in parentheses are row percentages. Table 5. Innovation in the metal fabricating firms. Degree of novelty Product Process Radical innovation - 36(27.1) Incremental innovation 33(24.8) 114(85.8) New to the firm/ imitation 133(100.0) 127(95.5) Creativity 4(3.0) 67(50.4) Note: Figures in parentheses are sample percentages. objects of innovation observed are classified into radical, incremental, new to the firm/imitation and creativity. Process innovation is very weak throughout the industry. There were however 33(24.8%) and 4(3.0%) cases of incremental innovation and creativity respectively. Also, 133(100%) firms confirmed the introduction of new production method (new to the firm) into their business as part of their innovative effort. By contrast, product innovation is high ly prevalent throughout the sector with the incidence of radical (27.1%), incremental (85.8%), imitation/copying (95.5%) and creativity (50.4%) active- ties in the industry. Only, ‘new to the firm’ type of proc- ess innovation agree with the findings of Egbetokun [8] in their study of innovation capability in the cable and wire manufacturing industry in Nigeria, where the inci- dence of process innovation (0.8) was higher than prod- uct innovation (0.6). 4.6. Technological Capability Index Table 6 shows the frequency distribution of the techno- logical capability index (TCI) scores for the 133 metal fabricating firms. The data shows a variation in the TCI scores of fabricating firms in relation to the size of firms. Almost all the medium-size firms had scores of between 1.41 and 1.80 except one (1) firm which has a score be- low 1.41. The TCI scores for majority of the micro firms were between 0.61 to 1.00 while most small firms had TCI scores of between 1.01 - 1.40. From this result, while the medium firms (1.41 - 1.60 and 1.61 - 1.80) had technological capabilities that compared well with those found in the developed countries; however, the overall Table 6. Technological capability index by firm size. Firm size TCI class Micro Small Medium 0.00 - 0.20 - - - 0.21 - 0.40 - - - 0.41 - 0.60 - - - 0.61 - 0.80 29 1 - 0.81 - 1.00 24 17 - 1.01 - 1.20 6 22 - 1.21 - 1.40 - 16 1 1.41 - 1.60 - - 12 1.61 - 1.80 - - 5 1.81 - 2.00 - - - Total 59 56 18 technological capability of th e firms sampled is far below the average obtainable in the fabricating industry interna- tionally. Average Technological Capability Index Table 7 shows the average TCI scores for all firms ac- cording to their size; and the corresponding average scores for individual capabilities (INVT I., PDTN I., INNO I., and LNKG I.) that make-up the TCI scores. The average TCI clearly shows a better result according to the firm size. It reveals the difference in the level of technological capability among the various firm sizes (micro, small, and medium) of metal fabricating firms in Southwestern Nigeria. The micro firms have an average TCI score of 0.82, which is considered to be very low, and even below the total average TCI scores (1.00). The average TCI score (1.10) of the small firms is a little above the average TCI score. The medium scale firms have an average TCI score of 1.54 which is considered to be the highest. Further analysis based on the individual capabilities that make up the TCI revealed the differences Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria 182 Table 7. Distribution of average TCI. Score Firm size N TCI INVT. I PDTN. I INNO. I LNKG. I Micro 59 0.82 0.93 0.84 0.82 0.68 Small 56 1.10 1.17 1.15 1.13 0.89 Medium 18 1.54 1.89 1.73 1.20 1.22 Note: N indicates number of firms; TCI—Technological Capability Index; INVT. I—Investment Index; PDTN. I—Production Index; INNO. I—Inno- vation index; LNKG. I—Linkage Index. and the nature of technological activities of all the sectors (micro, small, and medium) of sampled firms. The in- vestment index reveals that the micro, small, and mediu m firms had scores of 0.93, 1.17 and 1.89 respectively. Comparably, the data suggests a big technological gap in the investment capability when a comparison is made between micro, small and medium firms. Also, produc- tion and linkage capabilities fo llowed a similar pattern as observed in the investment capability. The production index scores were micro (0.84), small (1.15) and medium (1.73) firms for production capability while the linkage index scores are 0.68, 0.89 and 1.22 for micro, small and medium firms respectively for linkage capability. Furthermore, by comparing the