Cost Analysis of Introducing a Log Identification System Using RFID in the Wood Supply Chain:

A Case Study at a Swedish Forest Company

134

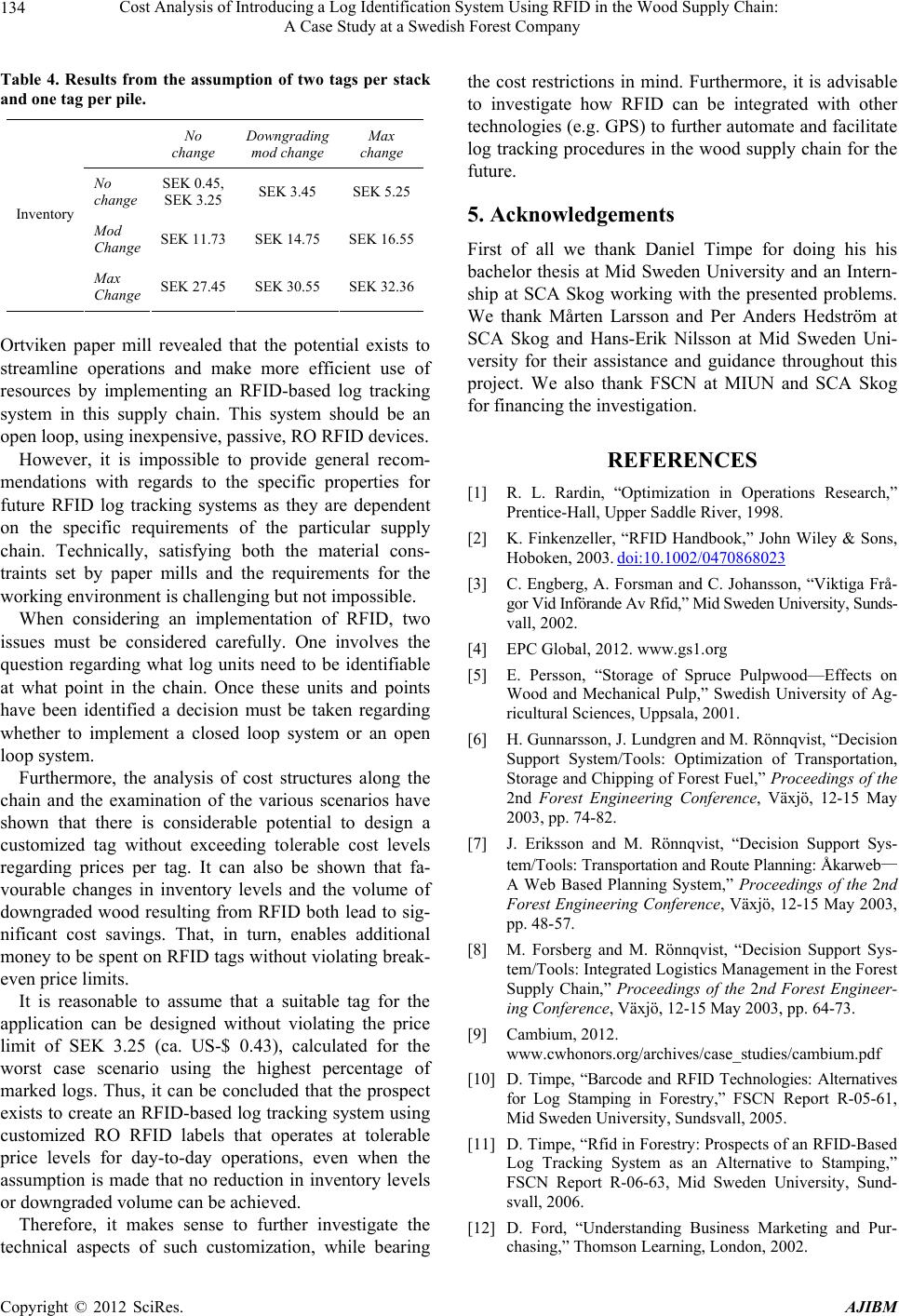

Table 4. Results from the assumption of two tags per stack

and one tag per pile.

No

change Downgrading

mod change Max

change

No

change SEK 0.45,

SEK 3.25SEK 3.45 SEK 5.25

Mod

Change SEK 11.73SEK 14.75 SEK 16.55

Inventory

Max

Change SEK 27.45SEK 30.55 SEK 32.36

Ortviken paper mill revealed that the potential exists to

streamline operations and make more efficient use of

resources by implementing an RFID-based log tracking

system in this supply chain. This system should be an

open loop, using inexpensive, passive, RO RFID devices.