difference among these capabilities that followed the same pattern, production capability presented a difference value of 0.58. This could be as the result of some quality control tests like Pressure test, Radiography (X-ray), fatigue and hydro test conducted by medium firms on their various metal products. Whereas, the micro and small enterprises most- ly based their quality control on much of raw materials selection, vision and hydro test of their finished products. They did not perceive any advantage that pro duct quality certification provides to their business, as none of the products of the firms was certified. In a similar manner, linkage capability showed a difference of 0.33 between the medium and small firms. This suggests that medium firms have better networking arrangement with other MSMEs fabricating firms. The medium firms on many occasions engage the services of the other firms by out- sourcing part of their on-going projects to these firms. This type of relationship has numerous advantages of transferring the best practice from the medium firms to the micro firms in the sector. However, networking with other fabricating firms between small and micro firms seems to be absent or weak where available. Lastly, in- vestment capability revealed a capability difference of 0.72 between the medium and small fabricating firms. This difference reflects in the way medium firms conduct their recruitment and training exercise for new technical staff. Also, innovation capability sho ws a similar pattern. The innovation index scores are 0.82, 1.13 and 1.20 for the micro, small and medium firms respectively, with medium firms coming out stronger than other category of sampled firms. In addition, innovation index scores seem to explain the difference in the average TCI scores be- tween medium and small firms. This suggests that small and medium firms are good imitators. They seem to adopt technolog y follower strategy [27] as a catch-up for developing their technological capab ility. 5. Conclusion and Recommendations Majority of the micro and small fabricating firms in south- western Nigeria had low technological capability. This was found to be lower than that obtainable in the industry. However, the medium fabricating firms operating in the same area have a technological capability which is at par with international best practice in the metal fabricating industry. Metal fabricating firms in southwestern Nigeria seems to have considerable capability in investment and production, while their performance in innovation and linkage capabilities are weak. The major innovations found among the metal fabricating firms in Southwestern Nigeria are products and introduction of new production method, while process innovations is still lacking. In ad- dition, the main sources of innovations for the fabricating firms are imitations and copying from imported pro ducts. The study concludes that th ere is need for policy inter- vention to enhance the knowledge and skills of these operators with a view to improving the technological cap- ability and productivity of the metal fabricating firms. This will enhance their national competitiveness and comparative advantage in the globalized economy. REFERENCES [1] T. Khalil, “Competitiveness,” In: T. Khalil, Ed., Mana- gement of Technology: The Key to Competitiveness and Wealth Creation, Thomas Casson, 2000, pp. 153- 191. [2] F. Ogbimi, “Solution to Mass Unemployment in Nigeria,” In: F. Ogbimi, Ed., Achieving Rapid Industrialisation and Democratisation in Nigeria, Obafemi Awolowo Uni- versity Press, Ile-Ife, 2007. [3] A. Hoogvelt, “Industry and Trade in a Global Economy with Special Reference to Sub-Saharan Africa,” Industrial Policies and Research, United Nations Industrial Deve- lopment Organization, 2000. http://www.unido.org/fileadmin/user_media/Publications/ Pub_free/Industry _and_trade_in_ a_global_ec ono my _with_ special_reference_to_subSaharan_Africa.pdf [4] J. Jin, and M. Von Zedtwitz, “Technological Capability Development in China’s Mobile Phone Industry,” Tech- novation, Vol. 28, No. 6, 2008, pp. 327-334. doi:10.1016/j.technovation.2007.06.003 [5] S. Lall, “Technological Capabilities and Industrialisation,” World Development, Vol. 20, No. 2, 1992, pp. 165-186. doi:10.1016/0305-750X(92)90097-F Copyright © 2012 SciRes. AJIBM  Technological Capability in Metal Fabricating Firms in Southwestern Nigeria Copyright © 2012 SciRes. AJIBM 183 [6] E. Dike, “Vision 2020: Where is the Technological Capabi- lity?” 2009. http://www.nigeriavillagesquare.com/articles/guest-article s/vision-2020-where-is-the-technological-capability.html [7] T. Biggs, M. Shah and P. Srivastava, “Technological Capa- bilities and Learning in Africa Enterprises,” World Bank Technical Paper, Washington DC, 1999. [8] I. E. S. Amdi, “Institutions Supporting Technical Change in Nigeria: The Role of Industrial Development Centres,” 1995. http://web.idrc.ca/en/ev-30805-201-1-DO_TOPIC.html [9] D. Pierre, H. Staut and R. Bernard, “Strategic Techno- logy Management: Integrating Product Technology into Global Business Strategies for the 1990s,” John Wiley and Sons, Hoboken, 1992. [10] G. Laditan, “Upgrading Technologies in the Small Scale Metal Working Industry in Nigeria: A Case Study of Oyo and Osun States,” Nigeria Institute of Social and Eco- nomic Research Monograph, Ibadan, 1997. [11] I. Abereijo, “Evaluation of Capabilities of Small and Me- dium Industrial Enterprises for Acquisition of New Technologies in Southwest Nigeria,” M.Sc. Thesis, Oba- femi Awolowo University, Ile-Ife, 2006. [12] A. Egbetokun, W. Siyanbola and A. Adeniyi, “Assess- me nt of Innovation Capability in the Cable and Wire Manufactur- ing Industry in Nigeria: A Case Study Approach,” 2007. http://www.merit.unu.edu/MEIDE/papers/2007/EGBETO KUN_SIYANBOLA_ADENIYI_A ssessment%20of%20i nntion%20capability...cable%20&%20wire%20manufact uring%20industry.pdf [13] S. Oke, “An Evaluation of the National Innovation Sys- tem and Technological Capability Building in the Manu- facturing Sector,” M.Sc. Thesis, Obafemi Awolowo Uni- versity, Ile-Ife, 2005. [14] F. Garcia- Muina and J. Nav as-Lopez , “Explai ning and Mea- suring Success in New Business: The Effect of Tech- nological Capabilities on Firm Result s,” Technovation, Vol. 27, No. 1-2, 2007, pp. 30-46. doi:10.1016/j.technovation.2006.04.004 [15] C. Marjolein and H. Romijn, “Technological Learning in Small Enterprise Clusters: Conceptual Framework and Policy Implications,” In: S. Mani and H. Romijn, Eds., Innovation, Learning and Technological Dynamism of Developing Countries, UNU Press, Tokyo and New York, 2004, pp. 135-157. [16] M. Gillian, “Technological Learning: A Strategic Imper- ative for Firms in Developing World,” Edward Elgar Publishing Limited, UK, 2004. [17] H. Romijn and M. Albaladejo, “Determinants of Inno- vation Capability in Small Electronics and Software Firms in Southeast England,” Research Policy, Vol. 31, No, 7, 2002, pp. 1053-1067. doi:10.1016/S0048-7333(01)00176-7 [18] A. Egbetokun, “Assessment of Innovation Capability in the Cable and Wire Manufacturing Industry in Nigeria: A Case Study Approach,” M. Sc. Thesis, Obafemi Awolowo University, Ile-Ife, 2009. [19] H. Armbruster, A. Bikfalvi, S. Kinkel and G. Lay, “Orga- nisational Innovation: The Challenge of Measuring Non- technical Innovation in Large Scale Surveys,” Technova- tion, Vol. 28, No. 7, 2008, pp. 644-657. doi:10.1016/j.technovation.2008.03.003 [20] R. Garcia and R. Calantone, “A Critical Look at Tech- nological Innovation Typology and Innovativeness Ter- minology: A Literature Review,” Journal of Product In- novation Management, Vol. 19, No. 2, 2002, pp. 110-132. doi:10.1016/S0737-6782(01)00132-1 [21] L. Kim, “Imitation to Innovation: The Dynamics of Ko- rea’s Technological Learning,” Harvard Business School Press, Boston, 1997. [22] O. Olamade, “Technological Capabilities in the Nigerian Telecommunication Industry,” M.Sc. Thesis, Obafemi Awo- lowo University, Ile-Ife, 2001. [23] S. Massa and S. Testa, “Innovation and SMES: Misalign- ed Perspectives and Goals among Entrepreneurs, Acade- mics and Policy Makers,” Technovation, Vol. 28, No. 7, 2008, pp. 393-407. doi:10.1016/j.technovation.2008.01.002 [24] N. Amara, R. L andr y, N . Bech eik h and M. Ou im en t, “ Lear n- ing and Novelty of Innovation in Established Manufac- turing SMEs,” Technovation, Vol. 28, No. 7, 2008, pp. 450- 463. doi:10.1016/j.technovation.2008.02.001 [25] G. Wignaraja, “Firm Size, Technological Capabilities and Market-Oriented Policies in Mauritius,” Discussion Pa- pers Series of the United Nations University, Institute for New Technologies, 2001. [26] M. Ilori, “From Science to Technology and Inno vation Ma- nagement,” Obafemi Awolowo University Press Limited, Ile-Ife, 2006. [27] S. Sanni and M. Ilori, “Strategic Management of Tech- nology: Readings in Technology Management,” National Centre for Technology Management Monograph, Ile-Ife, 1999, pp. 43-56.