However, it is impossible to provide general recom-

mendations with regards to the specific properties for

future RFID log tracking systems as they are dependent

on the specific requirements of the particular supply

chain. Technically, satisfying both the material cons-

traints set by paper mills and the requirements for the

working environment is challenging but not impossible.

When considering an implementation of RFID, two

issues must be considered carefully. One involves the

question regarding what log units need to be identifiable

at what point in the chain. Once these units and points

have been identified a decision must be taken regarding

whether to implement a closed loop system or an open

loop system.

Furthermore, the analysis of cost structures along the

chain and the examination of the various scenarios have

shown that there is considerable potential to design a

customized tag without exceeding tolerable cost levels

regarding prices per tag. It can also be shown that fa-

vourable changes in inventory levels and the volume of

downgraded wood resulting from RFID both lead to sig-

nificant cost savings. That, in turn, enables additional

money to be spent on RFID tags without violating break-

even price limits.

It is reasonable to assume that a suitable tag for the

application can be designed without violating the price

limit of SEK 3.25 (ca. US-$ 0.43), calculated for the

worst case scenario using the highest percentage of

marked logs. Thus, it can be concluded that the prospect

exists to create an RFID-based log tracking system using

customized RO RFID labels that operates at tolerable

price levels for day-to-day operations, even when the

assumption is made that no reduction in inventory levels

or downgraded volume can be achieved.

Therefore, it makes sense to further investigate the

technical aspects of such customization, while bearing

the cost restrictions in mind. Furthermore, it is advisable

to investigate how RFID can be integrated with other

technologies (e.g. GPS) to further au tomate and facilitate

log tracking procedures in the wood supply chain for the

future.

5. Acknowledgements

First of all we thank Daniel Timpe for doing his his

bachelor thesis at Mid Sweden University and an Intern-

ship at SCA Skog working with the presented problems.

We thank Mårten Larsson and Per Anders Hedström at

SCA Skog and Hans-Erik Nilsson at Mid Sweden Uni-

versity for their assistance and guidance throughout this

project. We also thank FSCN at MIUN and SCA Skog

for financing the investigation.

REFERENCES

[1] R. L. Rardin, “Optimization in Operations Research,”

Prentice-Hall, Upper Saddle River, 1998.

[2] K. Finkenzeller, “RFID Handbook,” John Wiley & Sons,

Hoboken, 2003. doi:10.1002/0470868023

[3] C. Engberg, A. Forsman and C. Johansson, “Viktiga Frå-

gor Vid Införande Av Rfid,” Mid Swed en University, Sunds-

vall, 2002.

[4] EPC Global, 2012. www.gs1.org

[5] E. Persson, “Storage of Spruce Pulpwood—Effects on

Wood and Mechanical Pulp,” Swedish University of Ag-

ricultural Sciences, Uppsala, 2001.

[6] H. Gunnarsson, J. Lundgren and M. Rönnqvist, “Decision

Support System/Tools: Optimization of Transportation,

Storage and Chipping of Forest Fuel,” Proceedings of the

2nd Forest Engineering Conference, Växjö, 12-15 May

2003, pp. 74-82.

[7] J. Eriksson and M. Rönnqvist, “Decision Support Sys-

tem/Tools: Transportation and Ro ute Planning: Åk arweb—

A Web Based Planning System,” Proceedings of the 2nd

Forest Engineering Conference, Växjö, 12-15 May 2003,

pp. 48-57.

[8] M. Forsberg and M. Rönnqvist, “Decision Support Sys-

tem/Tools: Integrated Logistics Management in the Forest

Supply Chain,” Proceedings of the 2nd Forest Engineer-

ing Conference, Växjö, 12-15 May 2003, pp. 64-73.

[9] Cambium, 2012.

www.cwhonors.org/archives/case_studies/cambium.pdf

[10] D. Timpe, “Barcode and RFID Technologies: Alternatives

for Log Stamping in Forestry,” FSCN Report R-05-61,

Mid Sweden University, Sundsvall, 2005.

[11] D. Timpe, “Rfid in Forestry: Prospects of an RFID-Based

Log Tracking System as an Alternative to Stamping,”

FSCN Report R-06-63, Mid Sweden University, Sund-

svall, 2006.

[12] D. Ford, “Understanding Business Marketing and Pur-

chasing,” Thomson Learning, London, 2002.

Copyright © 2012 SciRes. AJIBM