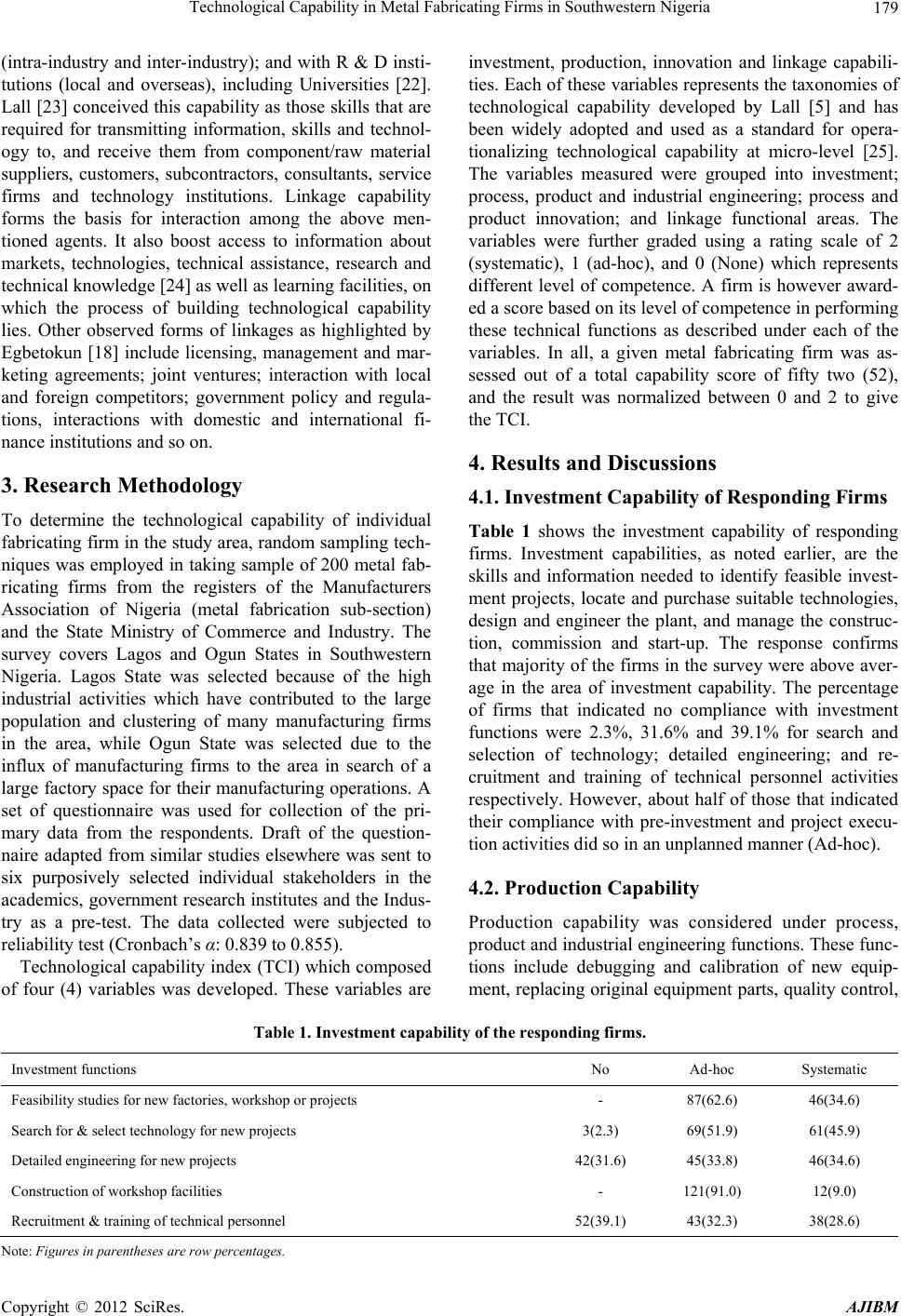

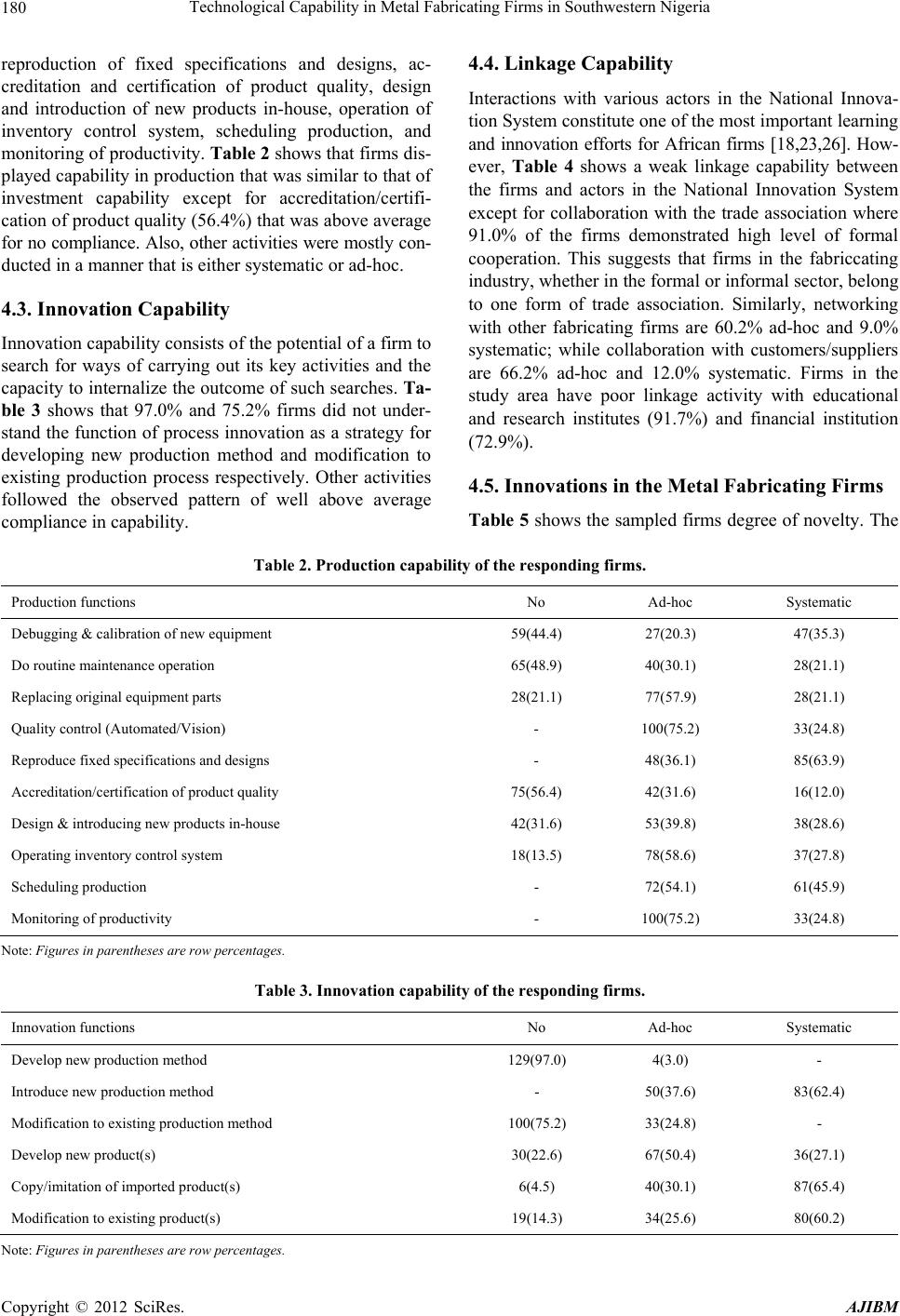

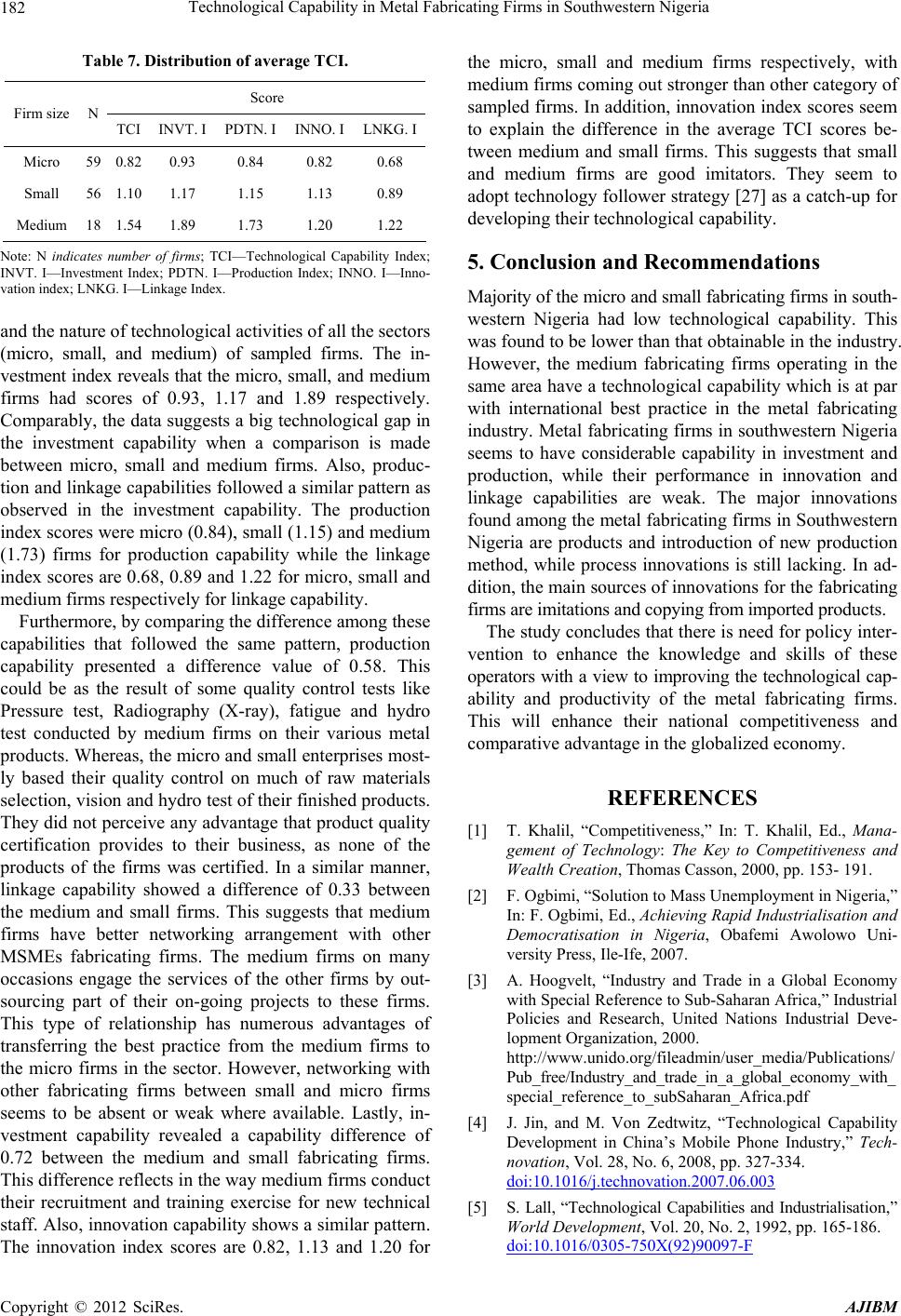

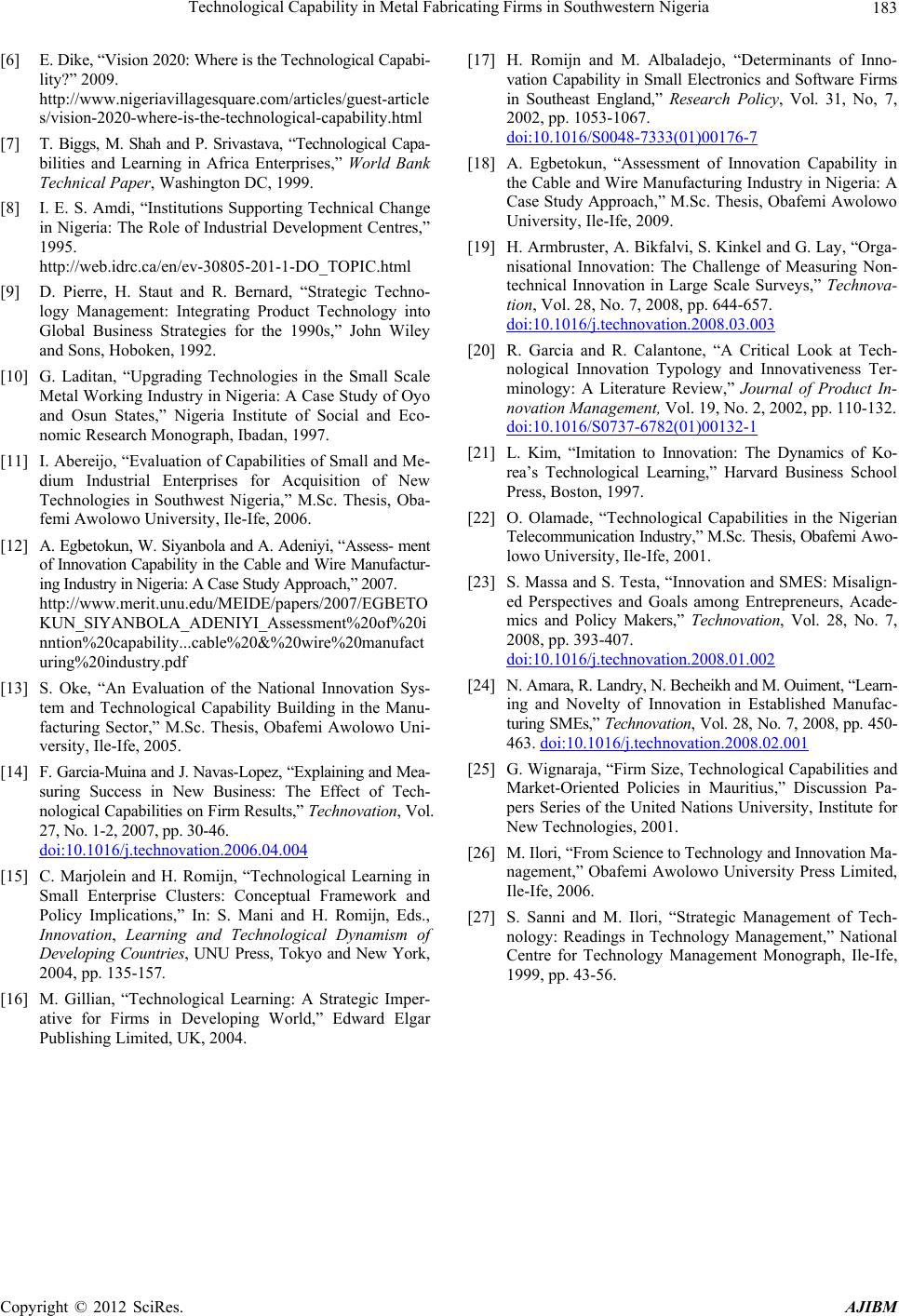

|